Advertisement

Quick Assembly Guide

Parts List:

Item

Part Name/Description

1

Left Side Support

2

Right Side Support

3

Top header

4

Bottom header

5

Door, curved

6

Left side door, end cap

7

Right side Door, end cap

8

Gasket seal

9

Metal Guard

10

Rubber seal

11

L-screw hook

1

Insert top and bottom

headers into the right-side

lateral support.

5

Properly secure the MWI

lateral supports using a

rubber mallet.

Use caution!

NOTE:

The following guidelines should be used and closely followed when assembling and installing MWI.

In order to assure proper performance and correct functioning of the inlets, the installer must understand the importance of quality construction-work and use

quality materials. Attention to details relating the assembly work, proper sealing or prevention of air leaks is a must and must be undertaken by the installer.

WARNINGS: Do not overtighten the screws! Tighten until flush. Do not dent the housing! Overtightening the screws will result in damage to MWI.

Ag/MIT/IGB-2414-12/18 Rev 6.0

QTY/

QTY/

Inlet

Box

1

6

1

6

1

6

1

6

1

6

1

6

1

6

2

12

1

6

1

6

2

12

2

Slide the curved louver in

the bottom header slot.

6

Insert the rubber seal in

the top header slot and

along door sides.

3

10

6

1

4

11

Slide the metal grid in the

headers slot.

!

WARNING:

DO NOT use metal hammer to secure the MWI. The use

of a metal hammer can result in damage to MWI.

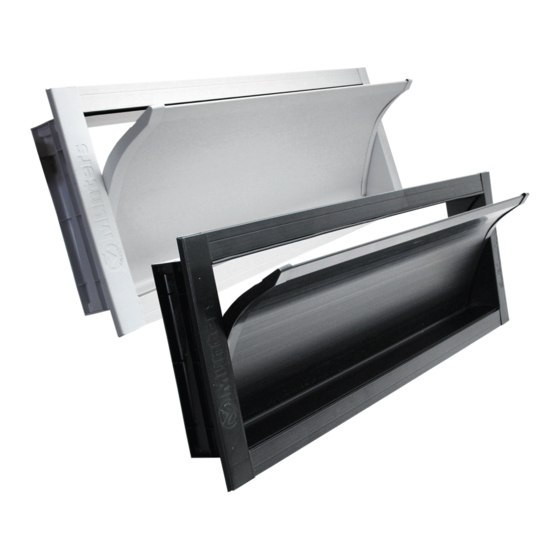

MWI

Side Wall Inlet

5

7

9

3

Slide insert the left side

lateral support.

2

8

4

1

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Munters MWI Series

- Page 1 Quick Assembly Guide Side Wall Inlet Parts List: QTY/ QTY/ Item Part Name/Description Inlet Left Side Support Right Side Support Top header Bottom header Door, curved Left side door, end cap Right side Door, end cap Gasket seal Metal Guard Rubber seal L-screw hook Insert top and bottom...

- Page 2 NOTES: Avoid interference with the pulling cable or rod. Caulk all sides four internal edges of the MWI after Australia Phone 61 2 8843 1594, agh.info@munters.com.au, Brazil Phone +55 41 3317 5050, contato@munters.com, Canada Phone +1 517 676 7070, aghort.info@munters.com,...

Need help?

Do you have a question about the MWI Series and is the answer not in the manual?

Questions and answers