Brother DCP-9010CN Service Manual

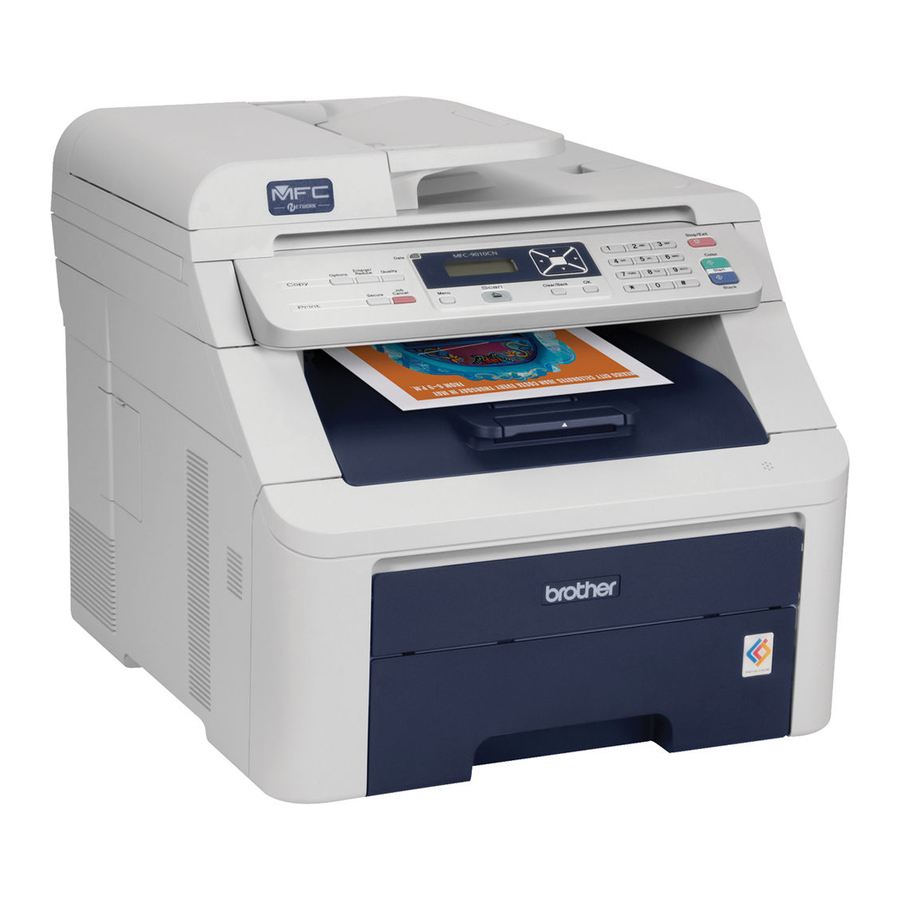

Color fax/mfc

Hide thumbs

Also See for DCP-9010CN:

- Network user's manual (249 pages) ,

- User manual (215 pages) ,

- Quick start manual (6 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Brother DCP-9010CN

-

Page 1: Service Manual

Color FAX/MFC SERVICE MANUAL MODEL: DCP-9010CN/MFC-9010CN MFC-9120CN/MFC-9125CN MFC-9320CW/MFC-9325CW Read this manual thoroughly before maintenance work. Keep this manual in a convenient place for quick and easy reference at all times. July 2009 SM-FAX113 8CE203 Confidential... - Page 2 TRADEMARKS The Brother logo is a registered trademark of Brother Industries, Ltd. Apple and Macintosh are trademarks of Apple Inc., registered in the United States and other countries. PCL is either a trademark or a registered trademark of Hewlett-Packard Company in the United States and other countries.

-

Page 3: Required After Parts Replacement

Function Center (hereinafter referred to as “the machine”). This information is vital to the service personnel to maintain the high printing quality and performance of the machine. This service manual covers the DCP-9010CN, MFC-9010CN/9120CN/9125CN/9320CW/ 9325CW machines. This manual consists of the following chapters:... - Page 4 Details of adjustments and updating of settings, which are required if the main PCB and some other parts have been replaced. This chapter also covers how to update the firmware. CHAPTER 7: SERVICE FUNCTIONS Describes the maintenance mode which is exclusively designed for the purpose of checking the settings and adjustments using the buttons on the control panel.

- Page 5 REGULATION For Europe and Other Countries ■ Radio interference (220 to 240 volt model only) This machine follows EN55022 (CISPR Publication 22)/Class B. Before you use this product, make sure that you use the following interface cable. - A USB cable. The cable must not be more than 2 meters long.

- Page 6 Important A shielded interface cable should be used to ensure compliance with the limits for a Class B digital device. Changes or modifications not expressly approved by Brother Industries, Ltd. could void the user’s authority to operate the equipment. ■ Industry Canada Compliance Statement (For Canada) This Class B digital apparatus complies with Canadian ICES-003.

-

Page 7: Safety Information

SAFETY INFORMATION ■ Definitions of Warnings, Cautions, Notes and Memos The following conventions are used in this manual: Mark Contents Warnings tell you what to do to prevent possible personal injury. Electrical Hazard icons alert you to a possible electrical shock. Hot Surface icons warn you not to touch machine parts that are hot. - Page 8 ■ Safety Precautions Listed below are the various kinds of “WARNING” messages included in this manual. WARNING There are high voltage electrodes inside the machine. Before you clean the inside of the machine or replace parts, make sure that you have turned off the power switch and unplugged the machine from the AC power outlet.

- Page 9 WARNING To prevent injuries, be careful not to put your hands on the edge of the machine under the document cover as shown in the illustration. To prevent injuries, be careful not to put your fingers in the areas shown in the illustrations. Confidential...

- Page 10 WARNING DO NOT use flammable substances, any type of spray or any organic solvent/liquids contains alcohol or ammonia to clean the inside or outside of the machine. Doing this may cause a fire or electrical shock. If the machine becomes hot, blows smoke, or generates obscure odor, immediately turn off the power switch and unplug the machine from the AC power outlet.

-

Page 11: Specifications

CHAPTER 1 SPECIFICATIONS Confidential... -

Page 12: Table Of Contents

CHAPTER 1 SPECIFICATIONS This chapter lists the specifications of each model, which enables you to make a comparison of different models. CONTENTS 1. COMPONENTS ..................1-1 2. SPECIFICATIONS LIST ................1-2 2.1 General ........................1-2 2.2 Network Connectivity ....................1-11 2.3 Service Information....................1-17 2.4 Consumables...................... -

Page 13: Components

COMPONENTS ADF unit Document scanner unit Panel unit NCU PCB ASSY Joint cover sub ASSY LED head control PCB ASSY LED ASSY Back cover Top cover arm R Top cover arm L Side cover R ASSY Fuser cover Main fan ASSY Fuser unit Paper eject guide ASSY LV fan ASSY... -

Page 14: Specifications List

SPECIFICATIONS LIST General Model DCP9010CN MFC9010CN MFC9120CN MFC9320CW Print method Electrophotographic LED printer (Single-pass) ® ® ® Resolution Windows Server 2008, Windows Vista , Windows Server ® 600 (main scanning) x 600 2003 x64 Edition, Windows XP Professional x64 Edition, ®... - Page 15 Model MFC9125CN MFC9325CW Print method Electrophotographic LED printer (Single-pass) ® ® ® Resolution Windows Server 2008, Windows Vista , Windows Server ® 600 (main scanning) x 600 2003 x64 Edition, Windows XP Professional x64 Edition, ® ® (sub scanning) dpi, 2,400 dpi Windows Server 2003, Windows XP Home Edition/...

- Page 16 Model DCP9010CN MFC9010CN MFC9120CN MFC9320CW Noise level Sound Printing: 53 dB (A) pressure Ready: 30 dB (A) Sound Printing: LWAd = 6.5 Bell (A) power Ready: LWAd = 4.8 Bell (A) Environment Temperature Operating: 10 to 32.5 °C (50 to 90.5 °F) Non operating: 0 to 40 °C (32 to 104 °F) Storage: -20 to 40 °C (-4 to 104 °F) Humidity...

- Page 17 BR-Script 3 (PPD file for Mac OS X 10.3.9 or greater) Linux Linux printer driver for CUPS printing system (x86, x64 environment) Linux printer driver for LPD/LPRng printing system (x86, x64 environment) Download from http://solutions.brother.com/ <Viewer> Model DCP9010CN MFC9010CN MFC9120CN MFC9320CW ®...

- Page 18 XP (SP 2 or higher) or ® Windows 2000 (SP4 or higher) only <PC-Fax> Model MFC9125CN MFC9325CW ® Windows Send Yes (FaxShare Software by Brother) ® ® ® Receive Yes (for Windows Vista /Windows XP/ Windows 2007) ® Macintosh Send...

-

Page 19: Configuration Tool

Linux Web Base Management <Direct Print feature> Model DCP9010CN MFC9010CN MFC9120CN MFC9320CW Direct Print PDF version 1.7, JPEG, Exif+JPEG, (created by own printer driver), TIFF (scanned by Brother models), XPS version 1.0 Specifications are subject to change without notice. Confidential... - Page 20 Network Remote Setup Linux Web Base Management <Direct Print feature> Model MFC9125CN MFC9325CW Direct Print PDF version 1.7, JPEG, Exif+JPEG, PRN (created by own printer driver), TIFF (scanned by Brother models), XPS version 1.0 Specifications are subject to change without notice. Confidential...

- Page 21 ® Internet Explorer 5.5 or greater. For WIA, 1,200 (main scanning) x 1,200 (sub scanning) resolution. Brother Scanner Utility enables to enhance up to 19,200 (main scanning) x 19,200 (sub scanning) dpi. Specifications are subject to change without notice. Confidential...

- Page 22 Processor 1 GB 2 GB 10.6.x ® Internet Explorer 5.5 or greater. For WIA, 1200x1200 resolution. Brother Scanner Utility enables to enhance up to 19200 x 19200 dpi. ® ® PaperPort 11SE supports Microsoft SP2 or higher for Windows Specifications are subject to change without notice.

-

Page 23: Network Connectivity

2000 Professional ® Mac OS X 10.3.9 or greater If you want to use the IPv6 protocol, visit http://solutions.brother.com/ for more information. BRAdmin Professional and Web BRAdmin are available as a download from http://solutions.brother.com/ Specifications are subject to change without notice. - Page 24 2008 R2 ® Mac OS X 10.4.11, 10.5.x, 10.6.x If you want to use the IPv6 protocol, visit http://solutions.brother.com/ for more information. BRAdmin Professional and Web BRAdmin are available as a download from http://solutions.brother.com/ Specifications are subject to change without notice.

-

Page 25: Wireless Network

, Windows Server 2003, Windows XP and ® Windows 2000 TCP/IP printing ® Mac OS X 10.3.9 or greater printing If you want to use the IPv6 protocol, visit http://solutions.brother.com/ for more information. Specifications are subject to change without notice. 1-13 Confidential... - Page 26 XP Professional x64 Edition, Windows Server ® 2003, Windows XP Home Edition/Professional ® Edition, Windows 2000 Professional ® Mac OS X 10.3.9 or greater BRAdmin Professional and Web BRAdmin are available as a download from http://solutions.brother.com/ Specifications are subject to change without notice. 1-14 Confidential...

- Page 27 XP, Windows ® and Windows Server 2008 R2 TCP/IP printing ® Mac OS X 10.4.11, 10.5.x, 10.6.x printing If you want to use the IPv6 protocol, visit http://solutions.brother.com/ for more information. Specifications are subject to change without notice. 1-15 Confidential...

- Page 28 XP Home Edition/Professional ® ® Edition, Windows 7, Windows Server 2008 R2 ® Mac OS X 10.4.11, 10.5.x, 10.6.x BRAdmin Professional and Web BRAdmin are available as a download from http://solutions.brother.com/ Specifications are subject to change without notice. 1-16 Confidential...

-

Page 29: Service Information

Service Information These are key service information to maintain the product. - Machine life: approximately 100,000 pages or 5 years - MTBF (Meantime between failure): 4,000 hours - MTTR (Meantime to repair): 30 minutes - Maximum monthly volume: 25,000 pages - Periodical maintenance parts: Part Approximate life... -

Page 30: Consumables

Consumables Model All models Toner cartridge Life expectancy: Black Standard : Approximately 2,200 pages/cartridge Black Starter : Approximately 1,000 pages/cartridge Yellow, Magenta, Cyan Standard : Approximately 1,400 pages/cartridge Yellow, Magenta, Cyan Starter : Approximately 1,000 pages/ cartridge * When printing A4/Letter-size paper in accordance with ISO/IEC 19798. -

Page 31: Paper

Paper 2.5.1 Paper handling Model All models Paper Input Standard tray 250 sheets Manual feed 1 sheet slot Option Up to 35 sheets Paper Face-down 100 sheets output Face-up 1 sheet (Straight paper path) Duplex Calculated with 80 g/m (20 lb) paper 2.5.2 Media specifications Model... -

Page 32: Type And Size Of Paper

2.5.3 Type and size of paper The printer loads paper from the installed paper tray or the manual feed slot. The names for the paper trays in the printer driver as follows: The name for the paper trays The name for the paper trays in the printer driver Paper tray Tray Manual feed slot... -

Page 33: Printable Area

Printable Area ■ PCL5C emulation When using PCL5C emulation, the edges of the paper that cannot be printed on are shown below. Portrait Physical page Printable area Logical page Physical page length Maximum logical page length Distance from edge of physical page to edge of logical page Note: Therefore, the machine can only print within the shaded area when you use a PCL driver. - Page 34 The table below shows the printable areas when printing on Portrait for each paper size. Size (mm) 215.9 279.4 203.2 279.4 6.35 4.23 Letter (inch) 0.25 0.17 (dots) 2,550 3,300 2,400 3,300 (mm) 215.9 355.6 203.2 355.6 6.35 4.23 Legal (inch) 0.25 0.17...

- Page 35 Landscape Physical page Printable area Logical page Physical page length Maximum logical page length Distance from edge of physical page to edge of logical page Note: - “Logical page” shows the printable area for a PCL driver. - Therefore, the machine can only print within the shaded area when you use a PCL driver. Specifications are subject to change without notice.

- Page 36 The table below shows the printable areas when printing on Landscape for each paper size. Size (mm) 279.4 215.9 269.2 215.9 5.08 4.23 Letter (inch) 10.6 0.17 (dots) 3,300 2,550 3,180 2,550 (mm) 355.6 215.9 345.4 215.9 5.08 4.23 Legal (inch) 13.6 0.17...

- Page 37 ■ PS3/PCL6 (PCLXL) emulation When using PS3/PCL6 (PCLXL) emulation, the edges of the paper that cannot be printed on are shown below. Portrait Physical page Printable area Physical page length Maximum logical page length Note: This is equivalent to the printable area for a PS driver. Specifications are subject to change without notice.

- Page 38 The table below shows the printable areas when printing on Portrait for each paper size. Size (mm) 215.9 279.4 207.4 270.9 4.23 4.23 Letter (inch) 8.17 10.67 0.17 0.17 (dots) 2,550 3,300 2,450 3,200 (mm) 215.9 355.6 207.4 347.1 4.23 4.23 Legal (inch)

- Page 39 Landscape Physical page Printable area Physical page length Maximum logical page length Note: This is equivalent to the printable area for a PS driver. Specifications are subject to change without notice. 1-27 Confidential...

- Page 40 The table below shows the printable areas when printing on Landscape for each paper size. Size (mm) 279.4 215.9 270.9 207.4 4.23 4.23 Letter (inch) 10.67 8.17 0.17 0.17 (dots) 3,300 2,550 3,200 2,450 (mm) 355.6 215.9 347.1 207.4 4.23 4.23 Legal (inch)

-

Page 41: Print Speeds With Various Settings

Print Speeds with Various Settings Print speed is up to 18 ppm for A4 size and 19 ppm for Letter size when loading A4 or Letter size paper from the paper tray in the plain paper mode. Actual print speed varies depending on the media type or paper size as shown in the tables below: <A4/Letter size>... -

Page 42: Telephone

Telephone Model DCP9010CN MFC9010CN MFC9120CN MFC9320CW Handset Chain dialing Automatic redial PBX feature USA: N/A Europe: Yes Speaker phone Hold/Mute key Music on hold Handset volume Speaker volume Yes (3 steps + OFF) Beeper volume Yes (3 steps + OFF) Ring volume Yes (3 steps + OFF) One-touch dial... - Page 43 Model MFC9125CN MFC9325CW Handset Chain dialing Automatic redial PBX feature Speaker phone Hold/Mute key Music on hold Handset volume Speaker volume Yes (3 steps + OFF) Beeper volume Yes (3 steps + OFF) Ring volume Yes (3 steps + OFF) One-touch dial 8 (4 x 2) locations Speed dialing...

-

Page 44: Fax

Model DCP9010CN MFC9010CN MFC9120CN MFC9320CW Modem speed 33,600 bps (Fax) Transmission speed Approximately 2 seconds (Brother#1 Std resolution, JBIG) ITU-T group Super G3 Coding method MH/MR/MMR/JBIG/JPEG Color FAX Sending Yes (Not available for saving the data into the Memory) Receiving... - Page 45 Approximately 2.5 seconds/ (Memory page (A4standard) transmission) Memory up to 500 pages (ITU-T Test transmission Chart#1, Standard Resolution, (ITU-T Chart) JBIG) up to 600 pages (Brother #1 Chart, Standard Resolution, JBIG) Error Re-Transmis- sion Broadcasting Yes (258 locations) Manual Yes (50 locations)

- Page 46 Model MFC9125CN MFC9325CW Modem speed 33,600 bps (Fax) Transmission speed Approximately 2 seconds (Brother#1 Std resolution, JBIG) ITU-T group Super G3 Coding method MH/MR/MMR/JBIG/JPEG Color FAX Sending Yes (Not available for saving the data into the Memory) Receiving Yes (Not available for saving the data into the Memory)

- Page 47 Approximately 2.5 seconds/page (A4standard) (Memory transmission) Memory up to 500 pages (ITU-T Test Chart#1, Standard Resolution, transmission JBIG) (ITU-T Chart) up to 600 pages (Brother #1 Chart, Standard Resolution, JBIG) Error Re-Transmis- sion Broadcasting Yes (258 locations) Manual Yes (50 locations)

-

Page 48: List/Report

2.10 List/Report Model DCP9010CN MFC9010CN MFC9120CN MFC9320CW Activity report/Journal report Yes (Up to 200) Transmission verification report Coverpage Yes (Super) Help list Call back message Caller ID list Tel Index list Numeric Alphabetic Memory status list System setup (User setting) list Model MFC9125CN... -

Page 49: Copy

2.11 Copy Model DCP9010CN MFC9010CN MFC9120CN MFC9320CW Copy speed Monochrome Up to 16 cpm (A4 size) simplex Up to 17 cpm (Letter size) Color First copy Monochrome Less than 19 seconds out time Color Less than 24 seconds (from ready mode) Multi copy Stack... -

Page 50: Scanner

2.12 Scanner Model DCP9010CN MFC9010CN MFC9120CN MFC9320CW Color/Monochrome Color Resolution Maximum scanning 1,200 (main scanning) x 2,400 dpi (sub (Optical) scanning) Maximum scanning 1,200 (main scanning) x 600 dpi (sub scanning) Resolution (Interpolated) 19,200 (main scanning) x 19,200 (sub scanning) dpi Scanning Monochrome 2.35 (Letter)/2.49 (A4) seconds speed... - Page 51 Model MFC9125CN MFC9325CW Color/Monochrome Color Resolution Maximum scanning 1,200 (main scanning) x 2,400 dpi (sub (Optical) scanning) Maximum scanning 1,200 (main scanning) x 600 dpi (sub scanning) Resolution (Interpolated) 19,200 (main scanning) x 19,200 (sub scanning) dpi Scanning Monochrome 2.35 (Letter)/2.49 (A4) seconds speed Color 7.04 (Letter)/7.48 (A4) seconds...

-

Page 52: Usb Direct Interface

1.0 Media drive Model MFC9125CN MFC9325CW PictBridge Direct print PDF version 1.7, JPEG, Exif+JPEG, PRN (created by own printer driver), TIFF (scanned by Brother model), XPS version 1.0 Media drive Specifications are subject to change without notice. 1-40 Confidential... -

Page 53: Theory Of Operation

CHAPTER 2 THEORY OF OPERATION Confidential... - Page 54 CHAPTER 2 THEORY OF OPERATION This chapter gives an overview of the printing mechanisms as well as the sensors, actuators and control electronics. It aids in understanding the basic principles of operation as well as locating defects for troubleshooting. CONTENTS 1.

- Page 55 3.7 Location of Sensors ....................2-30 3.8 Adjustment of Color Registration ................2-34 3.8.1 Color registration error in sub/main scanning direction ........2-34 3.9 Adjustment of Color Density ..................2-34 Confidential...

-

Page 56: General Block Diagram

GENERAL BLOCK DIAGRAM Video control system CIS unit Interface USB device or DIMM (USB direct) Digital camera ADF sensor 144 pin (USB direct interface model) Speaker Interface Internal (Wired LAN) Battery (FAX model) Interface (Wireless LAN module) Low-voltage (Wireless LAN model) power supply block Video control block Telephone... -

Page 57: Electronics General Block Diagram

ELECTRONICS GENERAL BLOCK DIAGRAM Develop drive motor Toner/New sensor PCB Paper feed motor Drum motor origin sensor PCB Belt drive motor Internal temperature thermistor Develop release motor Engine PCB Fuser/eject drive motor Drum drive motor Registration solenoid Pick-up solenoid Density sensor shutter solenoid LV fan High-voltage HVPS... -

Page 58: Mechanics

MECHANICS Cross-section Drawing ■ Printer part Exposure drum (M) Exit roller 2 Cleaner sponge Pinch roller 2 Exit roller Exposure drum (C) Exposure drum (Y) Exposure drum (K) Pinch roller Develop roller Paper eject guide Supply roller Back cover Registration rear actuator Paper eject rear actuator <Front>... - Page 59 ■ ADF part Separation roller shaft ASSY Ejection roller Separation pad Suction roller Separation roller Pressure roller Pressure roller Paper feed roller Pulley ASSY Pressure roller Document rear actuator CIS unit Document front sensor Document rear sensor Timing belt Document front actuator <Left side>...

-

Page 60: Scanner Mechanism

Scanner Mechanism This mechanism consists of the document cover, the document scanner unit (scanner cover), and the automatic document feeder (ADF). The document scanner unit consists of a scanner top cover, CIS unit, CIS drive ASSY, and scanner base. Document cover ADF &... -

Page 61: Document Scanner Unit

3.2.1 Document scanner unit The document scanner unit is equipment which scans the paper using the CIS unit. This machine prints the scanning data (copy) or data is sent by fax (fax transmission). There are two kinds of scanning method of the document scanner unit. One is operation to scan with the document scanner unit, the paper is placed on the document glass, the CIS unit moves is the bottom of it, and it scans the paper, and other is operation to scan in connection with the ADF unit, scan the paper which has been sent over the immovable CIS unit. - Page 62 (5) Scanning operation (The CIS unit moves under the immovable document.) Open the document cover, place a sheet of the document (or opened book) onto the document glass, and close the document cover. Then, the machine starts scanning by the operation of the panel, and the CIS drive mechanism is started and the scanning operation is started.

-

Page 63: Adf Unit

3.2.2 ADF unit The ADF unit is equipment which sends one document or the document for every plurality to the ADF scanning part of the document scanner unit, and performs continuous scanning. ■ Performance of the ADF - The number of maximum capacity: Up to 35 sheets - Maximum resolution: Up to 1,200 (main scanning) x 600 (sub scanning) dpi - Maximum scanning speed: 17 pages/minute (Letter size) 16 pages/minute (A4 size) (Simplex scanning) - Page 64 (4) Internal structure The automatic document feeder (ADF) consists of the separation roller shaft ASSY, paper feed roller, ejection roller, ADF motor, document rear sensor, document front sensor and ADF cover open sensor. For further details on the sensors, refer to “3.7 Location of Sensors”...

-

Page 65: Paper Feeding

Paper Feeding Paper eject function (Refer to “3.3.4”) Manual feed slot path <Front> <Back side> Manual feed function (Refer to “3.3.5”) Paper pick-up function (Refer to “3.3.2”) Plate-up function Paper tray path (Refer to “3.3.1”) Fig. 2-9 Confidential 2-10... -

Page 66: Plate-Up Function Of The Paper Tray

3.3.1 Plate-up function of the paper tray The plate of the paper tray is pushed up by the force exerted by the motor not by springs so as to keep the pressure on the paper pick-up roller at a certain level and enhance the paper-feeding performance irrespective of the quantity of remaining papers in the tray. -

Page 67: Paper Supply

3.3.2 Paper supply When the paper pick-up solenoid is turned ON, the power of the paper feed motor rotates the paper pick-up roller, and it picks up a few sheets or one sheet of paper from the top of the sheets in the paper tray every time it is rotated and feeds it to the separation roller. -

Page 68: Paper Registration

3.3.3 Paper registration Passing of each sheet of paper which is separated by the separation roller is detected by the registration front actuator. Then, the paper is fed further for a certain time, and its front edge hits the stopped PF registration roller so that the paper skew is corrected. After such correction, the registration solenoid is turned OFF, the power of the paper feed motor rotates the PF registration roller, and the paper is fed to the belt unit. -

Page 69: Paper Eject

3.3.4 Paper eject Drive of the fuser/eject drive motor rotates the heat roller and pressure roller of the fuser unit, and toner on paper is fused as the paper is being fed. Paper moves along the paper eject guide and is ejected into the output tray from the exit roller 2 with its print side down. Exit roller 2 Paper eject guide Paper eject rear actuator... -

Page 70: Paper Supply From Manual Feed Slot And Paper Eject From Back

3.3.5 Paper supply from manual feed slot and paper eject from back When making print from the manual feed slot, set papers on it with the print side up. A sheet of paper which is inserted from the manual feed slot one by one presses the manual paper actuator, and consequently the actuator detects that there is a sheet of paper. -

Page 71: Toner Cartridge

Toner Cartridge 3.4.1 Type of toner cartridge This product has four types of toner cartridges, K (black), Y (yellow), M (magenta), and C (cyan), and each toner cartridge has starter toner cartridge and standard toner cartridge. The toner cartridges supplied with the product are starter toner cartridges, and the toner cartridges which are sold as consumable parts are standard toner cartridges. -

Page 72: Method Of Detecting Toner Life

3.4.3 Method of detecting toner life This product detects the life of the toner cartridges using the following two means. ■ Detection by the toner sensor This product has a function to detect the remaining toner by checking the level at which toner in a cartridge interrupts light using a transmissive light sensor. - Page 73 <Life of toner cartridge> The life of the toner cartridge varies according to the average number of print pages per job. (See the table below.) The number of printable pages is larger when making continuous prints in one job because deterioration of the develop roller is low. Relationship between average print page per 1 job and life of toner cartridges Average print page (page/job) Cartridge life (Standard-K)

-

Page 74: New Toner Detection

3.4.5 New toner detection When a toner cartridge is replaced and a new toner cartridge is mounted, there is a need to reset the develop bias voltage value (refer to next page) to the initial value and to reset prohibition of the print operation by clearing the display of “Toner Low” or “Replace Toner.” The old and new toner cartridges can be identified using the new toner detection mechanism shown below. - Page 75 ■ Developing bias voltage Toner in use tends to have a low print density at the beginning of its use, but the density gradually becomes higher after a certain period of use if the bias voltage is kept at a certain level during development.

-

Page 76: Method Of Counting The Number Of Toner Replacements

3.4.6 Method of counting the number of toner replacements This machine keeps the number of times that the toner cartridges are replaced and the page counters to learn the usage of the machine. These counters will not be deleted even if the power is turned OFF. -

Page 77: Principle Of Color Overlapping

Principle of Color Overlapping The human eye distinguishes one color from others by receiving light’s three primary colors (Red, Green, Blue). When monochrome lights are received, each color can be sensed. However, when two-color lights, red (R) and green (G), are received, they are recognized as “yellow”;... -

Page 78: Basic Printing Principle

Basic Printing Principle The printing process consists broadly of 6 processes: Charging, Exposure, Development, Transfer, Fusing and Cleaning. <Printing process> (1) Charging: The surface of the drum is electrically charged (Primary Charge). (2) Exposure: A printed image is formed on the surface of the drum by applying LED beam (Electrostatic Latent Image). -

Page 79: Charging

3.6.1 Charging The exposure drum needs to be evenly electrified to coat toner beautifully on the exposure drum. Ions are produced by supplying high-voltage power to the corona wire. The flow of the ion charge is controlled by the constant voltage of the grid approximately 700 V and electrified the exposure drum surface evenly. -

Page 80: Exposure

3.6.2 Exposure Exposure is conducted by LED (Light Emitting Diode) arrays. Four LED arrays for K, Y, M and C are mounted as an LED ASSY on the top cover unit of the main unit. These four LED arrays do not emit different colors corresponding to toner colors, and they are the same parts in terms of structure. -

Page 81: Development

3.6.3 Development Toner is attracted to the latent-image area on the exposure drum where surface potential is lowered due to exposure. By controlling the developing bias voltage supplied to the develop roller, the amount of toner taken to the exposure drum is adjusted to keep printing density constant. 400 V (Changes depending on use condition) LED beam... -

Page 82: Transfer

3.6.4 Transfer By applying a minus charge to the transfer roller of the belt unit, the toner adhered to the exposure drum is transferred to paper which is traveling on the feed belt. Exposure drum (K) Exposure drum (Y) Exposure drum (M) Exposure drum (C) Belt unit Feed belt... -

Page 83: Fusing

3.6.5 Fusing The toner transferred on to the paper passes between the heat roller and the pressure roller in the fuser unit and are fused by heat and pressure. The main CPU detects surface temperature of the heat roller using the thermistor and turns ON/OFF the halogen heater lamp to keep the temperature constant. -

Page 84: Toner Cleaning

3.6.6 Toner cleaning <Flow of toner cleaning> (1) Toner remaining on the exposure drum which has not completely been transferred on to the paper is pulled onto the drum cleaner with a lower potential and the drum is cleaned. (2) After the above step, the potential of the drum cleaner is raised during printing, and such attracted toner is returned to the exposure drum again. - Page 85 Location of Sensors Name of sensor Type Position Function Paper eject rear Photosensor On the eject rear sensor The paper eject rear sensor PCB ASSY in the paper actuator detects that eject guide ASSY the paper passes through the fuser unit to check that no paper jam occurs between the heat roller and exit...

- Page 86 Name of sensor Type Position Function Belt thermistor Thermistor Registration sensor Detects temperature holder ASSY in the product (at the center). Drum motor origin Photosensor On the drum motor Detects the phase of sensor origin sensor PCB ASSY the drum motor. in the side frame L Fuser/eject drive Photosensor...

- Page 87 ■ Location of sensors Registration mark sensor L Belt thermistor Registration mark sensor R Density sensor Eject gear cover Waste toner sensor holder Registration rear sensor Fuser/eject drive motor sensor Registration front sensor Registration front/rear Registration sensor sensor PCB ASSY holder ASSY Manual sensor Waste toner sensor...

- Page 88 Fuser center thermistor Fuser side thermistor Fuser unit <Front> Fig. 2-32 Document front sensor ADF cover open sensor ADF unit Document rear sensor ADF sensor PCB ASSY Document scanner unit <Front> Fig. 2-33 2-33 Confidential...

-

Page 89: Adjustment Of Color Registration

Adjustment of Color Registration In this device, the drum and develop unit are prepared for K, Y, M, and C respectively. Four color images are combined into one image, and therefore color registration error might occur. Auto color registration error correction control is to calculate the color registration error amount and adjust the exposure timing as a means to prevent color registration error. - Page 90 CHAPTER 3 ERROR INDICATION AND TROUBLESHOOTING Confidential...

- Page 91 CHAPTER 3 ERROR INDICATION AND TROUBLESHOOTING This chapter details error messages and codes which the incorporated self-diagnostic function of the machine will display if any error or malfunction occurs. If any error message appears, refer to this chapter to find which parts should be checked or replaced. The latter half of this chapter provides sample problems which could occur in the main sections of the machine and related troubleshooting procedures.

- Page 92 7.1 Definition of Error Codes on the Communications List ..........3-88 8. TROUBLESHOOTING OF THE CONTROL PANEL COVER ASSY..3-94 8.1 Nothing is Displayed on the LCD................3-94 8.2 The control panel cover ASSY does not Work............3-95 9. TROUBLESHOOTING OF FAX FUNCTIONS .........3-96 9.1 FAX can't Send it.

-

Page 93: Introduction

INTRODUCTION Troubleshooting is the countermeasure procedures that the service personnel should follow if an error or malfunction occurs with the machine. It is impossible to anticipate all of the possible troubles which may occur in future and determine the troubleshooting procedures, so this chapter covers some sample troubles. -

Page 94: Components

Components ADF unit Document scanner unit Panel unit NCU PCB ASSY Joint cover sub ASSY LED head control PCB ASSY LED ASSY Back cover Top cover arm R Top cover arm L Side cover R ASSY Fuser cover Main fan ASSY Fuser unit Paper eject guide ASSY LV fan ASSY... -

Page 95: Initial Check

Initial Check Check the following items before attempting to repair the machine. ■ Operating environment (1) Put your machine on a flat, stable surface such as a desk that is free of vibration and shocks. (2) Use the machine in a well-ventilated room; use the machine within the following ranges of temperature and humidity: temperature between 10 °C and 32.5 °C (50 °F to 90.5 °F) , and the relative humidity is maintained between 20 % and 80 %. - Page 96 ■ Others (1) Condensation When the machine is moved from a cold place into a warm room, condensation may occur inside the machine, causing various problems as listed below. - Condensation on the optical surfaces such as the LED array may cause the print image to be light.

-

Page 97: Error Indications

ERROR INDICATIONS This machine includes a self-diagnosis function. If the machine does not work normally it judges that an error has occurred, and indicates the corresponding error message on the LCD, which in turn helps the service men to quickly find out the problem. Error Codes Error Refer... - Page 98 Error Refer Error Refer Problem Problem codes codes Drum life end (C) 3-23 Machine cooling down inside 3-32 Drum life end soon (K) 3-24 Fuser unit error (The center thermistor 3-26 detects rapid temperature rising.) Drum life end soon (Y) 3-24 Drum life end soon (M) 3-24...

- Page 99 Error Refer Error Refer Problem Problem codes codes 3-39 Identification failure for a new toner 3-46 Detection of incorrect registration sensor cartridge (C) measurement value when implementing adjustment of color registration from the Pressure engagement/disengagement 3-47 control panel cover ASSY failure of toner cartridge 3-31 Insufficient memory...

-

Page 100: Error Messages

Error Messages The error messages displayed on the LCD of the product and their description and measure are shown in the table below. Description/Measure Error message Refer to: Access Error The USB device was removed while data was 3-48 (USB direct interface processing. - Page 101 Description/Measure Error message Refer to: Jam XXX Carefully pull out the jammed paper from the area shown 3-37 in the message. 3-38 3-58 Low Temperature Increase room temperature to allow the machine to operate. Manual Feed Put the same size of paper in the manual feed slot as is 3-41 shown on the LCD.

- Page 102 Description/Measure Error message Refer to: Replace PF Kit1 It is time to replace the paper feeding kit. Replace the 3-24 paper feeding kit. Scan Unable XX The machine has a mechanical problem. 3-43 3-45 Short paper Open the back cover (back-output tray) to let the printed 3-27 paper out on the back-output tray and then press Start/ Black button.

-

Page 103: Error Cause And Remedy

Error Cause and Remedy Check the User Check items first. If an error cannot be resolved, follow the procedures in numerical order in the Step field. ■ Error code 10 Color registration adjustment failure (Error, which cannot be recorded, occurs.) Step Cause Remedy... - Page 104 ■ Error code13 An error, which cannot be recorded, occurs while correction of developing bias is performed. <User Check> - Replace the belt unit with a new one. Step Cause Remedy Registration mark L PCB ASSY Replace the registration sensor holder failure ASSY.

- Page 105 ■ Error code 16 An error, which cannot be recorded, occurs while auto color registration is performed. <User Check> - Replace the belt unit with a new one. Step Cause Remedy Registration mark L PCB ASSY Replace the registration sensor holder failure ASSY.

- Page 106 ■ Error code 1A Print Unable 1A Turn the power switch off and open the top cover, wait 30 minutes, and then turn it on again. Dew condensation might have occurred in the machine. (The temperature/humidity sensor on the high voltage control PCB detects sudden environmental change.) / High-voltage power supply PCB error <User Check>...

- Page 107 ■ Error code 20 (K), 21 (Y), 22 (M), 23 (C) Print Unable 20 Turn the power off and then back on again. Print Unable 21 Turn the power off and then back on again. Print Unable 22 Turn the power off and then back on again. Print Unable 23 Turn the power off and then back on again.

-

Page 108: Error Code 25

■ Error code 25 Print Unable 25 Turn the power off and then back on again. Develop drive motor error (Incorrect synchronized signal of the develop drive motor) Error code 26 Print Unable 26 Turn the power off and then back on again. Belt drive motor error Error code 28 Print Unable 28... - Page 109 ■ Error code 2A Print Unable 2A Turn the power off and then back on again. Develop release motor error Step Cause Remedy Harness connection failure of Check the harness connection of the develop release motor develop release motor and reconnect it. Develop release motor failure Replace the develop release motor ASSY.

- Page 110 ■ Error code 31 Print Unable 31 Turn the power off and then back on again. Density sensor error (Incorrect measurement value of the density sensor) Error code 32 Print Unable 32 Turn the power off and then back on again. Density sensor shutter performance malfunction <User Check>...

- Page 111 ■ Error code 33 Print Unable 33 Turn the power off and then back on again. Right color registration sensor error (Incorrect reading value of the color registration sensor (Right)) Error code 34 Print Unable 34 Turn the power off and then back on again. Left color registration sensor error (Incorrect reading value of the color registration sensor (Left)) <User Check>...

- Page 112 ■ Error code 36 Print Unable 36 Turn the power off and then back on again. Error occurs while the high-voltage power supply PCB is in ready state. Error code 40 Print Unable 40 Turn the power off and then back on again. Error occurs while the high-voltage power supply PCB is in operation * After the error code 36 is displayed for 5 seconds, the power of the main unit is forcibly turned off, and it takes 10 minutes to recover.

- Page 113 ■ Error code 38 Print Unable 38 Turn the power off and then back on again. External temperature sensor error Error code 39 Print Unable 39 Turn the power off and then back on again. External humidity sensor error Step Cause Remedy HVPS control PCB failure...

- Page 114 ■ Error code 42 Print Unable 42 Turn the power off and then back on again. HVPS control PCB transfer error Step Cause Remedy Harness connection failure of Check the harness connection between high-voltage power supply PCB the high-voltage power supply PCB ASSY ASSY and HVPS control PCB ASSY, and reconnect it.

- Page 115 ■ Error code 44 (K), 45 (Y), 46 (M), 47 (C) No Toner Open the Top Cover, then install Toner Cartridge. Black (K) No Toner Open the Top Cover, then install Toner Cartridge. Yellow (Y) No Toner Open the Top Cover, then install Toner Cartridge. Magenta (M) No Toner Open the Top Cover, then install Toner Cartridge.

- Page 116 ■ Error code 4C (K), 4D (Y), 4E (M), 4F (C) Drum End Soon (K) Drum End Soon (Y) Drum End Soon (M) Drum End Soon (C) The drum unit will reach the end of life soon. (The drum counter value reaches 90 % of life.) * When all four colors reach 90 % of the life at the same time.

- Page 117 ■ Error code 56 Cover is Open Close the Fuser Cover which can be found behind the Back Cover of the machine. Fuser cover opened (Eject front sensor sticking at ON) <User Check> - Check if the fuser cover is closed correctly. Step Cause Remedy...

- Page 118 Error code 6D Print Unable 6D Turn the power off and then back on again. Fuser unit error (The center thermistor detects lower temperature than the specified value.) Error code 6F Print Unable 6F Turn the power off and then back on again. Fuser unit error (The center or side thermistors detect extremely high temperature.) Error code 76 Print Unable 76...

- Page 119 ■ Error code 5B Short paper Open the Back Cover and then press Start. Paper of which size is not supported is used. (Paper of less than 148 mm length is fed.) <User Check> - Open the back cover and remove the paper. ■...

- Page 120 ■ Error code 5F WT Box End Soon The waste toner box near full. (The waste toner sensor detects the always ON state.) Note: The same message appears in the case of the error code F2. <User Check> - Prepare a new waste toner box. Step Cause Remedy...

- Page 121 ■ Error code 60 (C), 61 (M), 62 (Y), 63 (K) Replace Toner Open the Top Cover, replace Toner Cartridge. Cyan (C). Replace Toner Open the Top Cover, replace Toner Cartridge. Magenta (M). Replace Toner Open the Top Cover, replace Toner Cartridge. Yellow (Y). Replace Toner Open the Top Cover, replace Toner Cartridge.

- Page 122 ■ Error code 64 (C), 65 (M), 66 (Y), 67 (K) Toner Low (#) * Any of K, Y, M, or C, which refer to colors, is indicated in #. Toner cartridge will reach the end of life soon. (The counter value of the develop roller reaches 90 % of life, or the toner sensor detects toner near empty.) <User Check>...

- Page 123 ■ Error code 73 Print Unable 73 Turn the power off and then back on again. Recording ASIC read/write error Step Cause Remedy Harness connection failure of Check the harness connection between LED head control PCB ASSY the main PCB ASSY and LED head control PCB ASSY, and reconnect them.

- Page 124 ■ Error code 75 Cooling Down Cooling down the inside of the machine to protect it. The machine indicates “Cooling Down” in one of the conditions below. - The temperature inside the machine is high. - Both ends of the heat roller are heated extraordinarily. - The paper media is replaced.

- Page 125 ■ Electrodes location of the drum unit and toner cartridge * Black only Fig. 3-3 ■ Electrodes location of the belt unit Fig. 3-4 3-33 Confidential...

- Page 126 ■ Electrodes location of waste toner box Fig. 3-5 ■ Electrodes location of main body Fig. 3-6 < > How to clean the electrodes Turn off the power switch. Unplug the machine from the AC power outlet, and leave the machine for a few minutes.

- Page 127 ■ Error code 7F Size mismatch Fax received. Set correct paper size in menu. Fax paper setting mismatch (The setting paper becomes besides the A4/Letter/Legal/Folio) Error code 80 Size mismatch Reload correct paper. Fax paper size is incorrect (The paper is smaller 10 mm than the Letter size in Fax List/Report) <User Check>...

- Page 128 ■ Error code 81 Calibrate Calibration failed. See Troubleshooting chapter in User’s Guide. Incorrect density sensor measurement value when implementing adjustment of color density from the control panel cover ASSY. Error code 82 Calibrate Calibration failed. Press Start, and try again. Density patch measurement is not completed normally when implementing adjustment of color density from the control panel cover ASSY.

- Page 129 ■ Error code 84 Jam Rear Open the Back Cover and remove the jammed paper, then press Start. Paper jam at the back of the machine inside (The eject front sensor sticks at ON after the registration rear actuator is turned OFF.) Error code 88 Jam Inside Open the Top Cover, pull out all 4 Drum Units completely and remove the...

- Page 130 ■ Error code 8A Jam Tray 1 Remove the jammed paper from Tray 1, then press Start. Paper jam in the paper tray (The registration front sensor sticks at ON.) <User Check> - Check if the paper is jammed in the paper tray. If jammed, remove it. - Adjust the paper guide corresponding to the paper size.

- Page 131 ■ Error code 8E Registration Registration failed. Press Start, and try again. Error in the adjustment of color registration result when implementing it from the control panel cover ASSY. Error code 8F Registration Registration failed. See Troubleshooting chapter in User’s Guide. Detection of abnormal value of registration sensor sensitivity when implementing adjustment of color registration from the control panel cover ASSY Error code 9D...

- Page 132 ■ Error code 94 No Paper Load <size> paper, then press Start. - No paper in paper tray (The registration front actuator is not turned ON after a certain period of time has passed.) - Paper tray is not installed into the machine. <User Check>...

- Page 133 ■ Error code 9A Manual Feed Load <size> Paper. No paper in manual feed slot (The manual paper actuator is not turned ON.) Drum Cleaning Insert the blank paper into the Manual feed slot. No paper is inserted on the manual feed slot when drum cleaning is executed. (The manual paper actuator is not turned ON.) <User Check>...

- Page 134 ■ Error code A1 Cover is Open Close the Top Cover. Top cover opened (The top cover open switch sticks at OFF.) <User Check> - Close the top cover. Step Cause Remedy Harness connection failure of top Check the harness connection of the top cover switch ASSY cover switch ASSY and reconnect it.

- Page 135 ■ Error code A4 Cover is Open Close the ADF cover, then press Stop Key. The ADF cover open sensor is OFF. <User Check> - Close the ADF cover. Step Cause Remedy ADF cover open sensor actuator Correct catching of the ADF cover open catching on some position.

- Page 136 ■ Error code A7 Scan Unable A7 See Troubleshooting and routine maintenance chapter in User’s Guide. Scanning color parameter file failure Error code A8 Scan Unable A8 See Troubleshooting and routine maintenance chapter in User’s Guide. Scanning color parameter error for recording the image Step Cause Remedy...

- Page 137 ■ Error code B0 Scanner Error The harness of the CIS unit is inserted incompletely. * This error is indicated on the LCD in the maintenance mode. Step Cause Remedy Incomplete insertion of the Reconnect the harness for the CIS unit harness of the CIS unit correctly.

- Page 138 Error code BB Scanner Error White level data error * This error is indicated on the LCD in the maintenance mode. Error code BD Scanner Error Black level data error * This error is indicated on the LCD in the maintenance mode. Step Cause Remedy...

- Page 139 ■ Error code C6 Toner Error One or more Toner Cartridges are not detected. Pull out and reinsert all 4 Toner Cartridges. Pressure engagement/disengagement failure of toner cartridge (Develop release sensor output error) Step Cause Remedy Harness connection failure of Check the harness connection of the develop release motor develop release motor and reconnect it.

- Page 140 ■ Error code C9 DIMM Error Make sure that the DIMM is inserted correctly. DIMM error <User Check> - Check if the DIMM is installed correctly. - Replace the DIMM with a new one. ■ Error code CA Unusable Device Remove the Device.

- Page 141 ■ Error code CB No Belt Unit Open the Top Cover, pull out all 4 Drum Units completely and install the Belt Unit. Belt unit is not installed into the machine. (The density sensor detects that the belt unit is not installed.) <User Check>...

- Page 142 ■ Error code CF Replace WT Box Replace the Waste Toner Box. Refer to the User’s Guide for instructions. Waste toner box full (500 pages are printed after the waste toner sensor sticks at ON.) Note: The same message appears in the case of the error code F4. <User Check>...

- Page 143 ■ Error code E0 Print Unable E0 Turn the power off and then back on again. Program error <User Check> - Turn the power off and on. ■ Error code E1 Print Unable E1 Turn off and on. Program error <User Check>...

- Page 144 ■ Error code E9 Print Unable E9 Turn the power off and then back on again. Maintenance monitor error (The engine software detects an incorrect setting value.) Step Cause Remedy Harness connection failure of Check the harness connection between engine PCB ASSY the main PCB ASSY and engine PCB ASSY, and reconnect it.

- Page 145 ■ Error code EE Print Unable EE Turn the power off and then back on again. Unavailability of communication after connecting to the wireless LAN PCB is detected < > User Check - Relocate the printer because there is a possibility that large noise is generated in the environment where the printer is installed.

- Page 146 ■ Error code F4 Replace WT Box Replace the Waste Toner Box. Refer to the User's Guide for instructions. Waste toner box full. (Overcurrent flows to the cleaning roller due to the end of life of the cleaning roller.) Note: The same message appears in the case of the error code CF.

- Page 147 ■ Error code FA (K), FB (C), FC (M), FD (Y) No Toner Open the Top Cover, then install Toner Cartridge. Black (K) No Toner Open the Top Cover, then install Toner Cartridge. Cyan (C) No Toner Open the Top Cover, then install Toner Cartridge. Magenta (M) No Toner Open the Top Cover, then install Toner Cartridge.

- Page 148 ■ Error code FE Detection of incorrect measurement value of density sensor sensitivity calibration <User Check> - Check if the 4-color drum units are properly installed in the product. Step Cause Remedy Belt unit failure Replace the belt unit. Harness connection failure of Check the harness connection of the registration mark L PCB ASSY registration mark L PCB ASSY and...

-

Page 149: Paper Feeding Problems

PAPER FEEDING PROBLEMS Problems related to paper feeding are end user recoverable if following the User Check items. If the same problem occurs again, follow each procedure in the order of the number described in the Step column in the tables below. No Feeding <User Check>... -

Page 150: Double Feeding

Double Feeding <User Check> - Check if the paper is loaded into the paper tray correctly. - Turn over the stack of paper in the paper tray, or try rotating the paper 180° in the paper tray. - Check if the thickness of the paper is 60 to 105 g/m - Set out papers and reload them into the paper tray. -

Page 151: Dirt On Paper

■ Paper jam in the back cover and paper eject section Step Cause Check Remedy Result Foreign object Is there a foreign object Remove the foreign around fuser unit around the fuser unit? object. Paper eject rear Does the paper rear Replace the paper eject actuator top failure eject actuator top move... -

Page 152: Wrinkles On Paper

Wrinkles on Paper <User Check> - Check if the paper is loaded into the paper tray correctly. - Turn over the stack of paper in the paper tray, or try rotating the paper 180 ° in the paper tray. - Check if the thickness of the paper is 60 to 105 g/m Step Cause Check... -

Page 153: Print Image Defect From Pc/Usb/Fax Reception Troubleshooting

PRINT IMAGE DEFECT FROM PC/USB/FAX RECEPTION TROUBLESHOOTING Image Defect Examples Light on the whole page One color is light Faulty registration Dark All one color Image distortion Poor fixing Completely blank Vertical streaks Vertical streaks in a light background Dirt on the back of paper Vertical streaks in a dark background Horizontal stripes White vertical streaks on one color image... -

Page 154: Pitch Indicated In Roller Image

Pitch Indicated in Roller Image Image defects which occur periodically may be caused by a failure of the roller. By referring to the table below, specify the cause based on the pitch indicated in the image of each roller. Parts name The pitch which appears in the image Develop roller 31 mm... -

Page 155: One Color Is Light

■ One color is light <User Check> - Open and close the top cover and make print again. - Check the machine’s environment. High temperature and high humidity or low temperature and low humidity conditions can cause this problem. - Replace the toner cartridge or drum unit with a new one. - Adjust the color density from the control panel cover ASSY. -

Page 156: Faulty Registration

Step Cause Check Remedy Result HVPS control PCB Is the problem solved Replace the HVPS failure after replacing the control PCB ASSY. HVPS control PCB ASSY? High-voltage power Is the problem solved Replace the supply PCB failure after replacing the high-voltage power high-voltage power supply PCB ASSY. - Page 157 ■ Dark <User Check> - Check the machine’s environment. High temperature and high humidity or low temperature and low humidity conditions can cause this problem. - Clean the corona wire. - Replace the toner cartridge or drum unit with a new one. - Adjust the color density from the control panel cover ASSY.

-

Page 158: Poor Fixing

■ Poor fixing <User Check> - Open and close the top cover and make print again. - Adjust the color density from the control panel cover ASSY. - Check the machine’s environment. High temperature and high humidity or low temperature and low humidity conditions can cause this problem. - Replace the belt unit with a new one. -

Page 159: Image Distortion

■ Completely blank <User Check> - Replace the belt unit with a new one. - Replace the toner cartridge or drum unit with a new one. Step Cause Check Remedy Result Developing bias Are the electrodes on the Clean both electrodes. voltage conduction drum unit and machine (Refer to... -

Page 160: All One Color

■ All one color Memo: You can check this image defect with the function code 71. (Refer to “1.4.21 Color test pattern (Function code 71)” in Chapter Step Cause Check Remedy Result Corona wire Are the electrodes on Clean both electrodes. failure the drum unit of the (Refer to... - Page 161 ■ Dirt on the back of paper <User Check> - Replace the waste toner box with a new one. - Replace the belt unit with a new one. Step Cause Check Remedy Result Fuser unit dirty Is the pressure roller Print approximate 10 dirty? pages.

-

Page 162: Vertical Streaks

■ Vertical streaks <User Check> - This problem may occur with noise which is caused by dirt on the corona wire in the drum unit. In this case, clean the corona wire. - Replace the drum unit with a new one. - Replace the toner cartridge with a new one. - Page 163 ■ Vertical streaks in a light background <User Check> - Clean the inside of the machine and the corona wire in the drum unit. - Clean the LED array with a soft lint-free cloth. - Replace the toner cartridge with a new one. - Replace the drum unit with a new one.

-

Page 164: Horizontal Stripes

■ Horizontal stripes <User Check> - Clean the inside of the machine and the corona wire in the drum unit. - Replace the drum unit with a new one. Step Cause Check Remedy Result Dirt on the charged Are the electrodes on Clean both electrodes. - Page 165 ■ White vertical streaks on one color image <User Check> - Check if there is no dust in the gap between the toner cartridge and drum frame. - Clean the relevant color LED array on which color loss occurs with a soft lint-free cloth. - Replace the toner cartridge with a new one.

-

Page 166: Faint Print

■ White horizontal stripes on one color image <User Check> - The problem may disappear by itself. Try printing multiple pages to clear this problem especially if the machine has not been used for a long time. - Replace the toner cartridge with a new one. - The drum unit may be damaged. - Page 167 ■ White spots on one color image <User Check> - Toner may be empty. Replace the toner cartridge with a new one. - If the same problem occurs after printing a few pages, the adhesive of the label or the like, paper powder or dirt may be attached on the surface of the exposure drum.

- Page 168 Note: If there is any problem in the print quality, be sure to clean the drum unit in accordance with “Drum cleaning function of product” provided below. If the problem still persists, be sure to clean the drum unit manually in accordance with “Drum unit cleaning”...

- Page 169 Note: - Make sure that the paper is straight and in the correct position on the manual feed slot. If it is not, the paper may not be fed properly, resulting in a skewed printout or a paper jam. - Do not put more than one piece of paper in the manual feed slot at any one time, as it may cause a jam.

- Page 170 <Drum unit cleaning> (1) Pull the drum unit out of the machine and take all the toner cartridges out of the drum unit. Note: We recommend that you place the drum unit on a clean, flat surface with a piece of disposable paper underneath it in case you accidentally spill or scatter toner.

- Page 171 ■ One color spots or dirt <User Check> - Damp (wet) paper might be used. Try to changing to freshly unopened paper. - Toner may be empty. Replace the toner cartridge with a new one. - If the same problem occurs after printing a few pages, the adhesive of a label or the like, paper powder or dirt may be attached on the surface of the exposure drum.

-

Page 172: One Color Band

■ One color band <User Check> - Clean the inside of the machine and the corona wire in the drum unit. If the same problem occurs after cleaning, replace the drum unit with a new one. - The paper tray ground terminal provided in the machine body may be dirty. Clean the contact with a dry cloth. -

Page 173: Horizontal Lines

■ Horizontal lines <User Check> - The paper tray ground terminal provided in the machine body may be dirty. Clean the contact with a dry cloth. - Replace the drum unit with a new one. - Replace the toner cartridge with a new one. Step Cause Check... -

Page 174: Color Misregistration

■ Ghost <User Check> - Check the machine’s environment, conditions such as high humidity may cause this situation to occur. - Check that the appropriate media type is selected in the printer driver. - Replace the drum unit with a new one. Step Cause Check... - Page 175 ■ Fogging <User Check> - Replace the toner cartridge with a new one. - Replace the drum unit with a new one. - Do not use acid paper. Step Cause Check Remedy Result Toner/new Is the toner sensor Replace the toner/new sensor PCB failure performed normally by sensor PCB ASSY.

- Page 176 ■ Unstable color density <User Check> - Make a print on a different type of paper. - Replace the belt unit with a new one. - Replace the drum unit with a new one. - Replace the waste toner box with a new one. - Replace the toner cartridge with a new one.

-

Page 177: Hollow Print

■ Hollow print <User Check> - Select “Improve Toner Fixing” in the printer driver, or select “Thicker Paper” in Paper Type. - Check the machine’s environment, conditions such as high humidity and low humidity may cause this situation to occur. - Make a print on a different type of paper. -

Page 178: Software Setting Problems

Machine For Macintosh, has the Verify the product ID. connection product ID been (Hexadecimal) verified? Product ID: DCP-9010CN: 0220 MFC-9010CN: 021E MFC-9120CN: 021D MFC-9125CN: 029Eh MFC-9320CW: 021C MFC-9325CW: 029Fh USB direct interface Is the problem solved Replace the USB direct... -

Page 179: Network Problems

NETWORK PROBLEMS Cannot Make a Print through Network Connection <User Check> - Check the descriptions in the network user’s guide. - Restore the settings at factory shipment. (Refer to User's guide) Step Cause Check Remedy Result Mismatch of MAC Is the problem solved Obtain the MAC address (Ethernet after obtaining the... -

Page 180: Troubleshooting Of The Communications Errors

TROUBLESHOOTING OF THE COMMUNICATIONS ERRORS If a communications error occurs, the machine (1) Gives the alarm (intermittent bleep) for approximately four seconds. (2) Indicates the appropriate error message on the LCD. (3) Prints the transmission report during fax transmission. Definition of Error Codes on the Communications List (1) Calling Code 1 Code 2... - Page 181 (2) Command reception Code 1 Code 2 Cause Unable to detect a flag field. Carrier was OFF for 200 ms or longer. Abort detected (“1” in succession for 7 bits or more). Overrun detected. A frame for 3 seconds or more received. CRC error in answerback.

- Page 182 (4) Instructions received from the remote terminal [checking the NSC, DTC, NSS, and DCS] Code 1 Code 2 Cause Illegal coding system requested. Illegal recording width requested. ECM requested although not allowed. Polled while not ready. No document to send when polled. Nation code or manufacturer code not correct.

- Page 183 (8) TCF transmission/reception Code 1 Code 2 Cause Fallback impossible. (9) Signal isolation Code 1 Code 2 Cause Unable to detect video signals and commands within 6 seconds after CFR is transmitted. Received PPS containing invalid page count or block count. (10) Video signal reception Code 1 Code 2...

- Page 184 (11) General communications-related Code 1 Code 2 Cause Unable to receive the next-page data. Unable to receive polling even during turn-around transmission due to call reservation. PC interface error. Communication canceled by pressing the Stop/Exit button before establishment of FAX communication*. Communication canceled by pressing the Stop/Exit button after establishment of FAX communication*.

- Page 185 (13) Maintenance mode Code 1 Code 2 Cause Failed to detect 1300 Hz signal in burn-in operation. Failed to detect PB signals in burn-in operation. (14) Equipment error Code 1 Code 2 Cause Equipment error (For X X, refer to “2.1 Error Codes”...

-

Page 186: Troubleshooting Of The Control Panel Cover Assy

TROUBLESHOOTING OF THE CONTROL PANEL COVER ASSY Nothing is Displayed on the LCD. <User Check> - Verify if the power switch is turned off. Step Cause Check Remedy Result Connection Are the main PCB and Reconnect the between main PCB panel PCB connected connector properly. -

Page 187: The Control Panel Cover Assy Does Not Work

The control panel cover ASSY does not Work. <User Check> - Check whether the function lock is not set. Step Cause Check Remedy Result Key sticking Is there a key on the Clean up the control panel stuck? panel cover ASSY, or remove the burrs from control panel cover ASSY and panel keys. -

Page 188: Troubleshooting Of Fax Functions

TROUBLESHOOTING OF FAX FUNCTIONS FAX can't Send it. <User Check> - Verify that the telephone cord is securely inserted into the right socket. Step Cause Check Remedy Result Dialing mode Does a dialing signal Check the dialing mode setting (PB or DP) come out setting at customer's normally in each mode? again. -

Page 189: Speed Dialing And One-Touch Dialing Can't Be Used

Speed Dialing and One-touch Dialing can't be Used. <User Check> - Check that the Speed Dialing and One-touch Dialing are properly registered. Step Cause Check Remedy Result Speed dialing Can a fax transmission Replace the main PCB keys or one-touch be made using the ASSY. -

Page 190: No Bell Ring

No Bell Ring. Step Cause Check Remedy Result Ring delay Ring delay is set to “0”. Change the ring delay settings to another value. Ring volume Ring volume is set to Change the ring volume “OFF”. setting to another value. Connection Are the main PCB and Reconnect the... -

Page 191: Dialing Function Does Not Switch Between "Tone" And "Pulse

Dialing Function does not Switch between “Tone” and “Pulse.” Step Cause Check Remedy Result Connection Are the main PCB and Reconnect the between main NCU PCB connected connector properly. PCB and NCU PCB properly? NCU PCB Is the problem solved Replace the NCU PCB after replacing the NCU ASSY. -

Page 192: Document Feeding Problems

10. DOCUMENT FEEDING PROBLEMS Problems related to document feeding are end user recoverable if following the User Check items. If the same problem occurs again, follow each procedure in the order of the number described in the Step column in the tables below. 10.1 No Feeding <User Check>... -

Page 193: Paper Jam

10.3 Paper Jam ■ Paper jam in the ADF cover <User Check> - Check if the document is jammed in the insertion part. Step Cause Check Remedy Result Foreign object Is there a foreign object Remove the foreign inside the area inside the area around object. -

Page 194: Wrinkles

10.4 Wrinkles <User Check> - Check if the document is loaded into the ADF correctly. - Check whether the document guide matches the document size. - Check whether the document does not curl. Step Cause Check Remedy Result Separation roller Is the separation roller Replace the roller worn out... -

Page 195: Scanning Image Defect Troubleshooting

11. SCANNING IMAGE DEFECT TROUBLESHOOTING 11.1 Image Defect Examples Light Faulty registration Dark Completely blank Vertical streaks White vertical streaks Fig. 3-18 11.2 Troubleshooting Image Defect Image defect related problems are end user recoverable if following the User Check items. If the same problem occurs, follow each procedure in the order of the number described in the Step column in the tables below. - Page 196 ■ Faulty registration (1) ADF Step Cause Check Remedy Result Fine adjustment Is the problem solved Perform the fine of scan start by performing the fine adjustment of scan start position adjustment of scan start position. misalignment position. (Function code (Function code Document rear Does the document rear...

- Page 197 ■ Completely blank Step Cause Check Remedy Result White level data Is the problem solved by Perform the acquisition malfunction performing the of white level data. acquisition of white level (Function code data. (Function code CIS unit failure Is the problem solved Replace the document after replacing the scanner unit.

-

Page 198: Others Problems

12. OTHERS PROBLEMS 12.1 The Machine is not Turned on, or the LCD Indication does not Appear. Step Cause Check Remedy Result Harness Is the harness of the Reconnect the panel connection failure panel PCB ASSY PCB ASSY harness. of panel PCB connected correctly? ASSY Harness... -

Page 199: The Fan Does Not Work

12.2 The Fan does not Work. Step Cause Check Remedy Result Harness Is the harness of the Reconnect the harness connection failure appropriate fan of the appropriate fan of the appropriate connected correctly? correctly. Failure of the Is the problem solved Replace the appropriate appropriate fan after replacing the... -

Page 200: The New Toner Is Not Detected

12.4 The New Toner is not Detected. Step Cause Remedy New toner actuator not operating Make sure correct movement of the smoothly or catching. new toner actuator of the appropriate color. Main PCB failure Replace the main PCB ASSY. Toner/new sensor PCB failure Replace the toner/new sensor PCB ASSY of the appropriate color. -

Page 201: Periodical Maintenance

CHAPTER 4 PERIODICAL MAINTENANCE Confidential... - Page 202 CHAPTER 4 PERIODICAL MAINTENANCE This chapter details consumable parts and periodical maintenance parts. This chapter also covers procedures for disassembling and assembling periodical maintenance parts. CONTENTS 1. SAFETY PRECAUTIONS ................4-1 2. CONSUMABLE PARTS ................4-1 3. PERIODICAL MAINTENANCE PARTS .............4-3 3.1 Periodical Maintenance Parts ..................4-3 3.2 Procedures to Replace Periodical Maintenance Parts ..........

-

Page 203: Safety Precautions

SAFETY PRECAUTIONS To avoid creating secondary problems by mishandling, follow the warnings below during maintenance work. WARNING - Always turn off the power switch and unplug the power cord from the power outlet before accessing any parts inside the machine. - When opening the joint cover or back cover to access any parts inside the machine, never touch the shaded parts shown in the following figures. - Page 204 ■ Life of drum unit < How to calculate the drum unit life > The drum unit life is based on the “drum counter” or the “number of drum rotations”. The drum counter is based on the total printed pages on each drum unit. This total printed pages should be reset every time you replace the drum unit with a new one.

-

Page 205: Periodical Maintenance Parts

PERIODICAL MAINTENANCE PARTS Periodical Maintenance Parts Periodical maintenance parts are the parts to be replaced periodically to maintain product quality. These parts would affect the product quality if they loose their functionality even if they do not appear to be damaged or there is no change in their appearance. The periodical maintenance parts listed in the table below should be replaced according to the service life. -

Page 206: Procedures To Replace Periodical Maintenance Parts

Procedures to Replace Periodical Maintenance Parts ■ Preparation Prior to proceeding with the disassembly procedure, (1) Unplug - the AC cord, - the modular jack of the telephone line, - the USB cable, if connected, - the LAN cable, if connected, - the USB cable for PictBridge or USB flash memory drive, if connected, and - the modular jack of the external telephone set if connected. -

Page 207: Fuser Unit

3.2.1 Fuser unit <Uninstalling procedure> (1) Open the Back cover. Back cover <Back side> Fig. 4-1 (2) Release the Hook and remove the Back cover stopper L and R from the Main body. Main body Hook Back cover stopper L Back cover Back cover stopper R <Back side>... - Page 208 (3) Remove the Bush of the Back cover from the Shaft at the right side of the Main body. Bush Main body Shaft <Right side> Shaft Back cover Bush <Back side> Fig. 4-3 (4) Remove the Back cover from the Shaft at the left of the Main body. Main body <Left side>...

- Page 209 (5) Release the Fuser cover lock lever L and R, and open the Fuser cover. Fuser cover lock lever L Fuser cover lock lever R Fuser cover lock lever L Fuser cover <Back side> Fuser cover lock lever R Fig. 4-5 (6) Take out the Shaft at the left side of the Fuser cover from the Notch on the Bush of the Side frame L.

- Page 210 (8) Remove the Taptite bind B M3x12 screw, and then remove the Fuser cover L from the Fuser unit. Fuser cover L Taptite bind B M3x12 Fuser unit <Back side> Fig. 4-7 (9) Remove the Taptite bind B M3x12 screw, and then remove the Fuser cover R from the Fuser unit.

- Page 211 (10) Disconnect the two Connectors (CN1, CN3) from the Eject front sensor PCB ASSY. Connector Eject front sensor PCB ASSY Connector <Back side> Fig. 4-9 (11) Disconnect the two Electrode terminals from the Fuser unit. Electrode terminal (small) Electrode terminal (large) Fuser unit <Back side>...

- Page 212 (12) Remove the two Taptite pan B M4x14 screws, and then remove the Fuser unit from the Main body while holding the “A.” Main body Taptite pan B M4x14 “A” Pressure roller ASSY Fuser unit Taptite pan B M4x14 <Back side> Fig.

-

Page 213: Installing Procedure

<Installing procedure> (1) Assemble the Fuser unit while holding the “A”, and then secure it with the two Taptite pan B M4x14 screws. Main body Taptite pan B M4x14 “A” Pressure roller ASSY Fuser unit <Back side> Taptite pan B M4x14 Fig. - Page 214 (2) Connect the two Electrode terminals into the Fuser unit. Electrode terminal (small) Electrode terminal (large) Fuser unit <Back side> Fig. 4-15 (3) Connect the two connectors (CN1, CN3) into the Eject front sensor PCB ASSY. Connector Eject front sensor PCB ASSY Connector <Back side>...

- Page 215 (4) Assemble the Fuser cover R to the Fuser unit with the Taptite bind B M3x12 screw. Note: Do not pinch the harness from the low-voltage power supply PCB ASSY to the Fuser unit. Fuser cover R Taptite bind B M3x12 Fuser unit <Back side>...

- Page 216 (6) Assemble the Shaft at the right side of the Fuser cover to the Bush of the LVPS cover. (7) Assemble the Shaft at the left side of the Fuser cover to the Notch on the bush of the Side frame L.

- Page 217 (9) Assemble the Back cover to the Shaft at the left side of the Main body. Main body Shaft <Left side> Back cover Fig. 4-21 (10) Assemble the Bush of the Back cover to the Shaft at the right side of the Main body. Bush Main body Shaft...

- Page 218 (11) Assemble the Back cover stopper L and Back cover stopper R to the Main body. Main body Hook Back cover stopper L Back cover <Back side> Back cover stopper R Fig. 4-23 (12) Close the Back cover. Back cover <Back side>...

-

Page 219: Paper Feeding Kit

3.2.2 Paper feeding kit <Uninstalling procedure> (1) Release the two Hooks of the Separation pad ASSY from the Paper tray. (2) Release the two Pins to remove the Separation pad ASSY from Paper tray. Hook Separation pad ASSY Hook Paper tray Fig. - Page 220 (4) Push the Lift arm to the back and remove “B” of the Roller holder ASSY from “A” of the Lift arm, and the Roller holder ASSY rotates in the direction of the arrow 4b. “A” Roller holder ASSY “B” Paper feed unit Lift arm “B”...

- Page 221 <Installing procedure> (1) Align the Shaft of the Roller holder ASSY to the Hole of the Paper feed unit and insert it into the Hole. Paper feed unit Paper feed unit Roller holder ASSY Shaft Hole Fig. 4-29 (2) Slide the Roller holder ASSY in the direction of the arrow 2a and 2b in this order, and fit the “B”...

- Page 222 (3) Turn the Roller holder ASSY in the direction of the arrow 3a and insert the “D” of the Roller holder ASSY into the “C” of the Lift arm. “C” Roller holder ASSY “D” Paper feed unit Lift arm “D” Roller holder ASSY “C”...

- Page 223 (5) Put the two Pins of the Separation pad ASSY into the Paper tray. Note: Apply grease to the Separation pad ASSY before mounting the Paper tray. (Refer to “4. LUBRICATUION” in Chapter Separation pad ASSY Paper tray Fig. 4-33 (6) Set the Pad spring in a way that the “E”...

-

Page 224: Disassembly And Assembly

CHAPTER 5 DISASSEMBLY AND ASSEMBLY Confidential... - Page 225 CHAPTER 5 DISASSEMBLY AND ASSEMBLY This chapter describes procedures for disassembling and assembling the machine with relates notes. The provided disassembly order flow enables you to take in the quickest way to get an involved part at a glance. At the start of disassembling, you can check the disassembly order flow which guides you through a shortcut to get to the part.

- Page 226 8.17 Upper Document Chute ASSY ................5-64 8.18 Separation Rubber ASSY ..................5-65 8.19 Paper Feed Roller ASSY ..................5-66 8.20 Ejection Roller ASSY ....................5-67 8.21 ADF Sensor PCB ASSY ..................5-68 8.22 Drive Frame ASSY ....................5-71 8.23 Paper Stack Lever ....................5-75 8.24 Document Hold ASSY ....................

- Page 227 8.56 Main PCB Insulation Sheet/Engine Insulation Sheet..........5-139 8.57 Main PCB Shield Plate ..................5-140 8.58 Engine Shield Plate ....................5-141 8.59 Registration Mark Relay PCB ASSY ..............5-142 8.60 Drum Develop Drive Unit ..................5-143 8.61 Develop Drive Motor ..................... 5-148 8.62 Paper Feed Motor ASSY ..................

-

Page 228: Safety Precautions

SAFETY PRECAUTIONS To avoid creating secondary problems by mishandling, follow the warnings and precautions below during maintenance work. WARNING Some parts inside the machine are extremely hot immediately after the machine is used. When opening the joint cover or back cover to access any parts inside the machine, never touch the shaded parts shown in the following figures. -

Page 229: Packing

PACKING Carton option 3 Quick Setup guide Printed bag ASSY Carton option Drum/Toner ASSY (Y) Carton option 2 AC cord bag ASSY Carton option 3 Polystyrene pad R Drum/Toner ASSY (M), (C) Polystyrene pad L Machine Drum/Toner ASSY (K) Polystyrene pad base Carton Confidential... -

Page 230: Screw Torque List

SCREW TORQUE LIST Note: For verifying the shape of each screw, refer to “APPENDIX 4 SCREW CATALOGUE”. Tightening torque Location of screw Screw type Q'ty · · m (kgf Cord hook Taptite cup B M3x8 0.50±0.10 (5±1) Fuser cover L Taptite bind B M3x12 0.60±0.10 (6±1) Fuser cover R... - Page 231 Tightening torque Location of screw Screw type Q'ty · · m (kgf USB direct interface relay PCB Taptite bind B M3x8 0.40±0.05 (4±0.5) ASSY or panel ground plate 2 FG harness Taptite bind B M3x8 0.40±0.05 (4±0.5) USB holder Taptite bind B M3x8 0.40±0.05 (4±0.5) Front cover Taptite bind B M4x12...

- Page 232 Tightening torque Location of screw Screw type Q'ty · · m (kgf PF registration solenoid Taptite bind B M3x10 0.55±0.10 (5.5±1) Pick-up solenoid Taptite bind B M3x10 0.55±0.10 (5.5±1) Pick-up solenoid lever Fuser/Eject drive motor Taptite bind B M4x12 0.90±0.10 (9±1) Taptite cup S M3x6 SR 0.80±0.10 (8±1) Eject gear cover...

-

Page 233: Lubrication

LUBRICATION The kind of the lubricating oil Lubrication point Quantity of lubrication (Maker name) MOLYKOTE PG-661 (W) Belt drive gear 2 mm dia. ball (Dow Corning) LED ASSY 1 mm dia. ball FLOIL BG-MU (Kanto Kasei) Belt drive gear 2 mm dia. ball MOLYKOTE EM-D110 Separation pad ASSY 2 mm dia. - Page 234 Paper tray 2 places (one for each to the right and left) EM2: MOLYKOTE EM-D110 (2 mm dia. ball) 1 place LED ASSY PG1: MOLYKOTE PG-661 (W) (1 mm dia. ball) Confidential...

-

Page 235: Overview Of Gears

OVERVIEW OF GEARS When ordering spare parts, please refer to Parts reference list. ■ Develop drive <Development view> Drum develop drive unit Side frame L <Left side> <Layout view> Develop drive plate ASSY Drum develop drive unit <Name of gears> LU5128 Idle gear 100 LU5126... - Page 236 ■ Drum develop drive <Development view> Drum develop drive unit <Layout view> Drum develop drive unit <Name of gears> LU5139 Drum drive gear ASSY LU5136 Coupling idle gear 35 LU5132 Develop coupling gear LU6157 Drum drive gear 60 LU5136 Coupling idle gear 35 LU5132 Develop coupling gear LU6158...

- Page 237 ■ Cleaner PF <Development view> Side frame L <Left side> <Layout view> * Outside of side frame L <Name of gears> LU5108 Gear 70 LU5744 Registration differential gear LU5110 Idle gear 25 R LU5097 Gear 32/21 LU5110 Idle gear 25 R LU5100 Gear 26-51 LU5112...

- Page 238 ■ PF drive <Development view> Side frame L <Front> <Layout view> * Inside of side frame L <Name of gears> LR0910 Hook spring LU5089 Planetary clutch ASSY LU5093 LM hook B LR0910 Hook spring LU5094 LM hook C LU5105 Worm Z33 LU5095 P/P gear 26 sector LU5106...

-

Page 239: Harness Routing

HARNESS ROUTING Joint Cover Sub ASSY Joint cover sub ASSY Sub frame ASSY LED head control Hook PCB ASSY LED main FFC film Front Side frame L Side frame L LED head control PCB ASSY Slit Front Front Main PCB ASSY 5-12 Confidential... - Page 240 Registration Front/Rear Sensor PCB ASSY Side frame R Registration front/rear Front sensor PCB ASSY Paper feed unit Hook Hole HVPS control PCB ASSY Manual Sensor PCB ASSY Side frame R Front Registration front/rear sensor PCB ASSY Hook Hole Slit Hook Hole Front chute ASSY Hook...

- Page 241 PF Registration Solenoid, Pick-up Solenoid Pick-up solenoid Cleaner PF gear cover PF registration solenoid Hook Front Side frame L Hook Hook Front Side frame L PF line holder Hook Hook Hook Engine PCB ASSY PF line holder Cleaner PF gear cover Hook 5-14 Confidential...

- Page 242 Belt Drive ASSY Engine insulation sheet Belt drive ASSY Hook Engine PCB ASSY Front Side frame L Engine insulation sheet Hook Develop Release Motor ASSY PF line holder Hook Side frame L Develop release motor ASSY Hook Front Hook Hook Engine PCB ASSY PF line holder 5-15...

- Page 243 Drum Motor Origin Sensor PCB ASSY Drum motor origin sensor PCB ASSY Hook Side frame L Engine insulation sheet Hook Engine PCB ASSY Core Engine insulation sheet Front Hole Fuser/Eject Drive Motor, Fuser/Eject Drive Motor Sensor PCB ASSY Fuser/eject drive motor Eject gear cover Engine insulation sheet sensor PCB ASSY...