Summary of Contents for King Kutter Free Floating Finishing Mower

-

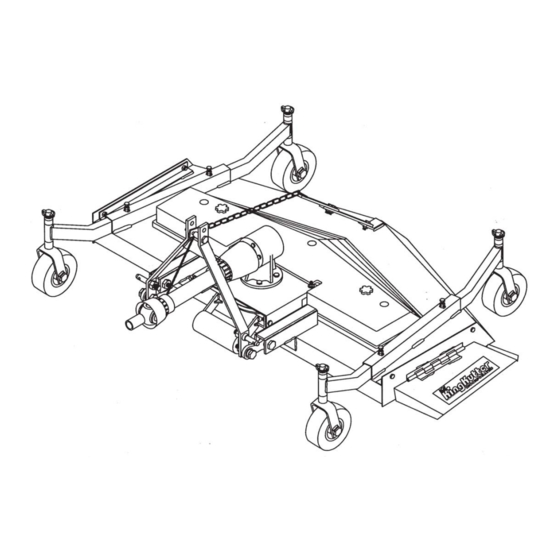

Page 1: Finishing Mower

PO Box 1200 305 Commerce Drive Winfield, Alabama 35594 FREE FLOATING FINISHING MOWER Part No 999997 www.kingkutter.com... -

Page 3: Customer Information

TO THE PURCHASER This manual contains valuable information about your new King Kutter Mower. It has been carefully prepared to give you helpful suggestions for operating, adjusting, ser- vicing and ordering repair parts. Keep this manual in a convenient place for quick and easy reference. - Page 4 Return the equipment or parts to the authorized King Kutter dealer, from where it was purchased, for ser- vice or replacement of defective parts that are covered by warranty. (The King Kutter Factory may inspect equipment or parts before warranty claims are hon- ored.)

-

Page 5: Table Of Contents

CONTENTS ITEM PAGE Safety ... 6 Assembly Instructions ... 8 Before Putting Into Service ... 10 Safety Training ... 11 Transportation Safety ... 15 Attaching To Tractor ... 16 Sizing PTO ... 18 Operating Instructions... 19 Maintenance ... 21 5-6-7 FT. Belt Replacement ... 22 4 FT. -

Page 6: Safety

If you have any questions not answered in this manual or require additional copies or the manual is damaged, please contact your dealer or King Kutter, Inc. P.O. Box 1200 Winfield, AL 35594 (205) 487-3202 or www.kingkutter.com... - Page 7 EQUIPMENT SAFETY GUIDELINES Safety of the operator and by standards is one of the main concerns in designing and developing a mower. However, every year accidents occur which could have been avoided by a few seconds of thought and a more careful approach to handling equipment. You, the operator, can avoid many accidents by observing the following precautions and insist those working with you, or for you, follow them.

-

Page 8: Assembly Instructions

FINISHING MOWER ASSEMBLY INSTRUCTIONS STEP 1 With finishing mower still in crate, lay flat on a level surface. Remove the top & side sections of the crate, leaving the finishing mower resting on the bot- tom section. Set aside PTO shaft and tail wheel arm assemblies. STEP 2 Insert tail wheel arms as shown in Figure A and tighten both the bolt &... - Page 9 Figure A Figure B...

-

Page 10: Before Putting Into Service

BEFORE PUTTING FINISHING MOWER INTO SERVICE (IMPORTANT-INSTRUCTIONS PRIOR TO START UP) SHIPPED WITHOUT OIL IN GEAR BOX AND WITHOUT GREASE IN GREASE FITTINGS. UNIT MUST BE SERVICED BEFORE USING. Fill Gearbox using Multi-Purpose Gear Oil (I.E. S.A.E. 80w/90 or • S.A.E. -

Page 11: Safety Training

SAFETY TRAINING Safety is a primary concern in the design and manufacture of our product. Unfortunately, our efforts to provide safe equipment can be wiped out by a single careless act of an operator or bystander. In addition to the design and configuration of equipment, hazard control and accident prevention are dependent upon the awareness, concern, prudence and proper training of personnel involved in the operation, trans- port, maintenance and storage of this equipment. - Page 12 PREPARTION Never operate the tractor and mower until you have read and completely understand this manual, the Tractor Operator’s Manual, and each of the safety messages found on the safety signs on the tractor and mower. Personal protection equipment including hardhat, safety glasses, safety shoes, and gloves are recommended during assembly, installation, operation, adjustment, maintenance, re- pairing, removal, or moving the implement.

- Page 13 OPERATIONAL SAFETY The use of this equipment is subject to certain hazards that cannot be protected against by the mechanical means or product design. All opera- tors of this equipment must read and understand this entire manual, pay- ing particular attention to safety and operating instructions, prior to using. If there is something in this manual you do not understand, ask your su- pervisor, or your dealer, to explain it to you.

- Page 14 OPERATIONAL SAFETY continued... Never allow the cutting blade to contact such items. Cut material higher at first, allowing finishing mower to clear hidden objects. Never assume an area is clear. Always Check! Always stop the tractor, disengage PTO, set brake, shut off the tractor engine, remove the ignition key, lower implement to the ground and allow cutter blades to come to a complete stop before dismounting tractor.

-

Page 15: Transportation Safety

OPERATIONAL SAFETY continued... Pass finishing mower diagonally through sharp dips and avoid sharp drops to prevent “hanging up” tractor and finishing mower. Practice will improve your skills in maneuvering on rough terrain. Always cut down slopes, never across the face. Always check tractor manual for proper use on slopes. -

Page 16: Attaching To Tractor

ATTACHING TO TRACTOR STEP 1 Attach to tractor's category 1 three point hitch as described in the Tractor's Operator’s Manual. WARNING Failure to install retaining clip on gearbox input shaft would allow driv- eline to swing freely if bolt is sheared causing possible injury or death. STEP 2 Determine if the PTO shaft needs to be shortened. - Page 17 If the PTO shaft has less than a 6 inch overlap, DO NOT USE. Contact your autho- rized King Kutter Dealer. NOTE If the PTO shaft length is too long go to SIZING PTO SHAFT (pg. 18)

-

Page 18: Sizing Pto

SIZING PTO SHAFT STEP 1 Cutting the PTO shaft to length. NOTE: Be sure to cut equal lengths of each PTO shaft section. Clamp end of PTO shaft in a vice and cut off shield where marked. (Figure 1-A & 1-B) STEP 2 Using cut section of the shield as a guide cut shaft off the same... -

Page 19: Operating Instructions

OPERATING INSTRUCTIONS This mower was designed to CUT LAWN GRASS ONLY. Use of your finishing mower to cut any material other than lawn grass may damage the mower and void your warranty. CUTTING HEIGHT ADJUSTMENT To prevent blades from striking the ground your finishing mower should be set to the highest position that will give desired grass height. - Page 20 FINISHING MOWER OPERATION STEP 1 Before each use perform the maintenance described in maintenance section (pg# 21) STEP2 Read, understand, and follow the information on safety training, preparation, starting and stopping safety, operational safety, transport safety warning sec- tions of this manual (pages 11 thru 16) STEP 3 With tractor running, lower finishing mower to ground so that the swivel links are parallel to the ground.

-

Page 21: Maintenance

MAINTENANCE Periodically check and maintain proper gear oil level. Every 8 hours, grease spindles (3), roller axle (1), wheel forks (4), wheel axles (4), PTO shaft universal joints (2), and PTO telescoping surface. NOTE: Use only a grade Type II tube grease. Keep tires inflated to rated PSI (listed on tire) at all times. -

Page 22: Ft. Belt Replacement

5-6-7 FT. FINISHING MOWER TO REPLACE BELT: STEP 1 Remove top cover. STEP 2 Release adjustment spring. STEP 3 Loosen nut on adjustment pulley to allow for movement. (See Fig- ure “D”) STEP 4 Loosen nut on right side of “L” bracket. (See Figure “D”) STEP 5 Loosen belt by moving adjustment pulley in opposite direction you would to tighten belt. - Page 23 Figure D Figure E...

-

Page 24: Ft. Belt Replacement

4 FT. FINISHING MOWER ONLY TO REPLACE BELT: STEP 1 Remove top cover. STEP 2 Loosen nut on adjustment pulley to allow for movement. (See Fig. “D”) STEP 3 Loosen nut on right side of L Bracket. (See Fig. “D”) STEP 4 Loosen belt by moving adjustment pulley in opposite diection you would to tighten belt. - Page 25 4 FT. FINISHING MOWER ONLY...

-

Page 26: Maintenance Safety

MAINTENANCE SAFETY Good maintenance is your responsibility. Poor maintenance is an invitation to trouble. Follow good shop practices. Keep service area clean and dry Be sure electrical outlets and tools are properly grounded Use adequate light for the job at hand. Make sure there is plenty ventilation. -

Page 27: Safety Decal's And Locations

SAFETY SIGN LOCATIONS The types of safety signs and locations on the equipment are shown in the illustration below. Good safety requires that you familiarize yourself with the various safety signs, the type of warning and the area, or particular function related to that area, that requires your SAFTY AWARENESS REMEMBER: IF safety signs have been damaged, removed, become illegible or parts have been replaced without signs, new safety signs must be applied. - Page 33 MODEL NO. DESCRIPTION SN# XXXXXXXXXX...

-

Page 34: Replacement Parts

FINISHING MOWER... - Page 35 Ref. Part Name Top Cover Gear Box Plate Idler Pulley Bracket Double - Idler Pulley Bracket Spindle Unit - Single Spindle Unit - Double Idler Pulley - Single Idler Pulley - Double Belt Adjustment Assembly V-Belt * V-Belt/Double Spring Gear Box Main Pulley-Single Main Pulley-Double Bolt 3/4"...

-

Page 36: Pto Shaft Parts

Ref. Part Name Roll Pin Kit Male Tube End Yoke Implement End Yoke Female Tube End Yoke Tractor End Yoke Inner Tube 14 Series Outter Tube 14 Series Cross Kit #4 Quick Disconnect Pin Safety Shield BYPY Safety Shield Eurocardan 147022 500131 151045... -

Page 37: Spindle Unit Parts

Ref. Part Name Bearing Kit-(2) Ball Bearings(6205), 1 & 2 (2)Seals (TCM25X52X7TC), (4)Snap Rings Spindle Pulley /w Nut & Key Blade Bolt Set (3) /w Washer 502303 502300 555009 555009 502311 502313 502310 502310 502301 555009 502312 502310... -

Page 38: Gearbox Parts

40 HP GEARBOX... - Page 39 Ref. 1" Castle Nut/w Washer & Cotter Pin Part Name Snap Ring Input Seal (NAK35X54X10) Front Cap Front Cap Gasket Snap Ring Snap Ring Bearing (Hoover 208) Input Gear Input Shaft Bearing (NSK6207) Housing Output Shaft Spacer Output Seal (NAK40X54X7) Bottom Cap Gasket Bottom Cap 1/2"...

-

Page 40: Pto Shaft Cover Removal

PTO SHAFTS COVER REMOVAL BONDIOLI- (BYPY) There are 3 white tabs around the cover as shown in (A in FIG. 1). Take a screwdriver and press against the tabs one at a time with downward an- gular pressure toward the end of shaft marked (B in FIG. 2). As you are pressing tab grasp cover at point marked (B in FIG. - Page 41 BONDIOLI COVER REMOVAL FIGURE- 1 EUROCARDAN SERIES 4 COVER REMOVAL FIGURE- 3 LA MAGDALENA COVER REMOVAL FIGURE- 5 FIGURE- 2 FIGURE- 4...

- Page 42 PTO SHAFTS COVER REMOVAL EUROCARDAN SERIES 5 There are 2 black tabs around the cover as shown in (B in FIG. 1). Take a flat screwdriver and pry under the tabs one at a time at point (B in FIG. 2) lifting tab over on top of (e-shaped lock).

-

Page 43: Warranty

Kutter. If King Kutter is unable to repair the product to conform to the warranty after a reasonable number of attempts, King Kutter will provide, at its option, one of the following: (a) a replacement for the product or, (b) a full refund of the purchase price.