Advertisement

p

SW/A/ S

OWNER'S

MANUAL

MODEL NO.

315.275110

CAUTION:

Read and follow

ALL safety rules

and instructions

before operating

this equipment.

I

I

I

Thank You for Buying

Craftsman

Tools

i

n

i

CRRFTSMRN°

Industrial Electronic

Plunge Router

Double Insulated

Warranty

Introduction

Unpacking

Features

Adjustments

Operation

Maintenance

Repair Parts

®

Sold by SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179 U.S.A.

972000-290

Printed In U.S.A.

10-00

Advertisement

Table of Contents

Summary of Contents for Craftsman 315.275110

- Page 1 Plunge Router before operating this equipment. Double Insulated Warranty Introduction Unpacking Features Adjustments ® Operation Thank You for Buying Maintenance Craftsman Tools Repair Parts Sold by SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179 U.S.A. 972000-290 Printed In U.S.A. 10-00...

-

Page 2: Rules For Safe Operation

RULES FOR SAFE OPERATION DOUBLE INSULATION is a safety concept in electric IMPORTANT- Servicing of a tool with double insulation power tools which eliminates the need for the usual requires extreme care and knowledge of the system three wire grounded power cord and grounded supply and should be performed only by a qualified service system. - Page 3 14 is recommended for an extension 34. WHEN SERVICING USE ONLY IDENTICAL CRAFTSMAN REPLACEMENT PARTS. cord 25 feet or less in length. A cord exceeding 25 feet is not recommended. If in doubt, use the next 35.

-

Page 4: Table Of Contents

INDUSTRIAL ELECTRONIC PLUNGE ROUTER If this Craftsman Industrial Electronic Plunge Router fails due to a defect in material or workmanship within one year from the date of purchase, Sears will repair it free of charge. WARRANTY SERVICE IS AVAILABLE BY SIMPLY RETURNING THE TOOL TO THE NEAREST SEARS STORE IN THE UNITED STATES. -

Page 5: Unpacking

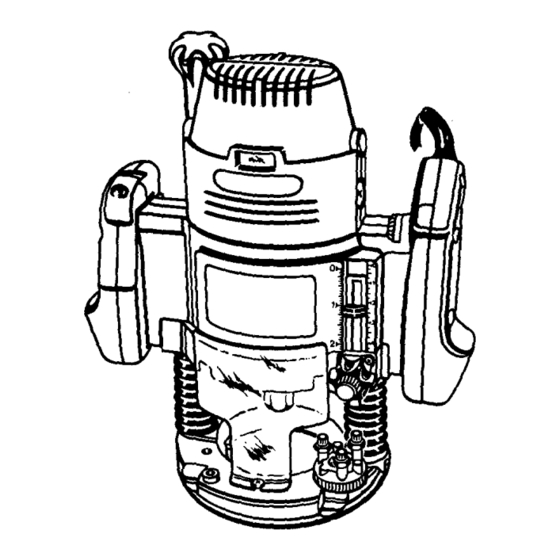

:UNPACKING Your new plunge router comes fully assembled. After removing it from the box, inspect it carefully to make sure that it is not damaged and that no parts are missing. See Figure 1. The following accessories should also be included in the box: Combination Wrench (3/8 In. -

Page 6: Features

FEATURES KNOW YOUR ELECTRONIC ROUTER Beforeattempting to use your router,familiarize yourselfwith alloperatingfeatures and safetyrequirements.See Figures1 and 2. WARNING: Do not allow familiarity with your router to make you careless. Remember that a careless fraction of a second is sufficient to inflict severe injury. DEPTH CONTROLKNOB FRONT VIEW... - Page 7 FEATURES REAR VIEW OF ROUTER DEPTH CONTROL KNOB VARIABLE SPEED CONTROL SELECTOR POWER CORD LOCK HANDLE "LOCK-ON" BUTTON "ON-OFF' TRIGGER SWITCH HANDLE PLUNGE .OCK SPEED ACTUATOR SELECTION CHART 5/16-18 UNC-2B ROUTER BASE FLANGE SUBBASE COLLETNUT Fig. 2 ELECTRICAL CONNECTION Your muter has a precision built electric motor. It should be connected to a power supply that is 120 volts, 60 Hz, AC only (normal household current).

-

Page 8: Adjustments

ADJUSTMENTS WARNING: Your router should never be connected to power supply when you are assembling parts, making adjustments, installing or removing cutters, or when not in use. Disconnecting your router will prevent accidental starting that could cause serious injury. INSTALLING/REMOVING cu'n'ERS See Figures3, 4, and 5. - Page 9 ADJUSTMENTS INSTALLING/REMOVING CUTTERS MOTORSHAFT 1/2IN. (Continued) COLLETNUT If installing cutter for the first time, it can be installed once collet nut is loose. If changing cutters, cutter will easily slip from collet after loosening collet nut. The 1/2 in. collet is machined to precision tolerances ___1/2 IN.

- Page 10 ADJUSTMENTS DEPTH OF CUT ADJUSTMENTS See Figures 6, 7 and 8. When routing a groove that is too deep to safely cut in one pass, it is best to make the cut in several passes. We recommend that several passes be made to reach deeper cuts.

- Page 11 ADJUSTMENTS DEPTH CONTROL KNOB See Figure9. Fine adjustments can be made to the depth of cut by use of the depth control knob. Another primary use of the depth control knob is setting depth of cut when router is mounted upside down on a router table.

- Page 12 ADJUSTMENTS. DEPTH STOP SYSTEM (Continued) SCALE Raise cutter by depressing plunge release actuator. ! -ZERO.ESET Place router on flat surface, and lower router until tip of cutter barely touches flat surface. ,.o,c.To. Squeeze plunge lock actuator to lock cutter at "zero" depth of cut.

-

Page 13: Operation

OPERATION WARNING: Always wear safety goggles or safety glasses with sid_ shields when using router. Failure to do so could result in dust, shavings, chips, loose particles, or foreign objects being thrown in your eyes causing possible serious injury. If operation is dusty, also wear a face or dust mask. "LOCK-ON"... - Page 14 See Figure 15. "Too-slow feeding" can a_socause your router to take off in a Your Craftsman router is an extremely high-speed tool (10,000 wrong direction from the intended line of cut. Always grasp - 22,000 RPM no-load speed), and will make clean, smooth...

- Page 15 OPERATION DEPTH OF CUT As previously mentioned, the depth of cut is important be- cause it affects the rate of feed which, in turn, affects the quality of a cut (and, also, the possibility of damage to your bit). A deep cut requires a slower feed than a shallow one, and WIDTH OF CUT a too deep cut will cause you to slow the feed so much that the bit is no longer cutting, it is scraping, instead.

- Page 16 OPERATION EDGE ROUTING Place router on workpiece, making sure the router bit does ROUTER not contact workpiece. Turn router on and let motor build to its full speed. Begin your cut, gradually feeding cutter into workpiece. WARNING: _LOT Keep a firm grip on router with both hands at all times. Failure to do so could result in loss of control leading to possible serious injury.

- Page 17 OPERATION ROUTING GROOVES See Figure 22. DIRECTION When muting across the face of boards, set router at desired OF CUT I_ depth of cut, place the edge of router base against workpiece, and turn on your router. Slowly feed the cutter into the workpiece along desired cutline.

- Page 18 OPERATION ROUTING WITH A ROLLER GUIDE See Figures 26 and 27. ADJUSTMENT A roller guide has been supplied with your router. It is useful for routing uneven edges and trimming laminates. KNOB i!it The roller guide attaches to the guide holder as shown in figure 26.

- Page 19 OPERATION ROUTING WITH GUIDE BUSHINGS (Cont'd) Secure template to the workpiece. Set router to desired depth of cut and turn it on. Place router base on the template with the collar of the guide bushing against the edge of the template.

-

Page 20: Maintenance

When servicing use only identical Craftsman replacement highly abrasive to bearings, brushes, commutators, etc. parts. Use of any other parts may create a hazard or Consequently it is not recommended that this tool be used for cause product damage. - Page 21 MAINTENANCE PROPER CARE OF CU'I-rERS PROPER CARE OFCOLLET Get faster more accurate cutting results by keeping cutters From time to time, it also becomes necessary to clean your clean and sharp. Remove all accumulated pitchand gum from collet and collet nut. To do so, simply remove collet nut from cutters after each use.

- Page 22 MAINTENANCE PLUNGE LOCK ACTUATOR ADJUSTMENTS r COMPRESSION See Figure 32. SPRI_ The plunge lock actuator has been properly set at the factory and no initial adjustments should be required. How- ever, after extended use slight readjustment may be re- quired, if this situation occurs, make adjustments as fol- lows: UNPLUG YOUR ROUTER.

- Page 23 MAINTENANCE DEPTH CONTROL KNOB ADJUSTMENTS See Figure 34. The depth control knob is spdng loaded against hex nut to prevent router motor from accidentally separating from router base. If depth control knob is turned too far up depth adjustment rod, the spring will cause depth control knob to pop off before hex nut, Do not remove hex nut.

- Page 24 If mounting your router to a router table, use only the three 5/16-18 UNC-2B tapped holes provided in the router base. The use of Craftsman routers in router tables offered Use 5/16-18 UNC-2A flat head screws that are 1-1/8 in.

- Page 25 NOTES Page 25...

- Page 27 CRAFTSMAN ROUTER - MODEL NUMBER 315.275110 ROUTER or when ordering repair parts. The model number will be found on a plate attached to the motor housing. Always mention the model number in all correspondence regarding your PARTS LIST Part Number Description Quan.

-

Page 28: Parts Ordering/Service

For repair of major brand appliances in your own home... no matter who made it, no matter who sold it! 1-800-4-MY-HOME sM An _ • ydme, aay or night (1-800-460-4883) www.sears.com To bring in products such as vacuums, lawn equipment and electronics for repair, call for the location of your nearest Sears Parts &...