Table of Contents

Advertisement

Quick Links

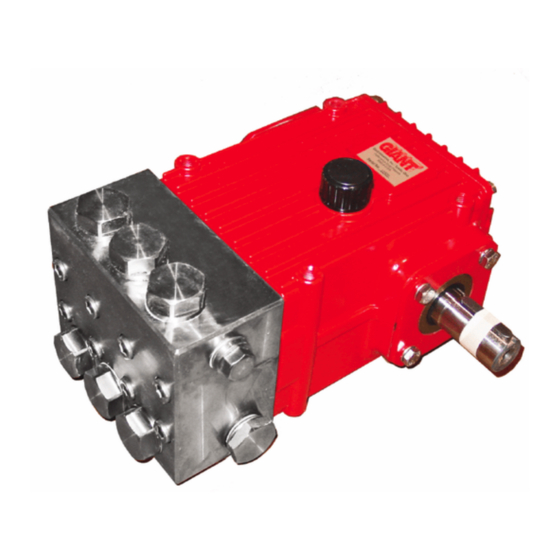

Pump Model

P450-5100

Corrosion Resistant Pump

07/09

Triplex Ceramic

Plunger Pump

Operating Instructions

Repair and Service Manual

Contents:

Warranty Information

page 2

page 3

page 4

page 5

pages 6-8

page 9

page 9

page 9

page 10

page 11

back page

Advertisement

Table of Contents

Summary of Contents for Giant P450-5100

-

Page 1: Table Of Contents

Pump Model Triplex Ceramic Plunger Pump P450-5100 Operating Instructions Repair and Service Manual Corrosion Resistant Pump Contents: Installation Instructions: page 2 Specifications: page 3 Exploded View page 4 Parts List / Kits page 5 Repair Instructions: pages 6-8 Pump mounting selection... -

Page 2: Installation Instructions

50 hours of operation, then at regular inter- Industries, Inc. vals of 500 hours or less depending on operating conditions. 4. Run the pump dry approximately 10 seconds to drain the water before exposure to freezing temperatures. NOTE: Contact Giant Industries for Service School Information. Phone: (419)-531-4600... -

Page 3: Specifications

Specifications Model P450-5100 U . S . (Metric) Volume ................5.5 GPM ........(20.8 l/m) Discharge Pressure ..........5075 PSI ......... (350 bar) Inlet Pressure .............. 90 PSI ........(6.2 bar) Stroke................0.79” ........... 20mm R P M ............................Up to 1450 RPM Plunger Diameter............ -

Page 4: Exploded View

P450-5100 Exploded View... -

Page 5: Parts List / Kits

P450-5100 PUMP PARTS LIST I T E M PART D E S C R I P T I O N QTY. I T E M PART D E S C R I P T I O N QTY. 08377 Crankcase... -

Page 6: Repair Instructions: Pages

REPAIR INSTRUCTIONS - P450-5100 Note: Always take time to lubricate all metal and nonmetal parts with a light film of oil before reassembly. This step will ensure proper fit, at the same time protecting the pump nonmetal parts (i.e., the elastomers) from cutting and scoring. - Page 7 Slide valve casing over plungers and seat firmly. Replace the 8 socket head cap screws (34) and tighten to 29.5 lb-ft (40 Nm) in a crossing pattern (as shown on the right). Contact Giant Industries for service school information. Phone: (419) 531-4600...

- Page 8 Gear End If oil leaks where the plunger (16) extends from the crankcase (1), the oil seals (19) and plungers (16) must be examined and replaced if necessary. Remove oil plug (5) and drain oil; remove crankcase cover (3). Remove valve casing (26), and seal case (20).

-

Page 9: Pump Mounting Selection Guide

(See page 5 for kit list) Oil Seal Kit (1 kit/pump) (See page 5 for kit lit) Valve Spare Parts (1 kit/pump) (See page 5 for kit list) P450-5100 PUMP TORQUE SPECIFICATIONS Position Item# Description Torque Amount Screw with Washer... -

Page 10: Trouble Shooting

Adjust or Replace packing seals Excessive vacuum Reduce suction vacuum Cracked plungers Replace plungers Inlet pressure too high Reduce inlet pressure High Crankcase Wrong Grade of oil Giant oil is recommended Temperature Improper amount of oil in crankcase Adjust oil level to proper amount... -

Page 11: Dimensions

P450-5100 PUMP DIMENSIONS - INCHES (MM) - Page 12 A Returned Goods Authorization (R.G.A.) number and completed warranty evaluation form is required prior to the return to Giant Industries of all products under warranty consideration. Call (419)-531-4600 or fax (419)-531-6836 to obtain an R.G.A. number.