Table of Contents

Advertisement

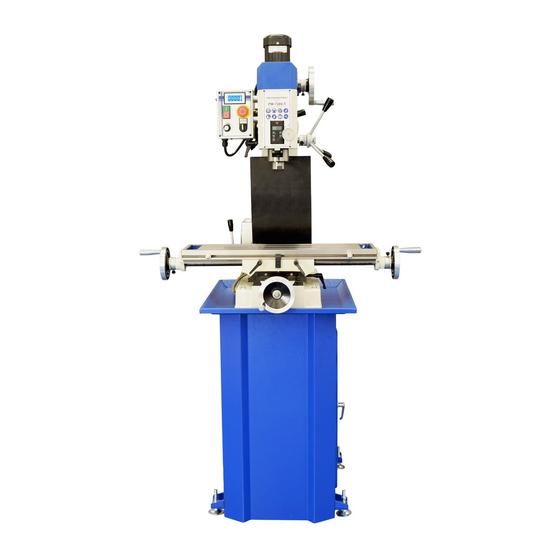

Model PM 728V-T Precision Milling Machine

Square column design, heavy cast iron construction

High weight-to-size factor: 370 lb excluding stand

1 HP (750W) brushless dc motor, 110 Vac single phase power

Quiet belt drive, no gears

Variable spindle speed from 100 to 4000 + rpm

Table size 7" x 28"

One-shot lubrication system standard

Quill DRO for precise downfeed measurement

PM-728V-T with optional stand

PM 728V-T v2 2020-10

1

Copyright © 2020 Quality Machine Tools, LLC

Advertisement

Table of Contents

Summary of Contents for Precision matthews PM 728V-T

- Page 1 Model PM 728V-T Precision Milling Machine Square column design, heavy cast iron construction High weight-to-size factor: 370 lb excluding stand 1 HP (750W) brushless dc motor, 110 Vac single phase power Quiet belt drive, no gears Variable spindle speed from 100 to 4000 + rpm Table size 7"...

- Page 2 (see our website www.precisionmatthews.com for support contacts). Your feedback is welcomed! Copyright © 2020 Quality Machine Tools, LLC This material was originated by Precision Matthews. No portion of the manual may be repro- duced or distributed in any form without the written approval of Quality Machine Tools, LLC.

-

Page 3: Section 1 Installation

Run a padded sling under the headstock, as Figure 1-2. Taking care not to damage the Z-axis locking handle and the electrical box, hook the sling, basket style, to the hoist's hook/chain. Figure 1-1 Access to the drawbar PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC... - Page 4 T-bolts With another person on hand to stabilize the headstock, remove the two attachment nuts, then move the table for- ward clear of the T-bolts. PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC...

-

Page 5: Initial Checks

You can now re-start the machine as shown starting in step 6 above. 11. Re-install the drawbar UNDER the spindle cap, Figure 1-1. PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC... -

Page 6: Section 2 Features & Specifications

19 in., Y = front/back motion of table 10 in., Z = headstock up/down, 16-1/4 in. (Installation of DRO scales on the table and headstock may limit these numbers.) 76-1/2" 44-1/2" 34-3/4 8-1/2" 3-1/4" PM-728V-T dimensions PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC... - Page 7 90 degrees - zero - 90 degrees Typical cutting capacities in steel Drilling 3/4 in., End milling 1 in., Face milling (with multi-tip tool) 3 in. Special accessory supplied: Spindle C-wrench PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC...

- Page 8 • Clean the machine routinely – remove chips by brush or vacuum, not com- pressed air (which can force debris into the ways). No list of precautions can cover everything. You cannot be too careful! PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC...

-

Page 9: Section 3 Using The Mill

If unsure, go slow! tightness of the belt. Do not over-tighten – aim for ± ¼” slack between the motor and spindle pulleys. PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC... - Page 10 Unscrew the drawbar with one hand while support- ing the R-8 device with the other hand. PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC...

- Page 11 This means that motion must always be in the same direction up to the point of reference, then on to the desired PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC...

- Page 12 Instead, do the find- ing by lowering the headstock, or lower the quill with the fine downfeed control — no locking in either case. PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC...

-

Page 13: Tapping Operations

For easier tapping it may be helpful to experiment with a larger hole than specified in the Figure 3-17 Headstock worm wheel PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC... - Page 14 8. Note the dial indicator and DRO readings, then back off the fine downfeed at least a couple of turns to avoid colli- sion when sweeping. 9. Reposition the 1-2-3 block to the opposite location on the table. PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC...

- Page 15 Figure 3-20 Indicating the vise The tip of a standard dial indicator, arrowed, rides along the side face of a ground reference bar (or the front face of the back jaw). PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC...

-

Page 16: Section 4 Maintenance

The back adjustment screw for this photo are machined oil grooves fed by the one-shot oiler. the Y axis gib (2) is under the solid rubber way cover behind the table. PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC... - Page 17 C-clip beneath the spindle cap, Figure 4-6. Spring force is not adjustable. Figure 4-7 Quill return spring Spindle Return spring cup Figure 4-6 Removing the special C-clip PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC...

-

Page 18: Section 5 Parts

F_058=250.0 than 250Vdc Three beeps Output current is F_056 =7.0 higher than 7A Four beeps Drive temperature is F_057=80.0 higher than 80 ° C Model PM-728V-T Electrical Fig 1 PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC... - Page 19 Model PM-728V-T HEADSTOCK & SPINDLE Fig 2 There may be detail differences between this representative drawing and the machine as supplied PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC...

- Page 20 Clamp knob Z5994 Cap screw Z6032 Lever knob Z5995 Cap screw Z6033 Handle lever Z5996 Phl. hd. screw Z6034 Pinion shaft hub Z5997 Z6035 O-ring Z5998 Spindle spline block Z5999 PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC...

- Page 21 PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC...

- Page 22 Thrust bearing 51102 Z6065 Z6100 Z-axis leadscrew Z6066 One-shot oiler Z6101 Leadscrew nut Z6067 Phl. hd. screw Z6102 Machine base Z6068 Screw Z6103 Table Z6069 Tubing Z6104 Movable stop sleeve Z6070 PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC...

- Page 23 Z6117 Reset switch Z6109 Speed potentiometer Z6118 Limit switch Z6110 Power cord Z6119 Controller PCB Z6111 Cap screw Z6120 Cable bushing Z6112 Phl. hd. screw Z6121 Electrical box Z6113 PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC...

- Page 24 Nut M6 Z6135 Chip pan Z6127 Cap screw Z6136 Rear panel Z6128 Carriage screw M8 x 20 Z6137 Side panel Z6129 Washer Z6138 Washer Z6130 Nut 1/2 x XX Z6139 PM 728V-T v2 2020-10 Copyright © 2020 Quality Machine Tools, LLC...

Need help?

Do you have a question about the PM 728V-T and is the answer not in the manual?

Questions and answers