Table of Contents

Summary of Contents for Munters WM54F

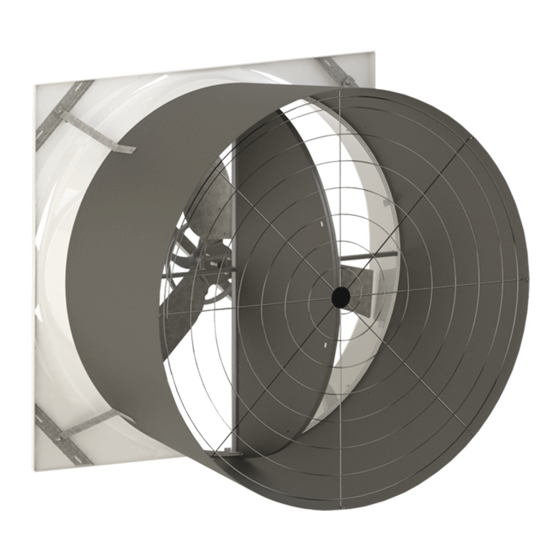

- Page 1 WM54F Wall Mount Fan Manual for use and maintenance with Damper Door including assembling instructions +CE Declaration of conformity WM54 Fiberglass Wall Mount Fan with Damper Door Air extraction fan Ag/MIT/UmGB-2483-07/17 Rev 1.0...

- Page 2 Please Note: To achieve maximum performance and insure long life from your Munters product it is essential that it be installed and maintained properly. Please read all instructions carefully before beginning installation. This manual for use and maintenance is an integral part of the apparatus together with the attached technical documentation and has been produced with reference to Directive 2006/42/EC, paragraph A, Annex II, and to ErP Directive 2009/125/CE Commission Regulation 327/2011.

-

Page 3: Table Of Contents

Index Chapters Page 1. CE Declaration 2. Unpacking the Equipment Parts List Fan Dimensions Tools for Installation Installation Instructions Install Damper Door Installation Cone Installation Motor Mounting Electrical Wiring Recommended Wiring Operation Maintenance Winterizing Winterizing Winter Weather Protection Troubleshooting Exploded View and part list Warranty WARNING All the components and spare parts MUST be storaged in dry and clean environment. -

Page 4: Ce Declaration

CE Declaration CE Declaration of conformity (complies with Subparagraph A Annex II Directive 2006/42/EC) Munters Italy S.pA. with registered officies in Strada Piani, 2 - 18027 Chiusavecchia (IM) - Italy (Company Registration nr. 00081050080) declares on its own responsability that the apparatus:... - Page 5 The information contained herein has been prepared by qualified experts within Munters. While we believe the information is accurate and complete, we make no warranty or representation for any particular purposes. The information is offered in good faith and with the understanding that any use of the units or accessories in breach of the directions and warnings in this document is at the sole discretion and risk of the user.

-

Page 6: Unpacking The Equipment

Unpacking the Equipment 2.1 Parts List Each WM54F Fan Requires: 1 – 54” Fiberglass Orifice 1 – 54” Propeller 1 – Central Support 1 – Motor 1 – Motor Pulley 1 – Drip Shield 1 – Main Frame Assembly 1 – Plastic Door Assembly 4 –... - Page 7 Chapter 2 Unpacking the Equipment Bolts and nuts for 1 – WM54F Fan Installation [A]….12 – Ø8x32 Washer [B]…. 2 – Ø6.3x19 Self-tapping Screw [C]…. 4 – M8x25 Hex Screw [D]…. 4 – Ø8 Ext Toothed Washer [E]…. 4 – M8 Hex Nut [F]….

-

Page 8: Fan Dimensions

Chapter 2 Unpacking the Equipment 2.2 FAN DIMENSIONS Fan Specifications: 50Hz shown Voltage: 230/400 VAC Phase: 3 Guard Dimensions: Size D - Dia. Wall Openings 54” 1524 x 1524 1245 185 max 1684 1435 x 1435 2.3 TOOLS REQUIRED FOR INSTALLATION Pneumatic screwdriver 17mm Spanner 8mm Long Spanner... -

Page 9: Installation Instructions

Installation Instructions 3.1 INSTALL Step 1 Construct framed opening to correct size according to the Wall Opening listed in chart A below. See Figure 1A When installing exterior sheet metal before fan, leave 50mm of the framing exposed on all sides so the and 1B. - Page 10 Chapter 3 Installation Instructions Step 2 Place the Central Support on saw horses or a flat work surface. The large center hole should be pointing horizontally. Attach the Motor Slide and the Tensioner Bracket to the Central Support using (3) Long Bolts [CC], (4) Washers [A] and (3) Nuts [DD].

- Page 11 Chapter 3 Installation Instructions Step 3 Attach Central Pulley to Hub using (4) Bolts [F] and Nuts [G] and tighten to 14 Nm.. See Figure 3. Central Pulley Nut [G] Bolt [F] Nut [G] Bolt [F] Central Pulley Figure 3 Step 4 Rotate the Central Support on the saw horses so the Motor Slide is pointing up.

- Page 12 Chapter 3 Installation Instructions Step 5 Place Fiberglass Orifice on saw horses with the round orifice pointing up and place (1) Cone/Strut Mounting Bracket in each corner of the Fiberglass Orifice. See Figure 5. Fiberglass Orifice Mounting Bracket Figure 5 Step 6 The corners of the Fiberglass Orifice with 2 holes are the corners where the Support Assembly attaches.

-

Page 13: Step 7

Chapter 3 Installation Instructions Step 7 Attach Propeller to Hub Assembly using (4) Bolts [C], Washers [D] and Nuts [E] and tighten to 22 Nm. Figure 7. Bolt [C] Washer [D] Propeller Nut [E] Figure 7 3.2 Damper Door Installation Step 8 Slide the Main Frame Assembly onto the Fiberglass Orifice with the pin on the Main Frame opposite the drain hole. -

Page 14: Figure

Chapter 3 Installation Instructions Step 9 Attach Drip Shield to bottom of framed opening using (3) proper Screws (Not Provided). 9B. If a See Figure 9A and 100mm wall is used a support board must be installed as shown in Figure 9B. - Page 15 Chapter 3 Installation Instructions Step 11A Carefully remove folded door assembly from box. Open the doors enough to reach the latch pin and pull it down until the end of the latch pin is flush with the top of the doors. Make sure the Long Hinge Pin does not fall out. See Figure 11A Latch Pin Figure 11A...

- Page 16 Chapter 3 Installation Instructions Step 11B Being careful not to let pin fall out, set Doors into Main Frame with the Hinge Pin in the hole at the bottom plate of the Main Frame and push the top of the Doors into place. See Figure 11B.

- Page 17 Chapter 3 Installation Instructions Step 12A Find the Cable [Q], insert it into the small hole in the upper plate of the Main Frame and pull it through until the ferrule stops at the plate. See Figure 12A. Cable [Q] Hole in Main frame Figure 12A Step 12B...

-

Page 18: Cone Installation

Chapter 3 Installation Instructions Step 12C From the inside attach each of the Tension Springs to the hole in the upper plate of the Main Frame using the end of the spring with the loop, then stretch the spring and insert the other end of the spring into the hole drilled in the door in the previous step. - Page 19 Chapter 3 Installation Instructions Step 14A Fasten each of the joints in the single outer hole using (1) Short Bolt [AA], Washer [A] and Nut [DD], with the nut on the side with the tabs. At the inner pair of holes of each joint attach (1) Cone Support Bracket to the inner hole using (1) Bolt [AA], Washer [A] and Nut [DD] with the bolt head on the side with the tabs.

- Page 20 Chapter 3 Installation Instructions Step 15A Install cone onto fan by putting the top of the cone over the top of the fan. The hole in the tab of the upper cone section should slide down over the pin in the Main Frame assembly, then allow the rest of the cone to slide over the rest of the orifice panel making sure the cone brackets remain on the outside of the cone.

- Page 21 Chapter 3 Installation Instructions Step 16 Insert guard into cone with the eyelets facing you. Install eyelets over bolts already installed in cone and fasten with Nut [DD] and then secure remaining eyelets using Short Bolt [AA], Washer [A] and Nut [DD]. See Figure Previously installed - Bolt and Nut Nut [DD]...

- Page 22 Chapter 3 Installation Instructions Step 18 If Fans are to be installed 1524mm O.C., cut the 3 o’clock and 9 o’clock guard wire in the position shown and push the side of the cone in as far as possible and fasten the cut guard wire to the attached guard wire using Clamp [R].

- Page 23 Chapter 3 Installation Instructions Step 20 Set the Motor on the Motor Slide. See Figure 20 Braket Slots Figure 20 Step 21A Secure Motor to Motor Slide and motor bracket stiffener using (4) Bolts [AA], Washers [H] and Nuts [DD]. The rear upper bolt is where the motor bracket stiffener is attached.

-

Page 24: See Figure

Chapter 3 Installation Instructions Step 21B Using channel locks and/or a hammer twist the motor bracket stiffener so that the holes in the bracket lay flat against the framing. Then attach bracket to framing using (1) proper Screw (Not Provided). See Figure 21B. - Page 25 Chapter 3 Installation Instructions Step 23B To adjust the belt tensioner to the proper setting, loosen 10 mm bolt (using 17mm spanner) to allow tensioner arm to rotate. Turn spanner clockwise until the single mark on base of the belt tensioner is aligned with mark 2 on the tensioner arm.

- Page 26 Chapter 3 Installation Instructions Step 24B Place the mesh against the framing and fasten it in place using (12) Plastic clips [P] and proper Screws (Not Provided). See Figure 24B. NOTE: the proper type of fixing screw has to be selected depending on the material of the wall of the installation. NOTE: The flat mesh can be installed in case of a thickness wall ≥...

-

Page 27: Electrical Wiring

For electrical connection requirements, refer to diagram on motor nameplate and to information enclosed with the Munters environmental control to be used. Fans: motor overload protection should be provided for each fan. A three-poles safety switch or slow Three Phase blow motor fuses must be used. -

Page 28: Recommended Wiring

Chapter 4 Electrical Wiring 4.1 Recommended Wiring Step 1 As the power cable exits the back of the motor form a drip loop and then run cable to power source. See Figure 26A and 26B. Drip loop Figure 26A Drip loop Figure 26B... -

Page 29: Operation

Turn on electrical power and confirm that the fan operates smoothly. 2) ADJUSTMENTS: Set the fan control to the temperature shown on your Munters ventilation system drawing, or to a value which will provide the Moving parts, disconnect power desired environmental conditions. -

Page 30: Maintenance

Maintenance 6. Maintenance The following inspection and cleaning procedures should be performed monthly: WARNING Tools Needed for Maintenance: Spanner 10mm, 13mm, 17mm, pneumatic screwdriver PROPELLER: Check that propeller is secure on drive hub and that INSPECT Moving parts, disconnect power before servicing. - Page 31 Chapter 6 Maintenance Roll the belt off and look at both pulleys. If the pulley has grooves in it or CHECKING PULLEYS: WARNING is no longer smooth, it needs replacement. A loose or slipping belt will reduce fan performance up to 60% and cause premature belt failure.

-

Page 32: Winterizing

Munters Product and System manufacturers recommendations. The supplier listing above is given Warranties do not cover cone or fan as a reference only. Munters does not endorse any specific snow guard product and no performance warranty is implied. damage from external sources. -

Page 33: Troubleshooting

Troubleshooting 7.1 Troubleshooting WARNING WARNING WARNING High Voltage, disconnect power Moving parts, disconnect power Moving parts, disconnect before servicing. before servicing. power before servicing. POSSIBLE CAUSES SYMPTOM CORRECTIVE ACTION 1. Fan control set above room 1. Set to a lower temperature Fan Not Operating temperature 2. - Page 34 Exploded View...

- Page 35 Chapter 8 Exploded View...

- Page 36 Chapter 8 Parts List Catalog No. WM54F Part Name/Description Item 2200761 Fiberglass orifice 2515360 Propeller 2245861 V-belt (A61) 2465692 Hub with bearing and shaft 2248001 Central pulley 2472000 Waterproof distance piece 2273600 M25 Hex nut 2248711 Motor pulley Motor 2446040 Motor stiffener...

-

Page 37: Warranty

Munters plant was required: if this is not done, the user is fully responsible for the damage which they could suffer. - Page 38 The use of non-original spare parts or incorrect assembly exonerates the manufacturer from all liability. Requests for technical assistance and spare parts must be made directly to the manufacturer, at the following address: Munters Italy S.p.A Strada Piani, 2 18027 Chiusavecchia (IM), Italy...

- Page 39 Phone +90 262 7513 750, info@muntersform.com, Phone +1 517 676 7070, aghort.info@munters.com, Export & Other countries Phone +39 0183 5211, info@munters.it Munters reserves the right to make alterations to specifications, quantities, etc., for production or other reasons, subsequent to publication. © Munters AB, 2015...

Need help?

Do you have a question about the WM54F and is the answer not in the manual?

Questions and answers