Table of Contents

Advertisement

Quick Links

Inkjet printer is the precision machine that has highly delicate mechanism.

Especially, little dust and paper powder may have effect on a head nozzle

firing ink, and may not get normal printing.

To use the inkjet printer in good condition, we recommend the following

daily care.

For safe operation ............................................................................. 2

Installation environment and Notes on cleaning .............................................2

Notes on cleaning ...........................................................................................2

Maintenance for frame components ...............................................................2

In case defective printing is not resolved ....................................... 3

The examples of defective printing .................................................................3

When nozzle clogging or deflection has occurred ..........................................4

When other discharge problem has occurred .................................................6

Maintenance when needed ...........................................................................11

Cleaning of wiper ..........................................................................................12

How to recover improper nozzle firing ..........................................................14

When the waste ink tank becomes full ......................................... 15

Disposing of waste ink ..................................................................................15

Avoiding dripping of ink droplet at printing ................................. 16

Cleaning of the head guard plate ..................................................................16

What to do when this machine is not used .................................. 18

How To Store ................................................................................... 19

Storage Of Antifreezing Liquid And Washing Liquid .....................................19

Storage Of Media ..........................................................................................19

Storage Of Ink Cartridge ...............................................................................19

Daily Care Manual

Request for daily care

Table Of Contents

URL: http: // www.mimaki. co. jp /

D202015-14

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

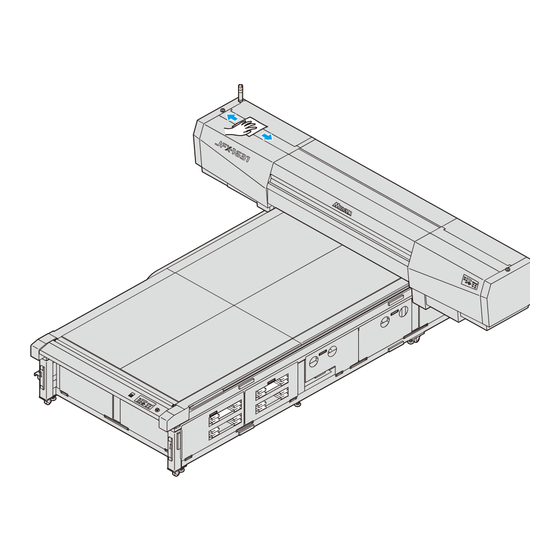

Summary of Contents for MIMAKI JFX series

-

Page 1: Table Of Contents

When this machine is not used for "eight days or more (for a long time)" ..18 How To Store ................... 19 Storage Of Antifreezing Liquid And Washing Liquid ........19 Storage Of Media ..................19 Storage Of Ink Cartridge ................19 MIMAKI ENGINEERING CO., LTD. URL: http: // www.mimaki. co. jp / D202015-14... -

Page 2: For Safe Operation

Be sure that not adhere water or alcohol to not only the nozzle and also near the head, the cap, wiper and so on. • JFX series is a printer that uses ultraviolet ray curing ink (UV ink).. When implementing the daily care, must wear supplied goggles and gloves. -

Page 3: In Case Defective Printing Is Not Resolved

In case defective printing is not resolved In the following cases, clean the suction nozzle using the cleaning kit. • The station interior is severely contaminated. • Defective printing is not resolved after executing the head cleaning function ( Operation Manual Chapter •... -

Page 4: When Nozzle Clogging Or Deflection Has Occurred

When nozzle clogging or deflection has occurred When nozzle clogging or deflection has occurred, perform test drawing ( Operation Manual Chapter 2) to check the nozzle condition. The result of test drawing and the maintenance The following examples are the result of test drawing when nozzle clogging or deflection has occurred. Test drawing condition Nozzle condition How to maintain... - Page 5 In case defective printing is not resolved Maintenance Flow Perform maintenance as the following flow. If the problem does not improve after performing the maintenance flow, repeat the same maintenance until it improves. Check the ink remaining in the ink cartridge. Perform test drawing to check the nozzle condition.

-

Page 6: When Other Discharge Problem Has Occurred

When other discharge problem has occurred When ink drops First, check the dirt of the head surface after cleaning. Start printing (Ensure that wiping is performed.) Perform “Cleaning of wiper” ( P.12) and ”Cleaning of the head guard plate” ( P.16). - Page 7 In case defective printing is not resolved When deflection often occurs The example for deflection First, check the dirt of the head surface after cleaning. Start printing (Ensure that wiping is performed.) Remove lifting and fuzz of the media to keep the head gap at the proper value "1.2 to 1.5 mm (recommended)".

- Page 8 When mist is generated The example for mist First, check the dirt of the head surface after cleaning. Start printing (Ensure that wiping is performed.) Remove lifting and fuzz of the media to keep the head gap at the proper value "1.2 to 1.5 mm (recommended)".

- Page 9 In case defective printing is not resolved When dots are missed during drawing The example for dot missing First, check the dirt of the head surface after cleaning. Start printing (Ensure that wiping is performed.) Remove lifting and fuzz of the media to keep the head gap at the proper value "1.2 to 1.5 mm (recommended)".

- Page 10 Notes for working environment Performing frequency of the print setting or maintenance is greatly influenced by the printing environment or the condition of the media used. Use this machine with a full understanding of the followings. Working environment Consideration • To keep the nozzle face clean, set to wipe periodically every time it prints about 1500 mm.

-

Page 11: Maintenance When Needed

In case defective printing is not resolved Maintenance when needed A proper maintenance schedule is determined by the operator who observes throughout a period of use of the printer. • Some media need maintenance every time of printing. • The maintenance schedule differs depending on the image to be printed. For example, when the image is almost filled, perform maintenance frequently. -

Page 12: Cleaning Of Wiper

Cleaning of wiper Turn ON the power. Open the right maintenance cover. • Remove the screws (2 pcs) and open the right maintenance cover. Select the “STATION” in the maintenance menu. (1) Press the key in the local mode. FUNCTION (2) Select the [MAINTENANCE] by pressing the key, and press the key. - Page 13 In case defective printing is not resolved Drip wiper M with several drops of cleaning liquid and clean it with non- woven cloth. • Avoid using the material that will leave dust or fiber after use such as paper towel. •...

-

Page 14: How To Recover Improper Nozzle Firing

In case defective printing is not resolved When the cleaning is completed, press the key. ENTER • The initial movement will be performed. Press the key several times to finish. How to recover improper nozzle firing When not using this plotter for a long time or according to environmental temperature,nozzle may be unsta- ble in firing.In the case of this, follow below procedures to recover nozzle. -

Page 15: When The Waste Ink Tank Becomes Full

When the waste ink tank becomes full The ink used for head cleaning or flushing is gathered in the waste ink tray. When the waste ink tray is full, an error is displayed. When an error appears, dispose of the waste ink into the waste ink tank as follows. -

Page 16: Avoiding Dripping Of Ink Droplet At Printing

Avoiding dripping of ink droplet at printing Cleaning of the head guard plate Ink droplets caused by drawing may appear on a head guard plate on a bottom face of the carriage. As they can cause stain on media by dripping of ink droplets or drawing trouble, conduct cleaning of the bottom face of the carriage periodically. - Page 17 Avoiding dripping of ink droplet at printing Press the key after completing the cleaning ENTER • Initial operation is executed. Press the key several times to turn the system to the local mode.

-

Page 18: What To Do When This Machine Is Not Used

What to do when this machine is not used Perform the followings when this machine is not used. When this machine is not used for "two days or less" • Set the [WAITING] level of REFRESH to "Level 3". Check before (Operation Manual Chapter 3 "Other useful settings") stopping the use •... -

Page 19: How To Store

How To Store Storage Of Antifreezing Liquid And Washing Liquid Be sure to store the Antifreezing liquid and the washing liquid in a cold and dark place. Store the Antifreezing liquid and the washing liquid in a place that is out of the reach of children. Storage Of Media Media should be stored in the little dust area, and not in direct sunlight. -

Page 20: Mimaki Engineering Co., Ltd

D202015-14-20102010 Printed in Japan FW : 2.20 © MIMAKI ENGINEERING Co., Ltd. 2010...

Need help?

Do you have a question about the JFX series and is the answer not in the manual?

Questions and answers