Table of Contents

Advertisement

Quick Links

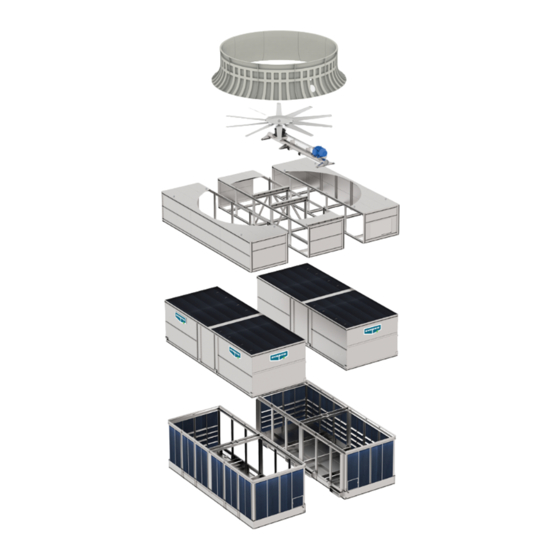

Assembly Instructions

Induced Draft, Modular Counterflow Cooling Towers

EVAPCO, Inc. — World Headquarters & Research/Development Center

North America

EVAPCO, Inc.

World Headquarters

P.O. Box 1300

Westminster, MD 21158 USA

410-756-2600 p

|

410-756-6450 f

marketing@evapco.com

EVAPCO East

5151 Allendale Lane

Taneytown, MD 21787 USA

410-756-2600 p | 410-756-6450 f

marketing@evapco.com

EVAPCO East

Key Building

Taneytown, MD USA

410-756-2600 p

marketing@evapco.com

EVAPCO Midwest

Greenup, IL USA

217-923-3431 p

evapcomw@evapcomw.com

EVAPCO West

Madera, CA USA

559-673-2207 p

contact@evapcowest.com

EVAPCO Iowa

Lake View, IA USA

712-657-3223 p

EVAPCO Iowa

Sales & Engineering

Medford, MN USA

507-446-8005 p

evapcomn@evapcomn.com

EVAPCO Newton

Newton, IL USA

618-783-3433 p

evapcomw@evapcomw.com

EVAPCOLD

Greenup, IL USA

217-923-3431 p

evapcomw@evapcomw.com

EVAPCO...S

Rigging and

AT ATLAS

EVAPCO products are manufactured worldwide

P.O. Box 1300 • Westminster, MD 21158 USA

410-756-2600 p • marketing@evapco.com • evapco.com

EVAPCO-BLCT Dry Cooling, Inc.

1011 US Highway 22 West

Bridgewater, NJ 08807 USA

1-908-379-2665 p

info@evapco-blct.com

EVAPCO-BLCT Dry Cooling, Inc.

Littleton, CO 80127 USA

1-908-379-2665 p

info@evapco-blct.com

EVAPCO Power México S. de R.L. de C.V.

Calle Iglesia No. 2, Torre E

Tizapan San Ángel, Del. Álvaro Obregón

Ciudad de México, D.F. México 01090

+52 (55) 8421-9260 p

info@evapco-blct.com

Refrigeration Vessels &

Systems Corporation

A wholly owned subsidiary of EVAPCO, Inc.

Bryan, TX USA

979-778-0095 p

rvs@rvscorp.com

EvapTech, Inc.

A wholly owned subsidiary of EVAPCO, Inc.

Edwardsville, KS USA

913-322-5165 p

marketing@evaptech.com

Tower Components, Inc.

A wholly owned subsidiary of EVAPCO, Inc.

Ramseur, NC USA

336-824-2102 p

mail@towercomponentsinc.com

EVAPCO Alcoil, Inc.

A wholly owned subsidiary of EVAPCO, Inc.

York, PA USA

717-347-7500 p

info@alcoil.net

PECiAliStS in

Visit EVAPCO's Website at:

Europe

EVAPCO Europe BVBA

European Headquarters

Heersterveldweg 19

Industrieterrein Oost

3700 Tongeren, Belgium

|

(32) 12-395029 p

(32) 12-238527 f

evapco.europe@evapco.be

EVAPCO Europe, S.r.l.

Milan, Italy

(39) 02-939-9041 p

evapcoeurope@evapco.it

EVAPCO Europe, S.r.l.

Sondrio, Italy

EVAPCO Europe GmbH

Meerbusch, Germany

(49) 2159 6956 18 p

info@evapco.de

EVAPCO Air Solutions

A wholly owned subsidiary of EVAPCO, Inc.

Aabybro, Denmark

(45) 9824 4999 p

info@evapco.dk

EVAPCO Air Solutions GmbH

Garbsen, Germany

(49) 5137 93875-0 p

info@evapcoas.de

Evap Egypt Engineering Industries Co.

A licensed manufacturer of EVAPCO, Inc.

Nasr City, Cairo, Egypt

2 02 24022866 / 2 02 24044997 p

primacool@link.net / shady@primacool.net

EVAPCO Middle East DMCC

Dubai, United Arab Emirates

+971 4 448 7242 p

info@evapco.ae

EVAPCO S.A. (Pty.) Ltd.

A licensed manufacturer of EVAPCO, Inc.

Isando 1600, Republic of South Africa

(27) 11-392-6630 p

evapco@evapco.co.za

H

t

P

EAt

rAnSfEr

rOduCtS And

evapco.com

Bulletin ATLAS20RIG

Asia/Pacific

EVAPCO Asia/Pacific Headquarters

1159 Luoning Road

Baoshan Industrial Zone

Shanghai 200949, P.R. China

(86) 21-6687-7786 p | (86) 21-6687-7008 f

marketing@evapcochina.com

EVAPCO (Shanghai) Refrigeration Equipment Co., Ltd.

Baoshan Industrial Zone Shanghai, P.R. China

(86) 21-6687-7786 p

marketing@evapcochina.com

Beijing EVAPCO Refrigeration Equipment Co., Ltd.

Huairou District Beijing, P.R. China

010-6166-7238 p

evapcobj@evapcochina.com

EVAPCO Air Cooling Systems (Jiaxing) Company, Ltd.

Building 10, 1133 Taoyuan Road,

Jiaxing, Zhejiang, China

(86) 573 83119379 p

info@evapcoacs.cn

EVAPCO Australia (Pty.) Ltd.

Riverstone NSW 2765, Australia

(61) 2 9627-3322 p

sales@evapco.com.au

EvapTech Asia Pacific Sdn. Bhd

A wholly owned subsidiary of EvapTech, Inc.

Puchong, Selangor, Malaysia

(60-3) 8070-7255 p

marketing-ap@evaptech.com

South America

EVAPCO Brasil

Equipamentos Industriais Ltda.

Al. Vênus, 151 – CEP: 13347-659

Indaiatuba –São Paulo – Brasil

(55+11) 5681-2000 p

vendas@evapco.com.br

Fan Technology Resources

Cruz das Almas – Indaiatuba

São Paulo, Brasil 13308-200

55 (11) 4025-1670 p

fantr@fantr.com

S

.

ErViCES

Advertisement

Table of Contents

Summary of Contents for EVAPCO AT ATLAS

- Page 1 Assembly Instructions AT ATLAS Induced Draft, Modular Counterflow Cooling Towers EVAPCO products are manufactured worldwide EVAPCO, Inc. — World Headquarters & Research/Development Center P.O. Box 1300 • Westminster, MD 21158 USA 410-756-2600 p • marketing@evapco.com • evapco.com North America Europe Asia/Pacific EVAPCO, Inc.

-

Page 2: Table Of Contents

AT ATLAS Induced Draft Counterflow Cooling Towers Table of Contents Introduction................... . 3 Shipping . -

Page 3: Introduction

Shipping Unless otherwise noted in the factory submittal, all EVAPCO AT ATLAS towers ship in seven (7) sections per cell plus the drive system, fan and fan cylinder. Any special shipping configurations will be listed in the factory submittal. Please contact your local EVAPCO representative for more information on alternate shipping configurations. -

Page 4: Structural Steel Support

AT ATLAS Induced Draft Counterflow Cooling Towers Structural Steel Support As standard, three structural “I” beams running the length of the unit are required for support of each cell. These beams should be located underneath the outer flanges of the unit (See Figure 1 and 1a). Transverse steel arrangements are also available (see Figures 1b and 1c). -

Page 5: Rigging Basin Sections

AT ATLAS Induced Draft Counterflow Cooling Towers Rigging Basin Sections Lifting devices are located along the inside edges of the bottom section for lifting and final positioning purposes as shown in Figure 2. The hook of the crane must be a minimum dimension of 26’ above the top of the basin section to prevent undue strain on the lifting devices. - Page 6 AT ATLAS Induced Draft Counterflow Cooling Towers 5. Repeat steps 2-4 for all 3 flume boxes. 6. Rig the second basin adjacent to the equalizer flume on the steel support as shown in Figure 3. 7. Clean the mating surfaces of the flume box and the surface of the flume opening on the adjacent section. Apply sealer tape to the flanged flume opening on the adjacent section.

-

Page 7: Application Of Sealer Tape To Basin Sections

AT ATLAS Induced Draft Counterflow Cooling Towers DRIP CHANNEL TAPPERS (GALVANIZED) 5/16" OR STAINLESS STEEL HARDWARE BOLTS (STAINLESS) SEALER TAPE RETAINING CLIP DRILLING IS REQUIRED IN THE FIELD FOR THESE HOLES DRIP CHANNEL SIDE PANEL SECTION Figure 3a - Drip Channel and Vertical Splash Guard Installation... -

Page 8: Rigging Casing Sections

AT ATLAS Induced Draft Counterflow Cooling Towers Rigging Casing Sections Lifting ears are provided in the corners of the casing sections and along the length (4 total lifting ears per side) for lifting and final positioning. The hook of the crane must be a minimum dimension 26’ above the casing sections to prevent undue strain on the lifting ears. - Page 9 The side flanges located in between cells can be accessed from inside the unit. Bolts can be driven upward through the mating flanges if access is restricted. All rigging hardware is provided by EVAPCO. Drift pins are by others. The recommended drift pin is 3/16” punch size with 10” overall length.

-

Page 10: Assembly Of Bottom Inlet Piping

AT ATLAS Induced Draft Counterflow Cooling Towers Assembly of Bottom Inlet Piping On the ATLAS tower, the inlet connection is located on the bottom as standard. Internal piping is provided that allows the process water to make its way to the hot water distribution system. Please follow the below steps to complete field installation of the bottom inlet after the unit is rigged. -

Page 11: Application Of Sealer Tape To Casing Sections

AT ATLAS Induced Draft Counterflow Cooling Towers Application of Sealer Tape to Casing Sections Once the casing sections have been rigged to the basin sections and all fasteners are installed, the top flanges should be wiped down to remove any dirt or moisture. Apply one layer of sealer tape, centered over the mounting holes (see Figure 9). On the flanges between casing sections, apply two strips of sealer tape, one partially overlapping the other on the entire length of the flanges. -

Page 12: Rigging Fan Sections

AT ATLAS Induced Draft Counterflow Cooling Towers Rigging Fan Sections Each ATLAS unit has 3 fan sections: left, right and middle. On the middle section, lifting ears are provided for lifting and final positioning. For the left and right sections, “U” bolts are provided. The hook of the crane must be a minimum of 26’ above the lifting device to prevent undue strain on the lifting ears and “U”... -

Page 13: Assembly Of The Fan Sections To The Casing Sections

AT ATLAS Induced Draft Counterflow Cooling Towers Assembly of the Fan Sections to the Casing Sections The fan sections rigging should begin with an end fan module, followed by the middle fan module and finally followed by the last end fan module. -

Page 14: Rigging Fan Sections On Multicell Units

AT ATLAS Induced Draft Counterflow Cooling Towers Rigging Fan Sections on Multicell Units In multicell installations, placing multiple towers side-by-side will limit access between cells and make rigging more difficult. Therefore multicell rigging channels will come attached to the inside of the casing and fan section panels, as shown in Figure 12. -

Page 15: Fan Sealing

AT ATLAS Induced Draft Counterflow Cooling Towers Fan Sealing After rigging, apply caulk to the top and end seams of the fan sections (Figure 13). This must be done from the inside of the unit. APPLY CAULK TO FAN SECTION TOP AND END... -

Page 16: Floating Shaft Installation & Alignment

AT ATLAS Induced Draft Counterflow Cooling Towers Floating Shaft Installation & Alignment The fan motor and gear reducer will ship mounted to the mechanical equipment support. The system will be prealigned in the factory, however alignment should be verified prior to rigging the mechanical equipment support to the fan section. -

Page 17: Fan Assembly Instructions

AT ATLAS Induced Draft Counterflow Cooling Towers Fan Assembly Instructions Once the gear drive has been aligned the fan should be assembled onto the mechanical equipment assembly. This simplifies assembly by completing it at ground level and reducing the number of lifts required. -

Page 18: Rigging Drive Assembly

AT ATLAS Induced Draft Counterflow Cooling Towers Rigging Drive Assembly Once the gear drive has been aligned and the fan assembled onto the gear output shaft, the entire assembly should be lifted onto the fan section (Figure 17). The hook of the crane must be a minimum of 17’ above the lifting ears. See Table 8 for hardware required to attach the drive assembly to the fan deck. -

Page 19: Fan Cylinder Assembly

AT ATLAS Induced Draft Counterflow Cooling Towers Fan Cylinder Assembly The fan cylinder will ship in 10 sections for assembly and installation in the field. Each section will be joined with a flange as shown in Figure 18. Fan cylinder assembly should be performed on the ground with one person holding the sections up until the assembly is able to stand alone. -

Page 20: Fan Cylinder Rigging

AT ATLAS Induced Draft Counterflow Cooling Towers Fan Cylinder Rigging Lower cylinder carefully around fan and drive shaft using the provided lifting ears. The hook of the crane must be a minimum of 17’ above the lifting ears. Make sure fan assembly is centered within the cylinder before attaching to fan section. Measure the clearance between each fan tip and the cylinder with a tape measure, making sure it is 7/8”... -

Page 21: Fan Cylinder Sealing

AND FAN SECTIONS Figure 20 - Fan Cylinder Sealing After fan, drive system and fan cylinder are entirely assembled, rigged and sealed, the fans must be balanced per the fan manufacturer’s procedure. Contact your local EVAPCO representative for more information. -

Page 22: External Platform And Vertical Ladder Installation

AT ATLAS Induced Draft Counterflow Cooling Towers External Platform and Vertical Ladder Installation If your unit is accessorized with an external service platform assembly with a vertical ladder, this equipment is shipped in the basin of your unit. In some cases, they are shipped separately due to other basin accessories that may interfere with storage. The platform is partially assembled prior to shipment to minimize field assembly. - Page 23 AT ATLAS Induced Draft Counterflow Cooling Towers FITTINGS ON LADDER MAY NEED TO BE ADJUSTED IN FIELD. FAN DECK ACCESS LADDER FITTINGS ON LADDER MAY CASING MOUNTED NEED TO BE ADJUSTED PLATFORM IN FIELD. CUT TIE WRAPS ON LADDER BRACKETS AND INSTALL LADDER MOUNTED USING SUPPLIED 3/8”...

- Page 24 EVAPCO, Inc. • P.O. Box 1300 • Westminster, MD 21158 USA Phone: 410-756-2600 • Fax: 410-756-6450 • E-mail: marketing@evapco.com Printed on recycled paper ©2020 EVAPCO, Inc. using soy-based ink...

Need help?

Do you have a question about the AT ATLAS and is the answer not in the manual?

Questions and answers