Table of Contents

Advertisement

© ELECTROLUX HOME PRODUCTS

ITALY S.p.A.

Spares Operations Italy

Corso Lino Zanussi, 30

I - 33080 PORCIA /PN

Fax +39 0434 394096

Edition: 2007-02-06

electronic control system

Publication no.

599 38 60-23

Technical and functional

EN

SERVICE MANUAL

Washing machines with

ENV06

EWM2100

EWM2500

characteristics

Styling: TC 2 / 3

With cabinet

ICON

WASHING

Advertisement

Table of Contents

Summary of Contents for Electrolux EWM2100

-

Page 1: Service Manual

SERVICE MANUAL WASHING Washing machines with electronic control system ENV06 © ELECTROLUX HOME PRODUCTS ITALY S.p.A. EWM2100 Publication no. Spares Operations Italy EWM2500 Corso Lino Zanussi, 30 I - 33080 PORCIA /PN 599 38 60-23 Technical and functional Fax +39 0434 394096... - Page 2 2/56 SOI/DT 2007-02 dmm 599 38 60-23...

-

Page 3: Table Of Contents

CONTENTS Purpose of this manual ............................5 PRECAUTIONS ...............................5 During the delivery............................6 During the reparation ..........................6 TC3 ..................................7 GENERAL CHARACTERISTICS......................7 CONTROL PANEL ...........................8 3.2.1 Styling ..............................8 3.2.2 Configuration of control panel ......................9 3.2.3 Programme selector (S1) ........................9 3.2.4 Programme configuration ........................9 3.2.5 Pushbuttons and LEDs........................10 3.2.6... - Page 4 10.11 Anti-foam control system........................42 10.12 “FUCS” (Fast Unbalance Control System)..................43 10.13 Table of alarm codes...........................45 10.14 Diagram with UNIVERSAL MOTOR EWM2100 .................48 10.15 Diagram with THREE-PHASE ASYNCHRONOUS MOTOR EWM2500 ..........50 ACCESSIBILITY............................52 11.1 To the electronic control system ......................52 11.1.1 Work top ............................52 11.1.2...

-

Page 5: Purpose Of This Manual

1 Purpose of this manual The purpose of this manual is to provide service engineers who are already familiar with the repair procedures for traditional washing machines with information regarding appliances fitted with the ENV06 electronic control system and produced in Porcia (Italy). The characteristic of the ENV06 electronic control system is to use only an electronic pressure switch to check the various water levels in the tub (with the elimination of the mechanical pressure switches: anti-overflow, anti- boiling, 1st-2nd level), and a new heater with two thermal fuses which interrupt if the temperature degree... -

Page 6: During The Delivery

During the delivery NEVER MOVE the appliance inclining it on the front side During the reparation NEVER LAY DOWN THE APPLIANCE On the front side On the right side IT IS POSSIBLE TO LAY DOWN THE APPLIANCE On the left side On the rear side 6/56 SOI/DT 2007-02 dmm... -

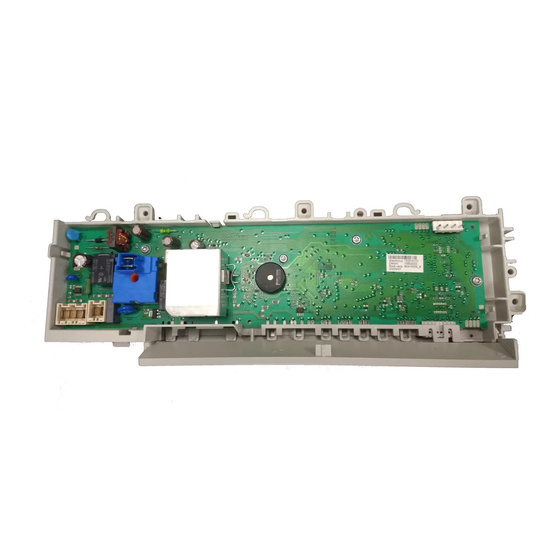

Page 7: Tc3

3 TC3 GENERAL CHARACTERISTICS The ENV060 electronic control system consists of a single PCB, which incorporates the power, control and display (where the LCD display is connected) functions and the programme selector is incorporated in the board. The PCB is mounted on a casing fitted to the control panel. -

Page 8: Control Panel

CONTROL PANEL 3.2.1 Styling • max. 8 buttons • 15 or 21-position programme selector • 18 LEDs • LCD display • Disposition of LEDs and buttons 8/56 SOI/DT 2007-02 dmm 599 38 60-23... -

Page 9: Configuration Of Control Panel

3.2.2 Configuration of control panel The washing programmes, the functions of the selector knob and the various pushbuttons vary according to the model, since these are determined by the configuration of the appliance. 3.2.3 Programme selector (S1) The selector features 15-21 positions and incorporates the ON/OFF switch. -

Page 10: Pushbuttons And Leds

3.2.5 Pushbuttons and LEDs The functions of each button are defined by the configuration of the appliance. • Button no. 1: this button is configurable and is related to LEDs (DL1÷DL5). Depending on the configuration of the appliance it can be connected both to the temperature regulation and the spin speed regulation. -

Page 11: Time Driven

• DL16 Door closed: It lights up when the safety device stops the door opening and switches off when it is possible to open it. It flashes when the device is about to unlock the door (with door interlock with PTC, which need one or two minutes to open). 3.2.6 Time DRIVEN The “Time driven”... -

Page 12: Lcd Display

Intensive cycle indicated for very dirty clothes which needs anti- stain treatments, soak and prewash. The levels are represented in the following table: COTTONS SYNTHETICS DELICATES INTENSIVE --------------- --------------- NORMAL (basic programme) NORMAL (basic programme) NORMAL (basic programme) DAILY DAILY DAILY LIGHT LIGHT... - Page 13 - Washing phases: wash, rinses, drain and spin light up in the selection mode if the programme includes these phases and during the execution of the phase. - Wrong choice of an option is displayed by Err, when a function not compatible with the chosen programme is selected.

-

Page 14: Tc2

4 TC2 GENERAL CHARACTERISTICS The ENV060 electronic control system consists of a single PCB, which incorporates the power, control and display (where the LCD display is connected) functions and the programme selector is incorporated in the board. The PCB is mounted on a casing fitted to the control panel. -

Page 15: Control Panel

CONTROL PANEL 4.2.1 Styling • max. 8 buttons • 15 or 21-position programme selector • 2 LEDs • LCD display • Disposition of LEDs and buttons 15/56 SOI/DT 2007-02 dmm 599 38 60-23... -

Page 16: Configuration Of Control Panel

4.2.2 Configuration of control panel The washing programmes, the functions of the selector knob and the various pushbuttons vary according to the model, since these are determined by the configuration of the appliance. 4.2.3 Programme selector (S1) The selector features 15-21 positions and incorporates the ON/OFF switch. -

Page 17: Buttons And Lcd

4.2.5 Buttons and LCD The functions of each button are defined by the configuration of the appliance. • Button no. 1: TEMPERATURE The temperature set by the programme is the base one, pressing the button it is possible to modify it from a max. -

Page 18: Time Driven

4.2.6 Time DRIVEN The “Time driven” has the function to modify the programme setting, according to the type of dirt so as to obtain a reduction or an increase of the washing time, displaying the dirt level through an icon, represented by a t-shirt and the time through the three digits positioned on the right of the LCD display. - Page 19 Intensive cycle indicated for very dirty clothes which need anti-stain treatments, soak and prewash. The levels are represented in the following table: COTTONS SYNTHETICS DELICATES INTENSIVE --------------- --------------- NORMAL (basic programme) NORMAL (basic programme) NORMAL (basic programme) DAILY DAILY DAILY LIGHT LIGHT LIGHT...

-

Page 20: Demo Mode

5 DEMO MODE 1. Switch off the appliance. 1. Press and hold down START/PAUSE button and the nearest option button simultaneously (as represented in figure). 2. Holding down both buttons, switch the appliance on by turning the programme selector by three positions clockwise. -

Page 21: Diagnostics Phases

Diagnostics phases Irrespective of the type of PCB and the configuration of the programme selector it is possible, after entering diagnostics mode, to perform diagnostics on the operation of the various components and to read the alarms by turning the programme selector clockwise. All the alarms are enabled during the diagnostics cycle. Function Selector position Components actioned... -

Page 22: Alarms

7 ALARMS Displaying the alarms to the user The alarms are displayed by the red LED of the START/PAUSE button flashing and simultaneously through the LCD or Display. The alarms displayed to the user are listed below: E10 - Water fill difficulty (closed tap) E20 - Drain difficulty (dirty filter) E40 - Door open They are represented through the flashing of the red LED inside the START-... -

Page 23: Displaying The Alarm

7.2.1 Displaying the alarm The alarm is displayed by a repeated flashing sequence of the START / PAUSE button with red and green light (0,5 seconds on, 0,5 seconds off with a 2,5 second pause between the sequences). • button indicator START / PAUSE with red light → indicates the first digit of the alarm code (family) •... -

Page 24: Rapid Reading Of Alarm Codes

Rapid reading of alarm codes The last three alarm codes can be displayed even if the programme selector is not in the tenth position (diagnostics) or if the appliance is in normal operating mode (e.g. during the execution of the washing programme): →... -

Page 25: Operating Time Counter

OPERATING TIME COUNTER Using a specific procedure, the operator can display the total operating time for the appliance, which is counted from the moment it is first switched on. This option is available only on models equipped with a display. The unit can count up to a maximum of 6550 hours of operating time. -

Page 26: Washing Programmes And Options

9 WASHING PROGRAMMES AND OPTIONS 9.1 Programmes The washing programmes can be configured. The basic programmes are listed in the table below. Programme Number of rinses Final spin (rpm) Temperature (°C) 67(*) (**) 55 (*) (**) 450/650/850/1000/1200/ Cotton 1300/1400/1600 44(*) (**) 50/40E cold... -

Page 27: Options (For Appliances Ewm 2100 With Universal Motor)

Options (for appliances EWM 2100 with universal motor) The table below lists the possible options for the washing programmes, the compatibility of the various options and with the cycle, and when it is possible to select or modify the options. The options can be selected in three ways: using the programme selector: in this case, the options are configured as special programmes;... - Page 28 OPTIONS 40°C 30°C Sport cold 30°C Shirts 40°C Mixed° 90°C 60°C Hygienize 50°C 40°C 60°C 50°C Grass 40°C 30°C Soak Rinses Rinses delicates Conditioner Delicate conditioner Drain Spin Delicate spin (*) Economy Cotton: 90°C = Eco 67°C; 60°C = Energy Label; 50°= Eco 48°C;40°C = Eco 44°C AA Synthetics: 60-60°C = Eco 40°C Option included in the programme and cannot be deleted 28/56...

-

Page 29: Options (For Appliances Ewm2500 With Asynchronous Motor And Inverter)

Options (for appliances EWM2500 with asynchronous motor and inverter) The table below lists the possible options for the washing programmes, the compatibility of the various options and with the cycle, and when it is possible to select or modify the options. The options can be selected in different ways: using the programme selector: in this case, the options are configured as special programmes;... - Page 30 OPTIONS 40°C 30°C Sport cold 30°C Shirts 40°C Mixed° 90°C 60°C Hygienize 50°C 40°C 60°C 50°C Grass 40°C 60°C Express 90°C 60°C 50°C Sensitive plus 40°C 30°C cold 30°C Rapid 30°C Soak Rinses Rinses delicates Conditioner Delicate conditioner Drain Spin Delicate spin (*) Economy Cotton: 90°C = Eco 67°C;...

-

Page 31: Compatibility Between Options

9.3.1 Compatibility between Options OPTIONS Rinse-hold Night cycle Pre-wash (*) (*) Stains Bleach (*) (*) X X X Super rinse Easy-iron Economy Intensive Normal Daily Light Quick Super Quick Reduced spin speed No spin Half-load Selection Phases in Pre-wash which Wash selection or modification... -

Page 32: Description Of Options

Description of options • Rinse-hold → Stops the appliance with water in the tub before the final spin cycle. → To drain the water, reset the programme and then select a drain or spin cycle. • Night cycle → Eliminates all spin phases and adds three rinses in COTTON cycles and two rinses in SYNTHETICS cycles. - Page 33 • Reduced spin speed → Reduces the speed of all spins as shown in the table. 900 1000 1100 1200 1300 1400 1550 Maximum spin speed (rpm) Reduction for COTTON (rpm) Reduction for ALL OTHER CYCLES (rpm) • No spin →...

-

Page 34: Technical Characteristics

10 TECHNICAL CHARACTERISTICS 10.1 Control system memory 10.1.1 General structure of the memory system The system features an EEPROM memory module, fitted externally to the microprocessor, which serves to memorize the configuration data, the description of the cycle, the status of the appliance in the event of a power failure, and the alarms. -

Page 35: Ram

Washing cycle tables: Each washing cycle consists of a series of phases (steps); the steps are the basic instructions which comprise the description of the cycle, which is common to all appliances having the same characteristics: Water fill Motor movement Reset Heating Drain... -

Page 36: Door Interlock

10.2 Door interlock There are two types of door interlock: • voltmetric with PTC • instantaneous 10.2.1 Voltmetric interlock with PTC 10 Suppressor 19 Door interlock 20 PCB ON/OFF = Main switch (programme selector) 10.2.1.1 Operating principle When the washing programme is started by pressing the START/PAUSE button, the bi-metal PTC (contacts 3-5) is powered by the triac on the PCB: after 2 –... -

Page 37: Instantaneous Door Interlock

10.2.2 Instantaneous door interlock • With this safety device it is possible to open the door immediately after the end of the cycle. Door interlock 19 Suppressor 20 PCB ON/OFF = Main switch (programme selector) 10.2.2.1 Operating principle When the ON/OFF switch closes and the appliance is switched on, power is applied to the bimetallic PTC switch (contact 4-2), but the door remains unlocked. -

Page 38: Water Fill System

10.3 Water fill system The electric valves are powered by the PCB by means of the triac and the control of the water level in the tub is carried out by the analogue pressure switch. Analogue pressure switch Prewash electric valve Wash electric valve Bleach electric valve 20 PCB... -

Page 39: Drain Pump

10.5 Drain pump 15 Drain pump 16 Thermal protector 20 PCB The PCB powers the drain pump via a triac as follows: until the electronic pressure switch closes on empty, after which the pump is actioned for a brief period or passes to the subsequent phase; for a pre-determined period (and eventually an alarm appears). -

Page 40: Heating

10.7 Heating NTC temperature sensor 13 Heating element (with thermal fuses) 14 PCB K1 Relay 1. Tubular casing 2. Thermal fuses 3. NTC Sensor 4. Connectors The heating element is powered by a relay (K1) of the electronic board and is provided with two thermal fuses, which interrupt if the temperature degree exceeds the values by which they are calibrated. -

Page 41: Universal Motor (Ewm 2100)

10.9 Universal motor (EWM 2100) 11 Tachometric generator 12 Stator 13 Protector 14 Rotor 20 PCB 10.9.1 Power supply to motor The PCB powers the motor via a triac. The direction of rotation is reversed by switching of the contacts on the two relays (K2-K3), which modify the connection between the rotor and the stator. -

Page 42: Anti-Foam Control System

10.11 Anti-foam control system The anti-foam control procedure (if featured) is performed via the electronic pressure switch. Spin phase without foam Spin phase with little foam Spin Spin Anti-foam (Electronic level) 450 rpm pulses 450 rpm pulses FUCS FUCS • Spin with little foam: if the contact of the electronic pressure switch closes on FULL, the spin phase is interrupted;... -

Page 43: Fucs" (Fast Unbalance Control System)

10.12 “FUCS” (Fast Unbalance Control System) The control procedure for unbalanced loads is performed dynamically, before each spin cycle, as follows: The phase begins at a speed of 55 rpm; the speed can never fall below this threshold, otherwise the check is repeated. - Page 44 • Balancing in the available longer interval Phase Unbalancing index Time-out (sec) • Unbalancing after all phases In this case the spin (or impulse) is not performed. 44/56 SOI/DT 2007-02 dmm 599 38 60-23...

-

Page 45: Table Of Alarm Codes

10.13 Table of alarm codes Alarm Possible fault Action/machine status Reset Tap closed or water pressure too low; Drain tube improperly positioned; Water fill Cycle is paused with door locked. START/RESET solenoid valve is faulty; Leaks from water circuit on pressure switch; Pressure switch faulty;... - Page 46 Alarm Possible fault Action/machine status Reset Motor defective; Wiring defective on inverter for motor, inverter board defective, Cycle stops with door locked (after 5 attempts). RESET abnormal motor operation (motor overloaded). Motor defective; Wiring defective on inverter for motor; Cycle stops with door locked (after 5 attempts). RESET Inverter board defective.

- Page 47 Alarm Possible fault Action/machine status Reset Power supply problems (incorrect / disturbance); PCB faulty. Wait for frequency nominal conditions. OFF/ON Power supply problems (incorrect / disturbance); PCB faulty. Wait for voltage nominal conditions. OFF/ON Power supply problems (incorrect / disturbance); PCB faulty. Wait for voltage nominal conditions.

-

Page 48: Diagram With Universal Motor Ewm2100

10.14 Diagram with UNIVERSAL MOTOR EWM2100 48/56 SOI/DT 2007-02 dmm 599 38 60-23... - Page 49 • Key to diagram with UNIVERSAL MOTOR EWM2100 Electrical components on appliance Components on main board 1. Display board DOOR_TY Door interlock Triac 2. Flowmeter DRAIN_TY Drain pump Triac 3. Analogue pressure switch REC-TY Recirculation pump Triac 4. NTC temperature sensor Heating element relay 5.

-

Page 50: Diagram With Three-Phase Asynchronous Motor Ewm2500

10.15 Diagram with THREE-PHASE ASYNCHRONOUS MOTOR EWM2500 50/56 SOI/DT 2007-02 dmm 599 38 60-23... - Page 51 • Key to diagram with THREE-PHASE ASYNCHRONOUS MOTOR EWM2500 Electrical components on appliance Components on main board 1. Display board DOOR_TY Door interlock Triac 2. Flowmeter DRAIN_TY Drain pump Triac 3. Analogue pressure switch REC-TY Recirculation pump Triac 4. NTC temperature sensor Heating element relay 5.

-

Page 52: Accessibility

11 ACCESSIBILITY 11.1 To the electronic control system 11.1.1 Work top Remove the two rear screws, push the top panel towards the rear and release from the cabinet. 11.1.2 Control panel Press the drawer lock. Extract. d. Remove the screw which secures the control panel to the dispenser. Remove the clamp which secures the wiring to the board casing. - Page 53 g. Loosen the screws which secure the cross-member to the cabinet. h. Release the hook which secures the dispenser to the cross-member. Lift the control panel up. Loosen the screws which secure the cross-member to the control panel. k. Release the hook which secures the control panel to the cross- member.

-

Page 54: Door Interlock

o. Before mounting the new board extract the knob pushing the hooks indicated by the arrow as represented in figure. While reassembling, repeat the same operations in reverse order and pay attention to the correct positioning of the knob. 11.2 Door interlock a. -

Page 55: New Drain Filter

11.3 New drain filter a. Open the filter door with the appropriate tool (supplied with the appliance), because it is locked. To empty the drain circuit: b. Remove the cap in the filter knob (after positioning a vessel to collect the water). c. -

Page 56: Inverter Board

11.4 Inverter board a. Release the hook. b. Push the hook inside, extract it. c. Push the wing which secures the board the cabinet. SOI/DT 2007-02 dmm 56/56 599 38 60-23...