Table of Contents

Advertisement

Service

Manual

E

Service Manual

Manual LFT 228-320 - 321

Service Manual

Manual LFT 228-320 - 321

ISSUE 1 - OTT. 2007

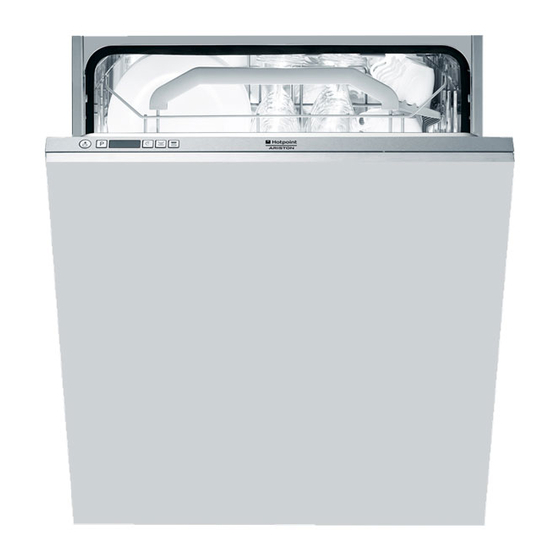

DISHWASHER

PLATFORM EOS.

BUILT IN

Model.

Covered

LFT 228 A/HA

LFT 320 HX/HA

LFT 321 HX/HA

LFT 228 AUK

LFT 321 HXUK

Edition

2007.10.15

Edition

2007.10.15

Comm.

Code

46454

46455

46456

49044

49045

Language

English

Language

English

Advertisement

Table of Contents

Summary of Contents for Indesit LFT 228 A/HA

- Page 1 ISSUE 1 - OTT. 2007 DISHWASHER PLATFORM EOS. BUILT IN Model. Comm. Covered Code LFT 228 A/HA 46454 LFT 320 HX/HA 46455 LFT 321 HX/HA 46456 LFT 228 AUK 49044 LFT 321 HXUK 49045 Service Manual Service Manual Edition Language Manual LFT 228-320 - 321 2007.10.15...

-

Page 2: Identification Product-Plate

INDEX Chapter 1 Description of Product Chapter 2 General Information Captions Dashboard General Technical Data Chapter 3 Installation of Product Chapter 4 Description of Product Programmes Technical Programme-Features Washing-Option Method of Use Innovative features Chapter 5 Components Chapter 6 Eletrical Layout Chapter 7 Help-mode Demo-mode... - Page 3 Top range Alu:Alumin. 0=10 Empty:Overflow BR:Brown 1=11 SCHOLTES: T E 12 2 08 D:Dishwashers Integrated Built-In Nr.Dishes (12) 1 Med.Range N.programs 2TOP Range INDESIT: D.Dishwasher I.Integrated F: 60m 0:55DB(a) n.programs A=Water-stop fullsize 1:53DB Interm.range 2:51DB(a) Empty: Overflow 3:49DB(a) Service Manual Edition...

-

Page 4: Function Selector Defintions

2.2 DASHBOARD Machines that have “Digit” interfacing are available with three different types of dashboards depending on the model. Herebelow are the dashboards available on the models “Full Integrated”: Function Selector Defintions 1. ON/OFF Light-indicator Switch 10. Shortime Option Mode 2. -

Page 5: General Technical Data

2.3: GENERAL TECHNICAL DATA TECHNICAL DATA Capacity 12 Standard Covers 12 Standard Covers Dimensions Width 59,5 cm 59,5 cm Height 82 cm 82 cm Depth 57 cm 57 cm Water Supply Connections Maximum pressure 10 bars 10 bars Minimum pressure 0,5 bars 0,5 bars Electric Connections... - Page 6 DISCHARGING PIPE CONNECTION Standhose Ensure that the flexible discharging-pipe has not been introduced too deep inside the standhose. Should the discharging-pipe be equipped with “support-flaps”, ensure that they too be completely introduced into the standhose. Above illustration: Recommended height of the standhose 500m (20”) This will prevent the hose from tipping-over during setting-up and use.

-

Page 7: Adjusting Posterior Legs

Eliminate any residuals on the discharge-syphon and ensure that the sealing-cap has been removed. The flexible hose must be directed and placed at a minimum height of 800mm (3 ½ “) Ensure that the diameter of the water-basin discharge-hose measure at least 32mm. Uncoil the extreme end of the flexible GREY hose from the back of the machine. -

Page 8: Chapter 4: Description Of The Product

CHAPTER 4: DESCRIPTION OF THE PRODUCT 4.1 PROGRAMMES Indications for Programmes Detergent Programmes that Compatile Prog.Time -+10% Programme- (A)=Dispenser A envisage drying options tollerance Hrs/mins selection (B)=Dispenser B mode Powder Liquid Tablet 30g (A) 30ml 1(A) A-B-C-D 2-15' Very dirty dishes +pots (not indicated for fragile ware 1.Self-Intensive 30g(A) -

Page 9: Washing-Options

4.2 TECHNICAL PROGRAMME DATA The underlying table indicates the washing-stages available on each programme, the temperature that can be achieved and in some cases the time required for a particular washing stage. BRUSHLESS-MOTOR DISHWASHERS LVS TYPE Cycle Pre-wash 1 Pre-wash 2 Wash Rinse 1 Rinse 2... -

Page 10: Accidental Interruptions

This mode allows to reduce the washing-cycle by approximately 30% (depending on the programme that has been selected) “ “Class A” washing-cycle is maintained; in order to do so it is just sufficient to increase the water-pressure through BLDC (Controlled Motor Management) which permits this process. “Shortime”... -

Page 11: Innovative Features

4.5 INNOVATIVE FEATURES Filling up with Water: Once a programme has been set, the first thing that the LVS will proceed to do is discharge the water. Following this, it will start to fill up with water in two stages: 1. -

Page 12: Sparkleing Rinse Agent Check Via Led

Sparkleing Rinse Agent check via LED The administering of Sparkling-rinse agents on Model EOS is done through a “Magnetic Read”sensor, mounted right inside the dispenser. It detects the presence or absence of the Sparkle-agent by means of a floating-ball. The User-Interface will read the message and will transmit it directly to the Main-board;... -

Page 13: Drying Cycle

THE “REGENERATING” PROCESS Fill up a certain quantity of water (about 90cc), which will activate the process and fill up electro-valve which will send the water onto the salt. Consequently the salt-water will be sent onto the resines, and the electro-valves will then close. Wait for about 10 minutes. -

Page 14: Chapter 5: Components

CHAPTER 5: COMPONENTS The Base: The base is in plastic and contains all the functional-parts of the dishwasher as well as acting as support for the wash-basin. Built-in dishwashers are provided with three legs that are for the purpose of levelling out the machine: two are on the fore-front and one at the back in the middle of the machine which is equipped with an adjustable-nut. -

Page 15: Turbine Litre-Count

Turbine Litre-count As on Model EVO3, it serves to check the quantity of water that enters the machine. The information in turn is assessed by the pressostat. Every 270 impulses emmitted by the turbine, are equivalent to a litre of water. This calibration has approximately a 2% tollerance margin. -

Page 16: Discharging Pipe

Discharging Pipe: The discharging-pump is sealed by compression to the water-collector and is fastened into place by means of two O-Rings. It is prevented from unhooking by means of a pipe fixed across a mechanical blocking device placed transversely on the bottom at the back of the dishwasher. -

Page 17: Further Components

Further Components: Other components are different in appearance but have the same functions as the ones on the previous model EVO3. This does not necessarily mean that they are interchangeable, as their techinical features are quite different eg. as in the Pressostat. Electric Volts Frequency... -

Page 18: Demo Mode

CHAPTER 6: ELECTRIC-CIRCUIT (ELC PLATFORM) MOTOR (BLDC) BRUSHLESS Table of captions: Supply network Washing Water-element Turbine Litre-Count Noise-proof Filter Thermo-protector (95°C) Alternate Wash-motor Door switch Discharge Pump Soiled water sensor Pressostat Wash motor-Pump Dispenser solenoid valve 1 Conventional Read salt Interfacing 2 Full filling up solenoid-valve... - Page 19 7.2.1 ACTIVATION OF SELF-TEST PROCEDURE “SAT” The machine must be off and the door must be opened: Switch on the dishwasher (Press On/Off button) Switch off the dishwasher(Press On/Off button) Keep button “P” pressed for 3 seconds till a “beep” is heard. Switch on the dishwasher (Press On/Off Button, the Led will flash slowly and on the Digit display the number “2”...

- Page 20 7.2.3. HOW FAULTS ARE DISPLAYED Dishwashers envisaged with a Digit Display, will show the fault in writing on the digit-display as for example Fault 05 will display number “5” which will flash and so with Fault “11” so forth and so on. 7.2.4.

-

Page 21: How Is The Main-Board Administered

7.3 PC, PALM, SMART READER Electronic dishwasher models EOS have been envisaged with a Main-board DEA 601; which has been evolved from the DEA 600 used on Seven Digit machines. Two types are available: one used on LVS with synchro-motors and another on machines with BLDC motors. In Built-In dishwashers, the Main Board is accessible by removing the hooks fastening the front-panel (under the machine) and opening it. -

Page 22: Chapter 8: Dismantling

CHAPTER 8: DISMANTLING Detergent Dispenser: Unfasten the 2 screws placed on the sides of the innerdoor and remove the Frontpanel. Unfasten the 2 screws placed infront of the door, behind the external finished panel. Disconnect the dispenser cables and unscre the 6 screws that fix it to the inner door-panel. Remove by lifting the dispenser from the inner door-panel. -

Page 23: Charging-And-Discharging Pipe

Charging-and-discharging Pipe: Unfasten the 4 screws (2 on the front and 2 at the back) fixing the right hand side-panel and remove it. Turn the machine upside-down. Remove the basket by unhooking the “teeth” blocking the lower support fixing the pipes and pulling it out towards the front part of the dishwasher. -

Page 24: Washing Electro-Pump

Washing Electro-pump Turn the machine upside-down. Unhook the basket Unhook the floating-ball Unfasten the tape using pliers Pull out the electro-pump by removing the rubber-support. Disconnect the ground heating-element. Disconnect the supply-element Diconnect the motor feed-back cable Disconnect the motor-supply. Pull out the electro-pump. - Page 25 Service Manual Edition Language Manual LFT 228-320 - 321 2007.10.15 English Service Manual Edition Language Manual LFT 228-320 - 321 2007.10.15 English...

Need help?

Do you have a question about the LFT 228 A/HA and is the answer not in the manual?

Questions and answers