Advertisement

Quick Links

Download this manual

See also:

User Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

DESCRIPTION

GENERAL

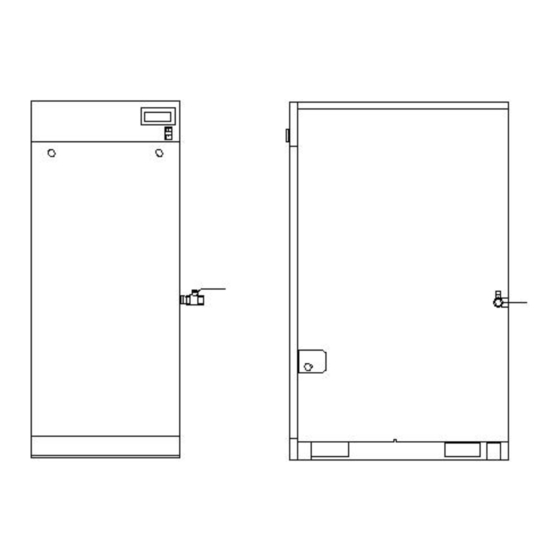

Powerex Scroll Enclosure Air Compressors are designed to

supply continuous oil-free air by using the most advanced

scroll technology. These turn-key packages are extremely quiet

and offer electronic control that will reduce electrical power

consumption.

The Powerex Oil-less Rotary Scroll Air Compressor has

advanced scroll compressor technology through the

development of a completely oil-less unit. The Powerex Scroll

Compressor offers a dynamically balanced air end which

insures vibration-free operation. The rotary design permits a

continuous 100% duty cycle. No oil separation, oil filtration,

or inlet valves are required on the Powerex Scroll unit. The

compressor is virtually maintenance free.

The Powerex Oil-less Rotary Scroll Air Compressor is based

on the theory of scroll compression. A scroll is a free standing,

intricate spiral bounded on one side by a solid, flat plane or

base. A scroll set, the basic compression element of a scroll

compressor, is made up of two identical spirals which form

right and left hand parts. One of these scroll components is

indexed or phased 180° with respect to the other so the scrolls

can mesh. Crescent-shaped gas pockets are formed and

bounded by the spirals and the base plate of both scrolls. As

the moving scroll is orbited around the fixed scroll, the pockets

formed by the meshed scrolls follow the spiral toward the

center and diminish in size. The moving scroll is prevented

from rotating during this process so the 180° phase

relationship of the scrolls is maintained. The compressor's

inlet is at the outer boundary of the scrolls. The entering gas is

trapped in two completely opposite gas pockets and

compressed as the pockets move toward the center. The

compressed gas is discharged through the outlet at the center

of the fixed scroll so no valves are needed.

Table of Contents

Specifications

Pg 1–2

Safety Guidelines Pg 2-3

Installation

Pg 3-7

Operation

Pg 8-11

Powerex - 150 Production Drive - Harrison, Ohio 45030 - USA

1-888-769-7979 - www.powerexinc.com

10HP - 20HP Scroll Enclosure Air Compressors

Maintenance

Pg 12

Electrical

Pg 13-15

SPECIFICATIONS

Product

SE Series Enclosed Scroll Air

Compressor

Performance

See page 2

Specifications

Lubrication

Grease-filled Bearing

Operating

3Ø - 208-230/460/575 Volts, 60 Hz

Voltages

Compression

Scroll

Cycle

Motor Overload

Motor Protector/Circuit Breaker

Protection

Pressure Settings

Cut in: 90 psig Cut out: 116 psig

Cut in: 119 psig Cut out: 145 psig

(High Pressure Units)

Overpressure

Safety Valve Factory Set and Sealed

Protection

Outlet Air

See page 2

Connections

Tank Sizes

See Page 6, Chart 2

Drive

3V Belt

Agency Approvals UL/CSA Certified

Pg 1

04/13

IN562802AV

Advertisement

Summary of Contents for Powerex SED1007HP

- Page 1 The rotary design permits a continuous 100% duty cycle. No oil separation, oil filtration, Product SE Series Enclosed Scroll Air or inlet valves are required on the Powerex Scroll unit. The Compressor compressor is virtually maintenance free. Performance...

-

Page 2: Specification Chart

Keep visitors away and NEVER allow children in the PURPOSE OF BREATHING AIR APPLICATION AND work area. PROPER IN-LINE SAFETY AND ALARM EQUIPMENT IS NOT SIMUTANEOUSLY USED, EXISTING WARRANTIES ARE VOID, AND POWEREX DISCLAIMS ANY LIABILITY WHATSOEVER FOR ANY LOSS, PERSONAL INJURY OR DAMAGE. Pg 2... - Page 3 10 HP - 20 HP Scroll Enclosure Air Compressors GENERAL SAFETY CONT. STORAGE Do not wear loose clothing or jewelry that will get When not in use, the unit should be covered to prevent caught in the moving parts of the unit. the ingress of dirt and foreign matter and stored in a cool, dry place.

- Page 4 10 HP - 20 HP Scroll Enclosure Air Compressors VENTILATION INSTALLATION CONT. 1. If the scroll compressor is located in a totally enclosed PRECAUTIONS DURING TRANSPORTATION AND room, an exhaust fan with access to outside air must be MOVEMENT installed. TRANSPORTATION BY FORKLIFT 2.

- Page 5 10HP - 20HP Scroll Enclosure Air Compressors All electrical hook-ups must be performed by a qualified INSTALLATION Cont’d electrician. Installations must be in accordance with local and WIRING national electrical codes. 1. A service disconnect and fuses or a circuit breaker must be installed to supply electric power to this compressor.

- Page 6 10HP - 20HP Scroll Enclosure Air Compressors REMOTE INTAKE PIPING INSTALLATION Cont’d Powerex compressor systems with pipe thread connectors on the intake filters are intended for installation with remote air intake. Piping for the remote intake system should be Never install a shut-off valve between a compressor pump installed at the final operating site.

- Page 7 CONTROL PANEL - DISPLAY AND INPUT The Powerex scroll enclosure air compressor has a power control switch and a touch screen or HMI panel on the front to allow operation and monitoring of the unit. See Controls section for details on operating the unit using the touch screen.

- Page 8 Touch the rectangle to enter the Authorization Code and enter 4. Check the belts for tightness. seven digits using the keypad that appears. Powerex suggests 5. Be sure all pressure connections are tight. using the last seven digits of the serial number.

- Page 9 10HP - 20HP Scroll Enclosure Air Compressors quantity of air ends in accordance with air consumption and OPERATION Cont’d energy-saving operation by eliminating waste of electricity. SHUT-DOWN The chart below shows the relationship between pressure and 1. Stop the compressor by pushing the OFF button. the quantity of air ends operating for an SEQ model.

- Page 10 The Scroll Enclosure Air Compressor is controlled by a PLC HIGH operating pressure and the smallest differential that programmed at the Powerex factory. The operating status is avoids exceeding the motor start frequency limit. displayed on the HMI– touch screen panel on the front of the PERFORMING PRESSURE ADJUSTMENTS compressor unit.

- Page 11 AUTOMATIC RESTART until the alarm is cleared and the motor protector reset. The When power is applied to the Powerex scroll enclosure com- circuit will be restarted as needed. If a motor overload occurs, pressor control, the display will illuminate and go to the SYS- the root cause should be determined and corrected or motor TEM STATUS screen.

- Page 12 10HP - 20HP Scroll Enclosure Air Compressors NEW BELT INSTALLATION PROCEDURE MAINTENANCE 1. Loosen the two slide bolts near the motor pulley and the ADJUSTING BELT TENSION two slide bolts on the front edge of the base. Keep enough Moving Parts! Lock out power torque on them to take up any slack between the slider and before servicing unit! the main base, but enough slack to allow the slider to move.

- Page 13 10HP - 20HP Scroll Enclosure Air Compressors BRANCH CIRCUIT PROTECTION TABLE (A) Load Specifications (B) Branch Circuit Protection (provided by installer) Motor Size (A) Power (A) Motor Panel Load Non-time Time Inverse Time System Type (HP) Each (V/PH) Load Each Total Delay Fuse Delay...

- Page 14 10HP - 20HP Scroll Enclosure Air Compressors ELECTRICAL DIAGRAM Pg 14...

- Page 15 10HP - 20HP Scroll Enclosure Air Compressors ELECTRICAL DIAGRAM Pg 15...

- Page 16 10HP - 20HP Scroll Enclosure Air Compressors NOTES: Pg 16...

Need help?

Do you have a question about the SED1007HP and is the answer not in the manual?

Questions and answers