Subscribe to Our Youtube Channel

Summary of Contents for ViscoTec Preeflow eco-CONTROL EC200-K

- Page 1 Dosing system Operation and maintenance instructions eco-CONTROL EC200-K Translation of the German original operating manual...

- Page 2 Item No. 20202 Print 20.1.12...

-

Page 3: Table Of Contents

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Contents Introduction Features Scope of supply Safety Informal safety measures - - - - - - - - - - - - - - - - - - - - - - - 7 Symbols used - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8 Appropriate use, warranty - - - - - - - - - - - - - - - - - - - - - - - 8... - Page 4 Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18 5.9.1 Dosing amount 5.9.2...

- Page 5 Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Copyright © Version 1.8 5 / 35...

-

Page 6: Introduction

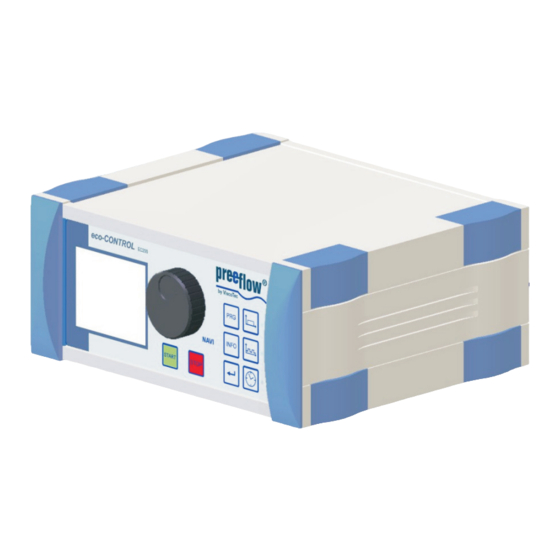

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Introduction Dear customer, we congratulate you on buying your Dosing system. We are certain that it will fully meet your requirements. We wish you trouble-free and successful operation. The dosing system eco-CONTROL EC200-K is made up of the dosing control and one or more dispensers. -

Page 7: Features

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Features Functions in brief with your transactions in the document: Feature Section Page 3 dosing programs: Quantity Start/stop Time program 5.7.1 Teach in, the simplest way to determine and save the required dosing 5.9.1 quantity 24 different dosing programs (operation with memory card) -

Page 8: Symbols Used

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Symbols used The following symbols are used in these instructions: Italicised Designation of keys, plugs, sections, screenshots, proprietary names and text input dialogs Listing of the work flow sequence • Numbered listing of a work flow sequence Legend numbers in an illustration Warning: If these instructions are not followed, there is a risk of damage or injury or bothDosing system. -

Page 9: Organizational Measures

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Organizational measures The owner is to provide any personal protective equipment that is required. All the safety devices are to be checked regularly. Wear protective glasses and a protective suit for operation and cleaning to protect against any chemicals that are sprayed out. -

Page 10: Operation

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Operation Before starting up the Dosing systems the safety information in section4, Safety, starting on page 7, must have been read and understood. Displays and controls Designation Function, description Graphic display Pressure regulating valve To regulate the primary pressure (air pressure) that is to be applied to the medium. -

Page 11: Connections

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Connections Designation Function, description Pressure OUT Output compressed air, connection to supply tank / cartridge / medium tank Pressure IN Input compressed air, hose connection, 4 mm (Quickstar) System plugs See section 8.3, page 34 for the pin-outs Motor 1 / 2 For dispensers 1 and 2 Sensor... -

Page 12: Symbols On The Screen

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Symbols on the screen Designation / function Description Dosing program See 5.7.1, Dosing programs, page 15 quantity of the quantity program Dosing program See 5.7.1, Dosing programs, page 15 start / stop Start / stop program Dosing program See 5.7.1, Dosing programs, page 15... -

Page 13: Functional And Operational Schematic

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Functional and operational schematic The interaction of the screen displays, the input dialog and the function keys: The control system has an intuitive input dialog. The selection or the change of a value is offered on the screen to suit the relevant program section. -

Page 14: Starting Up

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Starting up Caution: Only remove and insert the mains plug of a dispenser (plug 16, section 5.2, Connections on page 11) once the power has been switched off. Otherwise the electronics of the drive motor could be damaged. •... -

Page 15: Dosing Programs

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions 5.7.1 Dosing programs Quantity program The quantity program is used to give out a fixed and defined quantity of medium. Depending on the dispenser and the medium used, it is possible to set very small amounts (0.001 ml) per dosing (ml / g per minute). -

Page 16: Calibrating

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Dosing by means of an external controller As in the case of dosing with the foot switch, but the triggering and termination of the dosing are done by supplying an electrical signal. See 8.3, Interfaces, page 34. Note: If a memory card is being used, press the foot switch briefly to load the saved and most recently run program and to display it on the screen. -

Page 17: Calibration Manual

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Selection whether the calibration is to be done with Calibration auto quantity unit ml(µl) or g(mg)* and confirm this, the set quantity can be set as desired. Desired qty 00.500 ml Actual qty 00.000 ml * If the saved density value corresponds to the value Flow rate... -

Page 18: Settings

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Quantity program • Press the PRG key, system selection menu, display 2 Start/stop Time program appears. Calibration auto • Select and confirm Calibration manual, the Calibration Calibration manuel Teach in function manual menu, display 40 appears. Administration Service 10 47h... - Page 19 Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Setting the dosing quantity with the Teach in function Note: The Dosing system cannot be operated by either the foot switch or an external control signal can be used during the Teach In function. Quantity program Press the PRG key, system selection menu, Start/stop...

-

Page 20: Dosing Time

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions 10. Create an external signal (e.g., press the foot switch), the dispenser is started up. 11. Once the dosing quantity has been reached, switch off the external signal. The dosing quantity is displayed, accept it with OK. -

Page 21: Sucking Back

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions 5.9.4 Sucking back In order to effectively prevent any dripping of the medium, a value for the sucking back can be set in ml. The maximum amount for sucking back that can be set is 0.5 ml. •... -

Page 22: Tolerance Value Primary Pressure Monitoring

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions • Select Change program, the input dialog for Change a program appears, display 26. Select program Change program Tolerance of pressure Password protection Analog input Adjust time • Rotate the NAVI wheel on page 2 to navigate to the program* to be changed, display 27 appears. -

Page 23: Password Protection

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions • Select Pressure tolerance, display 29 appears. Select program Change program Tolerance of pressure Password protection Analog input Adjust time • Input the Pressure tolerance tolerance in the input Tolerance of pressure dialog and confirm with OK, display 25 appears. - Page 24 Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Password protection • Press the Navi wheel, display On, changes to Off, Protection active appears in the status bar. • Select and confirm the password (code). • Set the password by turning* the Navi wheel. Code 5000 •...

-

Page 25: Analogue Input

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions 5.9.8 Analogue Input Description: The flow rate (ml/min) of the connected pump(s) is controlled proportional to the applied analogue signal (V or mA). This function is only active in the Start / Stop program. Technical connection data on the system connector (15) Analogue Input resistance / resolution... -

Page 26: Time And Date

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions 5.9.9 Time and date • Press the PRG key, system selection menu, Quantity program display 2 appears. Start/stop Time program • Select Administration, display 25 appears. Calibration auto Calibration manuel Teach in function Administration Service 10 47h... -

Page 27: Clearing Error Messages

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Error message SD chipcard Can´t find memory card. If the chipcard is defective or has not been inserted, when the Dosing systems is switched on a corresponding message (display 37) is shown for 3 seconds. -

Page 28: Select The Dosing Program

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions 5.12 Select the dosing program Only possible if using a memory card. If there is no memory card, then only program 00 (volatile memory) is available. • Press the PRG key, system selection menu, Quantity program display 2 appears. -

Page 29: Dosing

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions • Activate Select program, display 26 appears. Select program Change program Program 00 (volatile memory) or the last program that Tolerance of pressure was used is shown. Password protection Analog input Adjust time •... -

Page 30: Bleed The Dispenser (After Filling, Cleaning)

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Program no. 00 Program no. 00 Program no. 00 Volume 00.100ml Time 01.00s Flow rate Speed 03.000ml/m Speed 03.000ml/m Speed 03.000ml/m Suckback 0.000ml Suckback 0.000ml Suckback 0.000ml Speed 03.000ml/m Speed 03.000ml/m Speed 03.000ml/m Pause 0.00 s... -

Page 31: Service

• Select and confirm the Service function, Calibration manuel Teach in function display 38 appears. Administration Service 10 47h Esc OK Fr 18.03.11 ViscoTec C200 Serial number 1034 Software C200 V1.004 All the main system and operating times are displayed. 00002h13m Motor totally The language for the displays can be set. -

Page 32: Accessories / Spare Parts

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Accessories / spare parts Item Part No. Designation Comment 20118 Chipcard for controller eco-CONTROL EC 200 20159 Mains adapter 2.7 A for eco-Control EC 200K (1 motor) For motor 1 20183 Protective cap socket motor 1+2 20194 Protective cap for 9-pole Sub-D, RS 232 20168... -

Page 33: Technical Data

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Level of medium critical Not enough medium in the Fill up with the medium. If the supply tank error message remains, check the sensor and sensor input, if applicable, brief "emergency operation" without level monitoring. -

Page 34: Dispenser

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions Dispenser See the commissioning and maintenance manual supplied with the dispenser. Interfaces We offer this information for downloading from our Internet site. Please refer to http://www.preeflow.com/download.html Disposal The final disposal of the Dosing system is to be done in an environmentally- appropriate way. -

Page 35: Ec-Declaration Of Conformity

Dosing system eco-CONTROL EC200-K Operation and maintenance instructions EC-Declaration of Conformity in accordance with the EC-Machinery Directive 2006/42/EG, Appendix II A ViscoTec Pumpen- und Dosiertechnik GmbH Amperstraße 13 D-84513 Töging hereby declare that the machinery described below complies in its design and construction and in the version marketed by us with the basic safety and health requirements of the EC Directive 2006/42/EG.

Need help?

Do you have a question about the Preeflow eco-CONTROL EC200-K and is the answer not in the manual?

Questions and answers