Canon PIXMA MP500 Service Manual

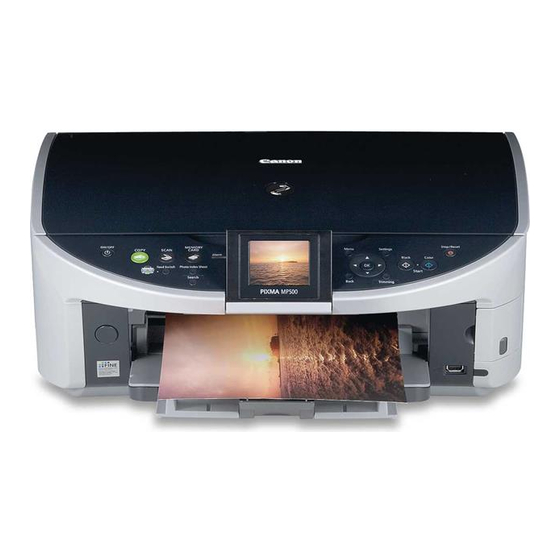

Pixma mp500

Hide thumbs

Also See for PIXMA MP500:

- User manual (164 pages) ,

- Quick start manual (39 pages) ,

- Installation instruction (9 pages)

Table of Contents

Advertisement

Quick Links

- 1 Adjustment, Periodic Maintenance, Periodic Replacement Parts, and Replacement Consumables by Service Engineer

- 2 List of Error Display / Indication

- 3 Troubleshooting by Symptom

- 4 Notes on Service Part Replacement (and Disassembling / Reassembling)

- 5 Adjustment / Settings

- 6 Service Test Print

- Download this manual

See also:

User Manual

Advertisement

Table of Contents

Summary of Contents for Canon PIXMA MP500

-

Page 1: Service Manual

PIXMA MP500 SERVICE MANUAL Canon Copyright 2005, Canon U.S.A. This technical publication is the proprietary and confidential information of Canon U.S.A. which shall be retained for reference purposes by Authorized Service Facilities of Canon U.S.A. Its unauthorized use is prohibited. - Page 2 When changes are made to the contents of the manual, Canon will release technical information when necessary. When substantial changes are made to the contents of the manual, Canon will issue a revised edition. The following do not apply if they do not conform to the laws and regulations of the region where the manual or product...

- Page 3 I. MANUAL OUTLINE This manual consists of the following three parts to provide information necessary to service the PIXMA MP500: Part 1: Maintenance Information on maintenance and troubleshooting of the PIXMA MP500 Part 2: Technical Reference New technology and technical information such as FAQ's (Frequently Asked Questions) of the PIXMA MP500...

-

Page 4: Table Of Contents

II. TABLE OF CONTENTS Part 1: MAINTENANCE 1. MAINTENANCE 1-1. Adjustment, Periodic Maintenance, Periodic Replacement Parts, and Replacement Consumables by Service Engineer 1-2. Customer Maintenance 1-3. Product Life 1-4. Special Tools 1-5. Serial Number Location 2. LIST OF ERROR DISPLAY / INDICATION 2-1. - Page 5 2. CONNECTOR LOCATION AND PIN LAYOUT 2-1. Logic Board Ass'y 2-2. Print Beam Board / PictBridge Board 2-3. Card Slot Board (Card Slot Unit) 2-4. Operation Panel Board 2-5. Carriage Board (Print Head Connector) 3. PIXMA MP500 SPECIFICATIONS 4. PRINT MEDIA SPECIFICATIONS...

-

Page 6: Part 1: Maintenance

Part 1 MAINTENANCE... -

Page 7: Adjustment, Periodic Maintenance, Periodic Replacement Parts, And Replacement Consumables By Service Engineer

1. MAINTENANCE 1-1. Adjustment, Periodic Maintenance, Periodic Replacement Parts, and Replacement Consumables by Service Engineer (1) Adjustment Approx. Adjustment Timing Purpose Tool time Destination At logic board ass'y To set the destination. None. 1 min. settings (EEPROM replacement Perform in the settings) service mode. -

Page 8: Customer Maintenance

(2) Periodic maintenance No periodic maintenance is necessary. (3) Periodic replacement parts There are no parts in this machine that require periodic replacement by a service engineer. (4) Replacement consumables There are no consumables that require replacement by a service engineer. 1-2. -

Page 9: Product Life

Black text: When printing the Canon standard pattern (1,500 characters per page) on A4 size plain paper, with the default settings in the Windows XP driver, using Word 2003. Color chart: When printing the ISO/JIS-SCID N5 pattern on A4 size plain paper in bordered printing, with the default settings in the Windows XP driver, using Photoshop 7.0. -

Page 10: Special Tools

1-4. Special Tools Name Tool No. Application Remarks FLOIL KG- QY9-0057- To be applied to the sliding portions of the carriage shaft and lift cam shaft. common 107A with the S500 S520. 1-5. Serial Number Location On the carriage flexible cable holder (visible on the right of the carriage after the machine is turned on, the scanning unit is opened, and the carriage moves to the center). -

Page 11: List Of Error Display / Indication

2. LIST OF ERROR DISPLAY / INDICATION Errors and warnings are displayed by the following ways: 1) Operator call errors are indicated by the Alarm LED lit in orange, and the error and its solution are displayed on the LCD in text and by icon. 2) In printing from a computer, warnings are displayed on the MP driver Status Monitor. - Page 12 properly, and confirm that the [1660] LED's of all the ink tanks light red. The print head is not Print head is not installed. Install Install the print head properly. installed [1401], or it is the print head. not properly installed ...

-

Page 13: Service Call Errors

Failed in automatic Auto head align has failed. Press Press the OK button. The error is indicated print head alignment. [OK] and repeat operation. <See - If paper is being fed at error when the pattern is not occurrence, the error is printed due to no ink or [2500] manual>... - Page 14 - Logic board ass'y (QM2- 3078) - Carriage motor (QK1- 1500) 3 times Line feed error [6000] An error occurred in the line feed signal. - Timing sensor unit (QM2- 2683) - Timing slit disk film (QC1-6229) - Feed roller ass'y (QL2- 0925) - Platen unit (QM2-2923) - Logic board ass'y (QM2-...

-

Page 15: Other Error Messages

- Purge unit (QM2-2925) 17 times Motor driver error [6D00] The AD conversion value indicating the motor - Logic board ass'y (QM2- driver temperature is not proper. 3078) 19 times Ink tank position sensor None of the ink tank position is detected. - Platen unit (QM2-2923) error [6502] - Logic board ass'y (QM2-... -

Page 16: Warnings

999. returns to the value before the error. Memory card is not set. Insert the No memory card is inserted in the slot. Set a memory card. card after checking the direction. DPOF information is not saved in DPOF print was selected in the menu, The error message is displayed for a the memory card. -

Page 17: Troubleshooting By Symptom

rise of the print head error code "5200" is displayed, indicating the specified limit, an intermission is inserted temperature print head temperature rise error. during printing. Restrictions on paper The current paper cannot be set. Change the Re-select the supported paper type and size. size and type. - Page 18 - LCD, or - logic board ass'y Paper feed problems (multi- - Examine the inside to confirm that no parts are feeding, skewed feeding, no damaged, and the rollers are clean. feeding) - Remove foreign material. - Adjust the paper guide properly. - Confirm the connection of each harness and the logic board.

- Page 19 No ejection of black ink. - Replace the - logic board ass'y - ink tank, or - print head - Remove foreign material from the purge unit caps, if any. - Replace the purge unit. Graphic or text is enlarged on When enlarged in the carriage movement printouts.

-

Page 20: Repair

3. REPAIR 3-1. Notes on Service Part Replacement (and Disassembling / Reassembling) Service part Adjustment / settings Operation check Notes on replacement Logic board ass'y - Before removal of the logic - EEPROM information After replacement: board ass'y, remove the print QM2-3078 1. - Page 21 Purge unit: QM2- secure the waste ink tube to 1. To protect the waste ink case unit, the tube 2925 the waste ink tube holder. tube from being pinched conditions are not visible. when reassembling the For confirmation of the Waste ink tube: QC1- machine unit chassis into tube conditions, perform...

-

Page 22: Special Notes On Repair Servicing

3-2. Special Notes on Repair Servicing (1) External cover and scanner unit removal (I) Remove 2 screws from the left and right sides of the paper support unit. (II) Open the scanner cover, and remove 2 screws from the front left and right sides of the unit. (III) While holding the scanner unit, remove the side cover L and R (QC1-7918 / 7919). - Page 23 (IV) Remove 2 flexible cables between the logic board and the scanner unit, 1 connector, 2 ground wires (the one between the scanner unit and the logic board, and the one between the scanner unit and the chassis AC adapter side), then separate the scanner unit from the machine unit.

- Page 24 (V) While pushing the tab to the left as shown below, remove the scanner stop arm unit (QM2-2928). When assembling the scanner stop arm unit, make sure it is in the correct orientation, as shown in the photos below (overhead view). 1-18...

- Page 25 (VI) To remove the main case unit, remove 2 screws on the left and right sides, as shown below. (VII) Remove 2 screws. 1-19...

- Page 26 (VIII) Release 2 hooks on the rear side of the machine, and remove the main case unit. (2) Panel front cover L and R (QC1-7592 / 7593) removal (I) Remove the operation panel L and R. (II) While releasing the internal hook by inserting a pair of tweezers or a flat-blade screwdriver into the hole, remove the panel front cover L and R, as shown in the photos below.

- Page 27 How to use the screwdriver to release the hook (the panel front cover is removed for clear vision): (3) Document pressure sheet replacement Follow the procedures below when replacing the document pressure sheet: (I) Position one of the corners of the document pressure sheet at the reference mark. (II) The 4 corners of the document pressure sheet will be fixed to the document cover with the adhesive tape when the cover is closed.

- Page 28 (4) Flexible cable and harness wiring, connection Be careful of wiring of the flexible cables and harness. Improper wiring or connection may cause breakage of a line, leading to ignition or emission of smoke. (I) Logic board ass'y wiring (II) Paper feed motor side wiring 1-22...

- Page 29 (5) Machine unit and bottom case unit assembly In assembling the machine unit chassis into the bottom case unit, be cautious of the following points to protect the waste ink tube from being pinched: Platen unit (QM2-2202), purge unit (QM2-2208), waste ink tube (QC1-6548), waste ink tube holder (QC1-6460): (I) At replacement, fix the waste ink tube to the machine chassis and waste ink tube holder with tape (at 2 locations).

- Page 30 (II) After securing the waste ink tube with tape, be careful not to damage the tube in installing the machine unit chassis in the bottom case unit. With the units assembled, the tube conditions are not visible. To confirm the tube is free from damage, perform the manual purging 3 or 4 times, and confirm that no strange noise is heard.

-

Page 31: Adjustment / Settings

3-3. Adjustment / Settings (1) Paper feed motor adjustment Perform the following adjustments when the paper feed motor unit is replaced: 1) When attaching the motor, fasten the screws so that the belt is properly stretched (in the direction indicated by the blue arrow in the figure below). - Page 32 slides KG107A Carriage shaft sliding CR Shaft Floil portion (to the end of the 9 to 18 mg Spring L KG107A spring) Adjust Floil Carriage shaft cam R sliding 18 to 36 mg Plate R KG107A portion Carriage shaft surface where the carriage slides (and Floil 9 CR Shaft (9)

- Page 33 3) PR shaft / LF roller bushing Number of locations to Where to apply Grease / oil Grease / oil Number of Part name apply grease / oil name amount drops* grease / oil+H18 LF Roller LF roller bushing Floil (11) 4.5 to 9 mg...

- Page 34 (3) Waste ink counter setting When the logic board ass'y is replaced, reset the waste ink counter. In addition, according to the waste ink amount, replace the waste ink absorber (ink absorber kit). The standard amount for waste ink absorber replacement is given in the table below.

-

Page 35: Service Test Print

Automatic / manual print head Set a sheet of plain paper (A4 or letter) in the ASF. alignment Bottom plate cleaning Fold a sheet of plain paper (A4 or letter) in half crosswise, then unfold and set it in the ASF with the folded ridge facing down. Contrast adjustment (5) Service mode Function... - Page 36 print. Service test print 2 times Green (COPY) EEPROM information See 3-4. Verification Items, (2) EEPROM print information print. 3 times Orange (Alarm) EEPROM initialization Once in the service mode: Press the On/Off 4 times Green (COPY) Waste ink counter button 2x after pressing the Stop button 4x.

- Page 37 Asia Supported 7 times Orange (Alarm) China Supported 8 times Green (COPY) Taiwan Supported 9 times or Orange (Alarm) Return to the menu selection more Note: After setting the destination, be sure to initialize the EEPROM. The destination setting may not be valid unless the EEPROM is initialized after destination settings.

- Page 38 5) Press the ON/OFF button to set the selected value to the EEPROM. Print EEPROM information to confirm that the value is properly set to the EEPROM. <Button and LCD test procedures> Purpose: To confirm the operation after replacement of the operation panel unit, logic board, or LCD. Procedures: 1) Press the Stop/Reset button.

-

Page 39: Verification Items

3-4. Verification Items (1) Service test print <EEPROM information contents> On the service test print (sample below), confirm the EEPROM information as shown below. (The information is given in the upper portion of the printout.) MP500: Model name JPN: Destination Vx.xx: ROM version USB (xxxxxx): USB serial number FA = xx xx xx: Reserved for plant use... - Page 40 <Service test print sample> 1-34...

- Page 41 (2) EEPROM information print <How to read EEPROM information print> Print sample: MP500 JPN V1.02 IF(USB2=1) D=004.5 ST=2005/06/27-18:30 ER(ER0=1000 ER1=5100) LPT=2005/07/09-09:09 PC(M=002 R=000 T=001 D=009 C=000) CLT(BK=2005/06/28-18:30 CL=2005/07/01-18:30) CH=00002 CT(PBK=012 BK=015 Y=013 M=001 C=001) IS(PBK=0 BK=0 Y=0 M=0 C=0) P_ON(S=00009) A_REG=1 M_REG=0 UR(A(BKoe)=-01 B(Coe)=-02 C(Moe)=-02 D(SCoe)=+01 E(SMoe)=+01 F(PBKoe)=-02 G(CLbi)=000 H(SCLbi)=+01 I(C-SC)=-01 J(M-SM)=-01 K(BK-CL)=+01 L(BKbiPP)=000 M(CLbiPP)=000 N(SCLbiPP)=000 O(NZctr)=000 P(NZedge)=000...

- Page 42 13. Power-on count (soft) 14. Automatic print head alignment by user 15. Manual print head alignment by user 16. User print head alignment values (Bkoe/Coe/Moe/SCoe/SMoe/PBKoe/CLbi/SCLbi/C-SC/M-SM/BK- CL/BKbiPP/CLbiPP/SCLbiPP/NZctr/NZedge) 17. Wiping count 18. Camera Direct Print-supported device connection record (Canon legacy, Canon PictBridge, Competitor PictBridge) 19. Bluetooth-supported device connection record 20. Longest period where printing stops 21.

- Page 43 HDEEPROM 55. Version 56. Serial number 57. Lot number 58. Print head ID 59. Ink ejection level (PBK, BK, Y, M, M2, C, C2) <Scan error history> 60. Scanner error status record (the last 2 errors, including user errors and scan errors during copying; consecutive same errors are recorded individually) To the table of contents To the top...

-

Page 44: Machine Transportation

4. MACHINE TRANSPORTATION This section describes the procedures for transporting the machine for returning after repair, etc. 1) In the service mode, press the ON/OFF button to finish the mode, and confirm that the paper lifting plate of the sheet feed unit is raised. 2) Keep the print head and ink tanks installed in the carriage. -

Page 45: Part 2: Technical Reference

Part 2 TECHNICAL REFERENCE... -

Page 46: New Technologies

1. NEW TECHNOLOGIES (1) New ink tank system (PGI-5, CLI-8) An LED is installed in each ink tank. By the LED indication, wrong installation of the ink tanks will be prevented, and the remaining ink level can be visually recognized with the ink tanks seated in the carriage. The combination of the new pigment-based black ink with higher resistance against bleeding or marker pens and the new dye-based inks with higher photo quality and weather resistance makes the new ink system strong in both photo and text printing. - Page 47 (9) Printing via Bluetooth communication (optional) The Bluetooth Unit BU-20 is available as an option. Adopting a compatible USB adapter, the BU-20, when attached to the machine, enables wireless printing from a Bluetooth-compliant computer or mobile phone. To the table of contents To the top <Part 2: 1.

-

Page 48: Cleaning Mode And Amount Of Ink Purged

2. CLEANING MODE AND AMOUNT OF INK PURGED To prevent printing problems due to bubbles, dust, or ink clogging, print head cleaning is performed before the start of printing (when the cleaning flag is on), except in the following cases: - Cleaning on arrival: Performed when the scanning unit (printer cover) is closed. - Page 49 start of the next printing. Timer cleaning - 10 If 8,640 or longer hours have elapsed (All in sequence) since the previous Black/Color cleaning till the start of the next printing. At print head 0.45 (Black) When the print head is removed and replacement 1.50 (Color) installed.

-

Page 50: Print Mode

3. PRINT MODE 3-1. Resolution (1) Normal color printing (2) Grayscale printing ... - Page 51 (3) Borderless printing (4) Duplex printing (5) Camera Direct printing (6) Copying...

- Page 52 (7) Card Direct printing To the table of contents To the top <Part 2: 3. PRINT MODE>...

-

Page 53: Faq (Problems Specific To The Mp500 And Corrective Actions)

4. FAQ (Problems Specific to the MP500 and Corrective Actions) Possible call or No. * Function Phenomenon Condition Cause Corrective action complaint Skewed paper - Paper feeding from Due to its Change the paper - Paper feeds at feeding the cassette, Photo mechanism, feeding method an angle. - Page 54 by the platen's ink remains after 3 - With Photo Paper absorber. Absorbed times of Plus Double Sided ink may attach to Bottom plate or postcards, the the platen rib(s) cleaning, wipe phenomenon is after several dozen the platen rib(s) likely to be sheets are printed, and their...

- Page 55 feeder, manually print each side of paper. - PP-101D, PP-101, When multiple Set only a single PR-101, SG-101, sheets of paper are sheet of paper in etc. set, the back side of the auto sheet Print paper being picked feeder. - Paper feeding from results up scratches the...

- Page 56 are in landscape. If the Trimming button is pressed while thumbnails are displayed, the thumbnail which reflects the trimming effects on the original image is temporarily displayed in portrait, causing the orientation Layout difference. print / - For easy operation, thumbnails are used in photo selection for...

- Page 57 *3: How to prepare and set the ASF sub-roller cleaning sheet: 1) Fold a sheet of plain paper lengthwise in half. 2) Fold the paper at approx. 60 mm from the end, and fold the folded end in half backward, as shown below. ...

- Page 58 4) With the machine turned on in the user mode, press the Menu button. Select Maintenance / Settings, Maintenance, then Roller cleaning. See "Standalone machine operation," for details. * Occurrence level: A: The symptom is likely to occur frequently. (Caution required) B: The symptom may occur under certain conditions, but likeliness is assumed very low in practical usage.

- Page 59 Part APPENDIX...

- Page 60 3. PIXMA MP500 SPECIFICATIONS <Machine> Type Desktop serial color bubble jet printer Paper feeding method Auto sheet feed (ASF, cassette, automatic duplex printing, CD / DVD printing Resolution 9,600 x 2,400dpi (Max.) - 4 x 6, borderless printing: Approx. 42 sec. (standard mode, PP-101, Full Page SCID No.

- Page 61 Serial number location On the carriage flexible cable holder (visible when the scanning unit is open) Remaining ink amount Available (automatic detection by optical method and dot count, enabled at default) detection Paper type detection Not available Available (automatic or manual alignment via MP driver Maintenance, or via the operation Print head alignment panel button in Camera Direct Printing, automatic alignment at default) *1: Only for CD / DVD printing supported regions...

- Page 62 Function Read / Write Operation panel 2.5 color LCD, 19 buttons, 6 LEDs File format JPEG (DCF, CIFF, Exif 2.21 or prior, JFIF), DPOF compliant Supported print [See 4, PRINT MEDIA SPECIFICATIONS] paper Print quality Standard, High Image correction Photo Optimizer PRO, VIVID, noise reduction, face brightener, image function optimizer Image adjustment...

- Page 63 - A photo from a 5 mega-pixel digital camera - No image correction Throughput - 4 x 6 borderless - Standard print quality - Process from pressing the printing start button to ejecting paper Supported mobile Mobile phone equipped with IrDA 1.2 port, or with Bluetooth 1.2 port phone (when the optional BU-20 is attached to the machine) Printable data...

- Page 64 Note: The ink tanks for the Japanese models are not compatible with those for the non-Japanese models. Be sure to use the appropriate ink tanks in servicing. To the table of contents To the top <Part 3: 3. PIXMA MP500 SPECIFICATIONS> 3-21...

-

Page 65: Print Media Specifications

4. PRINT MEDIA SPECIFICATIONS <Plain paper / specialty paper> The following types of paper are recommended: Paper Sheet feeder Camera Card Print feeding stacking Type Name Size Direct Direct Beam method capacity Printing Printing Printing (auto) (max.) Plain paper 64 to 105 A4, B5, LTR, ASF, 13 mm... - Page 66 T-shirt transfer TR-301 ASF, 1 sheet Cassette Envelope COM #10 241 x 105 mm ASF / 10 / 5 Cassette envelopes DL-size 220 x 110 mm ASF / 10 / 5 Cassette envelopes *1: ASF only for LGL *2: When A4 or LTR is selected for Paper Size, plain paper is selectable for Paper Type. With plain paper selected for Paper Type, printing is done with borders even when borderless printing is selected.