Advertisement

Quick Links

JY997D65101C

Side

ENGLISH

A

Side

CHINESE

B

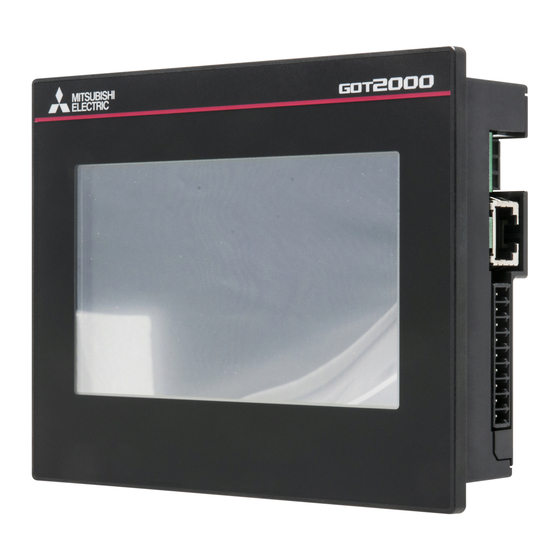

GT2104-PMBD, GT2104-PMBDS

GT2104-PMBDS2, GT2104-PMBLS

GT21 General Description

Manual Number

JY997D65101C

Date

Sep. 2016

This manual describes the part names, dimensions, mounting, and specifications

of the product. Before use, read this manual and manuals of relevant products

fully to acquire proficiency in handling and operating the product. Make sure to

learn all the product information, safety information, and precautions.

And, store this manual in a safe place so that you can take it out and read it

whenever necessary. Always forward it to the end user.

Registration

Ethernet is a trademark of Xerox Corporation in the United States. The company

name and the product name to be described in this manual are the registered

trademarks or trademarks of each company.

Effective Sep. 2016

Specifications are subject to change without notice.

2015 MITSUBISHI ELECTRIC CORPORATION

Safety Precaution

(Read these precautions before using.)

Before using this product, please read this manual and the relevant manuals

introduced in this manual carefully and pay full attention to safety to handle the

product correctly.

The precautions given in this manual are concerned with this product.

In this manual, the safety precautions are ranked as "WARNING" and "CAUTION".

Indicates that incorrect handling may cause hazardous

conditions, resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous

conditions, resulting in medium or slight personal injury

or physical damage.

Depending on circumstances, procedures indicated by "CAUTION" may also be

linked to serious results. In any case, it is important to follow the directions for

usage

DESIGN PRECAUTIONS

Some failures of the GOT or cable may keep the outputs on or off. Some

failures of a touch panel may cause malfunction of the input objects such as a

touch switch. An external monitoring circuit should be provided to check for

output signals which may lead to a serious accident. Not doing so can cause

an accident due to false output or malfunction.

Do not use the GOT as the warning device that may cause a serious

accident. An independent and redundant hardware or mechanical interlock is

required to configure the device that displays and outputs serious warning.

Not doing so can cause an accident due to false output or malfunction.

When the GOT detects its backlight failure, the GOT disables the input

operation on the touch switch(s). Thus, operators cannot operate the GOT

with touches. The GOT backlight failure can be checked with a system signal

of the GOT.

Even when the display section has dimmed due to a failure of the liquid

crystal section or the backlight on the GOT, the input operation of the touch

switches may still be enabled. This may cause an incorrect operation of the

touch switches. For example, if an operator assumes that the display section

has dimmed because of the screen save function and touches the display

section to cancel the screen save, a touch switch may be activated. h

touches. The GOT backlight failure can be checked with a system signal of

the GOT.

The display section of the GOT is an analog-resistive type touch panel.

Simultaneous pressing of two or more areas on the display section may

activate the switch between those areas. Do not press two or more areas

simultaneously on the display section. Doing so may cause an accident due

to incorrect output or malfunction.

When programs or parameters of the controller (such as a PLC) that is

monitored by the GOT are changed, be sure to shut off the power of the GOT

promptly and power on the GOT again. Not doing so can cause an accident

due to false output or malfunction.

If a communication fault (including cable disconnection) occurs during

monitoring on the GOT, communication between the GOT and PLC CPU is

suspended and the GOT becomes inoperative. A system where the GOT is

used should be configured to perform any significant operation to the system

by using the switches of a device other than the GOT on the assumption that

a GOT communication fault will occur. Not doing so can cause an accident

due to false output or malfunction.

Side

A

DESIGN PRECAUTIONS

When the security of the GOT and relevant information need to be protected

against illegal access from an external device via the Internet, take measures at

the user's discretion.

Failure to do so may cause the configured information to be read out illegally.

DESIGN PRECAUTIONS

Do not bundle the control and communication cables with main-circuit, power or

other wiring. Run the above cables separately from such wiring and keep them a

minimum of 100 mm apart. Not doing so noise can cause a malfunction.

Do not press the GOT display section with a pointed material as a pen or driver.

Doing so can result in a damage or failure of the display section.

When a GOT2000 series model and a GOT1000 series model are on an Ethernet

network, do not set the IP address 192.168.0.18 for the GOTs and the controllers

on this network.

Doing so can cause IP address duplication at the GOT startup, adversely

affecting the communication of the device with the IP address 192.168.0.18.

The operation at the IP address duplication depends on the devices and the

system.

Turn on the controllers and the network devices to be ready for communication

before they communicate with the GOT. Failure to do so can cause a

communication error on the GOT.

When the GOT is subject to shock or vibration, or some colors appear on the

screen of the GOT, the screen of the GOT might flicker.

MOUNTING PRECAUTIONS

Be sure to shut off all phases of the external power supply used by the system

before mounting or removing the GOT main unit to/from the panel. Not doing so

can cause the unit to fail or malfunction.

MOUNTING PRECAUTIONS

Use the GOT in the environment that satisfies the general specifications

described in this manual. Not doing so can cause an electric shock, fire,

malfunction or product damage or deterioration.

When mounting the GOT to the control panel, tighten the mounting screws in the

specified torque range (0.20 N·m to 0.25 N·m) with a Phillips-head screwdriver

No.2. Undertightening can cause the GOT to drop, short circuit or malfunction.

Overtightening can cause a drop, short circuit or malfunction due to the damage

of the screws or the GOT.

Remove the protective film of the GOT. When the user continues using the GOT

with the protective film, the film may not be removed.

Operate and store the GOT in environments without direct sunlight, high

temperature, dust, humidity, and vibrations.

Do not use the GOT in an environment with oil or chemicals. Doing so may cause

failure or malfunction due to the oil or chemical entering into the GOT.

WIRING PRECAUTIONS

Be sure to shut off all phases of the external power supply used by the system

before wiring. Failure to do so may result in an electric shock, product damage or

malfunctions.

WIRING PRECAUTIONS

Please make sure to ground FG terminal of the GOT power supply section by

applying 100 Ω or less which is used exclusively for the GOT. Not doing so may

cause an electric shock or malfunction.

Correctly wire the GOT power supply section after confirming the rated voltage

and terminal arrangement of the product. Not doing so can cause a fire or failure.

Tighten the terminal screws of the GOT power supply section in the specified

torque range (0.22 N·m to 0.25 N·m). Undertightening can cause a short circuit or

malfunction. Overtightening can cause a short circuit or malfunction due to the

damage of the screws or the GOT.

Exercise care to avoid foreign matter such as chips and wire offcuts entering the

GOT. Not doing so can cause a fire, failure or malfunction.

Plug the communication cable into the GOT interface or the connector of the

connected unit, and tighten the mounting screws and the terminal screws in the

specified torque range. Undertightening can cause a short circuit or malfunction.

Overtightening can cause a short circuit or malfunction dueto the damage of the

screws or unit.

TEST OPERATION

PRECAUTIONS

Before performing the test operations of the user creation monitor screen (such as

turning ON or OFF bit device, changing the word device current value, changing

the settings or current values of the timer or counter, and changing the buffer

memory current value), read through the manual carefully and make yourself

familiar with the operation method. During test operation, never change the data

of the devices which are used to perform significant operation for the system.

False output or malfunction can cause an accident.

STARTUP/MAINTENANCE

PRECAUTIONS

When power is on, do not touch the terminals. Doing so can cause an electric

shock or malfunction.

Before starting cleaning or terminal screw retightening, always switch off the

power externally in all phases. Not doing so can cause the unit to fail or

malfunction. Undertightening can cause a short circuit or malfunction.

Overtightening can cause a short circuit or malfunction due to the damage of

the screws or unit.

STARTUP/MAINTENANCE

PRECAUTIONS

Do not disassemble or modify the unit. Doing so can cause a failure,

malfunction, injury or fire.

Do not touch the conductive and electronic parts of the unit directly. Doing so

can cause a unit malfunction or failure.

The cables connected to the unit must be run in ducts or clamped. Not doing so

can cause the unit or cable to be damaged due to the dangling, motion or

accidental pulling of the cables or can cause a malfunction due to a cable

connection fault.

When unplugging the cable connected to the unit, do not hold and pull from the

cable portion. Doing so can cause the unit or cable to be damaged or can cause

a malfunction due to a cable connection fault.

Do not drop the module or subject it to strong shock. A module damage may

result.

Before touching the unit, always touch grounded metals, etc. to discharge static

electricity from human body, etc. Not doing so can cause the unit to fail or

malfunction.

Replace battery with GT11-50BAT by Mitsubishi electric Co. only.

Use of another battery may present a risk of fire or explosion.

Dispose of used battery promptly.

Keep away from children. Do not disassemble and do not dispose of in fire.

TOUCH PANEL

PRECAUTIONS

For the analog-resistive film type touch panels, normally the adjustment is not

required. However, the difference between a touched position and the object

position may occur as the period of use elapses. When any difference between

a touched position and the object position occurs, execute the touch panel

calibration.

When any difference between a touched position and the object position occurs,

other object may be activated. This may cause an unexpected operation due to

incorrect output or malfunction.

PRECAUTIONS WHEN THE

DATA STORAGE IS IN USE

If the SD card mounted on drive A of the GOT is removed while the GOT is

accessed, processing for the GOT might be interrupted about for 20 seconds.

The GOT cannot be operated during this period. The functions that run in the

background including a screen updating, alarm, logging, scripts, and others are

also interrupted. Since this interruption makes an impact to the system

operation, it might cause failure. After inhibiting access to the SD card on the

GOT utility screen, check that the SD card access LED is off and remove the SD

card.

PRECAUTIONS WHEN THE

DATA STORAGE IS IN USE

If the data storage mounted on the GOT is removed while the GOT is accessed,

the data storage and files are damaged. To remove the data storage from the

GOT, check that the access to the data storage in SD card access LED, the

system signal, and others is not performed.

When removing the SD card from the GOT, make sure to support the SD card

by hand as it may pop out. Failure to do so may cause the SD card to drop from

the GOT, resulting in a failure or break.

Before removing the USB device from the GOT, follow the procedure for

removal on the utility screen of the GOT. After the successful completion dialog

is displayed, remove the USB device by hand carefully. Failure to do so may

cause the USB device to drop from the GOT, resulting in a failure or break.

DISPOSAL PRECAUTIONS

When disposing of this product, treat it as industrial waste.

When disposing of batteries, separate them from other wastes according to the

local regulations.

(Refer to the GOT2000 Series User' Manual (Hardware) for details of the

battery directive in the EU member states.)

TRANSPORTATION

PRECAUTIONS

When transporting lithium batteries, make sure to treat them based on the

transport regulations.

(Refer to the GOT2000 Series User' Manual (Hardware) for details of the

regulated models.)

TRANSPORTATION

PRECAUTIONS

Make sure to transport the GOT main unit and/or relevant unit(s) in the manner

they will not be exposed to the impact exceeding the impact resistance

described in the general specifications of this manual, as they are precision

devices. Failure to do so may cause the unit to fail. Check if the unit operates

correctly after transportation.

When fumigants that contain halogen materials such as fluorine, chlorine,

bromine, and iodine are used for disinfecting and protecting wooden packaging

from insects, they cause malfunction when entering our products. Please take

necessary precautions to ensure that remaining materials from fumigant do not

enter our products, or treat packaging with methods other than fumigation (heat

method). Additionally, disinfect and protect wood from insects before packing

products.

Certification of UL, cUL standards

Using GOT

GOT is for use on a Flat Surface of a Type 1 Enclosure.

Notification of CE marking

The following products have shown compliance through direct testing (to the

identified standards) and design analysis (forming a technical construction file) to the

European Directive for Electromagnetic Compatibility (2004/108/EC) when used as

directed by the appropriate documentation.

This product is designed for use in industrial applications

- Type: Graphic Operation Terminal

- Models: GOT series

Standard

Remark

Compliance with all relevant aspects of the standard.

EN61131-2 : 2007

EMI

(Radiated Emissions)

Programmable

controllers -

Compliance with all relevant aspects of the standard.

Equipment,

(ESD, RF electromagnetic field, EFTB, Surge, RF

EMS

requirements and

c onduc ted dis turbanc es and P owe r frequ ency

tests

magnetic field)

For more details please contact your local Mitsubishi Electric sales site.

For details of CE marking, refer to the following.

GOT2000 series User's Manual

Manual

The following shows manuals relevant to this product.

Detailed Manual

Manual number

Manual name

(Model code)

GOT2000 Series User's Manual (Hardware)

SH-081194ENG-A (1D7MJ5)

GOT2000 Series User's Manual (Utility)

SH-081195ENG-A (1D7MJ6)

For detailed manuals, refer to the PDF manuals stored in the DVD-ROM for the

drawing software used.

Relevant Manuals

For relevant manuals, refer to the Help or the PDF manuals stored in the DVD-ROM

for the drawing software used.

The latest manuals are also available from MITSUBISHI ELECTRIC FA Global

Website (http://www.MitsubishiElectric.co.jp/fa).

© 2014 MITSUBISHI ELECTRIC CORPORATION

Before using the GOT

Connect the connector of the GOT to the connector of the battery.

Refer to the GOT2000 Series User's Manual (Hardware) for the connection instructions.

For details on the GOT specifications, installing instructions, wiring, maintenance

and inspection, or checking procedure for the version and the compatible standard,

refer to the GOT2000 Series User's Manual (Hardware).

Bundled Items

Model name

Remark

GT2104-PMBD/

PMBDS/

GOT main unit

PMBDS2/

(The maintenance supplies below are packed with the product.)

PMBLS

Model name

Remark

PLC Communication Connector

Panel Mounting Bracket (with M4 × 20 screws)

Panel Mounting Packing

GT21 General Description (This manual)

1

4

1

1

Advertisement

Summary of Contents for Mitsubishi Electric GT2104-PMBD

- Page 1 For more details please contact your local Mitsubishi Electric sales site. For the analog-resistive film type touch panels, normally the adjustment is not ...

-

Page 2: Wiring Of Connection Cable

Terminating resistor : OPEN/110 Ω/ Terminating resistor : OPEN/110 Ω/ Mitsubishi Electric. *1 The cable for GT2104-PMBD does not have the connection to a signal name 330 Ω 330 Ω (RSA, RSB, CSA, CSB). This product has been manufactured under strict quality control. However... - Page 3 RS-422/485 Terminating resistor : OPEN/110 Ω/ Terminating resistor : OPEN/110 Ω/ *1 The cable for GT2104-PMBD does not have the connection to a signal name Mitsubishi Electric. 330 Ω 330 Ω (RSA, RSB, CSA, CSB). ...

- Page 4 可从三菱电机FA网站 计和施工以及作图等项请分别参照GT Designer3 相关手册。 在使用本产品之前, 请务 象位置和触摸位置有可能错离。 对象位置和触摸领域如发生错离, 请调整触摸面 必熟读本手册以及各相关手册, 了解机器本身的功能和安全信息以及注意事项后使 (http://www.MitsubishiElectric.co.jp/fa)获取最新手册。 安装注意事项 板。 用。 2014 MITSUBISHI ELECTRIC CORPORATION Ethernet 是美国Xerox Corporation 的注册商标。 在本手册出现的各种商标分别对应 对象位置和触摸位置发生错离时, 有可能导致其他对象动作、 或由于误输出、 误 各公司的名称, 产品名称。 动作导致其他意料之外的动作。 请在符合本说明书中所规定的一般规格环境下使用GOT。 在不符合说明书中规定的 使用之前 请在使用GOT之前将GOT的连接器与电池 (另售GT11-50BAT) 的连接器连接。...

- Page 5 黑色 内置接口 38400/19200/9600/4800bps 38400/19200/9600/4800bps 白色 的营业窗口。 接口形状:5针接口端子排 接口形状:9针接口端子排 RS-422/485 - - 虽然本产品是在严格的质量管理体制下进行制造的,但是在计划将本产品 GT2104-PMBD用电缆没有向信号名 (RSA、 RSB、 CSA、 CSB) 的连接。 终 端电 阻 : OPEN/110Ω/330Ω 终端 电 阻 : OPEN/110Ω/330Ω 应用于由于本产品的故障有可能导致重大事故或者损失的设备上时,请在 连接某些PLC时需要自制电缆。 (使用终端电阻设置用开关切 (使用终端电阻设置用开关切 系统上设置备用及失效安全系统。 详情请参考GOT2000系列连接手册。 换) 换) 1ch 传 送 速 度 :115200/57600/ 剥线直径...

- Page 6 黑色 内置接口 38400/19200/9600/4800bps 38400/19200/9600/4800bps 白色 的营业窗口。 接口形状:5针接口端子排 接口形状:9针接口端子排 RS-422/485 - - 虽然本产品是在严格的质量管理体制下进行制造的,但是在计划将本产品 GT2104-PMBD用电缆没有向信号名 (RSA、 RSB、 CSA、 CSB) 的连接。 终 端电 阻 : OPEN/110Ω/330Ω 终端 电 阻 : OPEN/110Ω/330Ω 应用于由于本产品的故障有可能导致重大事故或者损失的设备上时,请在 连接某些PLC时需要自制电缆。 (使用终端电阻设置用开关切 (使用终端电阻设置用开关切 系统上设置备用及失效安全系统。 详情请参考GOT2000系列连接手册。 换) 换) 1ch 传 送 速 度 :115200/57600/ 剥线直径...