Table of Contents

Advertisement

Quick Links

SERVICE MANUAL

EN

IMPORTANT:

Read and follow all

instructions and SAFETY PRECAU-

TIONS before using this equipment.

Retain for future reference.

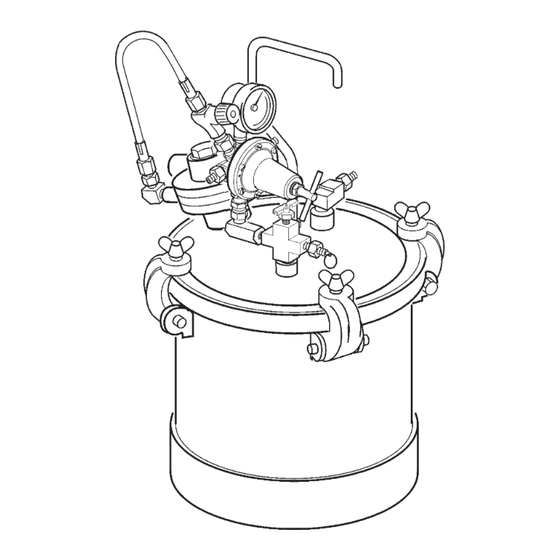

DESCRIPTION

The 83Z pressure tanks are designed as a

pressure container to supply liquid mate-

rial at a constant preset pressure up to a

maximum of 80 PSI. The tanks are built to

ASME specifications. All models include

stainless steel wetted parts, a stainless steel

lid and polyethylene liner, allowing use with

waterborne materials. All models are for

light to medium duty use only.

Models:

83Z-210: Single regulation (fluid), air inlet/

outlet, fluid outlet, safety valve

83Z-220: Dual regulation (air and fluid),

otherwise same as 83Z-210

83Z-211: Single regulation (fluid), air driven

agitator assembly, fluid outlet, safety valve

83Z-221: Dual regulation (air and fluid),

otherwise same as 83Z-211

PROP 65 WARNING

WARNING: This product

CA PROP

65

contains chemicals known

to the State of California to

cause cancer and birth

defects or other

reproductive harm.

SBBI-21-043-N (6/2017)

83Z PRESSURE TANK

(WATERBORNE COMPATIBLE)

Small Tank – Up To 2.8 Gallons

Halogenated hydrocarbon solvents

- for example: 1,1,1, - trichloroeth-

ane and methylene chloride - can

chemically react with aluminum

parts and components and cause

an explosion hazard. These solvents

will also corrode the galvanized

tank coating. Read the label or data

sheet for the material. Do not use

materials containing these solvents

with these pressure tanks.

Refer to specifications chart to en-

sure that fluids and solvents being

used are chemically compatible

with the tank wetted parts. Before

placing fluids or solvents in tank,

always read accompanying manu-

facturer's literature.

Air pressure loads that are higher

than design loads, or changes to the

pressure feed tank can cause the

tank to rupture or explode.

• A safety valve protects the tank

from over pressurization. During

each use pull the ring on the safety

valve to make sure it operates freely

and relieves air pressure. If the valve

is stuck, does not operate freely,

or does not relieve air pressure, it

must be replaced. Do not eliminate,

make adjustments or substitutions

to this valve.

• Changes to the air tank will weaken

it. Never drill into, weld or change

the tank in any way.

• The maximum working pressure

of this tank is 80 psi.

1 / 8

Static electricity is created by the

flow of fluid through the pressure

tank and hose. If all parts are not

properly grounded, sparking may

occur. Sparks can ignite vapors

from solvents and the fluid being

sprayed.

If static sparking, or slight shock, is

experienced while using this equip-

ment, stop spraying immediately.

Ground the pressure tank by connect-

ing one end of a 12 gauge minimum

ground wire to the pressure tank and

the other end to a true earth ground.

Local codes may have additional

grounding requirements.

See illustration, page 4, for grounding

and grounding hardware required.

Pressure Relief Procedure

High pressure can cause a serious

injury. Pressure is maintained in

a pressure tank after the system

has been shut down. Before at-

tempting removal of fill plug or

cover, pressure must be relieved

using the following steps:

1. Turn off the main air supply

to the tank.

2. Shut off air regulator or re-

move air supply line from tank.

3. Bleed off air in the tank by

turning the air relief valve thumb

screw counterclockwise. Wait un-

til all the air has escaped through

the valve before removing the

pressure tank cover or fill plug.

4. Leave the air relief valve open

until you have reinstalled the

cover.

www.carlisleft.com

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Binks 83Z

- Page 1 DESCRIPTION Pressure Relief Procedure The 83Z pressure tanks are designed as a pressure container to supply liquid mate- High pressure can cause a serious rial at a constant preset pressure up to a injury. Pressure is maintained in maximum of 80 PSI.

- Page 2 SAFETY PRECAUTIONS This manual contains information that is important for you to know and understand. This information relates to USER SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please pay particular attention to these sections. Note Important information that tells how to pre- Information that you should pay special...

- Page 3 (P-H-5516) or, with the to control the speed of the agitator. The additional air regulator provided with air motor requires low air consumption, “dual regulation” tank models (83Z-220 approximately 3-6 C.F.M. at 60 P.S.l. (Max. or 83Z-221). input air pressure 100 P.S.l.) See Spray Gun instructions for opera- tion of the gun.

- Page 4 Street Elbow 1/4" NPT (F) x 1/4" NPT (M) n 6 H-2008 Nipple 1/4" NPT(M) (83Z 210&220) Fluid Out x 1/4"NPS(M) (83Z 211 & 221) 7 HA-57011 Hose Assembly 8 HAV-500 Air Adjusting Valve1/4" NPS (F) x 1/4" NPS (M)

- Page 5 #PT-419 Agitator Shaft Assembly not included in KK-5006 Strainer Screen & Felt Kit. with PT-427 Assembly. Must be ordered sepa- ▫ Parts are included in KK-5074 Air Motor Adapter Kit rately. for 83C and 83Z Series tanks. SBBI-21-043-N (6/2017) 5 / 8 www.carlisleft.com...

- Page 6 7. Turn on the air supply to spray gun. 8. Place cloth over air cap on the gun and pull trigger. This will force material back through the hose, into the tank. Binks Solvent Saver 83 G3-5200 can be used to clean hoses and gun fluid passage 9.

- Page 7 NOTES SBBI-21-043-N (6/2017) 7 / 8 www.carlisleft.com...

- Page 8 ©2017 Carlisle Fluid Technologies, Inc. All rights reserved. Binks is part of Carlisle Fluid Technologies, a global leader in innovative finishing technologies. For technical assistance or to locate an authorized distributor, contact one of our international sales and customer support locations.

Need help?

Do you have a question about the 83Z and is the answer not in the manual?

Questions and answers