Summary of Contents for Reflex Fillcontrol Auto Compact

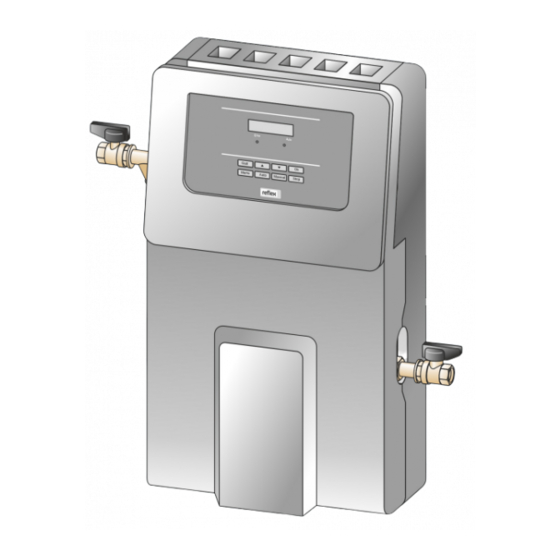

- Page 1 20.10.2020 - Rev. D Fillcontrol Auto Compact Operating manual Original operating manual...

-

Page 2: Table Of Contents

11 Disassembly ................14 Execution ...................... 6 12 Annex ..................15 6.3.1 Fitting the add-on components ..........6 12.1 Reflex Customer Service ................15 6.3.2 Wall mounting ................6 12.2 Conformity and standards ............... 15 6.3.3 Hydraulic connection ..............6 12.3... -

Page 3: Notes On The Operating Manual

Reflex Winkelmann GmbH accepts no liability for any damage resulting from Personnel requirements failure to observe the information in this operating manual. In addition to the... -

Page 4: Description Of The Device

Set minimum operating pressure max. pressure saftey valve Factory set actuating pressure of the factory - aline safety valve at site Set actuating pressure of the safety valve 4 — English Fillcontrol Auto Compact — 20.10.2020 - Rev. D... -

Page 5: Scope Of Delivery

This action is a prerequisite for the making of warranty claims. – Have the Reflex Customer Service carry out commissioning and the annual maintenance. Fillcontrol Auto Compact — 20.10.2020 - Rev. D English — 5... -

Page 6: Installation Conditions

Connection to the system WC Connection of the make-up line to the mains separator tank Connection of the mains separator tank overflow Connection of the make-up line to the system circuit 6 — English Fillcontrol Auto Compact — 20.10.2020 - Rev. D... -

Page 7: Switching And Make-Up Variants

Fillsoft); available as optional accessories, see chapter 4.6 "Optional equipment and accessories" on page 5 . When using a Reflex Fillsoft, the PIS pressure transducer is installed downstream of the fitting and other installed components, such as a water meter. This prevents malfunctions when measuring the pressure. -

Page 8: Terminal Diagram

Not used • Communication with control centres. • Communication with other equipment. Not used Note! RS-485 interface If required, please request the RS-485 interface protocol from the Reflex Shielding Customer Service. Digital inputs • Connection details. • Water meter •... -

Page 9: Requirements For Initial Commissioning

Pump damage may occur when the pump starts up if you turn the pump motor at the impeller using a screwdriver. • Switch the pump to a zero-volts state before turning the pump at the fan wheel with a screwdriver. Fillcontrol Auto Compact — 20.10.2020 - Rev. D English — 9... -

Page 10: Starting Automatic Mode

Note! The make-up with fresh water must be ensured even outside of the operation of If necessary, contact the Reflex Customer Service, see chapter 12.1 the heating and cooling systems. Do not shut down the device when the "Reflex Customer Service" on page 15 . -

Page 11: Controller

NO: The system does not offer more queries main menu. regarding the softening process. • Press "OK" to open the next sub-menu. • Press "OK" to confirm the changed setting in the sub-menu. Fillcontrol Auto Compact — 20.10.2020 - Rev. D English — 11... -

Page 12: Customer Menu

• Manufacturer specification for the replacement This menu is protected with a password. It can be accessed only by the Reflex interval of the softening cartridges, regardless of Customer Service. A partial summary of the settings stored in the Service menu is the calculated soft water capacity. - Page 13 Short-circuit of input voltage. Check the wiring at the digital inputs (water meter, for example). Analogue input voltage faulty Short-circuit of input voltage. Check the wiring at the analogue inputs (pressure/level). Fillcontrol Auto Compact — 20.10.2020 - Rev. D English — 13...

-

Page 14: Maintenance

Check the following device components for leaks: – "PU“ pumps and screw fittings. • Seal any leaks at the connections or replace the connections, if required. • Seal leaking screw connections or replace, if required. 14 — English Fillcontrol Auto Compact — 20.10.2020 - Rev. D... -

Page 15: Annex

The operating authority is required to place appropriate warning signs in the vicinity of the device. 12.2 Conformity and standards Device conformity declarations are available on the Reflex homepage. CAUTION www.reflex-winkelmann.com/konformitaetserklaerungen Risk of injury due to pressurised liquid If installation or maintenance work is not carried out correctly, there is a risk... - Page 16 The settings in the controller match the local conditions. Typ / Type: Fabr. Nr. / Serial-No. 16 — English Fillcontrol Auto Compact — 20.10.2020 - Rev. D...

- Page 17 Reflex Winkelmann GmbH Gersteinstraße 19 59227 Ahlen, Germany +49 (0)2382 7069-0 +49 (0)2382 7069-9546 www.reflex-winkelmann.com...

Need help?

Do you have a question about the Fillcontrol Auto Compact and is the answer not in the manual?

Questions and answers