Advertisement

Quick Links

E-SS20/16A-I-0607

Operators Instruction Manual

SS-20 & SS-16A

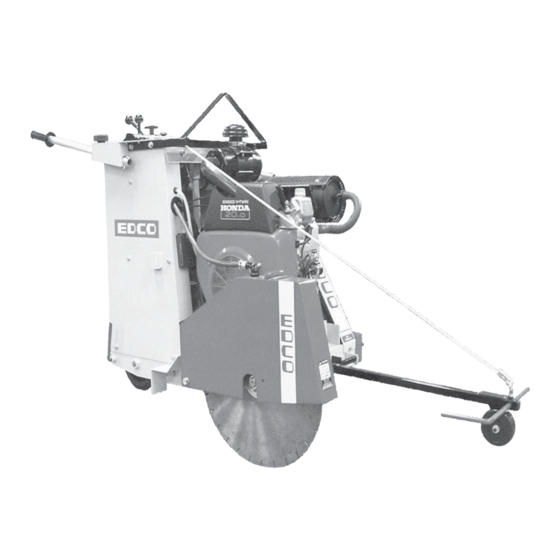

SS-20 Shown

Self Propelled

Concrete/Asphalt Saw

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Printed in USA

Fax (301) 663-1607 • 1-800-447-3326

©2007

Website: www.edcoinc.com

TVW

®

Page 1

A Division of Equipment Development Company, Inc.

Email: sales@edcoinc.com

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Edco SS-16A

- Page 1 E-SS20/16A-I-0607 Operators Instruction Manual SS-20 & SS-16A SS-20 Shown Self Propelled Concrete/Asphalt Saw 100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA Phone (301) 663-1600 • 1-800-638-3326 Printed in USA Fax (301) 663-1607 • 1-800-447-3326 ©2007 Website: www.edcoinc.com ® Page 1 A Division of Equipment Development Company, Inc.

- Page 2 E-SS20/16A-I-0607 READ AND UNDERSTAND THE OPERATORS INSTRUCTION MANUAL THOROUGHLY BEFORE ATTEMPTING TO OPERATE THIS EQUIPMENT. Death or serious injury could occur if this machine is used improperly. SAFETY SAFETY MESSAGES • Do not disconnect power by pulling cord. To disconnect, grasp MESSAGES the plug, not the cord.

-

Page 3: Table Of Contents

A (handles extended) HOW TO ORDER REPLACEMENT PARTS 201cm 201cm 45 1/2” 45” B (handles retracted) To insure product safety and reliability, always use genuine EDCO 116cm 114cm replacement parts when making repairs to the equipment. 24” 24” 61cm 61cm When ordering parts, please specify the MODEL and SERIAL 39”... -

Page 4: Safety Guidelines

E-SS20/16A-I-0607 Read and understand the Operator’s Manual, the Rx for Concrete Saws, and the Engine Manufacturer’s Owner’s Manual before operating this equipment. Death or serious injury can result if this machine is used improperly. Safety Guidelines Maintain a safe operating distance from fl ammable materials. Sparks from the cutting-action of this saw can ignite fl... -

Page 5: Operating Instructions

(Freewheel) SS-20. Push right to engage CLOCKWISE to lock cable in position once desired engine DRIVE. Push to left to release drive wheels, SS-16A only. speed is reached. 11 - Hour Meter: Gives readout of engine run-time. One sug-... -

Page 6: Maintenance

E-SS20/16A-I-0607 Before Starting the Engine: • Read Rx for Concrete Saws before operating. • Inspect machine before each use according to the Maintenance Schedule on page 15. • Locate and be familiar with all engine and saw controls (Figure 2). •... - Page 7 Note: If while cutting, the front wheels start to lift, reduce forward speed. For positioning the saw, the maximun forward speed is 200ft. per minute. For safety reasons when in reverse, the SS-20 and SS-16A is designed to move at a slow walking pace. Do not force it to go faster.

-

Page 8: Transporting The Saw

E-SS20/16A-I-0607 To Stop Cutting: • Move Speed Control lever to the NEUTRAL position. • Turn Depth Control Handwheel clockwise until blade is clear of slab. • Push Clutch Lever forward, away from operator to the FREE WHEEL position; this will stop all forward motion. (Figure 8) •... -

Page 9: Maintenance

E-SS20/16A-I-0607 The following maintenance instructions are brief explanations of some of the items suggested in the Maintenance Schedule chart on page 15. These instructions are not replacements for the Engine Manufacturer’s Maintenance Instructions. Maintenance Should the Engine Stop While Operating: •... -

Page 10: E-Ss20/16A-I

For safety reasons, EDCO does not recommend the use of any abrasive blades. Abrasive blades can break and cause serious personal injury to operator and/or bystanders. If abrasive blades are used by choice, only use those which are marked as reinforced abrasive blades. - Page 11 E-SS20/16A-I-0607 (Left side not shown) Important! Arbor Shaft Bearings MUST be lubricated EVERY FOUR HOURS! Drive Axle Bearings (2) Grease Bearings - (9 Total) Arbor Shaft Bearings (2) must be greased every 4 hours. All other Bearings (7) must be greased every 40 hours. Those include: Front Fork Bearings (2), Rear Wheel Bearings (2), Drive Axle Bearings (2), and the Depth Control Handle...

- Page 12 E-SS20/16A-I-0607 Check Engine Oil Before Each Operation - Check Engine Manufacturer’s Owner’s Manual for specifi c instructions. Change Oil & Filter Every 50 Hours of Operation (Sooner if Necessary). Check Drive Chains Before Operation - Lubricate Weekly Open gas tank door - Drive chain is just inside, on the right.

Need help?

Do you have a question about the SS-16A and is the answer not in the manual?

Questions and answers