Shark BR-442537 Operating Instructions And Parts Manual

Hide thumbs

Also See for BR-442537:

- Operating instructions and parts manual (36 pages) ,

- Operating instructions and parts manual (36 pages) ,

- Operating instructions and parts manual (34 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Shark BR-442537

- Page 1 MODEL: BR OPERATING INSTRUCTION AND PARTS MANUAL ■ BR-442537 ■ BR-353237 ■ BR-373537 ■ BR-404027 ■ BR-455037E ■ BR-343087E For technical assistance or the SHARK dealer nearest you, call 1-800-771-1881 or visit our website at www.shark-pw.com 97-723...

-

Page 3: Table Of Contents

CONTENTS Important Safety Information ..............4-5 Component Identifi cation Small ............... 6 Component Identifi cation Large............... 7 Assembly Instructions................8 Operating Instructions ................9-10 Applying Detergent and General Operating Techniques......11 Shut Down and Clean-Up ..............12 Storage ....................12 Troubleshooting ................13-14 Preventative Maintenance .............. -

Page 4: Important Safety Information

INTRODUCTION & IMPORTANT SAFETY INFORMATION Thank you for purchasing a this pressure washer. CAUTION: Risk of as phyx i a tion CAUTION — Use this product only in a well All in for ma tion in this man u al is based on the lat est ven ti lat ed area. -

Page 5: Important Safety Information

INTRODUCTION & IMPORTANT SAFETY INFORMATION WARNING: High pressure spray 12. When applying detergents, fol low the safety rules WARNING on the de ter gent label. can cause paint chips or other par ti cles to become air borne and 13. Use detergent from a covered D.O.T. approved fl... -

Page 6: Component Identifi Cation Small

COMPONENT IDENTIFICATION — SMALL MODELS Nozzle Wand Spray Gun Starter Grip Pump High Pressure Discharge Water Inlet High Pressure Hose Pump — Develops high pressure. Wand — Must be connected to the spray gun. Starter Grip— Used for starting the engine man u al ly. High Pressure Hose —... -

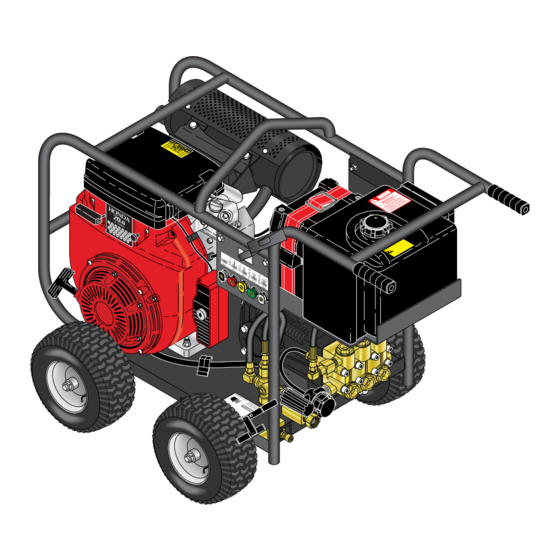

Page 7: Component Identifi Cation Large

COMPONENT IDENTIFICATION — LARGE MODELS Nozzle Wand Spray Gun Starter Grip Pump Water Inlet High Pressure Discharge High Pressure Hose 96-718, 97-721, 97-723 • REV. 8/05a... -

Page 8: Assembly Instructions

ASSEMBLY INSTRUCTIONS Pressure Pressure Nozzle Spray Nozzle Wand Wand Coupler Safety Coupler Latch High Pressure Wand Hose Collar STEP 1: Attach the high pres sure STEP 2: Pull the spring-load ed col- STEP 3: Release the coupler col lar hose to the spray gun using tefl on lar of the wand coupler back to in sert and push the nozzle until the collar tape on hose threads. -

Page 9: Operating Instructions

OPERATING INSTRUCTIONS Engine Dipstick Tank STEP 1: Check engine oil level. Oil level should be level with the bottom STEP 2: Fill gas tank with un- of the oil fi ller neck. Be sure the ma chine is level when checking the oil lead ed gasoline. -

Page 10: Operating Instructions

OPERATING INSTRUCTIONS (CON'T) On-Off Switch STEP 7: Turn the engine switch to "ON" position. STEP 8: Pull the starter grip. If the engine fails to start after 2 pulls, squeeze the trigger gun to release pres sure and repeat step. Return start er gently. After the en gine warms up enough to run smoothly, move choke to run position and throt tle to fast position. -

Page 11: Applying Detergent And General Operating Techniques

THERMAL PUMP APPLYING DETERGENT PROTECTION AND GENERAL CLEANING TECHNIQUES If you run the engine on your pres sure wash er for 3-5 min utes with out pressing the trig ger on the spray gun, WARNING: Some de ter gents cir cu lat ing water in the pump can reach high tem per a- WARNING may be harm ful if in haled or tures. -

Page 12: Shut Down And Clean-Up

SHUTTING DOWN AND CLEAN-UP On-Off Switch STEP 1: Remove detergent suc tion STEP 2: Turn engine switch to "OFF" STEP 3: Turn off water tube from container and insert into position. sup ply. one gallon of fresh water. Slide noz zle for ward for low pressure or to con nect black detergent nozzle. -

Page 13: Troubleshooting

TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION LOW OPERATING Insuffi cient water supply. Closed Use larger garden hose; clean inlet water PRESSURE faucet. Inlet hose kinked screen. Open faucet. Clogged inlet hose strainer Check plumbing system for leaks. Retape leaks with tefl on tape. Faulty or misadjusted unloader Adjust unloader for proper pressure. - Page 14 TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION ENGINE OPERATES Not enough gas or engine oil Fill tank with gas. Check oil level. FOR 15 MIN. THEN Vapor lock developed by heat of Keep gas tank full to avoid vapor locking. STOPS Obstruction in fuel fi lter Clean or replace fuel fi...

-

Page 15: Preventative Maintenance

PREVENTATIVE MAINTENANCE This pressure washer was produced with the best avail able ma te ri als and quality craftsmanship. However, you as the own er have certain re spon si bil i ties for the correct care of the equip ment. At ten tion to reg u lar pre ven ta tive main te nance pro ce dures will as sist in preserving the per for mance of your equipment. -

Page 16: Exploded View - Large

EXPLODED VIEW - LARGE 38 35 All Models Except 4040 8, 9 Models 404027, 343087E,343089E, 404029 404027, 404029 Models 59, 60, 61 96-718, 97-721, 97-723 • REV. 8/05a... -

Page 17: Exploded View Parts List

EXPLODED VIEW PARTS LIST- LARGE ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 10-02011 Label, This Tank For Gas Only 2-10942 Swivel, 1/2"MP x 3/4" GHF (455037E, 455039E, 455034E) 1 w/Strainer 10-020090 Label, Diesel (343087E, 2-1105 Swivel, 1/2" JIC Fem, Push-On 2 343089E) 2-1923 Strainer, 1/2"... - Page 18 EXPLODED VIEW PARTS LIST- LARGE ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 4-12804000 Nozzle, SAQCMEG 0004, Red 90-102746 Bolt, 1/2" x 5" NC HH Tap (404027, (343087E,343089E,404029, 404029, 405039E, 455039E, 404027,455039E,455034E, 455034E, 455037E) 455037E) 90-102751 Bolt, 1/2" x 3-1/2", NC, HH 4-12804015 Nozzle, SAQCMEG 1504, Yellow (343087E, 343089E) (343087E,343089E,404029,...

-

Page 19: Exploded View Parts List

EXPLODED VIEW PARTS LIST- LARGE ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 90-100543 Screw, 5/16"-18 x 3/4" M PH 2-0053 Elbow, 1/2" JIC, 3/8", 90° 77-VHRM4 Muffl er, Honda, GX620/670 Right 2-1046 Plug, 1/4" Countersunk (405039E, (405039E, 455037E, 455039E, 455034E,455037E, 455039E) 455034E) ▲... -

Page 20: Exploded View - Small

EXPLODED VIEW - SMALL Model 442539 96-718, 97-721, 97-723 • REV. 8/05a... -

Page 21: Exploded View Parts List

EXPLODED VIEW PARTS LIST- SMALL ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 10-02025A Label, "Hot/Caliente" w/Arrows 4-12805500 Nozzle, SAQCMEG 0005.5, Red Warning (442534,442537) 4-12805515 Nozzle, SAQCMEG 1505.5, Yellow 10-02029 Label, Danger Cool Engine (442534,442537) 10-08017 Label, Intended For Outdoor Use1 4-12805525 Nozzle, SAQCMEG 2505.5, Green 10-9999 Label, Clear Lexan,... - Page 22 EXPLODED VIEW PARTS LIST- SMALL ITEM PART NO. DESCRIPTION 2-1102 Adapter, 1/2" Female x 3/8" Male (343089E,442534) 2-1100 Adapter, 1/2 x 1/2 (353234, 373534, 353237, 442537, 373539) 9.800-049.0 Label, Manufacturer's Cleaning Solution 96-718, 97-721, 97-723 • REV. 8/05a...

-

Page 23: Hose And Spray Gun Assembly

HOSE & SPRAY GUN ASSEMBLY 1, 2 1, 2 HOSE & SPRAY GUN ASSEMBLY PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 4-0110331 Wand, Side Grip w/Couplers 47.5" 4-020750C Hose, 3/8" x 50 ft., 2 Wire, Pressure (373539, 404029, 343089E) Flex, w/Coupler (353237, 373537, 373539, 404029, 353234, 4-012192... -

Page 24: Specifi Cations

SPECIFICATIONS Machine Engine Pulley Engine Bushing Pump Pump Pump Bushing Model Pulley Desc. Bushing# Desc. Pulley Desc. Bushing# Desc. 373539 5-40503201 2BK32H 5-511100 Hx1" 5-40509001 2BK90H 5-512024 24mm 404029 5-40503601 2BK36H 5-511100 Hx1" 5-40509001 2BK90H 5-512025 25mm 405039E 5-407034 3TB34 5-531112 P2x1"... - Page 25 SPECIFICATIONS Machine Belt Belt Pump Unloader Engine Model (QTY) Desc. Part No. Part No. Part No. 373539 5-604039 (2) BX39 5-1220 5-32080 5-010721 404029 5-604042 (2) BX42 5-1808 5-32080 5-0306 405039E 5-604042 (3) BX42 5-1238 5-3014 5-01093 455039E 5-604042 (3) BX42 5-1238 5-3014...

- Page 27 FOR A PARTICULAR PURPOSE. SHARK does not authorize any other party, including authorized Dealers, to make any representation or promise on behalf of SHARK, or to modify the terms, conditions, or limitations in any way. It is the buyer’s responsibility to ensure that the installation and use of SHARK products conforms to local codes. While SHARK attempts to assure that its products meet national codes, it cannot be responsible for how the customer chooses to use or install the product.

- Page 28 Form #97-723 • Revised 8/05a • Printed in U.S.A.

Need help?

Do you have a question about the BR-442537 and is the answer not in the manual?

Questions and answers