Subscribe to Our Youtube Channel

Summary of Contents for RNA SRC-N 200-2

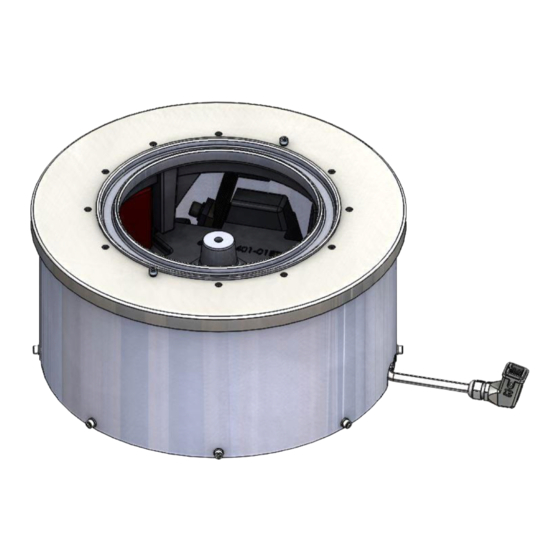

- Page 1 Installation and Operating Instructions Vibratory Feeders SRC-N 160-2 SRC-N 200-2 SRC-B 200-2 SRC-N 250-2 SRC-B 250-2 SRC-N 400-1 SRC-N 400-2 SRC-N 630-1 SRC-N 800-1 SRHL 400-1 SRHL 400-2...

-

Page 2: Table Of Contents

Table of Contents General ..........................4 1.1. Technical data........................4 Safety directives ........................7 2.1. Applicable directives and standards ..................8 Design and functional description ..................8 Shipment and installation ..................... 10 Commissioning ........................12 5.1. Feeder speed decreases? ....................13 5.2. - Page 3 Declaration of Incorporation According to the Low-Voltage Directive 2014/35/EU We hereby declare that the product meets the following requirements: Low-Voltage Directive 2014/35/EC Applied harmonised standards: DIN EN 60204 T1 Remarks: We assume that our product will be incorporated into a stationary machine. Rhein-Nadel-Automation --------------------------------- Managing Director...

-

Page 4: General

1. General 1.1. Technical data Vibratory feeder type SRC-N 160-2 SRC-N 200-2 SRC-B 200-2 SRC-N 250-2 SRC-B 250-2 SRC-N 400-1 Dimensions Ø x H (mm) 157 x 132.5 180 x 165 180 x 165 290 x 215 290 x 215... - Page 5 Notice All vibratory feeders listed in this table shall be operated only in conjunction with an RNA controller and with a mains voltage of 230 V / 50 Hz. For special voltages and frequencies please refer to the separate data sheet.

- Page 6 Pin assignment With jumper: The jumper must be inserted between connections 3 + 4. Rhein-Nadel Automation GmbH VT-MA-SRC 160-800-EN_2019 / 20.03.2019 SJ...

-

Page 7: Safety Directives

Observe the legally binding provisions for the qualifications of qualified electrical workers and instructed workers as defined by standards IEC 364 and DIN VDE 0105, part 1. Notice Electrical protection is provided by RNA's controller. Rhein-Nadel Automation GmbH VT-MA-SRC 160-800-EN_2019 / 20.03.2019 SJ... -

Page 8: Applicable Directives And Standards

Noise emission The noise level at the place of use depends on the complete line in which the hopper will be incorporated and on the material to be sorted. For this reason, sound pressure levels in accordance with the 'Machinery' directive can only be determined at the place of installation. - Page 9 A vibratory feeder is a resonant system (spring-mass system). As a result, its factory set-up will rarely meet your on- site requirements. Section 5 describes in detail how you can adapt the vibratory feeder to your specific requirements. Our optional accessories include a range of bowls covering a wide field of applications. For special applications we of- fer customized solutions.

-

Page 10: Shipment And Installation

Installation At the place of installation the vibratory feeder should be mounted on the specially designed RNA support. If other supports are used make sure that they have sufficient load carrying capacity. This support must be dimensioned to ensure that no vibrations from the vibratory feeder can be transmitted. - Page 11 Bolt circle Bolt circle angles in ° Shock absorber thread type Ø SRC-N 160-2 3 x 120 SRC-N 200-2 3 x 120 SRC-B 200 3 x 120 SRC-N 250-2 3 x 120 SRC-B 250 3 x 120 SRC-N 400-1...

-

Page 12: Commissioning

5. Commissioning Preparations Attention Make sure that the machine frame (rack, substructure, etc.) is connected to the protective earth conductor (PE). Protective earthing has to be provided by user as necessary. Attention It is imperative that the vibrating motor be connected to the equipotential bonding system of the overall equipment be- fore commissioning. -

Page 13: Feeder Speed Decreases

When you loosen the spring fastening screw you can observe a change in feeder speed. The following graph shows the resonance curve of a vibratory feeder. Feed rate Desired feeder speed Resonance frequency of the system Resonance curve Spring force (number of springs) increasing Notice The resonance frequency of the vibratory feeder must not be equal to the mains frequency, it should be lower than the driving frequency of the current. -

Page 14: Maintenance

Feeder speed is not constant? If the feeder speed in the bowl is no longer constant you can balance the bowl by adding counter-weights. • Attach a counterweight to the side that is running fast. If the addition of counter-weights is not possible, you can also proceed as follows: •... -

Page 15: What If

8. What if...Advice on troubleshooting Attention The control unit or terminal box must only be opened by a professional electrician. Pull the mains plug be- fore opening! Fault Potential cause Remedy Vibratory feeder does Mains connector of control unit not plugged-in Plug in the mains connector not start on power up Connecting cabled between vibratory feeder... - Page 16 Manufacturing and Sales Rhein-Nadel Automation GmbH Reichsweg 19-23 D-52068 Aachen Phone: +49 (0) 241-5109-0 Further manufacturing sites Fax: +49 (0) 241-5109-219 of the RNA Group E-mail: vertrieb@RNA.dede www.RNA.de Manufacturing Lüdenscheid branch Further RNA group companies: Rhein-Nadel Automation GmbH Nottebohmstraße 57 D-58511 Lüdenscheid...

Need help?

Do you have a question about the SRC-N 200-2 and is the answer not in the manual?

Questions and answers