Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Singer 337

- Page 1 F__ R...

- Page 2 K6644 in Great Britain Printed Form (865)

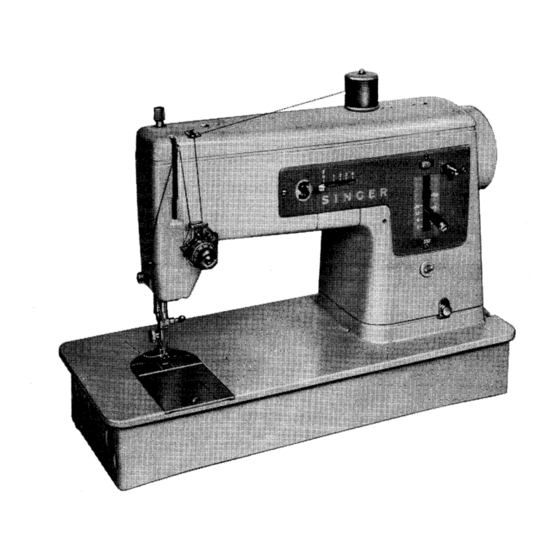

- Page 3 SINGER* Sewing Machine Model 337...

- Page 4 SINGER CENTER. Here, you can obtain the services of a trained SINGER repair man, warranted SINGER parts, sewing information and services, sewing aids and notions. Copyright Under International Copyright Union *A Trademark of THE SINGER COMPANY...

- Page 5 MACHINE PRINCIPAL PARTS STITCH WIDTH SELE( PRESSURE BOBBIN WINDER LEVER HAND WHEEL PRESSER FOOT BOBBIN WINDER SPINDLE NEEDLE THREAD TENSION REGULATOR STITCH L1GH'[ LEVER THREAD CUTTER SWITCH BOBBIN WINDER THROAT TENSION BRACKET SLIDE...

- Page 6 'HOW TO WIND BOBBIN TO Remove the Bobbin-- Open slide plate and lift out bobbin.

- Page 7 To Wind the Bobbin • Place spool of thread on spool pin. • Thread through guide between STOP-MOTION bobbin winder tension discs. SCREW • Lead of thread through hole bobbin and place bobbin on spindle. • Move bobbin winder lever to the right. •...

- Page 8 To Replace the Bobbin Hold bobbin so that thread leads off in • Place bobbin in case. direction shown. • Lead thread into slot and under spring. Draw thread into notch at end of spring; pull about 3 inches of thread across bobbin.

- Page 9 HOW TO THREAD MACHINE Raise take-up lever to highest point. Lead thread through threading points shown. ._'_ '_:; ! • Thread needle from front to back. • Draw about 4 inches of thread through eye of needle.

- Page 10 AND STITCH LENGTH CHART NEEDLE FABRIC, THREAD, MACHINE STITCHES NEEDLE PER INCH THREAD FABRICS SIZES SIZES STRAIGHT STITCHING Fine Mercerized DELICATE---tulle, chiffon, fine lace, silk, 15 to 20 100 to 150 Cotton organdy, fine tricot Synthetic Thread 50 Mercerized 12 to 15 80 to 100 Cotton LIGHTWEIGHTBbatiste, organdy,...

- Page 11 TO INSERT A NEEDLE This machine uses needle, Catalog 2020 (15 x 1). Sizes 9, 11, 14, 16 NEEDLE and 18. NEEDLE CLAMP For perfect stitching, select correct needle thread correspond with fabric according to table on page 8. Be sure to use like threads for both needle and bobbin.

- Page 12 STITCH CONTROLS Stitch Length Lever REVERSE Numerals on either side of the lever represent number of stitches per inch. The TO RELEASE higher the number, the shorter the stitch. The area above' 20 is used for adjusting zig-zag satin stitch length. To set stitch length Loosen thumb nut by turning it to the left.

- Page 13 Stitch Width Selector 1234 i [ l STRAIGHT STITCH SETTING ZIG-ZAG STITCH SETTINGS 1 to4 The stitch width selector regula[es the swing of the needle from a straight position 0 to a maximum zig-zag width 4 (5/32 inch). To position, slide selector to desired setting.

- Page 14 0 Hold needle thread lightly with left hand. through thread Pull end of bobbin throat plate.

- Page 15 PRESSURE ADJUSTMENTS To decrease pressure, turn thumb ,_,t_:_'\_'g_\ _z_%_'_ screw counterclockwise. i!i!i To increase pressure, turn thumb i!:ii. i Iti screw clockwise. '_,_,_' DECREASE INCREASE Smooth, even handling of several thicknesses of fabric results when pressure is correctly regulated. Surface finish, as well as the weight and texture of the fabric, must be considered in determining the amount of pressure needed.

- Page 16 NEEDLE THREAD TENSION, STRAIGHT STITCHING _11__ - ~_.t_ Needle thread tension Needle thread tension tight--correct by setting dial to loose---correct by setting dial to lower number, higher number. A perfectly locked straight stitch results with upper and lower tensions balanced so that needle and bobbin threads are drawn...

- Page 17 STRAIGHT STITCHING BOBBIN THREAD TENSION _._L Bobbin thread tension too loose-- Bobbin thread tension tight-- correct by turning screw clockwise. correct by turning screw counterclock- wise. locked straight stitch results with upper and lower tensions balanced perfectly so that needle and bobbin threads are drawn equally into fabric.

- Page 18 ZIG-ZAG SATIN STITCHING LENGTH ADJUSTMENT STITCH SATIN STITCH AREA Satin stitching, a series of closely spaced zig-zag stitches that form a smooth satin-like surface, is useful for both utility and decorative stitching. To Adjust Stitch Length for Satin Stitching. • Move stitch length lever above 20 to satin stitch area.

- Page 19 ADJUSTMENT FOR ZIG-ZAG SATIN STITCHING NEEDLE THREAD TENSION Zig-zag stitching requires less needle thread tension than straight stitching; and closely spaced zig-zag stitches that form a smooth satin-like surface require less tension than widely spaced, _pen zig-zag stitches. Further- more, the wider the satin stitching, the lighter the tension required.

- Page 20 ZIG-ZAG APPLICATIONS LINGERIE SEAMS KNIT FABRIC SEAMS Dainty lingerie seams are made durable A narrow zig-zag stitch is ideal for seaming with zig-zag stitching. After straight stitching knit fabrics. It is particularly suitable seam on wrong side, press both seam allow- underarm seams, other...

- Page 21 ZIG-ZAG APPLICATIONS SEAM FINISHES Seam edges support garment should be given a durable finish where fabrics have a tendency to ravel. The zig-zag stitch is ideal for seam finishing. Place stitching near edge of seam allowance, and then trim excess fabric. DARTS IN INTERFACING Interfacing...

- Page 22 ZIG-ZAG APPLICATIONS MENDING Zig-zag stitching is well suited for all types of household mending. It provides a firm, flexible bond for repair of tears and is ideal for reinforcement and application of elastic. Stitch length and width are regulated according to need.

- Page 23 ZIG-ZAG. APPLICATIONS APPLIQUE Motifs or designs, applied with a zig-zag Method stitch, beauty and interest to •wearing Position and outline design as for Method appareland household textiles. # 1. Follow the shape of the design, outlining Bands, flowers, leaves or figures in con- it entirely with zig-zag stitching.

- Page 24 BUTTONHOLES STITCH LENGTH: ABOVE STITCH WIDTH: 2 AND To establish exact stitch setting and buttonhole length a test sample is advisable. Be sure to use the same fabric and number of fabric layers as in the garment..Procedure: Mark button length on garment.

- Page 25 BUTTONHOLES (Cont'd) Final Bar Tack: With needle in fabric, raise presser foot and set stitch width at 4. Lower presser foot and duplicate tack previously made. Leave needle in fabric at point F. lower Fastening Stitch: With needle in fabric, raise presser foot and sgt stitch width at O, foot, take approximately three stitches_ Remove work, draw threads to wrong side and trim.

- Page 26 DARNING With just a little practice you will be able 5. Lower presser foot and start stitching, to darn clothing and household linens effort- alternately letting fabric feed normally away from you and then gently pulling lessly and quickly. fabric toward you. Continue this forward and backward motion until area to be Set Stitch Width Selector on O setting and...

- Page 27 FASHION* AIDS ATTACHMENTS Available forseparate purchase at your local SINGER CENTER Designed to cut down your sewing time, enlarge the scope of your accomplishment produce "professional-looking" results, the following attachments are available for your use on the 337 Machine. RUFFLER...

- Page 28 FASHION AIDS ATTACHMENTS (Cont'd) THE BUTTON SEWING FOOT..• holds ZIPPER FOOT... indispensable two- four-hole buttons securely the placement of stitching close to a raised stitching and provides for formation of thread edge. For zipper insertions, corded seams and shank. slip cover welting. GATHERING FOOT.

- Page 29 -_._ free brush saturated with SINGER* oil is necessary to protect machine against rust .."_'_,..""' CLEAN damage. -_"_:_ * A Trademark of THE SINGER COMPANY...

- Page 30 To Remove and Replace Throat Plate To remove the throat plate To replace the throat plate CLAMPING • Raise needle bar and presser foot. • Position fork of plate under clamping Open slide plate. pin as shown above. • Place thumb under right front end of...

- Page 31 To Remove and Replace Bobbin Case • Open slide plate and remove throat plate (see page 28). POSITIONING • Unlock bobbin case by lifting and pulling STUD holder to right as shown. Remove bobbin case from machine. Remove all lint, fluff or other foreign matter...

- Page 32 To Off the Machine To keep_your machine in top running condition, use SINGER Oil and SINGER* Lubricant. Both are quality products especially prepared for sewing machines, and should always be used in the care of your 337 machine. ' i1 ..

- Page 33 • Remove face plate (see page 27) and oil the places indicated. • Open slide plate and apply a drop of oil to hook raceway as indicated. • Close side plate, replace arm top cover and face plate.

- Page 34 To Oil the Machine (Cont'd) Tilt machine back and remove thumb nut from screw G, being careful not to lose felt washer, and remove cover from underside of machine. Oil each of the places indicated by arrows. Avoid getting oil on any part of the motor. Replace bottom cover.

- Page 35 Speed Controller. Speed of machine regulated by amount of pressure on pedal of foot controller or knee lever. CAUTION: Do not attempt to remave the arm end cover. PEDAL * A Trademark of THE SINGER COMPANY...

- Page 36 Electrical Information (Cont'd) Sewing Light To Remove Bulb. Press bulb intosocket turn it in " unlock" direction, as shown, withdraw. To Replace Bulb. Press bulb into socket with bulb in slot turn it in " lock" direction, as shown. LOCKS FINGER GRIP The built-in...

- Page 37 The Singer Company (all of which are duly Registered Trademarks) on any machine that has been repaired, rebuilt, reconditioned, or altered in any way whatsoever outside a SINGER factory or an authorized SINGER agency is forbidden.

- Page 38 SINGER representative or Approved Dealer or with parts other than those supplied by The Singer Company. IN ADDITION to the above guarantee of parts, each machine will be inspected adjusted whenever necessary without charge...