Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for MTU 12V2000M91

-

Page 1: Operating Instructions

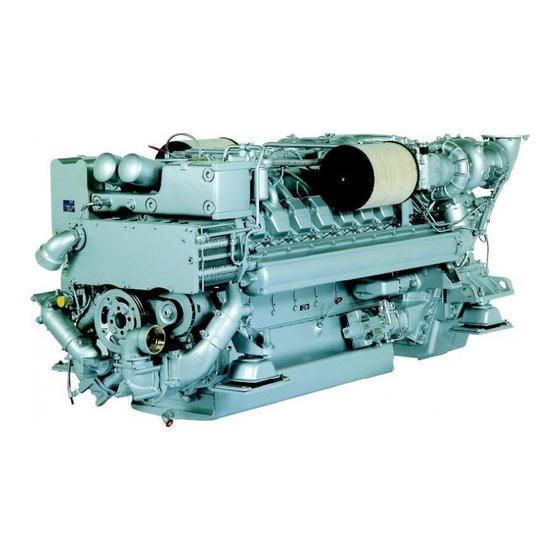

Operating Instructions Diesel Engine 12V2000M91 16V2000M91 MW15409/04E... - Page 2 All information in this publication was the latest information available at the time of going to print. MTU Friedrichshafen GmbH reserves the right to change, delete or supplement the information provided as and when required.

-

Page 3: Table Of Contents

Table of Contents 1 Safety 5.13 Emergency engine shutdown at LOP (without BlueLine automation system) 1.1 Important provisions for all products 5.14 After stopping the engine 1.2 Personnel and organizational requirements 5.15 Plant – Cleaning 1.3 Safety regulations for startup and operation 1.4 Safety precautions when working on the 6 Maintenance engine... - Page 4 9 Appendix A 8.17.6 HT coolant pump ‒ Relief bore check 9.1 Abbreviations 8.17.7 Engine coolant – Sample extraction and 9.2 MTU contact persons/service partners analysis 8.18 Raw Water Pump with Connections 10 Appendix B 8.18.1 Raw water pump – Priming 8.18.2 Raw water pump –...

-

Page 5: Safety

Nameplate, model designation or serial number can be found on the product. All EU-certified engines delivered by MTU come with a second nameplate. When operating the machine in the EU: The second nameplate must be affixed in a prominent position as described in the accompanying specifi- cations. - Page 6 The maintenance schedules of the manufacturer must be observed over the entire life cycle of the product. Replacing components with emission labels Emission labels are attached to all MTU engines. These must remain on the engine throughout its operational life.

-

Page 7: Personnel And Organizational Requirements

1.2 Personnel and organizational requirements Organizational measures of the user/manufacturer This manual must be issued to all personnel involved in operation, maintenance, repair, or transportation. Keep this manual handy in the vicinity of the product such that it is accessible to operating, maintenance, repair, and transport personnel at all times. -

Page 8: Safety Regulations For Startup And Operation

1.3 Safety regulations for startup and operation Safety regulations for startup Install the product correctly and carry out acceptance in accordance with the manufacturer's specifications before putting the product into service. All necessary approvals must be granted by the relevant authorities and all requirements for initial startup must be fulfilled. -

Page 9: Safety Precautions When Working On The Engine

1.4 Safety precautions when working on the engine Safety regulations prior to maintenance and repair work Have maintenance or repair work carried out by qualified and authorized personnel only. Allow the product to cool down to less than 50 °C (risk of explosion for oil vapors, fluids and lubricants, risk of burning). - Page 10 Never bend lines and avoid damaging lines, particularly the fuel lines. Ensure that all retainers and dampers are installed correctly. Ensure that O-rings are not installed in a slanted/twisted condition. Ensure that all fuel injection and pressurized oil lines are installed with enough clearance to prevent contact with other components.

- Page 11 During hydraulic installation/removal of components, ensure that no persons are in the direct vicinity of the component being pressed. Working with batteries Observe the safety instructions of the battery manufacturer when working with batteries. Gases released from the battery are explosive. Avoid sparks and naked flames. Do not allow battery acids to come into contact with skin or clothing.

-

Page 12: Fire Prevention And Environmental Protection, Fluids And Lubricants, Auxiliary Materials

The safety data sheet may be obtained from the relevant manufacturer or from MTU. Take special care when using hot, chilled or caustic materials. -

Page 13: Compressed Air

Lead • Adopt suitable measures to avoid the formation of lead dust. • Switch on extraction system. • When working with lead or pastes containing lead, avoid direct contact to the skin and do not inhale lead vapors. • Wash relevant areas after contact with lead or lead-containing substances. Compressed air Observe special safety precautions when working with compressed air: •... -

Page 14: Standards For Safety Notices In The Text

1.6 Standards for safety notices in the text DANGER In the event of immediate danger. Consequences: Death, serious or permanent injury! • Remedial action. WARNING In the event of a situation involving potential danger. Consequences: Death, serious or permanent injury! •... -

Page 15: Transport

Set the system down on a firm, flat surface only. Make sure that the consistency and load-bearing capacity of the ground or support surface is adequate. Never set the engine down on its oil pan unless expressly authorized to do so by MTU. MW15409/04E 2015-08 | Transport | 15... -

Page 16: Lifting Requirements

2.2 Lifting requirements Lifting requirements DANGER Suspended load. Danger to life! • Use appropriate lifting devices and appliances. • Never stand beneath a suspended load. Transportation without flange-mounted gearbox – 8V 1 Max. admissible diagonal 2 Center of gravity pull 10° 16 | Transport | MW15409/04E 2015-08... - Page 17 Transportation without flange-mounted gearbox – 12V/16V 1 Max. admissible diagonal 2 Center of gravity pull 10° MW15409/04E 2015-08 | Transport | 17...

- Page 18 Transportation with flange-mounted gearbox – 8V 1 Max. admissible diagonal 2 Center of gravity pull 10° 18 | Transport | MW15409/04E 2015-08...

- Page 19 Transportation with flange-mounted gearbox – 12V/16V 1 Max. admissible diagonal 2 Center of gravity pull 10° Note engine center of gravity Refer to the installation/arrangement drawings for details of engine center of gravity. MW15409/04E 2015-08 | Transport | 19...

-

Page 20: General Information

3 General Information 3.1 Engine side and cylinder designations 1 Left engine side (A-side) 3 Right engine side (B-side) 2 Engine free end in accord- 4 Engine driving end in ac- ance with DIN ISO 1204 cordance with (KGS = Kupplungsgegen- DIN ISO 1204 (KS = Kup- seite) plungsseite) -

Page 21: Product Description

• Data processing logistics for analog and binary signals; • Interface for data transfer to CAN field bus for remote control and ship-side monitoring; • RS 232 interface for connection of MTU dialog unit. MW15409/04E 2015-08 | General Information | 21... - Page 22 • Interface to CAN field bus for connected, communicating monitoring system components. SOLAS – Fire protection specifications All fuel lines with fuel pressure >1.8 bar are fitted with SOLAS-compliant covers as per MTU standard MTN5233. All oil lines with oil pressure >1.8 bar are fitted with SOLAS-compliant covers as per MTU standard MTN5233.

- Page 23 MW15409/04E 2015-08 | General Information | 23...

- Page 24 Lube oil system covers 24 | General Information | MW15409/04E 2015-08...

- Page 25 MW15409/04E 2015-08 | General Information | 25...

- Page 26 Special unions The following types of union are spray-proof in case of leakage even without covers and have been confirmed as being SOLAS-compliant by GL and DNV. Plug-in pipe union Design precludes lateral spray as the point of separation is shielded by the sleeve (4). Only seepage along the pipeline is possible whereby the pressure is greatly reduced by a faulty O-ring (3).

- Page 27 High-pressure unions 1 Jacket pipe 8 Thrust ring 15 Union nut 2 HP line 9 Union nut 16 Thrust ring 3 O-ring 10 Union nut 17 External pipe of HP line 4 Union nut 11 Connecting piece 18 Internal pipe of HP line 5 Recess for O-ring 12 Snap ring 19 Ball-type seal area...

- Page 28 Shielding of fuel filters and lube-oil filters Shielding with plastic ring The plastic ring (1) precludes lateral spray. The fluid is diverted to the catch basin whereby the pressure is greatly reduced. Shielding by overlapping design The overlap (1) precludes lateral spray. The fluid is diverted to the catch basin whereby the pressure is greatly reduced.

-

Page 29: Engine Layout - 2000 M91 Engines

3.3 Engine layout – 2000 M91 engines Engine layout - functional grouping 010 Crankcase and externally 080 Fuel system (low pressure) 180 Lube oil system mounted components 100 Exhaust turbocharger 200 Cooling system 020 Gear train 110 Intercooler 230 Mounting / support 030 Running gear 120 Air intake / air supply 250 PTO systems, driving end... -

Page 30: Technical Data

4 Technical Data 4.1 12/16V 2000 M91 engine data Explanation: DL Ref. value: Continuous power (CP) BL Ref. value: Fuel stop power (FSP) A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated, without change (e.g. of power setting) N Not yet defined value - Not applicable X Applicable... - Page 31 RAW WATER CIRCUIT (open circuit) Number of cylinders Raw water pump inlet pressure, min. -0.4 -0.3 Raw water pump inlet pressure, max. +0.5 +0.5 Pressure loss in external raw water system, max. LUBE OIL SYSTEM Number of cylinders Lube oil temperature before engine, from °C Lube oil temperature before engine, to °C...

- Page 32 Number of cylinders Transverse inclination, continuous max. (Option: max. operating degrees 22.5 22.5 inclinations) Transverse inclination, temporary max. (Option: max. operating in- degrees clinations) CAPACITIES Number of cylinders Engine coolant capacity (with cooling equipment) liter Engine oil capacity, initial filling (standard oil system) (Option: liter max.

-

Page 33: Firing Order

4.2 Firing order Firing order Number of cylin- ders A1-B4-A4-A2-B3-A3-B2-B1 12 V A1-B2-A5-B4-A3-B1-A6-B5-A2-B3-A4-B6 16 V A1-B5-A3-A5-B2-B8-A2-A8-B3-A7-B4-B6-A4-A6-B1-B7 MW15409/04E 2015-08 | Technical Data | 33... -

Page 34: Main Engine Dimensions

4.3 Main engine dimensions Main engine dimensions Overall height (C) Engine model Overall length (A) Overall width (B) 12V 2000 M91 approx. 2470 mm approx. 1400 mm approx. 1460 mm 16V 2000 M91 approx. 2815 mm approx. 1400 mm approx. 1520 mm 34 | Technical Data | MW15409/04E 2015-08... -

Page 35: Operation

5 Operation 5.1 LOP controls (without Blue Line automation system) LOP – Controls Meaning / Function Item Color Inscription White Function keys to control the man-machine interface. Functions vary and are displayed on the LCD screen. White White White White White ALARM ACKNOWL Pressing the button the first time stops alarm signaliza-... - Page 36 Meaning / Function Item Color Inscription White LAMP TEST Pressing the button initiates lamp test. TEST OVERSPEED Pressing the button initiates overspeed test. LED (spot) lights up as long as the overspeed test is run- ning. Green (depending on type of FPP: Pressing the button engages gear ahead.

-

Page 37: Putting The Engine Into Operation After Extended Out-Of-Service Periods (>3 Months)

5.2 Putting the engine into operation after extended out-of-service periods (>3 months) Preconditions ☑ Engine is stopped and starting disabled. ☑ MTU Preservation and Represervation Specifications (A001070/..) are available. Putting the engine into operation (out-of-service period > 3 months) Item Measure Engine Depreserve (→... -

Page 38: Putting The Engine Into Operation After Scheduled Out-Of-Service Period

5.3 Putting the engine into operation after scheduled out-of- service period Preconditions ☑ Engine is stopped and starting disabled. Putting into operation Item Action Lube oil system Check engine oil level (→ Page 116). Coolant circuit Check coolant level (→ Page 129). Coolant circuit Preheat coolant with preheating unit. -

Page 39: Engine Start At Lop (Without Blueline Automation System)

5.4 Engine start at LOP (without BlueLine automation system) Preconditions ☑ Gearbox is in neutral position. ☑ External start interlock is not activated. ☑ Emergency air-shutoff flaps (if applicable) are open. DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! •... -

Page 40: Starting The Engine At The Blueline Automation System (Control Stand)

5.5 Starting the engine at the BlueLine automation system (control stand) DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Before cranking the engine with starter system, make sure that there are no persons in the engine's danger zone. -

Page 41: Engine Emergency Stop At Blueline Automation System (Control Stand)

5.6 Engine emergency stop at BlueLine automation system (control stand) NOTICE An emergency stop causes extreme stress to the engine plant. Risk of overheating, damage to components! • Initiate emergency stop only in emergency situations. Engine emergency stop at BlueLine automation system Item Measure Engine... -

Page 42: Operational Checks

5.7 Operational checks DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine's danger zone. WARNING High level of engine noise when the engine is running. Risk of damage to hearing! •... -

Page 43: Coupling - Engaging From Lop

5.8 Coupling – Engaging from LOP Preconditions ☑ LOCAL OPERATION illuminated pushbutton lights up brightly (local operating mode is active). ☑ Engine speed in engagement window. ☑ No external engagement interlock active. DANGER Vessel is sailing blind. In Local Operation mode, the propulsion plant is controlled from the engine room. Risk of accidents! •... -

Page 44: Coupling - Disengaging From Lop

5.9 Coupling – Disengaging from LOP Preconditions ☑ LOCAL OPERATION illuminated pushbutton lights up brightly (local operating mode is active). ☑ Engine speed in disengagement window. Disengaging coupling without reversing gearbox (CPP, WJ, VS) Item Measure Press COUPLING OUT illuminated pushbutton (→ Page 35). •... -

Page 45: Waterjet - Flushing From Lop (Optional)

5.10 Waterjet – Flushing from LOP (optional) Preconditions ☑ LOCAL OPERATION illuminated pushbutton is lit brightly (local operating mode is active). ☑ Vessel is at a standstill and waterjet bucket is below the waterline. ☑ Engine speed is in engagement window. ☑... -

Page 46: Engine Shutdown At Lop

5.11 Engine shutdown at LOP (without BlueLine automation system) Preconditions ☑ Engine is running in Local mode NOTICE Stopping the engine when it is running at full load causes extreme stress to the engine. Risk of overheating, damage to components! •... -

Page 47: Stopping The Engine At The Blueline Automation System (Control Stand)

5.12 Stopping the engine at the BlueLine automation system (control stand) NOTICE Stopping the engine when it is running at full load causes extreme stress to the engine. Risk of overheating, damage to components! • Before shutting down, disengage gear and run the engine at idle speed for at least 10 minutes until engine temperatures have dropped and constant values are displayed. -

Page 48: Emergency Engine Shutdown At Lop (Without Blueline Automation System)

5.13 Emergency engine shutdown at LOP (without BlueLine automation system) NOTICE An emergency stop causes extreme stress to the engine plant. Risk of overheating, damage to components! • Initiate emergency stop only in emergency situations. Emergency engine shutdown from LOP Item Action Open cap of illuminated pushbutton EMERGENCY STOP (→... -

Page 49: After Stopping The Engine

Switch off. Air intake and exhaust sys- Out-of-service-period > 1 week • Seal engine's air and exhaust sides. Engine Out-of-service-period > 1 month • Carry out engine preservation (→ MTU Preservation and Represervation Specifications A001070/..) MW15409/04E 2015-08 | Operation | 49... -

Page 50: Plant - Cleaning

5.15 Plant – Cleaning Preconditions ☑ Engine is stopped and starting disabled. ☑ No operating voltage is applied. Special tools, Material, Spare parts Designation / Use Part No. Qty. High-pressure cleaning unit Cleaner (Hakupur 50/136) X00056700 WARNING Compressed air gun ejects a jet of pressurized air. Risk of injury to eyes and damage to hearing, risk of rupturing internal organs! •... -

Page 51: Maintenance

6 Maintenance 6.1 Maintenance task reference table [QL1] The maintenance tasks and intervals for this product are defined in the Maintenance Schedule. The Mainte- nance Schedule is a stand-alone publication. The task numbers in this table provide reference to the maintenance tasks specified in the Maintenance Schedule. -

Page 52: Troubleshooting

7 Troubleshooting 7.1 Troubleshooting Engine does not turn when starter is actuated Cause Corrective action Battery flat or defective. u Charge or replace battery (see manufacturer's documentation). Cable connections on battery are u Check if cable connections are properly secured (see defective. - Page 53 Engine control unit ECU is defective. Charge-air temperature too high Cause Corrective action Incorrect engine coolant u Check (MTU test kit). concentration. Charge-air cooler is contaminated. u Contact Service. u Check fan Air inlet temperature in engine room is too high.

- Page 54 Coolant leaks at intercooler Cause Corrective action u Contact Service. Major coolant discharge at charge-air cooler. Charge-air cooler leaky. Black exhaust gas Cause Corrective action Air filter clogged. u Check signal ring position of contamination indicator (→ Page 112). Injector faulty. u Replace (→...

-

Page 55: Lop Fault Messages

7.2 LOP fault messages AL RCS Speed Demand Defect Cause Corrective action No speed demand signal. 1. Check remote control system. 2. Check LOP visually (→ Page 151). 3. Perform LOP test procedures (→ Page 153). 4. Check ECU plug-in connections (→ Page 147). 5. - Page 56 AL Gear Control Fail GCU Cause Corrective action u Contact Service. GCU fault. • Have GCU solenoid checked and replaced, if required. • Have GCU wiring checked and replaced, if required . AL Gear Oil Filter Clogged Cause Corrective action Gear oil filter clogged.

- Page 57 DL 211+A001-A001 Cause Corrective action DIS not detected on default CAN 1. Check LOP visually (→ Page 151). bus. 2. Perform LOP test procedures (→ Page 153). 3. Check ECU plug-in connections (→ Page 147). 4. Check engine wiring (→ Page 143). 5.

- Page 58 DL 211+A003-ECU Cause Corrective action ECU 4 not detected on default 1. Check LOP visually (→ Page 151). CAN bus. 2. Perform LOP test procedures (→ Page 153). 3. Check ECU plug-in connections (→ Page 147). 4. Check engine wiring (→ Page 143). 5.

- Page 59 MG Eng Speed High/Low (Clutch) Cause Corrective action u Speed reduction RCS message. MG Engagement Fault Cause Corrective action u Contact Service. RCS message. • Have GCU solenoid checked and replaced, if required. • Have GCU wiring checked and replaced, if required . MG Check Start Interlocks Cause Corrective action...

- Page 60 RL 211+A002-A040 Cause Corrective action GMU 1 (PIM No. 21.X+A002- 1. Check LOP visually (→ Page 151). A040) not detected on redundant 2. Perform LOP test procedures (→ Page 153). CAN bus. 3. Contact Service. • Have GCU/GMU checked and replaced if required. RL 211+A003-ECU Cause Corrective action...

- Page 61 SS Emergency Stop Cause Corrective action Safety system has initiated an 1. Determine cause for shutoff and rectify. emergency stop 2. Observe further display messages/alarms. SS Emergency Stop External Cause Corrective action Safety system has carried out an 1. Determine cause for shutoff and rectify. externally triggered emergency 2.

- Page 62 SS P-Lube Oil (EMU) Cause Corrective action Safety system detects that 1. Check lube-oil level and top up if required (→ Page 116). engine-oil pressure is too low. 2. Contact Service. SS Security Channel Def EMU Cause Corrective action Safety system fault message. u Contact Service.

- Page 63 TD P-Lube Oil Cause Corrective action The two lube-oil pressure sensors 1. Check LOP visually (→ Page 151). provide different values. 2. Perform LOP test procedures (→ Page 153). 3. Check ECU plug-in connections (→ Page 147). 4. Check engine wiring (→ Page 143). 5.

-

Page 64: Task Description

8 Task Description 8.1 Engine 8.1.1 Engine – Barring manually Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Ratchet F30006212 Socket F30005655 DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! •... -

Page 65: Engine - Barring With Starting System

8.1.2 Engine – Barring with starting system Special tools, Material, Spare parts Designation / Use Part No. Qty. Connector pliers 0135315483 DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! •... -

Page 66: Cylinder Liner

8.2 Cylinder Liner 8.2.1 Cylinder liner – Endoscopic examination Preconditions ☑ Engine is stopped and starting disabled Special tools, Material, Spare parts Designation / Use Part No. Qty. Rigid endoscope Y20097353 Preparatory steps Remove cylinder head cover (→ Page 76). Remove injector (→... - Page 67 Final steps Install injector (→ Page 82). Install cylinder head cover (→ Page 76). MW15409/04E 2015-08 | Task Description | 67...

-

Page 68: Instructions And Comments On Endoscopic And Visual Examination Of Cylinder Liners

8.2.2 Instructions and comments on endoscopic and visual examination of cylinder liners Terms used for endoscopic examination Use the terms listed below to describe the condition of the cylinder-liner surface in the endoscopic examina- tion report. Findings Explanations/Action Minor dirt scores Minor dirt scores can occur during the assembly of a new engine (honing products, particles, broken-off burrs). - Page 69 Evaluation of findings and further measures The findings in the start phase of oxidation discoloration and heat discoloration are similar. A thorough inves- tigation and compliance with the above evaluation criteria allow an unambiguous evaluation. To avoid unnec- essary disassembly work, it is recommended that another inspection be carried out after further operation of the engine.

-

Page 70: Crankcase Breather

8.3 Crankcase Breather 8.3.1 Crankcase breather – Cleaning oil pre-separator element Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Fuel Gasket (→ Spare Parts Catalog) WARNING Fuels are combustible and explosive. Risk of fire and explosion! •... -

Page 71: Crankcase Breather - Oil Separator Replacement, Diaphragm Check And Replacement

8.3.2 Crankcase breather – Oil separator replacement, diaphragm check and replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 6–50 Nm F30027336 Ratchet adapter F30027340 Filter element (→... - Page 72 Checking diaphragm Remove cover (4). Remove spring (5), seal (2) and dia- phragm (3). Check diaphragm (3) for damage, fit new dia- phragm if used one is damaged. Install diaphragm (3) on housing (1). Install new seal (2) and spring (5) together with cover (4).

-

Page 73: Valve Drive

8.4 Valve Drive 8.4.1 Valve clearance – Check and adjustment Preconditions ☑ Engine is stopped and starting disabled. ☑ Engine coolant temperature is max. 40 °C. ☑ Valves are closed. Special tools, Material, Spare parts Designation / Use Part No. Qty. -

Page 74: Adjusting Valve Clearance

Checking valve clearance at two crankshaft positions Check TDC position of piston in cylinder A1: • If the rocker arms are not under load on cylinder A1, the piston is in firing TDC. • If the rocker arms are under load on cylin- der A1, the piston is in overlap TDC. - Page 75 Insert feeler gauge between valve bridge and rocker arm to verify that the gauge just passes through the gap. Result: If not, adjust valve clearance. Final steps Remove barring device. For installation of removed parts, follow reverse sequence of working steps. MW15409/04E 2015-08 | Task Description | 75...

-

Page 76: Cylinder Head Cover - Removal And Installation

8.4.2 Cylinder head cover – Removal and installation Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 6–50 Nm F30027336 Ratchet adapter F30027340 Gasket (→ Spare Parts Catalog) Preparatory steps Remove air filter (→... -

Page 77: Injection Pump / Hp Pump

8.5 Injection Pump / HP Pump 8.5.1 Injection pump – Replacement Special tools, Material, Spare parts Designation / Use Part No. Qty. Injection pump (→ Spare Parts Catalog) Injection pump – Replacement Remove injection pump and install new one (→ Page 78). MW15409/04E 2015-08 | Task Description | 77... -

Page 78: Injection Pump - Removal And Installation

8.5.2 Injection pump – Removal and installation Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 20-100 Nm F30026582 Ratchet adapter F30027340 Box wrench F30038493 Spider patch spanner F30027424 Spider patch spanner F30027425... - Page 79 Removing injection pump Mark installation position of injection pump. Disconnect cabling (1) from injection pump. Remove fuel line (2). Unscrew securing screws of injection pump by approx. 6 mm. Result: The preloaded compression spring presses the injection pump out of the crankcase; If not: •...

- Page 80 Install injection pump, observing marked in- stallation position. Install securing screws of injection pump and tighten to specified torque using a torque wrench. Name Size Type Lubricant Value/Standard Securing screw Tightening torque 60 Nm + 12 Nm Install fuel line (2). Tighten union nut on injection pump to specified torque using a torque wrench.

-

Page 81: Injection Valve / Injector

8.6 Injection Valve / Injector 8.6.1 Injector – Replacement Special tools, Material, Spare parts Designation / Use Part No. Qty. Injector (→ Spare Parts Catalog) Replacing injector Remove injector and install new injector (→ Page 82). MW15409/04E 2015-08 | Task Description | 81... -

Page 82: Injector - Removal And Installation

8.6.2 Injector – Removal and installation Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Puller 3555890163/00 Fuel suction device F30378207 Torque wrench, 20-100 Nm F30026582 Ratchet adapter F30027340 Open-end wrench bit F30025897 Spider patch spanner F30027425... - Page 83 Removing injector Remove leak-off-fuel lines. Remove fuel line (3). Remove thrust screw (2). Pull off pressure pipe neck (1). Extract fuel from the exposed bores using the suction device. Remove screw (5). Remove clamp (4). Screw puller into injector. Remove injector with puller. Remove injector sealing ring (1) using a self- made hook.

- Page 84 Blow out fuel line (3) and pressure pipe neck (1) with compressed air. Coat sealing ring with assembly compound and fit onto pressure pipe neck (1). Coat sealing cone of pressure pipe neck with engine oil. Insert pressure pipe neck into cylinder head until it is in contact with the sealing ring.

-

Page 85: Fuel System

8.7 Fuel System 8.7.1 HP fuel line – Pressure pipe neck replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 20-100 Nm F30026582 Open-end wrench bit F30025897 Spider patch spanner F30027425 Spider patch spanner... - Page 86 Replacing pressure pipe neck Remove fuel line (3). Remove thrust screw (2). Pull off pressure pipe neck (1). Coat sealing ring with assembly compound and fit on new pressure pipe neck (1). Blow out fuel line (3) with compressed air. Coat sealing cone of pressure pipe neck with engine oil.

-

Page 87: Fuel - Draining

8.7.2 Fuel – Draining Preconditions ☑ Engine is stopped and starting disabled. WARNING Fuels are combustible and explosive. Risk of fire and explosion! • Avoid open flames, electrical sparks and ignition sources. • Do not smoke. • Wear protective clothing, protective gloves, and safety glasses / facial protection. Draining fuel Release threaded vent plugs on filter head. -

Page 88: Fuel System - Venting

8.7.3 Fuel system – Venting Preconditions ☑ Engine is stopped and starting disabled. WARNING Fuels are combustible and explosive. Risk of fire and explosion! • Avoid open flames, electrical sparks and ignition sources. • Do not smoke. • Wear protective clothing, protective gloves, and safety glasses / facial protection. Venting fuel system Unlock fuel priming pump, unscrew handle. - Page 89 Open nipple at fuel heat exchanger. Operate the pump with the handle until bub- ble-free fuel emerges at the nipple. Close nipple at fuel heat exchanger. Open nipple at fuel line. Operate the pump with the handle until bub- ble-free fuel emerges at the nipple. Close nipple on fuel line.

-

Page 90: Fuel Filter

8.8 Fuel Filter 8.8.1 Fuel filter – Replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Filter wrench F30379104 Fuel Easy-change filter (→ Spare Parts Catalog) Synthetic ring (→ Spare Parts Catalog) DANGER Rotating and moving engine parts. - Page 91 Easy-change fuel filter replace- ment with the engine stopped Cut out the filter to be replaced. A Both filters cut in (operating position) B Left filter cut out C Right filter cut out Unscrew switched off easy-change filter with oil filter wrench. Clean sealing surface on filter head.

-

Page 92: Fuel Prefilter - Differential Pressure Check And Adjustment Of Gauge

8.8.2 Fuel prefilter – Differential pressure check and adjustment of gauge DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine's danger zone. WARNING High level of engine noise when the engine is running. -

Page 93: Fuel Prefilter - Draining

8.8.3 Fuel prefilter – Draining Preconditions ☑ Engine is stopped and starting disabled. WARNING Liquid or gaseous media, e.g. fuel, are poisonous. Escaping vapors of highly volatile media, e.g. fuel or ether. Risk of fatal injury through swallowing; risk of poisoning through inhalation; irritation to eyes and skin! •... - Page 94 Open threaded vent plug (1) of the filter to be drained. Open drain valve (2). Drain water and contaminants from the filter until pure fuel emerges. Close drain valve (2). Connect filling pump to filling connection (1) on the intake side of the filter. Open vent valve (2) and fill with fuel until fuel emerges from the vent pipe (3).

-

Page 95: Fuel Prefilter - Flushing

8.8.4 Fuel prefilter – Flushing Special tools, Material, Spare parts Designation / Use Part No. Qty. Diesel fuel DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine's danger zone. WARNING Liquid or gaseous media, e.g. - Page 96 Open threaded vent plug (1) of filter to be flushed. Open drain valve (2) and drain fuel. Result: Fuel flows from filtered side back to the unfil- tered side, flushing the filter deposits down- wards out of the filter. Close threaded vent plug (1) and drain valve (2).

-

Page 97: Fuel Prefilter - Filter Element Replacement

8.8.5 Fuel prefilter – Filter element replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Diesel fuel Filter element (→ Spare Parts Catalog) Gasket (→ Spare Parts Catalog) WARNING Liquid or gaseous media, e.g. - Page 98 Open threaded vent plug (1) of contaminated filter. Unlock drain valve (5) by pressing toggle and open it. Drain water and dirt from filter. Close drain valve (5). Remove screws securing cover (2) and take off cover. Remove spring cartridge (3) and filter ele- ment (4).

- Page 99 8.9 Sensors, Actuators and Injectors on the Engine 8.9.1 Sensors and actuators – Overview Top view 12V 2000 M 1 B03 (intake air temperature) 4 B5.2 (lube oil pressure) 7 B07 (lube oil temperature) 2 B10 (charge-air pressure) 5 F25 (lube-oil pressure differ- 8 B05 (lube oil pressure) 3 B09 (charge-air tempera- ence over filter)

- Page 100 Left engine side 12V 2000 M 1 F33 (coolant level) 2 Y27 (turbocharger control 3 B21 (raw water pressure) valve) 100 | Task Description | MW15409/04E 2015-08...

- Page 101 Engine free end 12V 2000 M 1 B06 (coolant temperature) 2 B6.2 (coolant temperature) MW15409/04E 2015-08 | Task Description | 101...

- Page 102 Right engine side 12V 2000 M 1 B44 (turbocharger speed) 3 F46 (leak-off fuel level) 2 B16 (coolant pressure) 4 B33 (fuel temperature) 102 | Task Description | MW15409/04E 2015-08...

- Page 103 Driving end 12V 2000 M 1 B01 (camshaft speed) 3 B13 (crankshaft speed) 5 B4.21 (exhaust bulk tem- 2 B4.22 (exhaust bulk tem- 4 B13.2 (crankshaft speed) perature, A side) perature, B side) MW15409/04E 2015-08 | Task Description | 103...

- Page 104 Top view 16V 2000 M 1 B03 (intake air temperature) 4 B5.2 (lube oil pressure) 7 B07 (lube oil temperature) 2 B10 (charge-air pressure) 5 F25 (lube-oil pressure differ- 8 B05 (lube oil pressure) 3 B09 (charge-air tempera- ence over filter) ture) 6 B34 (fuel pressure after fil- ter)

- Page 105 Left engine side 16V 2000 M 1 F33 (coolant level) 2 Y27 (turbocharger control 3 B21 (raw water pressure) valve) MW15409/04E 2015-08 | Task Description | 105...

- Page 106 Free end 16V 2000 M 1 B06 (coolant temperature) 2 B6.2 (coolant temperature) 106 | Task Description | MW15409/04E 2015-08...

- Page 107 Right engine side 16V 2000 M 1 B44 (turbocharger speed) 3 F46 (leak-off fuel level) 2 B16 (coolant pressure) 4 B33 (fuel temperature) MW15409/04E 2015-08 | Task Description | 107...

- Page 108 Driving end 16V 2000 M 1 B01 (camshaft speed) 3 B13 (crankshaft speed) 5 B4.21 (exhaust bulk tem- 2 B4.22 (exhaust bulk tem- 4 B13.2 (crankshaft speed) perature, A side) perature, B side) 108 | Task Description | MW15409/04E 2015-08...

-

Page 109: Charge-Air Cooling

8.10 Charge-Air Cooling 8.10.1 Intercooler ‒ Checking condensate drain line for coolant discharge and obstruction DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine's danger zone. WARNING High level of engine noise when the engine is running. -

Page 110: Air Filter

8.11 Air Filter 8.11.1 Air filter – Replacement Special tools, Material, Spare parts Designation / Use Part No. Qty. Air filter (→ Spare Parts Catalog) Replacing the air filter Remove old air filter and install new air filter (→ Page 111). Reset signal ring of contamination indicator (→... -

Page 111: Air Filter – Removal And Installation

8.11.2 Air filter – Removal and installation Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 4–20 Nm F30044239 Air filter – Removal and installa- tion Release clamp (2). Remove air filter (1) and clamp (2) from con- necting flange of intake housing (3). -

Page 112: Air Intake

8.12 Air Intake 8.12.1 Service indicator – Signal ring position check Preconditions ☑ Engine is stopped and starting disabled. Checking signal ring position If the signal ring is completely visible in the control window (2), replace air filter (→ Page 110). After installation of new filter, press reset button (1). -

Page 113: Air Flap – Check Ease Of Movement

8.12.2 Air flap – Check ease of movement Preconditions ☑ Engine is stopped and starting disabled. Checking air flap for ease of movement Repeatedly shift lever between “A” and “B” positions by hand and check ease of move- ment. Contact Service if the mechanism does not move easily. -

Page 114: Exhaust Flap With Actuator

8.13 Exhaust Flap with Actuator 8.13.1 Exhaust flap – Check ease of movement Preconditions ☑ Engine is stopped and starting disabled. Checking exhaust flap for ease of movement Repeatedly shift linkage and actuating cylin- der between “A” and “B” positions by hand and check ease of movement. -

Page 115: Starting Equipment

8.14 Starting Equipment 8.14.1 Starter – Condition check Preconditions ☑ Engine is stopped and starting disabled. Checking starter condition Check securing screws of starter for secure seating and tighten if required. Check wiring (→ Page 143). MW15409/04E 2015-08 | Task Description | 115... -

Page 116: Lube Oil System, Lube Oil Circuit

8.15 Lube Oil System, Lube Oil Circuit 8.15.1 Engine oil – Level check Preconditions ☑ Engine is stopped and starting disabled. Checking oil level prior to en- gine start Withdraw oil dipstick from guide tube and wipe it. Insert oil dipstick into guide tube up to the stop, withdraw after approx. -

Page 117: Engine Oil – Change

8.15.2 Engine oil – Change Preconditions ☑ Engine is stopped and starting disabled. ☑ Engine is at operating temperature. ☑ MTU Fluids and Lubricants Specifications (A001061/..) are available. Special tools, Material, Spare parts Designation / Use Part No. Qty. Engine oil Sealing ring (→... -

Page 118: Oil Filtration / Cooling

8.16 Oil Filtration / Cooling 8.16.1 Oil dipstick — Marking Preconditions ☑ Engine is stopped and starting disabled. ☑ MTU Fluids and Lubricants Specifications (A001061/..) are available. Special tools, Material, Spare parts Designation / Use Part No. Qty. Engine oil Oil dipstick (→... -

Page 119: Engine Oil Filter – Replacement

8.16.2 Engine oil filter – Replacement Special tools, Material, Spare parts Designation / Use Part No. Qty. Oil filter wrench F30379104 Engine oil Oil filter (→ Spare Parts Catalog) Synthetic ring (→ Spare Parts Catalog) DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! •... - Page 120 Remove cut-out oil filter using the oil filter wrench. Clean the sealing face on the adapter. Check sealing ring of new oil filter and coat it with oil. Fit SOLAS shield (→ Page 21). Screw on and tighten new engine oil filter by hand.

-

Page 121: Centrifugal Oil Filter And Filter Sleeve Cleaning And Replacement

8.16.3 Centrifugal oil filter and filter sleeve – Cleaning and replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Oil filter wrench F30379104 Cold cleaner(Hakutex 50) X00056751 Filter sleeve (→... - Page 122 Cleaning centrifugal oil filter and replacing filter sleeve Remove nut, holding the rotor with an oil fil- ter wrench. Remove nut (1), washer (2), rotor cap (3) and O-ring (4). Remove filter sleeve (1). Measure the layer thickness of the oil resi- due.

- Page 123 Fit new O-ring (4). Set on rotor cap (3), observe marks. Fit washer (2). Hold rotor (new design) with oil filter wrench and tighten nut (1) to specified torque using a torque wrench. Name Size Type Lubricant Value/Standard M18 x 1.5 Tightening torque 10 Nm Hold rotor (old design) with oil filter wrench and tighten nut (1) to specified torque using a torque wrench.

-

Page 124: Circuit

8.17 Coolant Circuit, General, High-Temperature Circuit 8.17.1 Drain and venting points Top side 1 Engine coolant vent 3 Overflow line 5 Fuel filter 2 Intercooler 4 Engine coolant expansion 6 Engine oil filter tank 124 | Task Description | MW15409/04E 2015-08... - Page 125 Left side 1 Engine coolant drain plug 2 Engine coolant drain plug 3 Raw water pump drain plug MW15409/04E 2015-08 | Task Description | 125...

- Page 126 Free end (KGS) 1 Three-way cock 4 Raw water pump filling plug 7 Oil dipstick (connection left 2 Fuel filter 5 Raw water pump drain plug or right engine side option- 3 Fuel vent valve 6 Connection for oil extrac- tion 8 Oil filler neck (connection left or right engine side op-...

- Page 127 Right side 1 Engine coolant drain plug 4 Fuel priming pump 7 Oil dipstick (connection left 2 Engine coolant drain plug 5 Raw water pump filling plug or right engine side option- 3 Engine oil filter 6 Oil filler neck (connection left or right engine side op- 4 Leak-fuel tank tional)

- Page 128 Driving end (KS) 1 Engine coolant drain plug 4 Oil dipstick (connection left 7 Fuel vent 2 Oil filler neck (connection or right engine side option- left or right engine side op- tional) 5 Oil filler neck (connection 3 Oil dipstick (connection left left or right engine side op- or right engine side option- tional)

-

Page 129: Engine Coolant – Level Check

8.17.2 Engine coolant – Level check Preconditions ☑ Engine is stopped and starting disabled. ☑ MTU Fluids and Lubricants Specifications (A001061/..) are available. WARNING Coolant is hot and under pressure. Risk of injury and scalding! • Let the engine cool down. -

Page 130: Engine Coolant – Change

8.17.3 Engine coolant – Change Special tools, Material, Spare parts Designation / Use Part No. Qty. Coolant Engine coolant change Drain engine coolant (→ Page 131). Fill with engine coolant (→ Page 132). 130 | Task Description | MW15409/04E 2015-08... -

Page 131: Engine Coolant – Draining

8.17.4 Engine coolant – Draining Preconditions ☑ Engine is stopped and starting disabled. WARNING Coolant is hot and under pressure. Risk of injury and scalding! • Let the engine cool down. • Wear protective clothing, gloves, and goggles / safety mask. Preparatory steps Provide a suitable receptacle to catch the coolant. -

Page 132: Engine Coolant ‒ Filling

8.17.5 Engine coolant ‒ Filling Preconditions ☑ Engine is stopped and starting disabled. ☑ MTU Fluids and Lubricants Specifications (A001061/..) are available. Special tools, Material, Spare parts Designation / Use Part No. Qty. Engine coolant WARNING Coolant is hot and under pressure. -

Page 133: Ht Coolant Pump ‒ Relief Bore Check

8.17.6 HT coolant pump ‒ Relief bore check DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine's danger zone. WARNING High level of engine noise when the engine is running. -

Page 134: Engine Coolant – Sample Extraction And Analysis

8.17.7 Engine coolant – Sample extraction and analysis Preconditions ☑ Engine is stopped and starting disabled. ☑ MTU Fluids and Lubricants Specifications (A001061/..) are available. Special tools, Material, Spare parts Designation / Use Part No. Qty. MTU test kit 5605892099/00 WARNING Coolant is hot and under pressure. -

Page 135: Raw Water Pump With Connections

8.18 Raw Water Pump with Connections 8.18.1 Raw water pump – Priming Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Sealing ring (→ Spare Parts Catalog) Raw water pump – Priming Note: To prevent the raw water pump from running dry and being damaged and to ensure proper... -

Page 136: Raw Water Pump – Relief Bore Check

8.18.2 Raw water pump – Relief bore check Preconditions ☑ Engine is stopped and starting disabled. DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine's danger zone. WARNING High level of engine noise when the engine is running. -

Page 137: Belt Drive

8.19 Belt Drive 8.19.1 Drive belt – Condition check Preconditions ☑ Engine is stopped and starting disabled. ☑ Guard is removed. Drive belt – Condition check Item Findings Action Drive belt A Singular cracks None Drive belt B Cracks on entire circumference Replace (→... -

Page 138: Battery-Charging Generator

8.20 Battery-Charging Generator 8.20.1 Battery-charging generator drive – Drive belt check and adjustment Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Assembly device F6559691 Preparatory steps Remove limit switch (4). Remove indicator (1). - Page 139 Adjusting belt tension Hold adjustment lever (2) at square (5). Rotate adjusting lever until drive belt (4) is released. Loosen screws (1) and (3). Use assembly device to adjust distance (A) by turning adjustment lever (2). Tighten screws (1) and (3). Measure distance (A) with assembly device.

-

Page 140: Battery-Charging Generator Drive – Drive Belt Replacement

8.20.2 Battery-charging generator drive – Drive belt replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Mandrel 8205892861/08 Preparatory steps Remove safety equipment (if fitted). Remove screws of protective cover (engine free end). Remove protective cover. -

Page 141: Engine Mounting / Support

8.21 Engine Mounting / Support 8.21.1 Engine mounting – Checking condition of resilient mounts Preconditions ☑ Engine is stopped and starting disabled. ☑ Engine is filled with engine coolant and engine oil. ☑ Engine is under static load. Special tools, Material, Spare parts Designation / Use Part No. -

Page 142: Universal Shaft

8.22 Universal Shaft 8.22.1 Universal shaft – Greasing Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Lithium-soap greases according to DIN2–KP K–20 NOTICE Damage to component. Severe material damage! •... -

Page 143: Wiring (General) For Engine/Gearbox/Unit

8.23 Wiring (General) for Engine/Gearbox/Unit 8.23.1 Engine cabling – Check Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Solvent (isopropyl alcohol) X00058037 Engine cabling – Check Check securing screws of cable clamps on engine and tighten loose screw connections. Ensure that cables are securely seated in clamps and cannot move freely. -

Page 144: Accessories For (Electronic) Engine Governor / Control System

8.24 Accessories for (Electronic) Engine Governor / Control System 8.24.1 Engine governor and connectors – Cleaning Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Connector pliers F30017884 Isopropyl alcohol X00058037 Engine governor and connectors –... -

Page 145: Engine Monitoring Unit And Connectors Cleaning

8.24.2 Engine monitoring unit and connectors – Cleaning Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Connector pliers F30017884 Solvent (isopropyl alcohol) X00058037 Engine monitoring unit and con- nectors – Cleaning Remove coarse dirt from housing surface with isopropyl alcohol. -

Page 146: Start Interlock Limit Switch – Check

8.24.3 Start interlock limit switch – Check Preconditions ☑ Engine is stopped and starting disabled. Note: In its OFF position, the limit switch initiates start interlock, i.e. the engine cannot be started. Start interlock limit switch – Check Check if switch housing (1) and cover plate (3) are mounted and the switch (2) is in the on position. -

Page 147: Engine Control Unit – Plug Connection Check

8.24.4 Engine Control Unit – Plug connection check Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Connector pliers 0135315483 Checking Engine Control Unit plug connections Use connector pliers (3) to make certain that all plug connections on the Engine Control Unit are securely seated. -

Page 148: Engine Monitoring Unit – Plug Connection Check

8.24.5 Engine Monitoring Unit – Plug connection check Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Connector pliers F30017884 Checking plug connections on Engine Monitoring Unit Use connector pliers (3) to make certain that all Engine Monitoring Unit plug connections are securely seated. -

Page 149: Installation

8.24.6 Engine control system – Removal and installation Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Connector pliers F30017884 Caps for Cannon sockets Removing engine control sys- tem from engine Note or mark assignment of cables to con- nector sockets. -

Page 150: Emergency Instrumentation (Local Operating Panel)

8.25 Emergency Instrumentation (Local Operating Panel) 8.25.1 LOP and connectors – Cleaning Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Isopropyl alcohol X00058037 Cleaning LOP Wipe LCD display with dry cloth, without applying excessive pressure. Remove dirt from keys using isopropyl alcohol. -

Page 151: Lop – Visual Inspection

8.25.2 LOP – Visual inspection Preconditions ☑ Engine is stopped and starting disabled. Preparatory steps If READY FOR OPERATION illuminated pushbutton is illuminated brightly, press switch briefly. Result: READY FOR OPERATION illuminated pushbutton returns to basic brightness. Switch master power switch to OFF. Disconnect battery in accordance with battery manufacturer's instructions. - Page 152 Checking unassigned connector sockets Ensure that non-assigned connector sockets are protected with caps. Make sure that the two securing elements (1) are engaged in the lugs (2) so that the cap (3) is held firmly in place in the socket. If this is not the case, press the securing ele- ments (1) concerned in the direction of the arrow until they can be felt to engage.

-

Page 153: Lop – Test Procedures

8.25.3 LOP – Test procedures Preconditions ☑ Engine is stopped and starting disabled. Preparatory steps Connect battery in accordance with battery manufacturer's instructions. Switch master power switch to ON. Switch on engine management system ECS-5. Result: • LOCAL OPERATION button (1) is illuminat- ed brightly (local control mode is active). - Page 154 Overspeed test with the engine at standstill Note: Overspeed test with the engine at standstill can only be carried out if the engine is equip- ped with a monitoring unit. Press TEST OVERSPEED illuminated pushbut- ton (3). Observe speed limit and speed simu- lated by the engine monitoring unit on dis- play.

-

Page 155: Abbreviations

Association of American standardization organiza- tions Abgasturbolader Exhaust turbocharger (ETC) Baureihe Series Betriebsstoffvorschrift MTU Fluids and Lubricants Specifications, Publication No. A01061/.. Controller Area Network Data bus system, bus standard Cross Connection Gear Transfer gearbox CODAG Combined Diesel (engine) And Gas (tur-... - Page 156 Explanation Abbrevia- Meaning tion International Organization for Stand- International umbrella organization for all national ardization standardization institutes Kraftgegenseite Engine free end in accordance with DIN ISO 1204 Kraftseite Engine driving end in accordance with DIN ISO 1204 Liquid Crystal Display, Liquid Crystal Device Local Control Unit LOP subassembly...

- Page 157 Explanation Abbrevia- Meaning tion Werkzeugkatalog Tool Catalog (TC) Zugehörigkeit-Kategorie-Parameter Assignment category parameter; number scheme for signals from the ADEC engine governor MW15409/04E 2015-08 | Appendix A | 157...

-

Page 158: Mtu Contact Persons/Service Partners

Local support Experienced and qualified specialists place their knowledge and expertise at your disposal. For locally available support, go to the MTU Internet site: http://www.mtu-online.com 24h hotline With our 24h hotline and the outstanding flexibility of our service staff, we are always ready to assist you –... -

Page 159: Special Tools

10 Appendix B 10.1 Special Tools Assembly device Part No.: F6559691 Qty.: Used in: 8.20.1 Battery-charging generator drive – Drive belt check and adjustment (→ Page 138) Box wrench Part No.: F30038493 Qty.: Used in: 8.5.2 Injection pump – Removal and installation (→... - Page 160 Connector pliers Part No.: 0135315483 Qty.: Used in: 8.1.2 Engine – Barring with starting system (→ Page 65) Qty.: Used in: 8.24.4 Engine Control Unit – Plug connection check (→ Page 147) Connector pliers Part No.: F30017884 Qty.: Used in: 8.24.1 Engine governor and connectors –...

- Page 161 Feeler gauge Part No.: Y4342013 Qty.: Used in: 8.4.1 Valve clearance – Check and adjustment (→ Page 73) Filter wrench Part No.: F30379104 Qty.: Used in: 8.8.1 Fuel filter – Replacement (→ Page 90) Fuel suction device Part No.: F30378207 Qty.: Used in: 8.6.2 Injector –...

- Page 162 Mandrel Part No.: 8205892861/08 Qty.: Used in: 8.20.2 Battery-charging generator drive – Drive belt re- placement (→ Page 140) MTU test kit Part No.: 5605892099/00 Qty.: Used in: 8.17.7 Engine coolant – Sample extraction and analysis (→ Page 134) Oil filter wrench Part No.:...

- Page 163 Puller Part No.: 3555890163/00 Qty.: Used in: 8.6.2 Injector – Removal and installation (→ Page 82) Ratchet Part No.: F30006212 Qty.: Used in: 8.1.1 Engine – Barring manually (→ Page 64) Ratchet adapter Part No.: F30027340 Qty.: Used in: 8.3.2 Crankcase breather – Oil separator replacement, di- aphragm check and replacement (→...

- Page 164 Rigid endoscope Part No.: Y20097353 Qty.: Used in: 8.2.1 Cylinder liner – Endoscopic examination (→ Page 66) Socket Part No.: F30005655 Qty.: Used in: 8.1.1 Engine – Barring manually (→ Page 64) Spider patch spanner Part No.: F30027424 Qty.: Used in: 8.5.2 Injection pump –...

- Page 165 Torque wrench, 0.5-5 Nm Part No.: 0015384230 Qty.: Used in: 8.5.2 Injection pump – Removal and installation (→ Page 78) Torque wrench, 20-100 Nm Part No.: F30026582 Qty.: Used in: 8.5.2 Injection pump – Removal and installation (→ Page 78) Qty.: Used in: 8.6.2 Injector –...

- Page 166 Torque wrench, 6–50 Nm Part No.: F30027336 Qty.: Used in: 8.3.2 Crankcase breather – Oil separator replacement, di- aphragm check and replacement (→ Page 71) Torque wrench, 6–50 Nm Part No.: F30027336 Qty.: Used in: 8.4.2 Cylinder head cover – Removal and installation (→...

-

Page 167: Index

10.2 Index Numerics Drive belt – Condition check 137 12/16V 2000 M91 engine data 30 Emergency engine shutdown Abbreviations 155 – At LOP (without BlueLine automation system) 48 Actuators Engine – Overview 99 – Barring manually 64 After stopping the engine 49 – Shutdown Air filter ... - Page 168 Troubleshooting 52 – Fault messages 55 – Test procedures 153 – Visual inspection 151 Universal shaft – Greasing 142 Main engine dimensions 34 MTU contact persons 158 Valve clearance – Adjustment 73 – Check 73 Oil dipstick Venting points 124 – Marking 118 168 | Appendix B | MW15409/04E 2015-08...

- Page 169 Waterjet – Flushing – From LOP (option) 45 MW15409/04E 2015-08 | Appendix B | 169...

Need help?

Do you have a question about the 12V2000M91 and is the answer not in the manual?

Questions and answers