Table of Contents

Advertisement

Quick Links

OWNER'S GUIDE & INSTALLATION INSTRUCTIONS

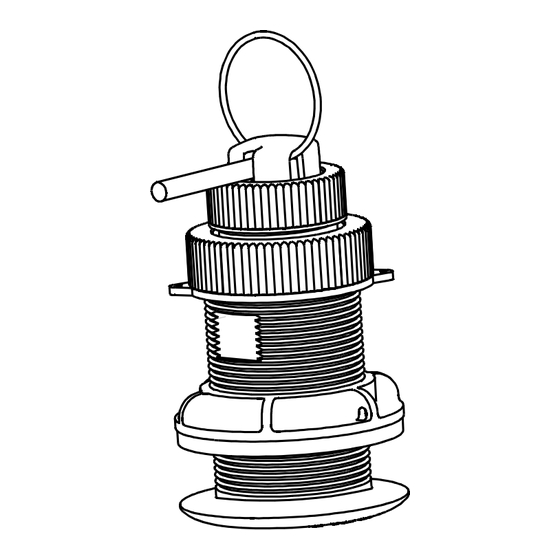

Thru-Hull, Retractable with Valve

Temperature or Speed & Temp. Sensor

Models: HT200, ST850

U.S. Patents: 7,110,908; 7,352,171. UK 2 409 527

Follow the precautions below for optimal

product performance and to reduce the risk of

property damage, personal injury, and/or death.

WARNING: Always wear safety goggles, a dust mask,

and ear plugs when installing.

WARNING: The valve is not a watertight seal! Always

use the insert or the blanking plug secured with the

safety wire for a watertight seal.

WARNING: The O-rings must be intact and well

lubricated to make a watertight seal.

WARNING: Always attach the safety wire to prevent

the insert or blanking plug from backing out in the

unlikely event that the cap nut fails or is screwed on

incorrectly.

WARNING: When the valve assembly is removed,

always insert the short emergency plug secured with

the CAP nut and safety wire for a watertight seal.

WARNING: Immediately check for leaks when the boat

is placed in the water. Do not leave the boat unchecked

for more than three hours. Even a small leak may allow

considerable water to accumulate.

CAUTION: Never pull, carry, or hold the sensor by its

cable; this may sever internal connections.

CAUTION: Never use a fairing with a plastic housing;

the protruding sensor would be vulnerable to damage

from impact.

CAUTION: Never install a metal housing in a vessel

with a positive ground system.

CAUTION: Never use solvents. Cleaner, fuel, sealant,

paint, and other products may contain solvents that

can damage plastic parts.

IMPORTANT: Please read the instructions completely

before proceeding with the installation. These

instructions supersede any other instructions in your

instrument manual if they differ.

Applications

• Plastic housing recommended for fiberglass or metal hulls only.

Never install a plastic housing in a wood hull since swelling of

the wood may fracture the plastic.

• Bronze housing recommended for fiberglass or wood hull only.

Never mount a bronze housing in a metal hull because

electrolytic corrosion will occur.

Record the information found on the cable tag for future reference.

Part No._________________Date___________

HT200

plastic

low profile

P17 housing

Pretest

Connect the sensor to the instrument. Check for the approximate

air temperature. If it has a paddlewheel, spin it and check for a

speed reading. If there is no reading(s) or it is inaccurate, check

the connections and try again. If there is still a problem, return the

product to the place of purchase.

Tools & Materials

Safety goggles

Dust mask

Ear plugs

Water-based anti-fouling paint (mandatory in salt water)

Electric drill with 10mm (3/8") or larger chuck capacity

Drill bit

Hole saw:

Countersink tool (installing a flush housing)

Sandpaper

Mild household detergent or weak solvent (such as alcohol)

File (installation in a metal hull)

Marine sealant (suitable for below waterline)

Slip-joint pliers (installing a metal housing)

Grommet(s) (some installations)

Cable ties

Installation In A Cored Fiberglass Hull (see page 4)

Hole saw for hull interior

Fiberglass cloth and resin

or Cylinder, wax, tape, and casting epoxy

Mounting Location

CAUTION: Never mount the speed sensor directly ahead of a

depth transducer, since turbulence generated by the

paddlewheel's rotation will adversely affect the transducer's

performance, especially at high speeds. Mount side by side.

CAUTION: Do not mount the sensor in line with or near water

intake or discharge openings or behind strakes, fittings, or hull

irregularities that may disturb the water flow.

Choose an accessible spot inside the vessel. Allow a minimum of

280mm (11") of headroom for the height of the housing, tightening

the nuts, and installing the insert.

HT200—The sensor must be in contact with the water at all times.

ST850—Turbulence-free water must flow under the paddlewheel

at all boat speeds.

ST850

plastic

low profile

P17 housing

3mm or 1/8"

51mm or 2"

60mm or 2-3/8"

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Airmar HT200

- Page 1 HT200—The sensor must be in contact with the water at all times. • Bronze housing recommended for fiberglass or wood hull only. ST850—Turbulence-free water must flow under the paddlewheel Never mount a bronze housing in a metal hull because electrolytic corrosion will occur.

- Page 2 It is easier to apply anti-fouling paint before installing the sensor, but allow sufficient drying time. Reapply paint every 6 months or HT200—Disregard any arrow on the housing; it is not needed. at the beginning of each boating season. Paint the following ST850—Align the arrow on the flange of the housing to point...

- Page 3 Airmar’s splash-proof Junction Box No. 33-035 and follow the instructions provided. Removing the waterproof connector or The HT200 and ST850 insert can be installed in a new or existing cutting the cable, except when using a watertight junction box, will ST650 housing.

- Page 4 Cut the cable a minimum of 1m (3') from the 7. Proceed with “Bedding” and “Installing” on page 2. insert to free the CAP nut. Later, splice the cable using Airmar’s splash-proof Junction Box No. 33-035.

- Page 5 10.Attach the safety wire to the short emergency plug, the cap desire greater strength, purchase an Airmar metal housing. If you nut, the insert nut, and the pull ring to prevent the insert from...

- Page 6 35 Meadowbrook Drive, Milford, New Hampshire 03055-4613, USA • www.airmar.com Copyright © 2005 - 2016 Airmar Technology Corp. All rights reserved.

Need help?

Do you have a question about the HT200 and is the answer not in the manual?

Questions and answers