Subscribe to Our Youtube Channel

Summary of Contents for Windsor LB1500

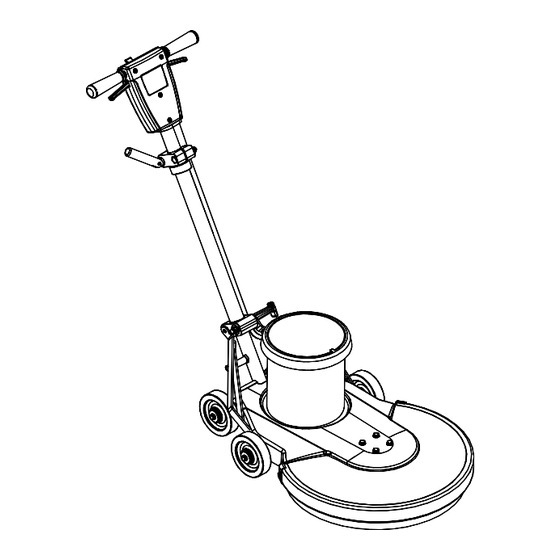

- Page 1 HIGH SPEED BURNISHER Operating Instructions (ENG) MODEL: LB1500 Read these instructions before using the machine 980101 11/15/03...

- Page 2 MACHINE DATA LOG/OVERVIEW MODEL______________________________ DATE OF PURCHASE ________________ SERIAL NUMBER____________________ YOUR DEALER Name: __________________________________________________________________________________________________ Address: _______________________________________________________________________________________________ For the name and address of your dealer contact: Windsor Industries Phone Number: _________________________________________________________________________________________ LB1500 980101 03/08/03...

-

Page 3: Table Of Contents

Technical Specifications ........3-1 Handle Installation..........3-2 Operation............3-3 Pad Driver Installation........3-4 MAINTENANCE Machine Troubleshooting.......4-1 Wiring Diagram/Service Schedule....4-2 GROUP PARTS LIST Motor Group...........5-1 Frame Group..........5-3 Drive/Pad Lock Group ........5-5 Handle Group..........5-7 Wiring Group..........5-9 Suggested Spare Parts........ 5-11 Warranty ............5-12 LB1500 980101 03/08/03... -

Page 4: How To Use This Manual

SERIAL NO. FROM – column indicates Parts may be ordered from authorized Windsor the first machine the part number is dealers. When placing an order for parts, the applicable to. When the machine design... -

Page 5: Important Safety Instructions

Do not pull or carry by cord, use cord as a handle, close a door on cord, or pull cord around sharp edges or corners. Do not pull/run machine over cord. Keep cord away from heated surfaces. Connect to a properly grounded outlet. See Grounding Instructions. SAVE THESE INSTRUCTIONS LB1500 980101 03/08/03... -

Page 6: Hazard Intensity Level

Unless Operation Guide is Read and understood. In Flammable or Explosive areas. In areas with possible falling objects. WHEN SERVICING MACHINE: Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the machine. Use Windsor approved replacement parts. LB1500 980101 03/08/03... -

Page 7: Grounding Instructions

Whenever the adaptor is used, it must be held in place by a metal screw. LB1500 980101 03/08/03... -

Page 8: Technical Specifications

The sound pressure level at the operator’s ear was measured to be 70 dBA. This was a nearfield, broad-band measurement taken in a typical industrial environment on a tile floor. This appliance contains no possible source of impact noise. The instantaneous sound pressure level is below 63 Pa. LB1500 980101 03/08/03... -

Page 9: Handle Installation

NOTE: The spacers (items 1) are required for the correct operation of the handle. The spacers are positioned completely inside the pivot holes in the casting, and are held in place by tightening the bolts and washers (items 2 and 3) against the spacer. LB1500 980101 03/08/03... -

Page 10: Operation

66334 outside of the machine and the flat on the PIVOT PIN C L opposite side of the handle is flush to the bracket. HANDLE C L LOCKING SIDE FLAT LB1500 980101 03/08/03... -

Page 11: Pad Driver Installation

The circuit breaker is located on the rear of the motor. Push the reset button to restart the machine. If the breaker trips again, correct the cause of overloading before proceeding. LB1500 980101 03/08/03... -

Page 12: Troubleshooting

Damaged or unevenly Replace pad. Do not rest machine on pad when not worn pad. in use. Damaged pad driver. Replace. Pad does not turn but Belt is loose or broken Adjust or replace belt. motor is running LB1500 980101 03/08/03... -

Page 13: Maintenance

Check pad driver system for damage Check handles, switches, and knobs for damage Store with pad off the floor Check all bearings for noise Check skirt/bumpers for damage and replace as necessary Check overall performance of machine LB1500 980101 11/15/03... -

Page 14: Motor Group

MOTOR GROUP LB1500 980101 03/08/03... - Page 15 INCLUDES ITEM 1 & 2 MOTOR COMPONENTS (NOT SHOWN) SERIAL NO. PART NO. DESCRIPTION NOTES: FROM 140411 CIRCUIT BREAKER, 20 AMP 67488 RECTIFIER, 50A 600V BRIDGE 14404 BRUSH SET MOTOR (PKG OF 4) 34378 FUSE 34379 FUSE HOLDER 09135 BEARING, MOTOR LB1500 980101 10/17/03...

-

Page 16: Frame Group

FRAME GROUP LB1500 980101 03/08/03... - Page 17 SCR, M8 X 20 HHMS PLTD 03116 AXLE, MAIN BURNISHER 70691 SCR, M6 X 25 HHMS BLK 87211 WASHER, M6 FLAT BLK 27871 CAP, EXTRUSION 14423 BUMPER, EXTRUSION 44.30 IN 70184 SCR, M8 X 25HHCS 57276 NUT, PUSH FLAT RD .51 ID LB1500 980101 03/08/03...

-

Page 18: Drive/Pad Lock Group

DRIVE/PAD LOCK GROUP LB1500 980101 03/08/03... - Page 19 COVER, BEARING 66337 PAD DRIVER, 20 IN BURNISHER 51353 LOCK, PAD DRIVER BLUE 70720 SCR, #10 X 3/8 PPHST TYPE B 70201 SCR, 1/4-20 X 3/4 FHCS DL 09134 BEARING, 25MM X 52MM 03115 AXLE, PAD DRIVER LB1500 980101 03/08/03...

-

Page 20: Handle Group

HANDLE GROUP 27, 11, 12 LB1500 980101 03/08/03... - Page 21 HOUSING, POLISHER HANDLE FRONT 70687 SCR, M6 X 50 SHCS BLK 38316 HANDLE, BRNSHR EXTND 730021 SPACER, POLISHER HANDLE 23206 CORDSET, 14/3 X 52” SJT BLK 730012 STRAIN RELIEF, 14/3 STRAIGHT 70701 SCR, M10 X 1.5 X 90 HHCS PLTD LB1500 980101 03/08/03...

-

Page 22: Wiring Group

WIRING GROUP PRIOR TO SN* LB1500 980101 11/15/03... - Page 23 CORD SET, 14/3 STO X 50' YLW 57069 NUT, ORG WIRE (2-5 18G/2-14G) 87208 WASHER, M5 SHAKEPROOF PLTD 70689 SCR, M4.8 X 10 HHTF TYPE B 23206 CORDSET, 14/3 X 52", SJT, BLK 20005 CLAMP, 5/16 NYLON 140674 BARRIER SHEET 5-10 LB1500 980101 11/15/03...

-

Page 24: Suggested Spare Parts

NUT, PUSH FLAT RD .51 RD 67449 RING, 20M EXTERNAL SNAP 66337 PAD DRIVER, 20IN BURNISHER 51353 LOCK, PAD DRIVER BLUE 09133 BEARING, 20MM X 52MM 14424 BELT, DRIVE 38 IN 09134 BEARING, 25MM X 52MM 27913 COVER, BEARING 5-11 LB1500 980101 03/08/03... -

Page 25: Warranty

The Machine Registration Card must be completed and returned immediately at the time of purchase. If proof of purchase cannot be identified, the warranty start date is 90 days after the date of sale to an authorized Windsor distributor. Parts replaced or repaired under warranty are guaranteed for the remainder of the original warranty period. - Page 26 If difficulty develops during the warranty period, contact the authorized Windsor agent from whom the product was purchased. Windsor Industries, Inc. may elect to require the return of components to validate a claim. Any defective part to be returned must be shipped freight prepaid to an authorized Windsor Distributor/Service Center or to the Windsor factory.

Need help?

Do you have a question about the LB1500 and is the answer not in the manual?

Questions and answers