Table of Contents

Advertisement

Quick Links

OPERATOR MANUAL

& PARTS CATALOG

143295 v1.5

SPEEDBLADE

D E G E L M A N

I N D U S T R I E S

L P

B O X

8 3 0 - 2 7 2

I N D U S T R I A L

D R I V E ,

15' & 18' MODELS

R E G I N A ,

S K ,

C A N A D A ,

S 4 P

3 B 1

F A X 3 0 6 . 5 4 3 . 2 1 4 0

P H 3 0 6 . 5 4 3 . 4 4 4 7

1 . 8 0 0 . 6 6 7 . 3 5 4 5

D E G E L M A N . C O M

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Degelman Speedblade 15

- Page 1 OPERATOR MANUAL & PARTS CATALOG 143295 v1.5 SPEEDBLADE D E G E L M A N I N D U S T R I E S B O X 8 3 0 - 2 7 2 I N D U S T R I A L D R I V E , 15’...

- Page 3 QUICK GUIDE INDEX Introduction Safety Operation Transport & Storage Troubleshooting Maintenance Blade Overall Dimensions Blade Center Section Components Access Panel - Hydraulic Electrical Details Blade Wing Section Components Wing Cylinder Components Mounting Options Skidsteer Adapter 3-Point Adapter Flatback Loader Adapters 46/5700 Dozer Adapter Hydraulic Hoses &...

-

Page 5: Proof Of Ownership

Introduction WELCOME PROOF OF OWNERSHIP Degelman is proud to welcome you to our rapidly Serial Number Plate increasing family of high quality and dependable product owners. This product was designed and built specifically for you, the customer. Through our research and with your input and feedback, we present to you our Degelman Speedblade ®... -

Page 6: Safety Alert Symbol

YOU are responsible for the SAFE operation and SAFETY ALERT SYMBOL maintenance of your Degelman implement. YOU must ensure that you and anyone else who is going to operate, maintain, or work around the machine be familiar with the operating and maintenance procedures, and related SAFETY information contained in this manual. -

Page 7: General Safety

Safety GENERAL SAFETY 1. Read and understand the Operator's Manual Wear Protective Equipment and all safety signs before using. Review safety Note: Before working on machine, always turn related items with all operators annually. tractor off, set controls in neutral, and remove 2. -

Page 8: Tractor Preparation

Operation TO THE NEW OPERATOR OR OWNER TRACTOR PREPARATION The Degelman Speedblade is a push type tractor Check Hydraulic Oil Level: ® attachment designed primarily for pushing and Check the oil level in the tractor hydraulic system removal of snow. -

Page 9: Operator's Responsibility

Operation OPERATOR’S RESPONSIBILITY OPERATING SPEED Every operator should read this manual and For normal operation, operate the tractor at a be instructed in safe operating procedures. An comfortable or manufacturer recommended speed. untrained operator is not qualified to operate this When operating over rough terrain or limited to machine and could place themselves or bystanders space, reduce engine speed. -

Page 10: Transport Safety

Transport & Storage TRANSPORT SAFETY STORAGE SAFETY • Read and understand ALL the information in the • Store unit in an area away from human activity. Operator's Manual regarding procedures and • Do not permit children to play near the stored unit. SAFETY when operating the machine in the field/ yard or on the road. -

Page 11: General Troubleshooting

Troubleshooting GENERAL TROUBLESHOOTING SYMPTOM PROBLEM SOLUTION Cutting Edge Wearing High downward force of dozer in contact Ensure blade cutting edge runs parallel to the ground. Excessively In Center with crown of road. Of The Dozer. Blade tilted forward too much causing improper wear. -

Page 12: Maintenance Safety

Maintenance MAINTENANCE SAFETY HYDRAULIC SAFETY 1. Review the Operator’s Manual and all safety 1. Always place all tractor hydraulic controls in items before working with, maintaining or neutral before dismounting. operating the machine. 2. Make sure that all components in the hydraulic 2. -

Page 13: Hydraulic Fluid

Maintenance LUBE AFTER EVERY 8 HRS. CHECK HARDWARE TORQUE Important: Check torque on all hardware Items to Grease Qty. periodically. Check after first 2, Tilt Ring 2 per side TORQUE 10, 40, then every 200 hours. Tilt Bell Plate 1 per side Tilt Bell Bushing 1 location •... -

Page 14: Safety Decals

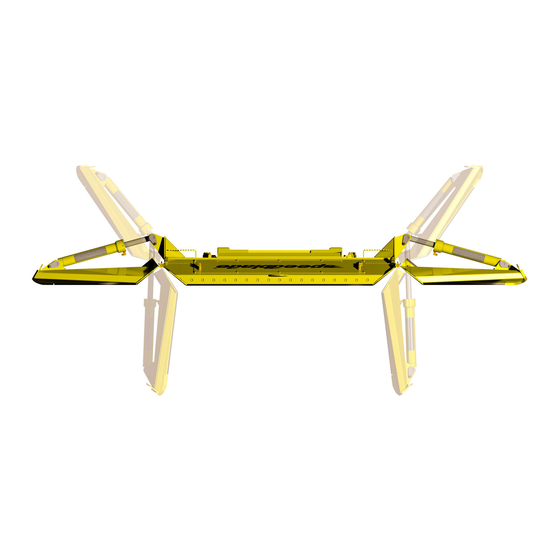

Reflective Decals 142556 Red Reflector, 2 x 9 142557 Amber Reflector, 2 x 9 142650 Fluorescent Reflector, 2 x 9 Product Decals 143198 Degelman Logo, 36 lg 142009 Degelman Logo, 16-1/4 lg Speedblade ® 143281 Decal 143295 - Speedblade (30-October-2019) - Page 15 Overall Dimensions - 15’ & 18’ Models 15’ MODEL 18’ MODEL (Rear View) (Rear View) (Front View) (Front View) 37-5/8” 15’ 18’ 2-1/2” 14’ 1-3/4” 12’ 4-1/4” 4’ 11-3/4” (Top View - Wings Back) (Top View - Wings Back) 56° 3’...

- Page 16 Center Section Components - 15’ & 18’ Models 780278 - Hose Clamp Block (2) CENTER SECTION COMPONENTS 780279 - Clamp Block Plate (2) 118144 - Bolt, 5/16 x 1-1/2 (2) 118503 - Lock Washer, 3/8 (10) 118005 - Bolt, 3/8 x 1 (10) 792150 - Access Panel Assembly (see hydraulic section) (Installed inside of blade through lower access panel)

- Page 17 Access Panel - Hydraulic & Electrical Details 792150 - ACCESS PANEL ASSEMBLY Hydraulic Hose Routings (Hoses are 2WB - 3/4 JIC f-sw w/Elbow) 126682 - Hose, 3/8 x 30 (2) 126681 - Hose, 3/8 x 14 (8) 141595 - Check Valve, Dual P.O.

- Page 18 Wing Section Components - 15’ & 18’ Models 15’ WING SECTION 792100 - Wing Hinge Pin Assembly, c/w Roll Pin (1) 118978 - Roll Pin, 3/8 x 1-1/2 (1) 118336 - Grease Fitting, 1/4-28 (4) 118337 - Plastic Cap (4) 792120 - Wing Assembly - 47”...

- Page 19 Wing Cylinder Components Important: The hydraulic system is pre-charged and tested with Boss UTF (Universal Tractor Fluid) hydraulic oil. To avoid oil contamination, check and confirm the current fluid type used in your tractor matches this pre-loaded system prior to hook-up. 118292 - Bolt, 1/2 x 1-3/4 (2) 118587 - Flat Washer, 1/2 SAE (2) 792045 - Cylinder Pin, 1-1/4 x 6 (2)

- Page 20 Mounting Options SKIDSTEER ADAPTER 792199 - Skidsteer Adapter Kit (1) 118794 - Bolt, 1/2 x 5 (1) 792180 - Bushing, 4 x 3/8 (1) 118420 - Lock Nut, 1/2 - Unitorque (1) 117479 - Bolt, 3/8 x 2-1/4 (2) 118511 - Flat Washer, 3/8 (2) 792040 - Tilt Bumper (2) 792190 - Skidsteer Bracket Assembly w/float (1)

- Page 21 Mounting Options FLATBACK LOADER ADAPTER - STANDARD 792220 - Flatback Loader Adapter Kit - Standard (1) 118794 - Bolt, 1/2 x 5 (1) 792180 - Bushing, 4 x 3/8 (1) 118420 - Lock Nut, 1/2 - Unitorque (1) 117479 - Bolt, 3/8 x 2-1/4 (2) 118511 - Flat Washer, 3/8 (2) 792040 - Tilt Bumper (2) 792221 - Flatback Tilt...

- Page 22 Mounting Options 46/5700 DOZER ADAPTER 792280 - 46/5700 Dozer Adapter Kit (1) 117479 - Bolt, 3/8 x 2-1/4 (2) 118511 - Flat Washer, 3/8 (2) 792040 - Tilt Bumper (2) 118417 - Lock Nut, 3/8 (2) 792180 - Bushing, 118420 - Lock Nut, 1/2 792300 - 46/5700 Adapter 4 x 3/8 (1) - Unitorque (1)

- Page 23 Mounting Options 46/5700 DOZER ADAPTER 792315 - 46/5700 Dozer Mounting Kit (1) MOUNTING COMPONENTS 3” Stop Included in this kit are 3” Cylinder stops (see below) and three sets of hoses and fittings to extend the connections to the rear of the tractor.

- Page 24 Hydraulic Hoses & Wiring Harness Hydraulic Hose Routings 126683 - Hose, 3/8 x 56 (4) 126656 - Hose, 3/8 x 86 (2) Existing 46/5700 Angle Hoses (2) Left Wing Right Wing Cylinder Cylinder -or- Connect wiring harness to Skid Steer the electrical connector on Input 141609 - Orifice Adapter,...

- Page 25 Optional Kits OPTIONAL 2-LEVER HYDRAULICS OPTION 2-LEVER HYDRAULICS KIT This kit is available for customers wanting to connect each wing cylinder directly to independent hydraulic circuits instead of using the solenoid/switch button configuration that comes default with the Speedblade. This requires the removal of existing hoses, capping the fittings on the Speedblade rear panel, and installation of new hoses from kit.

- Page 26 Top Extensions OPTIONAL 15’ BLADE ATTACHMENTS 792136 - Top Extension - 47” Left Wing 792080 - Top Extension - Center 792139 - Top Extension - 47” Right Wing OPTIONAL 18’ BLADE ATTACHMENTS 792085 - Top Extension - 66” Left Wing 792080 - Top Extension - Center 792090 - Top Extension -...

- Page 27 2. To any goods that have sustained damage or deterioration attributable to a lack of routine maintenance (eg. Re- torque of mounting hardware.) 3. If parts not made or supplied by Degelman have been used in the connection with the unit, if, in the sole judgement of Degelman such use affects its performance, safety, stability or reliability.

Need help?

Do you have a question about the Speedblade 15 and is the answer not in the manual?

Questions and answers