Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Sweepster TB Series

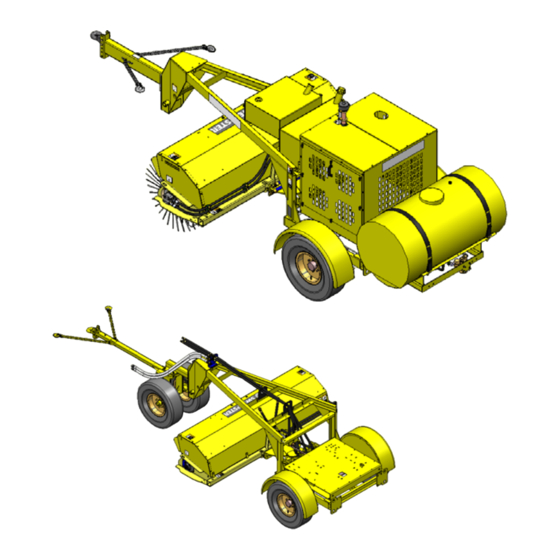

- Page 1 TB Series Tow Behind Sweeper Sweepster Serial Number_________________________ Manual Number: 51-4065 Release Date: July 2009 Serial Number 0930001 and Up 51-4065 1-800-456-7100 www.paladinlcg.com Sweepster 2800 N. Zeeb Rd., Dexter, MI. 48130 United States of America...

- Page 2 NOTES 51-4065...

-

Page 3: Table Of Contents

TaBlE Of CONTENTS INtRoDUctIoN ............................5 SAfety StAteMeNtS ..........................5 GeNeRAL SAfety PRecAUtIoNS......................6-7 SAfety SIGNS & LAbeLS .........................8 SeRvIce & RePAIR - SAfety ........................9 oPeRAtIoN ..............................9 StoRAGe ..............................11 LeveLING .............................12-13 MAINteNANce ............................14 RePLAcING bRUSh SectIoNS ......................15 MAINteNANce ScheDULe ........................16 MAINteNANce RecoRD .........................17 LUbRIcAtIoN PoINtS ..........................18 tRoUbLeShootING ..........................19-21 AxLe ASSeMbLy 5200 # .........................22... - Page 4 TaBlE Of CONTENTS eLectRIc vALve SwING/RUN/LIft ....................46-47 jUNctIoN box ASSeMbLy ........................48 coNtRoL boxeS ..........................49-58 MANIfoLD vALve - RUN/SwING/LIft ....................59 MANIfoLD vALve - RUN wIth ReLIef ....................59 bRUSh RUN, hyDRoStAtIc PUMP ....................... 60 wIRING foR ActUAtoR thRottLe/choke .................. 60-62 SwING ASSeMbLy ..........................

-

Page 5: Introduction

If you have any questions about information in this CaUTiON! THiS STaTEMENT iS USED manual or need to order parts, please call, write, fax WHERE MiNOR iNJURy COUlD or e-mail SweePSteR. RESUlT if THE iNSTRUCTiONS aRE NOT fOllOWED PROPERly. Sweepster 2800 North Zeeb Road... -

Page 6: General Safety Precautions

GENERal SafETy PRECaUTiONS GENERal SafETy PRECaUTiONS WaRNiNG! PROTECT aGaiNST flyiNG WaRNiNG! REaD MaNUal PRiOR TO DEBRiS iNSTall Always wear proper safety glasses, Improper installation, operation, goggles or a face shield when driving or maintenance of this equipment pins in or out or when operation could result in serious injury or causes dust, flying debris, or any other death. - Page 7 GENERal SafETy PRECaUTiONS GENERal SafETy PRECaUTiONS CONTiNUED CONTiNUED • wear safety glasses, protective clothing, and use a sound piece of • wear the protective clothing cardboard or wood when equipment specified by the tool searching for hydraulic leaks. manufacturer. DO NOT USE yOUR HaNDS! SEE illUSTRaTiON.

-

Page 8: Safety Signs & Labels

4. Safety signs are available, free of charge, from 4. Apply the safety sign to the position shown in your dealer or from SweePSteR. the diagram above and smooth out any bubbles. 51-4065... -

Page 9: Service & Repair - Safety

Repair damaged or loose lines, tubes and hoses. tire rating. Leaks can cause fires. See your SweePSteR •Remove from the sweeping area all property dealer for repair or replacement parts. that could be damaged by flying debris. - Page 10 Before Each Use Perform daily maintenance as indicated in •before leaving the operators area for any Maintenance Schedule. reason, lower the sweeper to the ground. Stop the prime mover engine, set the brakes and Run the prime mover and sweeper at a low idle. remove the key from the ignition.

-

Page 11: Storage

STORaGE Brush, Engine & Travel Speeds NOTiCE! Do not store the sweeper with weight on the brush. weight will vary brush, engine and travel speeds to match deform the bristles, destroying the sweeping conditions. sweeping effectiveness. large areas Do not store polypropylene brushes in direct sunlight. -

Page 12: Leveling

lEVEliNG Level the sweeper for even brush wear and effective use. CaUTiON! avoid injury. Before adjusting the sweeper, always turn off the sweeper and the prime mover engine and remove the key. 1. Move the sweeper to a flat, paved surface. 2. - Page 13 lEVEliNG high high high high figure 1 figure 3 high high high high figure 2 figure 4 7. Measure to see if the brush head assembly is Plate swing - to correct leveling problems level when shown in: angled. first, angle the brush head to the right. Measure •...

-

Page 14: Maintenance

MaiNTENaNCE Brush Pattern A properly adjusted brush offers the best sweeper performance. to check the brush pattern: 1. Move the sweeper to a dusty, flat surface. 2. Set the prime movers parking brake and leave the engine running. 3. Start the sweeper at a slow speed; then, lower it so the boom arms bottom out. -

Page 15: Replacing Brush Sections

REPlaCiNG BRUSH SECTiONS 1. Remove motor mount screws. Retain hardware for reinstallation. Remove motor mount(s). 2. Remove bearing mounting plate screws from side. Retain hardware for reinstallation. (Single motor only) 3. Lift sweeper frame leaving core on ground. 4. Remove core from brush head assembly. Remove plate ring core end. -

Page 16: Maintenance Schedule

MaiNTENaNCE SCHEDUlE Procedure Before Weekly Each Hours Hours Engine Manual check hydraulic oil Level Lubricate All Grease Zerks check brush Pattern check Lights for Proper operation Level brush head Assembly Inspect hitch and hitch hardware Inspect hitch Safety chains clean Safety Decals wash and clean Unit clean optional Sprinkler System filter check battery connections (electrolite Level if not... -

Page 17: Maintenance Record

MaiNTENaNCE RECORD Date Performed by Comments Maintenance Procedure Performed 51-4065... -

Page 18: Lubrication Points

lUBRiCaTiON POiNTS the following grease fittings should be greased before each use. See figure for locations. 1. Parallel Link Pins ( 4 fittings ) 2. outside bearing ( 1 fitting ) 51-4065... -

Page 19: Troubleshooting

TROUBlESHOOTiNG Brush Head assembly Problem Possible Cause Possible Solution brush rotates wrong direction hoses installed incorrectly Switch hoses at brush head tubes brush slows or stops when brush pattern too wide Adjust brush pattern to 2-4 inches sweeping (51-101mm) wide: see Maintenance Adjusting brush Pattern travel speed too fast travel no more than 5 mph (8... - Page 20 1 1/2 turns; tighten jam nut electric valve - Dirt or debris in contact Sweepster technical spools Service enabler valve not working check electrical connections hydraulic cylinder extends or...

- Page 21 Disconnect and reconnect; Replace correctly with high flow quick couplers hydraulic motor seals leak back pressure exceeds contact Sweepster 1000psi Motor is failing high number of hours on motor; contact dealer to rebuild or replace 51-4065...

-

Page 22: Axle Assembly 5200

aXlE aSSEMBly 5200 # your axle may vary from the one depicted. item Part Description 1. 07-0144 Nut, Lug, Gr2, 1/2-20 x 5/8 2. 07-1763 washer, flat, Gr8, 1/2 3. 07-4037 Nut, hex, Nylock, Gr8, 1/2-13 4. 07-5075 Screw, hhc, Gr8, 1/2-13 x 2 5. -

Page 23: Brush Head Assemblies

BRUSH HEaD aSSEMBly SiNGlE MOTOR NOTE: TOP PORT PRESSURE BOTTOM PORT RETURN item Part Description 1. 28-10095-7 1 Assembly, core 10 (7 ft) 28-10095-8 1 Assembly, core 10 (8 ft) 28-10095-9 1 Assembly, core 10 (9 ft) 2. 28-10309-7 1 Assembly, brush frame ( 7 ft ) 28-10309-8 1 Assembly, brush frame ( 8 ft ) - Page 24 BRUSH HEaD aSSEMBly DUal MOTOR NOTE: TOP PORT PRESSURE BOTTOM PORT RETURN item Part Description 1. 28-10095-7 1 Assembly, core ( 7 ft ) 28-10095-8 1 Assembly, core ( 8 ft ) 28-10095-9 1 Assembly, core ( 9 ft ) 2.

- Page 25 BRUSH fRaME aSSEMBly item Part Description 1. 07-0244 Pin, Lynch 2. 07-0249 chain, 1/4, 22 Links 3. 07-2952 Screw, hfh, cL10.9, M6-1 x 20 4. 07-3311 Link, quick, 5/16 5. 07-3617 Nut, Insert, hex, M6 x 1 6. 07-3736 washer, flat, cL8.8, M8 7.

- Page 26 SHafT aSSEMBly item Part Description 07-3747 washer, Lock, Split, Medium, M10 07-3749 Screw, hhc, cL10.9, M10-1.5 x 30mm 07-3756 washer, Lock, Split, Medium, M12 07-3762 Screw, hhc, cL10.9, M12-1.75 x 50mm 07-3842 Ring, Snap, 5160-125 07-6196 Ring, Snap 07-6766 Nut, hex, cL10.9, M12-1.75 08-0067 bearing, 1 1/4, 4 bolt 13-14133...

-

Page 27: Motor Bucket Assemblies

MOTOR BUCKET aSSEMBliES item Part Description 03-5612 Motor, 18.3 cI 03-5613 Motor, 28.3 cI 07-3747 washer, Lock, Split, Medium, M10 07-3749 Screw, hhc, cL10.9, M10-1.5 x 30mm 07-3754 washer, flat, cL10.9, M12 07-3756 washer, Lock, Split, Medium, M12 07-6683 Screw, hhc, cL10.9, M12-1.75 x 65mm 07-6766 Nut, hex, cL10.9, M12-1.75 13-14085 1... -

Page 28: Hydraulic Motor Assemblies

HyDRaUliC aSSEMBliES SiNGlE MOTOR DETAIL A DETAIL A item Part Description 03-1939 fitting, Adapter, hP, 7/8MoR, 5/8MfS 03-2003 o-Ring fS 3/4 03-3531 elbow, 90º, 12Mf-12Mf 03-5654 hose, .5 x 62, 10ff, 12ff, 3.5k (7 ft) 03-5655 hose, .5 x 68, 10ff, 12ff, 3.5k (8 ft) 03-5656 hose, .5 x 74, 10ff, 12ff, 3.5k (9 ft) 07-3738... - Page 29 HyDRaUliC aSSEMBliES DUal MOTOR DETAIL A DETAIL A item Part Description 03-1939 fitting, Adapter, hP, 7/8MoR, 5/8MfS 03-5160 fitting, tee, hP, bulkhead, 12MfS 03-5654 hose, .5 x 62, 10ff, 12ff, 3.5k (7 ft) 03-5655 hose, .5 x 68, 10ff, 12ff, 3.5k (8 ft) 03-5656 hose, .5 x 74, 10ff, 12ff, 3.5k (9 ft) 07-3738...

-

Page 30: Core Assemblies

CORE aSSEMBliES item Part Description 1. 07-3617 Nut, Insert, hex, M6 x 1 2. 07-3730 washer, Lock, Split, Medium, M6 3. 07-3731 Screw, hhc, cL10.9, M6-1 x 30mm 4. 13-13166 Plate, Ring, core, end 5. 13-15866-7 weld, core, 10 ( 7 ft ) 13-15866-8 weld, core, 10 ( 8 ft ) 13-15866-9... -

Page 31: 180° Hood Extensions

180° HOOD EXTENSiON item Part Description 1. 07-3522 Screw, hfh, cL10.9, M6-1 x 20, whiz Lock 2. 07-3617 Nut, Insert, hex, M6 x 1 3. 07-4942 washer, fender, 5/16 x 1 1/2 4. 07-7115 Nut, Insert, M8-1.25, 22-10ga (7 ft) 07-7115 Nut, Insert, M8-1.25, 22-10ga (8,9 ft) 5. - Page 32 180° HOOD EXTENSiON WiTH DRaPE item Part Description 07-3522 Screw, hfh, cL10.9, M6-1 x 20, whiz Lock 07-3617 Nut, Insert, hex, M6 x 1 07-3736 washer, flat, cL8.8, M8, (7 ft) 07-3736 washer, flat, cL8.8, M8, (8,9 ft) 07-3738 washer, Lock, Split, Medium, M8, (7 ft) 07-3738 washer, Lock, Split, Medium, M8, (8,9 ft) 07-3777...

-

Page 33: Hydraulic Tank

HyDRaUliC TaNK 03-4741 SEE NOTE 03-4741 03-3965 03-3965 SEE NOTE 07-6705 SEE NOTE item Part Description 1. 03-3678 fitting, Plug, Socket head, 3/4MoR 2. 03-4642 Strainer, filler Spout 3. 03-4709 Gauge, Sight, window, 1 Inch NPt 4. 03-5055 cap, breather 5. -

Page 34: Fuel Tanks

DiESEl fUEl TaNK Serial # 1021100 and lower item Part Description 03-1069-4 2 elbow, 90, 4fP-4MP 03-1309 fitting, 2fP-4MP 03-1669 barb, 3, 2MP, bR 03-1701 barb, 5, 4MP, bR 07-0538 clamp, Screw, MM-4 1/4-5/8 07-1717 bolt, carriage, Gr5, 3/8-16 x 1 1/4 07-3279 washer, flat, Gr8, 3/8 07-4036... - Page 35 DiESEl fUEl TaNK Serial # 1021100 and Up item Part Description 03-1069-4 2 elbow, 90, 4fP-4MP 03-1182-4 1 Plug, Square head, 8P 03-1309 fitting, 2fP-4MP 03-1669 barb, 3, 2MP, bR 03-1701 barb, 5, 4MP, bR 07-0538 clamp, Screw, MM-4 1/4-5/8 07-1717 bolt, carriage, Gr5, 3/8-16 x 1 1/4 07-3279...

-

Page 36: Pump Assemblies

PUMP aSSEMBliES item Part Description 03-0710 fitting, barb, hP, 90°, 1 1/4, 1 5/16MoR 03-1945 fitting, Adapter, hP, 1 1/16MoR, 3/4MfS 03-5038 fitting, barb, 1 1/4, 1 5/16 03-2736 Pump, Prince, 12gpm@2000rpm 03-2623 Pump, Prince, 20gpm@3000rpm 05-1406 hub, Splined, Adapter, 7/8-13 Spline 07-0045 Screw, hhc, Gr8, 1/2-13 x 1 1/2 07-0156... - Page 37 HyDRaUliC PUMP aSSEMBly item Part Description 1. 03-0366 Fitting, Elbow, HP, 90°, 1 5/16MOR, 1FP 2. 03-0569 Valve, Shut-Off, Ball, 3/4 3. 03-0745 Filter, Head, 1-12MNT, 25gpm, 3/4NPT Ports 4. 03-1022-10 Fitting, Nipple, HP, Hex, 3/4MP, 3/4MP 5. 03-1086 Kit, Mounting, Oil, Cooler 6. 03-1943 Fitting, Adapter, HP, 3/4MFS, 3/4MP 7. 03-2035 Fitting, Adapter, HP, 3/4MFS, 1 5/16MOR 8. 03-2148 Fitting, Adapter, HP, 3/4MFS, 3/4MOR 9. 03-2177 Fitting, Elbow, HP, 90°, 3/4MFS, 1 1/16MOR 10. 03-3390 Hose, 3/4 x 24, 2W, 3/4FFS, 3/4FFS90...

-

Page 38: Drive Pump/Manual Lift

DRiVE PUMP item Part Description 1. 07-1784 Screw, HHC, Gr8, 5/16-18 x 2 1/2 2. 07-3270 Nut, Hex, Nylock, Gr8, 5/16-18 3. 07-3275 Washer, Flat, Gr8, 5/16 4. 07-3640 Screw, HHC, Gr8, 1/4-20 x 1 3/4 5. 07-3702 Bolt, Carriage, Gr5, 3/8-16 x 1 6. 07-4032 Washer, Flat, Gr8, 1/4 7. 07-4033 Nut, Nylock, Gr8, 1/4-20 8. 07-5370 Nut, Hex, Lock, Gr8. 3/8-16 9. 07-7222 Actuator, 2 Inch Stroke 10. 13-13934 Plate, Pump, Control 11. 13-2296 Weld, Mounting, Actuator, Pump MaNUal lifT item Part Description 1. 03-1928-1 Cylinder, Hydraulic, 3 Bore, 4 1/2 Stroke... - Page 39 NOTES 51-4065...

-

Page 40: Manual Valve Run/Lift

MaNUal ValVE RUN/lifT BRUSH RETRUN BRUSH RUN 51-4065... - Page 41 MaNUal ValVE RUN/lifT item Part Description 03-1928-1 1 cylinder, hydraulic, 3 bore, 4 1/2 Stroke 03-1932 1 fitting, vent, 9/16MoR, with bell cap 03-1945 1 fitting, Adapter, hP, 1 1/16MoR, 3/4MfS 03-2093 1 hose, 3/8 x 48, 1w, 3/8ffS, 3/8ffS 03-2115 1 fitting, elbow, hP, 45°, 9/16MoR, 3/8MfS 03-2177 1...

-

Page 42: Manual Valve Swing/Run/Lift

MaNUal ValVE SWiNG/RUN/lifT 20 14 BRUSH RETURN BRUSH DETAIL A 51-4065... - Page 43 MaNUal ValVE SWiNG/RUN/lifT item Part Description 03-1928-1 1 cylinder, hydraulic, 3 bore, 4 1/2 Stroke 03-1932 1 fitting, vent, 9/16MoR, with bell cap 03-1945 2 fitting, Adapter, hP, 1 1/16MoR, 3/4MfS 03-2093 1 hose, 3/8 x 48, 1w, 3/8ffS, 3/8ffS 03-2115 3 fitting, elbow, hP, 45°, 9/16MoR, 3/8MfS 03-2177 1...

-

Page 44: Electric Valve With Relief

ElECTRiC ValVE WiTH REliEf PRESSURE TO BRUSH HEAD ¦¦¦¦¦ BRUSH HEAD PRESSURE TO BRUSH HEAD ¦¦¦¦¦ BRUSH HEAD item Part Description 1. 03-1945 Fitting, Adapter, HP, 1 1/16MOR, 3/4MFS 2. 03-1956 Fitting, Elbow, HP, 90°, 1 5/16MOR, 3/4MFS 3. 03-2556 Hose, 3/4 x 24, 2W, 3/4FFS, 3/4FFS90 4. 03-3390 Hose, 3/4 x 30, Tc, 3/4FFS, 3/4FFS90 5. 03-4142 Manifold, 12 Volt, Run/Relief 6. 07-0018 Screw, HHC, Gr8, 3/8-16 x 1 7. 07-1718 Washer, Lock, Split, Medium, 3/8 8. 07-2116 Screw, HHC, Gr8, 3/8-16 x 1 1/4... -

Page 45: Monarch Valve

MONaRCH ValVE POSITION MONARCH HERE FOR HONDA & ROBIN Item Part NO. ¦¦¦¦¦ ENGINE AND KUBOTA WITH 03-1733 SYS, HYD, MONARCH, HORZ, M682 GEAR PUMP 03-1928-1 CYL, HYD, 3 BORE, 4 1/2 STROKE 03-1932 FTG , VENT, 9/16 MOR W/ BELL CAP 03-2093 HOSE, 3/8 X 48, 1W, 3/8FFS, 3/8FFS 03-2115... -

Page 46: Electric Valve Swing/Run/Lift

ElECTRiC ValVE SWiNG/RUN/lifT ... - Page 47 ElECTRiC ValVE SWiNG/RUN/lifT item Part Description 1. 03-1928-1 Cylinder, Hydraulic, 3 Bore, 4 1/2 Stroke 2. 03-1932 Fitting, Vent, 9/16MOR, with Bell Cap 3. 03-1945 Fitting, Adapter, HP, 1 1/16MOR, 3/4MFS 4. 03-1956 Fitting, Elbow, HP, 90°, 1 5/16MOR, 3/4MFS 5. 03-2093 Hose, 3/8 x 48, 1W, 3/8FFS, 3/8FFS 6. 03-2115 Fitting, Elbow, HP, 45°, 9/16MOR, 3/8MFS 7. 03-2291 Fitting, Adapter, HP, 3/8MFS, 9/16MOR 8. 03-2364-2 Manifold, 12 Volt 9. 03-2556 Hose, 3/4 x 24, 2W, 3/4FFS, 3/4FFS90 10. 03-2978 Hose, 3/8 x 37 1/4, 1W, 3/8FFS, 3/8FFS 11. 03-3390 Hose, 3/4 x 30, TC, 3/4FFS, 3/4FFS90 12. 03-4887 Cylinder, Hydraulic, 2 1/2 Bore, 7 1/2 Stroke, 3500psi 13. 07-0018 Screw, HHC, Gr8, 3/8-16 x 1...

-

Page 48: Junction Box Assembly

JUNCTiON BOX aSSEMBly Gauges for kubota engines only: 07-7200 hour Meter 07-7202 water temperature 07-7203 Sender, temperature 07-7205 Sender, oil Pressure 07-7201 voltmeter 07-2076 vacuum Indicator 07-7204 oil Pressure 07-7206 fuel Gauge 07-7207 fuel Sender ... -

Page 49: Control Boxes

CONTROl BOX - POWER/SWiNG/lifT POWER 07-0343 07-0351A 07-0351A SWING LIFT item Part Description 1. 07-0343 Switch, Toggle, 2 Position 2. 07-0351 Box, Control 3. 07-0351A Switch, Toggle, 6 Prong 4. 07-0812 Terminal, Connector, 1/4 Female, 16-14 5. 07-0867 Terminal, Butt, 16-14 6. 07-0916 Terminal, Ring, #8, 16-14 7. 07-0926 Terminal, Spade, 6, 16-14 8. 07-1477 Strain, Relief, 3/4, .75-.88 9. 07-2135 40 ft Wire, Cord, 16ga Wire/ Control... - Page 50 CONTROl BOX - GEaR PUMP/POWER/SWiNG/lifT/RUN POWER 07-0343 BRUSH RUN 07-0351A 07-0351A item Part Description SWING 1. 07-0343 Switch, Toggle, 2 Position LIFT 2. 07-0351 Box, Control 3. 07-0351A Switch, Toggle, 6 Prong 4. 07-0812 Terminal, Connector, 1/4 Female, 16-14 5. 07-0926 Terminal, Spade, 6, 16-14 6. 07-1477 Strain, Relief, 3/4, .75-.88 7. 07-2135 40 ft Wire, Cord, 16ga 8. 07-2245 Nut, Strain, Relief, 3/4 9. 07-3637 Screw, HHC, Gr8, 1/4-20 x 1...

- Page 51 CONTROl BOX - GEaR PUMP/ iGNiTiON/SWiNG/lifT/RUN/ 07-7076 07-0343 BATT BRUSH 07-0351A 07-0351A item Part Description SWING LIFT 1. 07-0343 Switch, Toggle, 2 Position 2. 07-0351 Box, Control 3. 07-0351A Switch, Toggle, 6 Prong 4. 07-0812 Terminal, Connector, 1/4 Female, 16-14 5. 07-0867 Terminal, Butt, 16-14 6. 07-0916 Terminal, Ring, #8, 16-14 7. 07-0926 Terminal, Spade, 6, 16-14 8. 07-1477 Strain, Relief, 3/4, .75-.88 9. 07-2135 40 ft...

- Page 52 CONTROl BOX - GEaR PUMP/iGNiTiON/SWiNG/lifT/RUN/ SPRiNKlER 07-7076 item Part Description 07-0343 BATT 1. 07-0343 Switch, Toggle, 2 Position SPRINKLER BRUSH 2. 07-0351 Box, Control 3. 07-0351A Switch, Toggle, 6 Prong 07-0351A 07-0351A 4. 07-0812 Terminal, Connector, 1/4 Female, 16-14 5. 07-0867 Terminal, Butt, 16-14 6. 07-0916 Terminal, Ring, #8, 16-14 7. 07-0926 Terminal, Spade, 6, 16-14 SWING 8. 07-1477 Strain, Relief, 3/4, .75-.88 LIFT 9. 07-2135...

- Page 53 CONTROl BOX - GEaR PUMP/iGNiTiON/THROTTlE/CHOKE/ SWiNG/lifT/RUN/SPRiNKlER 07-7076 07-7054 BATT THROTTLE 3AMP CHOKE 07-0351A SPRINKLER 07-0351A 07-0343 BRUSH item Part Description SWING 1. 07-0343 Switch, Toggle, 2 Position LIFT 2. 07-0351A Switch, Toggle, 6 Prong 3. 07-0812 Terminal, Connector, 1/4 Female, 16-14 4. 07-0867 Terminal, Butt, 16-14 5. 07-0916 Terminal, Ring, #8, 16-14 6. 07-0926 Terminal, Spade, 6, 16-14 7. 07-1476 Box, Junction, 4 x 6 x 8 8. 07-1598...

- Page 54 CONTROl BOX - GEaR PUMP/iGNiTiON/THROTTlE/GlOW PlUG/ SWiNG/lifT/RUN item Part Description 07-7076 1. 07-0343 Switch, Toggle, 2 Position 07-7054 BATT THROTTLE GLOW 2. 07-0351A Switch, Toggle, 6 Prong 07-1305 PLUG 3AMP 3. 07-0867 Terminal, Butt, 16-14 4. 07-0916 Terminal, Ring, #8, 16-14 5. 07-0926 Terminal, Spade, 6, 16-14 07-0351A 6. 07-1305 Switch, Starter, Universal 7. 07-1476 Box, Junction, 4 x 6 x 8 07-0351A 07-0343 8. 07-1477...

- Page 55 CONTROl BOX - GEaR PUMP/iGNiTiON/THROTTlE/GlOW PlUG/ SWiNG/lifT/RUN/SPRiNKlER 07-7076 07-7054 SPRINKLER GLOW BATT THROTTLE PLUG 07-0343 07-1305 3AMP 07-0351A 07-0351A BRUSH 07-0343 SWING LIFT item Part Description 1. 07-0343 Switch, Toggle, 2 Position 2. 07-0351A Switch, Toggle, 6 Prong 3. 07-0812 Terminal, Connector, 1/4 Female, 16-14 4. 07-0867 Terminal, Butt, 16-14 5. 07-0916 Terminal, Ring, #8, 16-14 6. 07-0926 Terminal, Spade, 6, 16-14...

- Page 56 CONTROl BOX - HyDROSTaTiC/iGNiTiON/THROTTlE/CHOKE/ SWiNG/lifT/RUN/SPRiNKlER item Part Description 07-7076 1. 07-0343 Switch, Toggle, 2 Position 07-7054 BATT CHOKE THROTTLE 2. 07-0351A Switch, Toggle, 6 Prong 3AMP 3. 07-0812 Terminal, Connector, 1/4 Female, 16-14 4. 07-0867 Terminal, Butt, 16-14 07-0343 5. 07-0916 Terminal, Ring, #8, 16-14 SPRINKLER 07-0351A 6. 07-0926 Terminal, Spade, 6, 16-14 07-0351A BRUSH 7. 07-1476 Box, Junction, 4 x 6 x 8 8. 07-1598 Strain, Relief, 1, .875-.985 9. 07-2198...

- Page 57 CONTROl BOX - HyDROSTaTiC/iGNiTiON/THROTTlE/GlOW PlUG/SWiNG/lifT/RUN/SPRiNKlER 07-7054 BATT THROTTLE 07-7076 GLOW 07-1305 PLUG 3AMP 07-0343 SPRINKLER 07-0351A BRUSH SWING 07-3838 07-0351A LIFT 6AMP item Part Description 1. 07-0343 Switch, Toggle, 2 Position Wire/ Control Junction Box 2. 07-0351A Switch, Toggle, 6 Prong Terminal Box Wire function Wire Color 3. 07-0812 Terminal, Connector, 1/4 Female, 16-14 Number...

- Page 58 CONTROl BOX - POWER/SWiNG/lifT/SPRiNKlER POWER 07-0343 SPRINKLER 07-0351A 07-0351A SWING LIFT Wire/ Control Junction Box Terminal Box Wire function Wire Color Number Color Going Out black w/Red Start black w/Red Right Swing blue Lift blue orange-yellow Lower orange/yellow white battery white Green Left Swing...

-

Page 59: Manifold Valve - Run/Swing/Lift

MaNifOlD ValVE - RUN/SWiNG/lifT #9 ORANGE W/BLACK #4 ORANGE A PORT= RIGHT (ROD) ENABLER B PORT= LEFT (BARRELL) #3 BLUE #2 RED TO ENABLER #6 GREEN 07-2709 JUMP JUMP FROM#6 FROM #2 JUMP FROM#3 MaNifOlD ValVE - RUN WiTH REliEf Wire/ Control Junction Box... -

Page 60: Brush Run, Hydrostatic Pump

BRUSH RUN, HyDROSTaTiC PUMP Wire/ Control Junction Box Terminal Box Wire function Wire Color Number Color Going Out black w/Red Start black w/Red Right Swing blue Lift blue orange-yellow Lower orange/yellow white battery white Green Left Swing Green Red w/ black brush control Red w/black blue w/black... - Page 61 WiRiNG fOR MONaRCH SySTEM 03-4763 VENT PLUG BLACK#12 GREEN#6 YELLOW#4 BLUE#3 RED#2 WiRiNG fOR KUBOTa DiESEl GLOW PLUG STARTER 07-2226 RELAY RELAY TO STARTER 10GA (BLACK) TO GLOW PLUG BATT. 10GA (WHITE) (STARTER) BATTERY 10GA (RED) (STARTER) 10GA (RED) 07-2226 10GA BLACK FROM ¦¦¦¦¦¦...

- Page 62 WiRiNG fOR KUBOTa WG972 IGNITION RELAY #11 FROM JUNCTION BOX STARTER CARB FROM JUNCTION 07-2226 RELAY TO STARTER 10GA (BLACK) ¦¦¦¦¦ HARNESS INGITER 10GA (RED) 10GA BLACK FROM STARTER RELAY BLACK FUEL PUMP CENTER 07-5356 WHITE W/BLACK POST STARTER 07-5142 51-4065...

-

Page 63: Swing Assembly

SWiNG aSSEMBly item Part Description 1. 07-0066 Screw, HHC, Gr8, 5/8-11 x 2 2. 07-0079 Screw, HHC, Tap, Gr5, 3/4-10 x 2 1/2 3. 07-0786 Pin, Cotter, Gr2, 3/16 x 1 1/2 4. 07-1294 Nut, Hex, Gr8, 5/8-11 5. 07-1872 Washer, Lock, Split, Medium, 5/8 6. 07-3066 Nut, Hex, Gr8, 3/4-10 7. 11-0459 Pin, 7/8 x 3, 2 Holes 8. 11-1854 Bushing, 1 x 5/8 x 5/8 9. 13-10476 Weld, Swing, Frame 10. 13-10477 Weld, Plate, Swing... -

Page 64: Scissor Swing Assembly

SCiSSOR SWiNG aSSEMBly item Part Description 1. 07-0080 Screw, HHC, Tap, Gr5, 3/4-10 x 3 2. 07-0119 Bolt, Carriage, Gr5, 5/8-11 x 1 3/4 3. 07-0120 Bolt, Carriage, Gr5, 5/8-11 x 2 4. 07-0223 Fitting, Zerk, Straight, 1/8NPT 5. 07-0786 Pin, Cotter, Gr2, 3/16 x 1 1/2 6. 07-1294 Nut, Hex, Gr8, 5/8-11 7. 07-3066 Nut, Hex, Gr8, 3/4-10 8. 07-3120 Washer, Flat, Gr8, 5/8 9. 07-3655 Screw, HHC, Gr8, 3/8-16 x 1 1/2 10. 07-3934 Screw, Tap, Gr5, 5/8-11 x 4 11. 07-4031 Nut, Hex, Nylock, Gr8, 5/8-11 12. 07-4036 Nut, Hex, Nylock, 3/8-16 13. 11-0023 Pin, 7/8 x 27 5/8... - Page 65 NOTES 51-4065...

-

Page 66: Hydraulic Run/Swing/Lift

09-0088 TRIM, BATT, BOX, BLK, STD 13-15840 PLATE, MTG, BULK HEAD, TB06 13-15897 PLATE, HOSE SUPPORT, TB06 * = NOT SHOWN BRUSH RUN HyDRaUliC 4X4 RUN/SWiNG/lifT DETAIL A BRUSH RETURN OUTER: SWING CENTER: LIFT LOWER BRUSH RUN BRUSH RETURN BRUSH RUN DETAIL A BRUSH RETURN BRUSH... - Page 67 HyDRaUliC 4X4 RUN/SWiNG/lifT Item Part NO. 03-1928-1 CYL, HYD 03-1959 HOSE, 3 3100 PS 03-2115 FTG, ELB 03-3345 HOSE, 3 03-4887 CYL, HYD 3/8 ROD 03-5406 HOSE, 3 03-9536 FTG, BUL 03-9539 FTG, BUL 07-0186 NUT, HE 07-0206 PIN, COT 07-0539 PIN, CLE 07-1716...

- Page 68 HyDRaUliC 3X4 RUN/SWiNG/lifT BRUSH RUN BRUSH RETURN BRUSH BRUSH DETAIL A OUTER: SWING CENTER: LIFT/LOWER 51-4065...

- Page 69 HyDRaUliC 3X4 RUN/SWiNG/lifT BRUSH RUN BRUSH RETURN DETAIL A item Part Description OUTER: SWING 1. 03-1928-1 Cylinder, Hydraulic, 3 Bore, 4 1/2 Stroke CENTER: LIFT/LOWER 2. 03-1932 Fitting, Vent, 9/16MOR, with Bell Cap 3. 03-2115 Fitting, Elbow, HP, 45°, 9/16MOR, 3/8MFS 4. 03-3345 Hose, 3/8 x 120, TC, 3/8FFS, 3/8FFS 5. 03-4616 Hose, 3/4 x 120, TC, 3/4FFS, 3/4FFS 6. 03-4887 Cylinder, Hydraulic, 2 1/2 Bore, 7 1/2 Stroke 7. 03-5406 Hose, 3/8 x 96, 2W, 6FFS, 6FFS 8. 03-9536 Fitting, Bulkhead, 3/8MFS, 3/8MFS 9. 03-9539 Fitting, Bulkhead, 12MFS, 12MFS 10. 07-0186...

-

Page 70: Hydraulic Lift/Manual Angle

REMOTE HyDRaUliC lifT/MaNUal aNGlE DETAIL B DETAIL A item Part Description 1. 03-1928-1 Cylinder, 3 x 1.13 x 4.5 2. 03-2115 Fitting, Elbow, HP, 45, 9/16MOR,3/8MFS 3. 03-5369 Hose, .38 x 78, 6FF-6FF, 3K, TC 4. 03-5406 Hose, .38 x 96, 6FF-6FF, 4.75K 5. 03-9536 Fitting, Bulkhead, 3/8MFS, 3/8MFS 6. 07-0186 Nut, Hex, Gr8, 1-12 7. 07-0206 Pin, Cotter, Gr2, 3/16 x 2 8. 07-0539 Pin, Clevis, Gr2, 1 , W/Clip both ends 9. 07-1717 Bolt, Carriage, Gr5, 3/8-16 x 1 1/4 10. 07-2105 Pin, Lock, 3/8 Square Bail 11. 07-4036 Nut, Hex, Nylock, Gr8, 3/8-16 12. 07-4040... -

Page 71: Traction Drive Hydraulic Assembly

TRaCTiON DRiVE HyDRaUliC aSSEMBly DETAIL A DETAIL B DETAIL C item Part Description item Part Description 1. 03-0129 Valve, Relief, 3/4MP Ports 27. 07-3754 Washer, Flat, CL10.9, M12 2. 03-0710 Fitting, Barb, HP, 90°, 1 1/4, 1 5/16MOR 28. 07-3756 Washer, Lock, Split, M12 3. 03-1054 Fitting, Street Elbow, HP, 45°, 3/4P 29. 07-3758 Screw, HHC, CL10.9, M12-1.75 x 30mm 4. 03-1943 Fitting, Adapter, HP, 3/4MFS, 3/4MP 30. 07-3934 Screw, Tap, Gr5, 5/8-11 x 4 5. 03-1945... -

Page 72: Axle Traction Drive

aXlE TRaCTiON DRiVE item Part Description item Part Description 1. 03-1022-7 Fitting, Nipple, HP, Hex, 1/2 21. 07-4037 Nut, Hex, Nylock, Gr8, 1/2-13 2. 05-1278 Bushing, 1 3/4, 6 Spline 22. 08-0056 Bearing, 1 3/4 3. 06-0490 Sprocket, Rim Only 23. 11-9251 Weld, Wheel, Ratchet, Right 4. 07-0686 Washer, Machine, 1 3/4-1 1/32 24. 11-9252 Weld, Wheel, Ratchet, Left 5. 07-0699 Pin, Cotter, Gr2, 1/8 x 1 1/4 25. 11-9253 Axle, Traction Drive 6. 07-1124 Screw, HHC, Gr8, 1/2-13 x 2 1/2 26. 11-9254... -

Page 73: Hitch Towbar

HiTCH TOWBaR 07-7098 07-7099 07-1035 item Part Description 1. 07-0070 Screw, HHC, Gr8, 5/8 x 4 1/2 07-2479 2. 07-0206 Pin, Cotter, Gr2, 3/16 x 2 3. 07-1604 Chain, Gr43, 3/8, 40 Links 4. 07-2032 Clevis, Gr80, Double Link, 9/32 5. 07-4031 Nut, Hex, Nylock, Gr8, 5/8-11 6. 07-4040 Washer, Flat, Gr8, 1 7. 07-4815 Hook, Slip, with 3/8 Clevis 8. 13-15964 Weld, Hitch, Towbar 9. 13-15976 Pin, Hitch, Towbar 10. 50-0042 Label, Warning, Hitch fENDER aSSEMBly item Part Description 1. 13-15040... -

Page 74: Caster Assemblies

SiNGlE CaSTER aSSEMBly 5 BOlT item Part Description item Part Description 8. 07-7117 Bolt, Wheel, 1/2-20 x 7/8 1. 05-0535 Seal, Oil 9. 07-7122 Kit, Mounting 2. 05-0536 Bearing 10. 13-15182 Weld, Hitch, Conversion, to 3/4 Wheel 3. 05-0537 Bearing, Race 11. 13-15991 Weld, Frame, Caster, Mounting 4. 07-0066 Screw, HHC, Gr8, 5/8-11 x 2 12. 13-15996 Weld, Hub, Caster, Single, 5 Bolt 5. 07-2116 Screw, HHC, Gr8, 3/8-16 x 1 1/4 13. 13-15999 Tube, Spacer, Caster 6. 07-4031 Nut, Hex, Nylock, Gr8, 5/8-11... - Page 75 DUal CaSTER aSSEMBly item Part Description 1. 07-0066 Screw, HHC, Gr8, 5/8-11 x 2 2. 07-0144 Nut, Lug, Gr2, 1/2-20 x 5/8 (5 Bolts ) 07-0144 Nut, Lug, Gr2, 1/2-20 x 5/8 ( 6 Bolts ) 3. 07-4031 Nut, Hex, Nylock, Gr8, 5/8-11 4. 13-15182 Weld, Hitch, Conversion, to 3/4 Wheel 5. 13-16015 Weld, Caster, Dual, with 5 Bolts 13-15535 Weld, Caster, Dual, with 6 Bolts 6. 28-0197 Assembly, Hitch, Towbar Not Shown: 05-1467 Seal 07-1368 Dust Cap 08-0204 Outer Bearing 08-0205 Inner Bearing 51-4065...

-

Page 76: Hitches

HiTCH 2 WHEEl SiDE aDJUSTaBlE item Part Description 1. 05-0763 Fitting, Zerk, 1/4-28, Straight 2. 07-0066 Screw, HHC, Gr8, 5/8-11 x 2 3. 07-0070 Screw, HHC, Gr8, 5/8 x 4 1/2 4. 07-1604 Chain, Gr43, 3/8, 40 Links 5. 07-1704 Jack, 5000#, Swivel, with Foot 6. 07-2032 Clevis, Double Link, Gr80, 9/32 7. 07-3120 Washer, Flat, Gr8, 5/8 8. 07-3842 Ring, Snap 9. 07-4031 Nut, Hex, Nylock, Gr8, 5/8-11 10. 07-4815 Hook, Slip, with 3/8 Clevis 11. 07-7091 Pin, Hitch, 3/4 x 6 1/4, with Linch Pin 12. 13-15799 Weld, Hitch, Adjustable... -

Page 77: Tail Lights

SiNGlE Tail liGHT item Part Description 1. 07-0353 Holder, License, Plate 2. 07-0358A Light, Tail, Left 3. 07-0358B Light, Tail, Right 6. 07-1714 Screw, HHC, Gr8, 5/16-18 x 1 8. 07-1836 Loom, Tee, Flex, Guard, .35 9. 07-3270 Nut, Hex, Nylock, Gr8, 5/16-18 10. 07-3678 Screw, HHC, Gr8, 5/8-11 x 1 1/4 11. 07-4031 Nut, Hex, Nylock, Gr8, 5/8-11 12. 07-5161 Clamp, Rubber Coated, 5/8 x 1/2 13. 13-15510 Plate, Mounting, Tail light 14. 13-15511 Plate, Tail Light, Mounting, Bar Not Shown: 07-0824 Wire, Harness, 4 Wire, Rectangular Trunk 07-0825 Wire, Harness, 4 Wire, Rectangular Wishbone... - Page 78 DUal Tail liGHT item Part Description 1. 07-0353 Holder, License, Plate 2. 07-0358A Light, Tail, Left 3. 07-0358B Light, Tail, Right 10. 07-1714 Screw, HHC, Gr8, 5/16-18 x 1 12. 07-1836 Loom, Tee, Flex, Guard, .35 13. 07-3270 Nut, Hex, Nylock, Gr8, 5/16-18 14. 07-3678 Screw, HHC, Gr8, 5/8-11 x 1 1/4 15. 07-4031 Nut, Hex, Nylock, Gr8, 5/8-11 16. 07-5161 Clamp, Rubber Coated, 5/8 x 1/2 17. 13-15510 Plate, Mounting, Tail light 18. 13-15511 Plate, Tail Light, Mounting, Bar Not Shown: 07-0833 4 ft Wire, Yellow, 16ga 07-0839...

-

Page 79: Strobe Mounting Assembly

STROBE MOUNTiNG aSSEMBly item Part Description 1. 07-1717 Bolt, Carriage, Gr5, 3/8-16 x 1 1/4 2. 07-3279 Washer, Flat, Gr8, 3/8 3. 07-4036 Nut, Hex, Nylock, 3/8-16 4. 13-15935 Weld, Mounting, Strobe Light SPaRE TiRE MOUNTiNG item Part Description 1. 07-3279 Washer, Flat, Gr8, 3/8 2. 07-3659 Screw, HHC, Gr8, 3/8-16 x 2 3/4 3. 07-3671 Screw, HHC, Gr8, 1/2-13 x 1 3/4 4. 07-4036 Nut, Hex, Nylock, 3/8-16 5. 07-4037 Nut, Nylock, Gr8, 1/2-13 6. 13-16092 Plate, Mounting, Spare Tire 7. 13-16093 Weld, Mounting, Spare Tire... -

Page 80: Shroud Kubota Engine

6. 07-3728 Washer, Flat, CL8.8, M6 7. 07-4202 Handle, Plastic 8. 07-4361 Latch, Swell, Single Handle 9. 07-4530 Nut, Hex, Nylock, CL8.8, M6 x 1 10. 07-4905 Washer, Lock, Star, 1/4 11. 07-5284 Screw, Socket Head, Flat, M6 x 1.25mm 12. 13-15828 Sheet, Top, Left 13. 13-15829 Sheet, Top, Right (Kubota V1505) 13-16194 Sheet, Top, Right (Kubota WG972) 14. 13-15830 Sheet, Rear 15. 13-15831 Sheet, Side 16. 13-15832 Sheet, Front 17. 13-15833 Sheet, Door 18. 50-0192 Label, Logo, Sweepster, Large 19. R HW8642 Nut, Rivet, 5/16-18, .15-.312 Grip 51-4065... -

Page 81: Pre-Cleaners

PRE-ClEaNERS Kit 28-0153 for Kubota WG972 Kit 28-0152 for Kubota V1505 item Part Description 1. 07-1188 Clamp, Screw, #H28, 1 5/16-2 1/4 2. 07-1716 Bolt, Carriage, Gr5, 3/8-16 x 1 3. 07-3270 Nut, Hex, Nylock, Gr8, 5/16-18 4. 07-3438 Bolt, Carriage, Gr5, 5/16-18 x 1 5. 07-4036 Nut, Hex, Nylock, Gr8, 3/8-16 6. 07-5431 Adapter, Rubber, Insert, 2-1 3/4 7. 07-5856 Cleaner, Air, Pre, TIII, 2 Inch, 15-75CFM 8. 07-5857 Clamp, Muffler, 1.75 9. 07-5868 Tube, Flex, 24 x 2 x 1.75 10. 13-16183 Plate, Mounting, Kubota, WG972... -

Page 82: Sprinkler Assembly

SPRiNKlER aSSEMBly hood Sheet item Part Description item Part Description 19. 07-0917 8 ft Wire, Cord, 16ga 1. 03-0059 Clamp, Screw, HS12, 11/16-1 1/4 20. 07-1427 Strain, Relief, 1/2, White 2. 03-0076 Fitting, Nipple, BP, Close, 3/8 21. 07-1700 Switch, Pump, Shutoff, Auto 3. 03-0152 Fitting, Nipple, BP, Close, 1/2 22. 07-3638 Screw, HHC, Gr8, 1/4-20 x 1 1/4 4. 03-0181 Fitting, Street Elbow, BP, 90°, 3/8 23. 07-3869 Fitting, Barb, Tee, Nylon, 3/8 5. 03-0457 Fitting, Barb, Nylon, 3/8, 3/8MP 24. 07-4031 Nut, Hex, Nylock, Gr8, 5/8-11... -

Page 83: Sight Indicators

SiGHT iNDiCaTORS Kit: 11-5897 Kit: 28-9965 item Part Description 1. 07-3279 2 Washer, Flat, Gr8, 3/8 2. 07-4036 2 Nut, Hex, Nylock, 3/8-16 3. 07-6597 4 Screw, HFH, CL10.9, M6-1 x 30 4. 13-14857 2 Weld, Sight Indicator 5. 13-9567 2 Ball, 2 1/8, Red, with Hole 51-4065... -

Page 84: Brakes

PaRKiNG BRaKE aSSEMBly item Part Description item Part Description 1. 07-0205 Pin, Cotter, Gr2, 1/8 x 1 14. 07-3983 2. 07-1079 Lever, Brake, Park, with Spacer 15. 07-3984 Rear, Brake, Cable 16. 07-3985 Clamp, Cable 3. 07-1177 Clamp, Rubber, Coat, 1/2 x 3/4 17. 07-3986 Link, Spacer, 4. 07-1717 Bolt, Carriage, Gr5, 3/8-16 x 1 1/4 5. 07-1730 Bolt, Carriage, Gr5, 3/8-16 x 1 1/2 18. 07-3987 Clamp, Cable 6. 07-1973 Screw, HHC, Gr8, 5/16-18 x 1 1/4 19. 07-4030 Bolt, Carriage, Gr5, 3/8-16 x 3... - Page 85 SURGE BRaKE aSSEMBly item Part Description 1. 03-1152 Fitting, Nut, Brake, HP, 3/16MIV 2. 03-5532 Elbow, 2MP, 2FP 3. 07-0066 Screw, HHC, Gr8, 5/8-11 x 2 4. 07-0070 Screw, HHC, Gr8, 5/8 x 4 1/2 5. 07-1075 Rivet, Pop, Gr2, 3/16 x .626-.750 Grip 6. 07-1289 Nut, Hex, Nylock, Gr8, 1/2-20 7. 07-1704 Jack, 5000# SD Swivel, with Foot 8. 07-2027 Kit, Plumbing, Brakes, Surge 9. 07-2032 Clevis, Double Link, Gr80, 9/32 10. 07-3120 Washer, Flat, Gr8, 5/8 11. 07-3675 Screw, HHC, Gr8, 1/2-13 x 4 1/2 12. 07-4031 Nut, Hex, Nylock, Gr8, 5/8-11 13. 07-4815 Hook, Slip, with 3/8 Clivis & Latch for Safety Chains...

-

Page 86: Engines

HONDa ENGiNE 24 HP item Part Description item Part Description 14. 07-7036 Muffler, for Honda Gx670 1. 03-9591 Engine, Honda, 24hp, Air Cooled 2. 05-0326 Coupling, Half, 13 Spline 15. 13-1321 Key, 1/4 x 1/4 x 2 3. 05-0328 Chain, Coupling 16. 13-15407 Weld, Mounting, Engine Skid 4. 05-1443 Pump, Mounting 17. 13-16823 1 Plate, Shield, Pump, Honda, GX670 18. 28-0169 Kit, Pump, 12gpm 5. 05-1451 Coupling, Half 6. 07-0119 Bolt, Carriage, Gr5, 5/8-11 x 1 3/4 7. 07-1718 Washer, Lock, Split, Medium, 3/8 Not Shown:... - Page 87 KUBOTa DiESEl V1505 DETAIL A item Part Description 19. 13-15407 Weld, Mounting, Engine Skid 20. 13-15764 Plate, Spacer, Engine 21. 13-15821 Plate, Mounting, Throttle Cable 22. 13-15822 Plate, Mounting, Actuator, Throttle 23. 13-7539 Weld, Motor Mount item Part Description 24. RHW8642 Nut, Rivet, 5/16-18, .15-.312 Grip 1. 03-9592 Engine, Kubota, V1505, 33hp Not Shown: 2. 07-0045 Screw, HHC, Gr8, 1/2-13 x 1 1/2 07-5142 Cable, Battery, 3/8 Eye, Negetive Post...

- Page 88 KUBOTa GaS WG972 DETAIL A item Part Description item Part Description 24. 07-7180 Screw, Set, M4-.5 x 8mm 1. 03-9595 Engine, Kubota, WG972, 31hp 25. 07-7181 Screw, Set, M6-1 x 10mm 2. 07-0018 Screw, HHC, Gr8, 3/8-16 x 1 26. 09-0096 3ft Hose, Fuel, 5/16 3. 07-0045 Screw, HHC, Gr8, 1/2-13 x 1 1/2 27. 13-15407 Weld, Mounting, Engine Skid 4. 07-0119 Bolt, Carriage, Gr5, 5/8-11 x 1 3/4 28. 13-16112 Plate, Spacer, Engine 5. 07-0156...

-

Page 89: Torque Specifications

BOlT TORQUE SPECifiCaTiONS NOTE - Nylock nuts are utilized when greater resistance to vibrating loose is required, and greater operating temperatures are not a factor. In addition, like lock nuts, nylock nuts have a safety feature that if the bolt does vibrate loose, the nut will remain on the screw. Install nylock nuts to the standard torque shown above. - Page 90 HyDRaUliC TORQUE SPECifiCaTiONS face Seal: assembly, Tube to fitting NOTiCE - face seal fittings have the most reliable sealing method and therefore, should be used whenever possible. installation 1. Make sure threads and sealing surfaces are free of burrs, nicks, scratches, or foreign materials. 2.

- Page 91 HyDRaUliC TORQUE SPECifiCaTiONS Straight Thread O-ring fitting: assembly, fitting to Port NOTE - Straight thread o-ring fittings are utilized to adapt hydraulic systems to motors, pumps, cylinders, and valves. installation (adjustable fitting) 1. Make sure threads and sealing surfaces are free of burrs, nicks, scratches, or any foreign materials. 2.

-

Page 92: Glossary

GlOSSaRy angle or angle assembly - portion of the sweeper lift cylinder - means of raising the brush head assembly hydraulically. that allows the brush head assembly to angle. BP - black pipe. lps - liters per second. brush head assembly - assembly that includes the M - male. - Page 93 GlOSSaRy section - single brush wafer. section set - replacement brush wafers. sprinkler system - system that sprays water ahead of the sweeper used to reduce dust. sprinkler tank - assembly that includes the water reservoir and mounting used in a sprinkler system. stands - devices designed to keep the components off the ground when the sweeper is dismounted.

-

Page 94: Warranty

WaRRaNTy limited Warranty except for the excluded Products as described below, all new products are warranted to be free from defects in material and/or workmanship during the warranty Period, in accordance with and subject to the terms and conditions of this Limited warranty. excluded Products.

Need help?

Do you have a question about the TB Series and is the answer not in the manual?

Questions and answers