Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Instruction Manual

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Munters WM54K

- Page 1 WM54K Wall Mount Fan with Damper Door Instruction Manual 1-Pack Quick Kit WM Fiberglass Wall Mount Fan with Damper Door - 1-Pack Quick Kit Models: WM54xKxCB © Munters Corporation, September 2019 QM1233r0...

-

Page 2: Warranty

With the proper installation and maintenance it will provide many years of service. Please Note: To achieve maximum performance and insure long life from your Munters product it is essential that it be installed and maintained properly. Please read all instructions carefully before beginning installation. Warranty: For Warranty claims information see the “Warranty Claims and Return Policy”... - Page 3 Tools for Installation 2. Installation Instructions Wall Framing Fan Assembly Motor Mounting Cone Installation 3. Electrical Wiring Recommended Wiring Operation Maintenance Winterizing Winterizing Winter Weather Protection Troubleshooting 8. Exploded View and Parts List 29-31 © Munters Corporation, September 2019 QM1233r0...

-

Page 4: Unpacking The Equipment

4 – Cone/Strut Mounting Brackets, Galvanized 1 – Motor Mount Stiffener Bracket, Galvanized 1 – Bulk Parts Package (BK1151) BK1151 – Bulk Parts Package for WM54K 1 – Motor Base Bracket, Powder Coated 1 – Belt Tensioner Bracket, Powder Coated 1 –... - Page 5 Chapter 1 Unpacking the Equipment HP1177 – Hardware Package for 1 – WM54K Qty. Cat. No. Description KW3011 ⁄ ” x 1¼”O.D. Flat Washer, SS KS1931 M10-1.5 x 25mm Hex Bolt, ZP KW3509 10mm Splitlock Washer, ZP KS1007 ⁄ ” x 1.25” Hex Head Bolts, SS KS1029 ⁄...

-

Page 6: Fan Dimensions

10mm [ ⁄ ”] Socket 13mm [½”] Socket 17mm [ ⁄ ”] Socket or Wrench 27mm [1 ⁄ ”] Wrench ⁄ ” Socket Phillips Screwdriver, #3 Size ⁄ ” Hex Wrench Wire Cutting Pliers © Munters Corporation, September 2019 QM1233r0... -

Page 7: Installation Instructions

4 x 4 or 4 x 6 Posts 4 x 4 or 4 x 6 Posts 2 x 4 Framing (See chart A) 2 x 8 Banner boards Figure 1B 4 x 4 Post Construction - Elevation View © Munters Corporation, September 2019 QM1233r0... -

Page 8: Fan Assembly

See Figure 2B. Figure 2B The fan can either be installed on the wall before the drive system is installed or the drive system can be installed while the fan is in the crate. © Munters Corporation, September 2019 QM1233r0... - Page 9 Attach the Motor Base Bracket and the Belt Tensioner Bracket to the Tube Strut using (3) Long Bolts [F], (2) See Figure 4. Washers [A] and (3) Nuts [G]. Motor Base Bracket Bolt [F] Washer [A] Nut [G] Belt Tensioner Bracket Figure 4 © Munters Corporation, September 2019 QM1233r0...

-

Page 10: Motor Mounting

Sheave on the Motor shaft with the hub facing towards the motor. See Figure 6. ONLY tighten the set screw enough to hold the Sheave in place at this time. See Figure 6. Motor Sheave Motor Key Motor Figure 6 © Munters Corporation, September 2019 QM1233r0... - Page 11 Secure Motor to Motor Bracket and Motor Bracket Stiffener using (4) Short Bolts [D] and Nuts [G]. The rear upper bolt is where Motor Bracket Stiffener is attached. See Figure 8A. Stiffener Short Bolts [D] Nuts [G] Figure 8A © Munters Corporation, September 2019 QM1233r0...

- Page 12 Using channel locks and/or a hammer twist the Motor Bracket Stiffener so that the holes in the bracket lay flat against the framing. Then secure the bracket to the framing using (1) Lag Screw [H]. See Figure 8B. Framing Stiffener Lag Screw [H] Figure 8B © Munters Corporation, September 2019 QM1233r0...

- Page 13 Sheave. Continue rolling it onto the larger Sheave until it fits into groove. See Figure 10A. If desired the 2 drain holes in the Orifice Panel can be plugged using (2) Hole Plugs [NN]. Drain Holes Figure 10A © Munters Corporation, September 2019 QM1233r0...

- Page 14 Be sure not to deform Drip Shield when installing screws. Barn Screw Barn Screw (Not Provided) (Not Provided) Drip Shield Drip Shield Barn Screw (Not Provided) Support board Drip Shield Figure 11A Figure 11B © Munters Corporation, September 2019 QM1233r0...

- Page 15 Find Coated Cable and insert end opposite ferrule into small hole in upper plate of Main Frame. Pull it through until ferrule stops at plate. See Figure 13. Ferrule Hole in Main Frame Figure 13 © Munters Corporation, September 2019 QM1233r0...

-

Page 16: Cone Installation

(1) Short Bolt [D] and Nut [G] with the bolt head on the side with the tabs. See Figure 15A. Nut [G] Short Bolt [D] Outer Hole Short Bolt [D] Inner holes Nut [G] Cone Support Bracket Figure 15A © Munters Corporation, September 2019 QM1233r0... - Page 17 (1) Short Bolt [D] and Nut [G] with bolt head on inside of cone. See Figure 15B. Short Bolt [D] Cone Support Bracket Nut [G] Short Bolt [D] Nut [G] Figure 15B © Munters Corporation, September 2019 QM1233r0...

- Page 18 Cone Support Bracket, Cone, Main Frame and Orifice. Repeat process for all 4 Cone Support Brackets. See Figure 16B. Nut [G] Medium Bolt [E] Use this hole for WM54K Nut [G] Figure 16B © Munters Corporation, September 2019 QM1233r0...

- Page 19 Azuma Bolt & Nut [J]. Make sure cable is pulled snug. See Figure 18. Note: When installing cable in temperatures BELOW 60°F, leave cable slightly slack (do not overtighten). Azuma Bolt & Nut [J] Coated Cable Figure 18 © Munters Corporation, September 2019 QM1233r0...

- Page 20 Cut a section of the inlet guard out to fit over the motor as shown below for the appropriate fan. When cutting the guard wires make sure to cut them as close to the other wires as possible. See Figure 20A. 60” 8” 12” Figure 20A © Munters Corporation, September 2019 QM1233r0...

- Page 21 Position for Securing Guard Position for Guard Removal Shutter Clip [L] with Barn Screw (not provided) Shutter Clip [L] with Barn Screw (not provided) Position for Securing Guard Position for Guard Removal Figure 20B © Munters Corporation, September 2019 QM1233r0...

-

Page 22: Electrical Wiring

For electrical connection requirements, refer to diagram on motor nameplate and to information enclosed with the Munters environmental control to be used. Single Phase Fans: motor overload protection should be provided for each fan. -

Page 23: Recommended Wiring

As the power cable exits the back of the motor form a drip loop and then run cable to power source. See Figure 22A and 22B. Drip loop Figure 22A Drip loop Figure 22B © Munters Corporation, September 2019 QM1233r0... -

Page 24: Operation

Single phase fans are designed for single speed operation only. WARNING Three Phase Fans: If a frequency drive is used, the minimum operating frequency is 30 Hz. Moving Parts: Disconnect Power Before Servicing. WARNING Do Not Power Wash Electrical Devices. © Munters Corporation, September 2019 QM1233r0... -

Page 25: Maintenance

Electrical Devices. tions. Wiring should be secure and in good condition. Remove any dust build-up from control case and sensor using a soft brush or cloth. NEVER CLEAN ELECTRICAL EQUIPMENT WITH A PRESSURE WASHER! © Munters Corporation, September 2019 QM1233r0... - Page 26 Mark 2 on tensioner arm. Hold tensioner at this setting and tighten 10mm bolt to 40 ft.-lbs [54 N-m] torque. Mark 2 on Tensioner Arm Hex on Tensioner Arm 10mm Bolt Single Mark on Base © Munters Corporation, September 2019 QM1233r0...

-

Page 27: Winter Weather Protection

Munters Product and System manufacturers recommendations. The supplier listing above is given Warranties do not cover cone or fan as a reference only. Munters does not endorse any specific snow guard product and no performance warranty is implied. damage from external sources. -

Page 28: Troubleshooting

3. Motor or propeller shaft bent 3. Repair or replace motor or propeller shaft Fan Never Turns Off 1. Override thermostat set incorrectly 1. Set to the correct temperature 2. Control set for continuous operation 2. Set control correctly © Munters Corporation, September 2019 QM1233r0... -

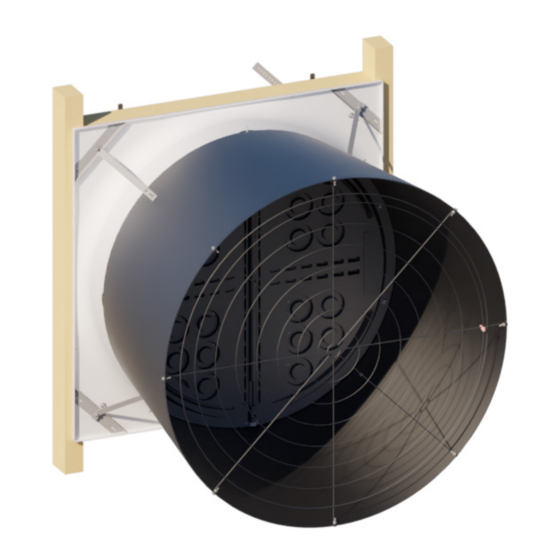

Page 29: Exploded View

Exploded View © Munters Corporation, September 2019 QM1233r0... - Page 30 Chapter 8 Exploded View © Munters Corporation, September 2019 QM1233r0...

- Page 31 KX1466 Tension Spring, 0.5”OD x 10.8”L , SS FH1365 Wing Add-on Kit, 2 Wings w/ Hardware * Parts listed are for specific fan configuration. Contact office for replacement part numbers for your fan configuration. © Munters Corporation, September 2019 QM1233r0...

- Page 32 WM54K is developed and produced by Munters Corporation, Lansing, Michigan U.S.A. 1-800-227-2376 Munters Europe AB, Isafjordsgatan 1, P.O. Box 1150, SE-164 26 Kista, Sweden. Phone +46 08 626 63 00, Fax +46 8 754 56 66. Munters Corporation 2691 Ena Drive Lansing, MI 48917 U.S.A. Phone +1 800-227-2376, Fax +1 517-676-7078 www.munters.us...

Need help?

Do you have a question about the WM54K and is the answer not in the manual?

Questions and answers