Summary of Contents for Maytag Built-in Refrigeration

- Page 1 Jenn-Air/Jade/Dacor Built-in Refrigeration © Maytag Technical Institute, 2005 L2006-029...

- Page 2 Authorized Training Center Campuses Maytag maintains an affiliation with ten institutions in the US and Canada to offer technical training sessions focused on Maytag branded product. Maytag supplies the course content and product but each school operates as an independent agent and collects fees accordingly.

-

Page 3: Table Of Contents

Product Familiarization A Refrigerator for a Different Kind of Consumer .............. 1 A New Level of Performance for Fresh Food Storage ........... 1 Long Term Storage With a Higher Level of Performance ..........3 Cooling Performance that Matches the Needs..............4 Sound Performance Beyond Many Expectations ............ - Page 4 Servicer’s Note......................52 Defrost System......................52 Servicer’s Note......................53 Dispenser System......................54 Servicer’s Note......................55 Cabinet ..........................57 Leveling System......................57 Servicer’s Note......................57 Door Assembly ......................57 Servicer’s Note......................58 Shelf Systems........................ 59 Servicer’s Note......................60 Non-Dispenser Model Options ................60 Dispenser Model Options ..................

- Page 5 Service Test 13 – Fresh Food Lights ................68 Service Test 14 – Freezer Lights .................. 69 Service Test 15 – Fountain Lamp ................. 69 Service Test 16 – Compressor Maximum Speed............70 Service Test 17 – Compressor Minimum Speed............71 Service Test 18 –...

-

Page 7: A Refrigerator For A Different Kind Of Consumer

A Refrigerator for a Different Kind of Consumer ® The new Jenn-Air Luxury™ Series of built in refrigerators provides a new level of performance for a specialty market. This line of refrigeration products is targeted to enter into a market with little competition. This market is characterized by custom kitchens that are a gourmet’s dream. -

Page 8: A New Level Of Performance For Fresh Food Storage

A New Level of Performance for Fresh Food Storage Warm air rises, cool air falls. As a refrigerator cabinet increases in size, maintaining temperature control becomes more challenging. As a cabinet becomes taller the air has a greater ability to settle in layers. This is called stratification. -

Page 9: Long Term Storage With A Higher Level Of Performance

Besides providing optimum storage temperature, the CZT modules also provide better humidity control. Conventional crisper drawers can often end up with condensation inside. This condensation can result in excessive moisture settling on the produce and cause premature aging. The CZT modules use a space-age polymer to regulate the amount of moisture in the compartment. -

Page 10: Cooling Performance That Matches The Needs

when refrigerator usage is at maximum, the system is defrosting and cannot provide the cooling needed to maintain optimum temperatures. With a preemptive adaptive defrost, the system looks forward and anticipates usage patterns to avoid defrosting at a time that may not be best. The control tracks information about how the owners use the refrigerator. -

Page 11: Sound Performance Beyond Many Expectations

One way to decrease operating costs is to operate the system at a lower speed over a longer period of time. The most efficient operation would occur if the system could be fine tuned to run continuously at a level that constantly matched the cooling requirements. -

Page 13: Features Should Be The Expectation Not The Exception

Features Should be the Expectation not the Exception Many of the built- in refrigerators currently in homes across America were designed for storage capacity more than they were designed for ease of use and functionality. If you want a lot of room for storage, they may be the right choice for you. If you want the same features that are available with even modestly priced refrigerators, you need to look away from them and towards a built-in system designed by a company who understands consumer expectations and convenience. -

Page 14: Options That Meet The User's Expectations

All of the water is filtered before going to the dispenser or the icemaker. Like any type of water filter, the filter cartridge needs to be replaced on a regular basis. The control system monitors the amount of water flowing through the filter and recommends when it is time to order a new cartridge on the control panel. - Page 19 JENN-AIR LUXURY™ SERIES ® Jenn-Air Built-in Refrigerators SIZE STYLE TYPE PACKAGE FRAME COLOR DISP. COLOR MODEL 48" STAINLESS DISPENSER No Frame Black JS48SEDBFA STEEL No Frame Black JS48SEDBDA NON- No Frame Non-Dispenser JS48SEFXFA DISPENSER LX1 No Frame Non-Dispenser JS48SEFXDA OVERLAY DISPENSER Silver Black...

- Page 20 Jenn-Air Built-in Refrigerator Accessories SECTION PLACEMENT ACCESSORY MODEL 48" Refrigerator Compartment Shelving Refrigerator Sealed Glass Shelf CJS483SSWA System Refrigerator Elevator Shelf CJS483ESWA Refrigerator A la Carte Storage Drawer CJS483STWA Interior Door Full-Width Dairy Compartment CJS484PDSA System Refrigerator Adjustable Door Bin CJS484POSA Freezer Compartment Shelving...

-

Page 21: Features And Benefits Are Not All You Should Expect

Features and Benefits are Not All you Should Expect One of the sad realities of any machine is that it will need service. Just as regular oil changes and tire rotations are needed to keep a car running smooth and efficiently, every appliance deserves regular maintenance. -

Page 22: Warranty Information

Warranty Information... -

Page 23: Making Sure The Available Space Is As Useful As Possible

Making sure the Available Space is as Useful as Possible Most conventional refrigerators have the cooling system mounted in the bottom of the cabinet. The interior space is shaped around the equipment and the end result is that usable space is lost to equipment. ®... - Page 24 triangle. The closer the triangle is to equal on each side, the better. The space between all three points should be free from obstruction with enough room for at least two people to work within the triangle without getting in each other’s way. If the kitchen will only be occupied by one person a smaller triangle will work.

-

Page 25: Setting Aside The Space

Setting Aside the Space Just as with any refrigerator, it is always important that you have enough space to work around the unit. The cabinet depth alone doesn’t tell the entire story. You need to consider the length of the open doors to determine the total space you need for use of the appliance. - Page 26 The 42” product requires an area that is 41½ inches wide and 48 inches deep. Two feet of the cabinet will be flush with the cabinets or built into the wall. This means that you need at least 24 inches clear in front of the system. If you want to be able to get past an open refrigerator, you will need even more space.

-

Page 28: After Alls In Place

After Alls in Place Once the unit is in place it must be leveled and secured to prevent any out of balance possibilities. A very important part of the installation process is installation of an anti-tip device. Anti- tip devices have been around for a long time on ranges. The length of the door in relation to the body of range makes it easy for an individual to tip the unit over if excess weight is applied to the open door. - Page 29 ® ™ The Jenn-Air Luxury Series of refrigerators includes heavy-duty leveling legs at all four corners. These leveling legs are adjusted from the front of the cabinet just as any other service would be performed. Even with new construction there may be slight unevenness to the flooring the system is installed upon.

-

Page 30: After The Install, The Finishing Touches

After the Install, The Finishing Touches ® ™ As stated previously, the exterior of the Jenn-Air Luxury Series of Refrigerators is completely customizable. The stainless steel version of the refrigerator comes ready for use. The exterior is suited for use in any kitchen with the space. Panels can be manufactured for installation on the doors and sides of both the panel and the overlay version. - Page 31 The door panels are slid in from the handle side of the door. If the owner wants to replace the black panels on either side of the ice and water dispenser, the freezer door would need to be disassembled to slide in the left trim panel. The equipment compartment panel is slid in from the end.

- Page 32 Side panels must be screwed into place. Spacers need to be added to support the panels for a secure mounting.

- Page 33 The end result is a beautiful addition to any kitchen. A refrigeration system that will serve a customer both now and in the future.

-

Page 37: Jenn-Air Luxury Series Refrigeration Q & A

® ™ Jenn-Air Luxury Series Refrigeration Q & A ® ™ Why would I buy a Jenn-Air Luxury Series Refrigerator over the competition’s built- in refrigerator? ® ™ The competition makes a fine product. We believe that the Jenn-Air Luxury refrigerator does a better job keeping food fresh. - Page 38 Is there a dispenser model? Yes. Filtered water, cubed ice and crushed ice are all available through the door. There is a filter monitor to remind you when to order a new filter and when to replace the filter. Is there a non-dispenser model? Yes.

- Page 39 Does it need any special electrical circuit? ® ™ Just as with any refrigerator, the Jenn-Air Luxury Series should be connected to a dedicated outlet. Most electrical codes require a fifteen amp circuit. It is recommended that the unit not be attached to a ground fault circuit interrupter. Does it need to be hard wired? No, the system has a cord just like a standard refrigerator.

-

Page 40: Installation Instructions

Installation Instructions... -

Page 47: Jenn-Air Luxury Line Of Refrigerators Technical Orientation

® ™ Jenn-Air Luxury Line of Refrigerators Technical Orientation Do Not remove or install the Climate Zone Technology (CZT) drawers with power applied to the system. Always disconnect the main power before relamping or removing a CZT assembly. Main power can be disconnected by switching the main power switch to the OFF position. -

Page 49: Servicer's Note

Circuit Board and Connector Locations Servicer’s Note This type of power supply has very sensitive short circuit protection. Should an excessive load be detected on one of the power supply lines the DC supply will shut down. After a short off time the power supply will attempt to restart. If the short is still present on the DC power line it will shut off again and attempt to restart. -

Page 51: System Control

Refer to the table below for typical resistances. The main objective is to locate resistances that are considerably lower than the values given in the table. Resistance JP7-1 JP7-3 1.9KOhm JP7-5 JP7-7 3KOhm JP7-15 JP7-16 1KOhm JP7-15 JP7-17 250Ohm If the low resistance is found to be between pins JP7-15 and either of pins JP7-16 or JP7- 17 you will need to further isolate the source of the low resistance between the two CZT assemblies and the dispenser assembly. -

Page 52: Temperature Monitoring

If you can adjust temperature on one CZT assembly but not the other, check the connections to the non-functioning unit. If data is present at the connector, the fault is likely to be in the CZT itself. If data is not present at the connector suspect a fault between the Main Board and the CZT. -

Page 53: Servicer's Note

The evaporator thermistor monitors the evaporator temperature and is used in the compressor speed algorithm. A second duty of the evaporator thermistor is termination of the defrost cycle. While there is a safety thermostat available in case of system failure, the end of defrost is determined by the thermistor reading. -

Page 54: Servicer's Note

Variable Capacity Compressor ® ™ The sealed system in the Jenn-Air Luxury Line of Refrigerators incorporates Variable Capacity Cooling. Most conventional refrigeration systems use single speed compressors. The capacity is constant and the controls meet the cooling demand by cycling the compressor on and off. - Page 55 measurements should be equal regardless of which two terminals you are checking. There are three identical windings attached to these terminals so the resistance of the windings should be equal. Because of the frequency of the following voltage tests, not all Multimeters may be capable of measuring the correct voltage.

-

Page 56: Sealed System

Sealed System The cooling system driven by the compressor incorporates a horizontally mounted evaporator mounted in the top of the freezer compartment and a vertical condenser coil mounted in the machine compartment. A post condenser loop (Yoder Loop) is used to minimize cabinet sweating. -

Page 57: Servicer's Note

fan shroud is removed the foam drip tray is accessible. The hose clamp holding the drain hose to the drip pan tray must be loosened and the hose removed as the drip tray is lowered. You now have access to the evaporator coil and defrost heaters. Should the coil need replacement, the heat exchanger comes with the evaporator. -

Page 58: Servicer's Note

cascade down over the contents. This constant airflow provides temperature control in all areas of the cabinet within one degree of the setpoint. When there is a call for cooling in the fresh food section, the fresh food damper will open and allow cooler air to be drawn from the freezer compartment. -

Page 59: Servicer's Note

There are three heaters wired in parallel for the defrost system. The glass defrost heaters are attached to the evaporator coil, the foil drip pan heater is under the drip tray and the tube heater is around the drain tube to prevent freeze-ups leading out of the evaporator section. -

Page 60: Dispenser System

Dispenser System The dispenser system in certain models provides through the door ice and filtered water. The main inlet valve is located in the bottom front center of the cabinet. This allows the cabinet to be placed before the water is connected. Water flow is from the main water valve to the water filter. -

Page 61: Servicer's Note

filter should be replaced every six months or 416 gallons, whichever comes first. The filter must be replaced while power is applied to the system. The act of opening the outermost switch and reactivating the switch will provide a reset signal to the filter monitor. - Page 62 Move the copper inlet from the primary valves to the secondary valves. This valve assembly will directly feed the icemaker and the dispenser with a minimum of tubing. Even with the filter eliminated from the water flow, the bypass cap must be in place to allow the water valves to energize.

-

Page 63: Cabinet

Cabinet Leveling System ® ™ The Jenn-Air Luxury Line of Refrigerators use a four point leveling system. The leveling legs must be extended down and the wheels lifted off of the floor for a safe installation. Failure to get the wheels off of the floor will result in cabinet walking. -

Page 64: Servicer's Note

Servicer’s Note There is lateral adjustment for the top of the cabinet doors but no depth adjustment. When observing the top door hinge, there are four screws installed at the time of manufacture. If any adjustments need to be made, remove the Phillips screw and discard. This screw is used as a locator and will not be needed if the other three screws have been adjusted. -

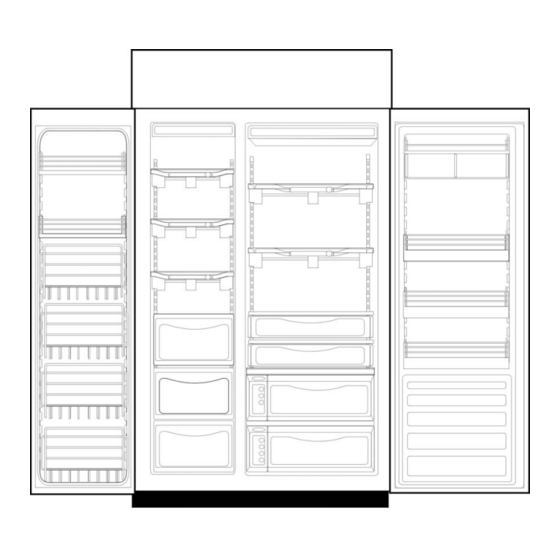

Page 65: Shelf Systems

Shelf Systems There are several shelf styles available for the interior of both the fresh food and freezer compartments. The consumer has the option of selecting the shelves they feel will fit their needs best. Any shelves outside of the standard packages are options and are purchased through the Jenn-Air dealer. -

Page 66: Servicer's Note

Servicer’s Note There are maximum numbers for the recommended shelving. This maximum is to assure proper airflow throughout the interior of the compartments. While the maximum recommended numbers of shelves are published, this does not necessarily mean that the customer will abide by the guidelines. The following information will provide the maximum number of recommended shelves. -

Page 67: Czt Storage Drawers

Fresh Food Interior ( )Elevator Shelf (max 4) ( )Standard Shelf (max 4) ( )A la Carte Drawer (max 2) ( ) Total (max 4 plus the 2 Climate Zone drawers that are always included) The maximum number of bins in the fresh food door is four. Looking at the chart, if there are four pickoff bins in the fresh food door, it is not recommended to add a dairy bin. -

Page 68: Servicer's Note

With the combination of good temperature and humidity control, it is possible for contents in the CZT drawer to last much longer than in a standard crisper drawer. Servicer’s Note Currently, the CZT drawer will be replaced as a module with the old unit returned for analysis. -

Page 69: User Interface (Controls)

User Interface (Controls) The control panel at the top of the fresh food section is constructed of touch sensitive glass. These switches will not repeat if held. If the consumer touches the switch area, contact must be broken to activate the switch again. The unit power switch is a “soft”... -

Page 70: Service Test Mode

Service Test Mode There are several test modes available through the diagnostic system. Use of these test modes can greatly decrease the time needed for troubleshooting. It is to the service technician’s advantage to be able to perform many tests in a very short period of time. Within the Service Test Mode the controls have alternate functions. -

Page 71: Service Test 01 - Software Revision

From this point forward the up and down arrows are used to move forward or backwards through the Service Tests. The Power Interrupt Button will activate the service test. If the service mode starts at any location other than 00 00 it is an indication that the Service Tests mode was not properly exited when last serviced. -

Page 72: Service Test 03 - Fresh Food Thermistor

Service Test 03 – Fresh Food Thermistor This test will give a “GO – NO GO” test of the fresh food thermistor. Pressing the Power Interrupt Button will report the condition of the thermistor. The condition displays that follow apply to the tests for all thermistors. Fresh Food thermistor PASSES test. -

Page 73: Service Test 07 - Fresh Food Fan

Service Test 07 – Fresh Food Fan This test will give a GO- NO GO test of the Fresh Food Stirrer fan. Pressing the Power Interrupt Button will result in one of the following displays. These same displays will apply to the evaporator fan test. The fan will always initially display Lo for fan too slow. -

Page 74: Service Test 10 - Close Damper

Service Test 10 – Close Damper This test will drive the electronic damper for the fresh food compartment to the closed position. Tap the Power Interrupt Button and the damper will move to the closed position. There is no change in the display while the damper closes. -

Page 75: Service Test 14 - Freezer Lights

Service Test 14 – Freezer Lights This test will energize the freezer lamps Pressing the Power Interrupt Button will energize the freezer light system. Line voltage should be present at JP 12 pin 3. Service Test 15 – Fountain Lamp This test will energize the fountain lamp. -

Page 76: Service Test 16 - Compressor Maximum Speed

Service Test 16 – Compressor Maximum Speed This test will energize the compressor at maximum speed. The compressor should have been off for at least five minutes prior to this test. If the off time is not five minutes, the short cycle protection within the compressor controller will prevent operation until enough time has elapsed. -

Page 77: Service Test 17 - Compressor Minimum Speed

Service Test 17 – Compressor Minimum Speed This test will energize the compressor at minimum speed. The compressor should have been off for at least five minutes prior to this test. If the off time is not five minutes, the short cycle protection within the compressor controller will prevent operation until enough time has elapsed. -

Page 78: Service Test 19 - Freezer Fan Speed

Service Test 19 – Freezer Fan Speed This Service Test will verify the feedback signal from the freezer fan to the Main Control board. Pressing the Power Interrupt Button will report the fan speed in revolutions per second. Service Test 20 – Fresh Food Thermistor Value This test will provide the current reading for the fresh food thermistor. -

Page 79: Service Test 22 - Ambient Thermistor Value

Service Test 22 – Ambient Thermistor Value This test will provide the current reading for the ambient thermistor. This reading is real time and does not involve the temperature control algorithm. This reading should be very close to the actual temperature of the ambient thermistor. -

Page 80: Service Test 25 - Fountain State

Service Test 25 – Fountain State This test reports back the current status of the dispenser. If the dispenser control does not change the output, suspect data communication problems with the dispenser control itself. Pressing the Power Interrupt Button will indicate the current state of the dispenser. -

Page 81: Service Test 27 - Filter Valve Switch

Service Test 27 – Filter Valve Switch This test indicates the current state of the filter switch. This switch must be reported as actuated for the filter monitor to operate. Pressing the Power Interrupt Button will display the current switch state. Filter is installed Filter is not installed Service Test 28 –... -

Page 82: Service Test 30 - Auger Motor

Service Test 30 – Auger Motor This test will energize the auger motor. Pressing the Power Interrupt Button will energize the motor when the dispenser switch is also actuated. Service Test 31 – Chute Solenoid This test will energize the chute solenoid. Pressing the Power Interrupt Button will energize the chute solenoid. -

Page 83: Czt Test Mode

CZT TEST MODE To perform the built-in diagnostics that test the CZT module, both door switches must be closed. Tape the fresh food compartment door switch closed. With the door switches closed, the CZT display should be blank. To enter the CZT test module, press and hold the Citrus and Produce keypads for five seconds. - Page 88 Be Aware, Be Alert Always work safely. On the Job, On the Road, In the Home Every Time, All the Time...