Table of Contents

Advertisement

Available languages

Available languages

Owner's Manual

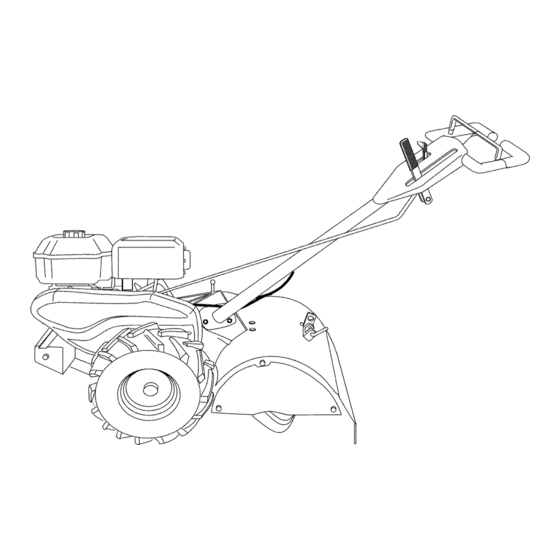

CRRFTSMRN °

REAR TINE TILLER WITH

COUNTER ROTATING TINES

6.0 HP

14 Inch Tine Width

Model No.

917.296020

©

• Espahol, p. 22

This product has a low emission engine which operates

[_

differently

from previously

built engines. Before

start the

you

engine, read and understand this Owner's Manual.

IMPORTANT:

Read and follow all Safety

Rules and Instructions

before

operating this equipment.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

U.S.A.

Visit our Craftsman

website:www.sears.com/craftsman

Advertisement

Table of Contents

Summary of Contents for Craftsman 917.296020

- Page 1 Before start the engine, read and understand this Owner's Manual. IMPORTANT: Read and follow all Safety Rules and Instructions before operating this equipment. Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A. Visit our Craftsman website:www.sears.com/craftsman...

- Page 2 • If this CraftsmanTiller is usedfor commercialor rentalpurposes,this Warrantyapplies for only thirty (30) days from the date of purchase. Warrantyservice is availableby returningthe craftsman powermowerto the nearest searsservice center/departmentin the united states.This warrantyapplies onlywhile this product is in use in the united states.

- Page 3 • Use extension cords and receptacles • Never operate the machine at high as specified by the manufacturer for all speeds on slippery surfaces. Look be- units with electric drive motors or elec- hind and use care when backing. tric starting motors.

- Page 4 .030") RC12YC AGREEMENTS CONGRATULATIONS on your purchase Congratulations on making a smart pur- of a Sears Tiller. It has been designed, chase. Your new Craftsman® product is engineered and manufactured to give you designed and manufactured for years of the best possible...

- Page 5 These accessorieswere availablewhen the tillerwas produced. They are also available at most Sears retailoutlets and servicecenters. Some of these accessoriesmay not apply to your tiller. ENGINE lS, ;U l ,sc, S T, TILLER PERFORMANCE FURROWOPENER TILLER MAINTENANCE BELT TINES SHEAR PIN HAIRPIN CLIP CONTENTS OF HARDWARE...

- Page 6 Your new tiller has been assembled at the factory with the exception of those parts left unassembled for shipping purposes. To ensure safe and proper operation of your tiller all parts and hardware you assemble must be tightened securely. Use the correct tools as necessary to insure...

- Page 7 Handle Column Handle Assembly "UP"Position a _,_ Tighten handle Cables ,i,,_,, l ockleverto hold Cable Clip Loosen Handle Lock_i_ handles CONNECT SHIFT Lever to Move Insert end of shift rod farthest from bend into hole of shift lever indicator. Insert hairpin clip through hole of shift...

- Page 8 These symbols may appear on your Tiller or in literature suppliedwith the product. Learn and understandtheir meaning. KNOW YOUR TILLER READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TILLER. Compare the illustrations with your tiller to familiarize yourself with the location various...

- Page 9 The operationof any tiller can result in foreignobjects throwninto the eyes, which can result in severeeye damage.Alwayswear safetyglasses or eye shields beforestartingyour tiller and while tilling.We recommenda wide vi- sion safety maskover spectaclesor standardsafetyglasses. HOW TO USE HARD TO SHIFT GEARS YOUR TILLER...

- Page 10 TURNING • For approximate capacity see "PROD- UCT SPECIFICATIONS" on page 3 of Release the drive control bar. this manual. All oil must meet A.P.I. Move throttle control to "SLOW" posi- Service Classification SG-SL. tion. • For cold weather operation you should Place shift lever indicator in "F"...

- Page 11 Spark Plug CAUTION: Alcohol blended fuels (called gasohol or using ethanol or methanol) attract moisture which leads to separa- tion and formation of acids during storage. Acidic gas can damage the fuel system of an engine while in storage. To avoid engine problems, the fuel system...

- Page 12 ADJUST WHEELS CULTIVATING Place blocks under right hand side of tiller and remove hairpin clip and clevis pin from right hand wheel. Move wheel outward approximately inch until hole in inner wheel hub lines up with inner hole in axle. Replace clevis pin and hairpin clip on...

- Page 13 MAINTENANCE SCHEDULE FILL IN DATES AS YOU COMPLETE REGULAR SERVICE Check Engine Oil Level Change Engine Oil Oil Pivot Points Inspect Spark Arrester / Muffler Inspect Air Screen Clean or Replace Air Cleaner Cartridge Clean Engine Cylinder Fins Replace Spark Plug RH Gear Case Grease...

- Page 14 Refill engine with oil. See "CHECK AI_CAUTION: Disconnect spark plug ENGINE OIL LEVEl" in the Operation wire before performing any maintenance section of this manual. (except carburetor adjustment) to prevent accidental starting of engine. Prevent fires! Keep the engine free of grass, leaves, spilled oil, or fuel.

- Page 15 COOLING SYSTEM SPARK PLUG Your engine is air cooled. For proper Replace spark plugs at the beginning gine performance and long life keep your each tilling season or after every 50 hours engine clean. of use, whichever comes first. Spark plug •...

- Page 16 TIRE CARE Guard _CAUTION: When mounting tires, unless Nut and beads are seated, overinflation can cause Washer an explosion. (Located • Maintain 20 pounds of tire pressure. Behind tire pressures are not equal, tiller will Tire) pull to one side. Screws •...

- Page 17 TINE REPLACEMENT • To maintain the superb tilling perfor- mance of this machine the tines should A(_,CAUTION: Tines are sharp. Wear be checked for sharpness, wear, and gloves or other protection when handling bending, particularly the tines which tines. are next to the transmission. If the gap A badly worn tine causes...

- Page 18 ENGINE TO ADJUST CARBURETOR The carburetor has been preset at the Maintenance, repair, or replacement factory and adjustment should not be the emission control devices and systems, necessary. However, engine performance which are being done at the customers can be affected by differences in fuel, tem- pense,...

- Page 19 Immediately prepare your tiller for storage NOTE: Fuel stabilizer is an acceptable at the end of the season or if the unit will alternative in minimizing the formation not be used for 30 days or more. fuel gum deposits during storage. _I_CAUTION: Never store the tiller with stabilizer...

- Page 20 TROUBLESHOOTING CHART: See appropriate section in manual unless directed to Sears service center PROBLEM CAUSE CORRECTION Will not start 1. Out of fuel. 1. Fill fuel tank. See "TO START ENGINE" Engine not "CHOKED" properly. the Operation section. Wait several minutes before Engine...

- Page 21 TROUBLESHOOTING CHART: See appropriate section in manual unless directed to Sears service center CAUSE PROBLEM CORRECTION Engine Low oil level/dirty oil. 1. Check oil level/change oil. overheats Dirty engine air screen. Clean engine air screen. Dirty engine. Clean cylinder fins, air screen, muffler area.

- Page 22 Mantenimiento ..........GARANTIA LIMITADA DE DOS AI_O PARA LA CULTIVADORA CRAFTSMAN Por un (1) aho, a partir de la fecha de compra, cuando esta Cultivadora Craftsman se mantenga, lubrique y afine segtJn las instrucciones para la operaci6n y el mantenimiento en el manual del due_o, Sears reparar_., gratis, todo defecto en el material y la mano de obra.

- Page 23 MANTENIMIENTO Y ALMACENAMIEN- • Despu_s de pegarle a un objeto extraSo, pare el motor, remueva el alambre de la bujfa, inspeccione la cultivadora cuidadosa- • Mantenga los accesorios y aditamentos de mente, para verificar si hay daSos, y repare la m_.quina en buenas condiciones para el el daSo antes de volver a arrancar y operar la funcionamiento.

- Page 24 Capacidad de 3 Cuartos Congratulaciones por su buena compra. asolina: Sin plomo, regular Su nuevo producto Craftsman® est,. diseSado Aceite(API-SG-SL): SAE 30 (Sobre 40°F) y fabricado para funcionar de modo fiable por (Capacidad: 19 oz.) SAE 5w-30 SAE 10w-30 muchos aSos. Pero como todos los productos, (Debajo 40°F)

- Page 25 Estos accesorios estaban disponibles cuando se produjo la cultivadora. Tambien est_.n disponibles en la mayoria de las tiendas de Sears yen los centros de servicio. Algunos de estos accesorios tal vez no se apliquen a su cultivadora. MOTOR BUJIA SILENCIADOR FILTRO DE AIRE LATA DE GASOLINA ACEITE DEL MOTOR...

- Page 26 Su cultivadora nueva ha sido montada en la f_.brica, con la excepci6n de aquellas partes que se dejaron sin montar por razones de envio. Para asegurarse que la cultivadora operar_, en forma segura y adecuada, todas las partes y los articulos de ferreteria que monte tienen que estar apre- tados en forma segura.

- Page 27 Columna del Conjunto del mango Mango . ,, I_', ,,_posoci6n"Arriba" d___ "', ',, Apriete la palanca Cables _--J_"_'_ ',,_,_:, de cierre del mango __i,_` para sujetarla Abrazadera del Cable cierre del mango para ___11_<,_ moverla CONEXION DE LA VARILLA DE CAMBIO Inserte el extremo de la varilla de cambio que est,.

- Page 28 Estossimbolos pueden apareser s obresucultivadora e nlaliterature proporcionada conel pro- ducto, a prenda y comprenda s ussignificados. CONOZCA SU CULTIVADORA LEA ESTE MANUAL DEL DUENOY LAS REGLAS DE SEGURIDAD ANTES DE OPERAR SU CULTIVADORA Compare las ilustraciones con su cultivadora para familiarizarse con la ubicaci6n de los...

- Page 29 La operaci6n de cualquier cultivadora puede hacer que salten objetos extrafios dentro de sus ojos, Io que puede producir dafios graves en estos. Siempre use anteojos de seguridad o protecciones para los ojos antes de hacer arrancar su cultivadora o mientras este labrando con _lla.

- Page 30 GIRO ANTES DE HACER ARRANCAR MOTOR Suelte la barra de control de la impulsi6n. Mueva el control de la aceleraci6n a la IMPORTANTE: Tenga mucho cuidado de no posici6n de "LENTO" (SLOW). permitir que entre mugre al motor cuando Ponga el indicador de la palanca de cambio revise o aSada aceite o combustible.

- Page 31 IMPORTANTE: Cuando se opere en temperatu- Permita que se caliente el motor por unos ras por debajo de 32°F (0°C) use gasolina de cuantos minutos antes de enganchar los invierno limpia y nueva para auedar a asegurar brazos. un buen arra.nque en clima frio. AVISO: A mucha altura (sobre 3000 pies) o PREOAUClON: Combustibles...

- Page 32 AJUSTE DE LAS RUEDAS PARA EL CULTIVO Ponga bloques debajo del lado derecho de la cultivadora y remueva la abrazadera de horquilla y la clavija de horquilla de la rueda del lado derecho. Mueva la rueda hacia afuera, aproximada- mente 1 pulgada, hasta que el agujero en el cubo de la rueda interior se alinee con el agujero interior en el eje.

- Page 33 PROGRAMA MANTENIMIENTO E EoSS.FEC.s SOE.EO.O SERV,C,O REGU'A F/O+/O'7 SOE SERV'C'O Revisar el nivel del aceite del motor Cambiar el aceite del motor Aceitar los puntos de pivote Inspeccionar el supresor del silenciador Inspeccionar la rejilla de aire Limpiar/cambiar el cartucho del filtro de aire Limpiar las aletas del cilindro...

- Page 34 Despues de que el aceite se haya drenado Ai_,PRECAUCl6N: Desconecte el alambre de completamente, vuelva a colocar el tapdn la bujia antes de dar mantenimiento (excepto del drenaje clel aceite y aprietelo en forma por el ajuste del carburador) para evitar que el segura.

- Page 35 SlSTEMA DE ENFRIAMIENTO BUJIA Su motor se enfria con aire. Para obtener el Cambie las bujias al comienzo de cada rendimiento del motor adecuado y larga temporada de cultivo, o despues de 50 horas duraci6n mantenga su motor limpio. de uso, Io que suceda primero. El tipo de bujia •...

- Page 36 CUIDADO DE LAS LLANTAS Protecci6nde la correa _L, PRECAUCl6N: Cuando monte las Ilantas, Tuerca a menos que los talones esten asentados, si Hexagonal se inflan demasiado se puede producir una y arandela explosi6n. (Ubicadas • Mantenga 20 libras de presi6n en las Ilantas. detras de la Si la presi6n de las Ilantas no es la misma, la cultivadora va a tirar hacia un lado.

- Page 37 CAMBIO DE BRAZOS • Para que esta m_.quina pueda mantener un rendimiento excelente en el labrado, se _,PRECAUCl6N:Losbrazos sonafilados. deben revisar los brazos para verificar si Useguantes u otraprotecci6n c uandomaneje losbrazos. est_.n afilados, desgastados o doblados, especialmente los que se encuentran al lado Sihayun brazo muydesgastado s u cultivadora de la transmisi6n.

- Page 38 MOTOR Cable del tornillo de sujeci6n El mantenimiento, la reparaci6n, o el reemplazo de cualquier dispositivos o sistemas del control Cable de la Aceleraci6n de la emisi6n, los cuales sean hechos al costo del cliente, pueden ser realizados por cualquier individuo o establecimiento de reparaci6n de motor.

- Page 39 AVlSO: El estabilizador de combustible es una Inmediatamente prepare su cultivadora para el almacenamiento al final de la temporada o si la alternativa aceptable para reducir a un minimo unidad no se va a usar por 30 dfas o m_.s. la formaci6n de depdsitos de goma en el com- bustible durante el periodo de almacenamiento.

- Page 40 IDENTIFICACION DE PROBLEMAS: Vea la seccibn apropiada en el manual a menos que est_ dirigido a un centro de servicio Sears. PROBLEMA CAUSA CORRECCION No arranca Sin combustible. 1. Llene el estanque de combustible. Motor sin la "ESTRANGU- 2. Vea"PARA ARRANCAR MOTOR"...

- Page 41 IDENTIFICACION DE PROBLEMAS: Vea la seccibn apropiada en el manual a menos que est_ dirigido a un centro de servicio Sears. PROBLEMA CAUSA CORRECCION Falta de fuerza 10.Rejilla de aire del motor sucia. 10. Limpie la rejilla de aire del motor. 11 .Silenciador sucio/taponado.

- Page 42 TILLER - - MODEL NUMBER 917.296020 HANDLES PART PART DESCRIPTION DESCRIPTION 189482 Throttle, Control STD541437 Nut, Crownlock 3/8-16 141406 19131611 Washer 13/32 x 1 x 11Ga. Grip, Handle 110673X Grommet, Handle 109228X Lever, Lock, Handle 127254X Bar, Drive Control Assembly 150628 Handle, Assemble 6712J...

- Page 43 TILLER - - MODEL NUMBER 917.296020 MAINFRAME, LEFT SIDE maJnfrar_m left PART PART DESCRIPTION DESCRIPTION STD551137 Washer, Lock 3/8 165501X613 Guard, Belt STD541037 Nut, Hex 3/8-16 132801 Belt, V 170127 Shield, Inner Belt Guard 104679X Pulley, Idler 164329 Pin Spiral Flared 12000032 Ring, Klip 110111X...

- Page 44 TILLER - - MODEL NUMBER 917.296020 MAINFRAME, RIGHT SIDE mainframe right PART PART DESCRIPTION DESCRIPTION 102190X Tire 73970500 Locknut, Hex, Flange 5/16-18 183122X624 102332X Bracket, Reinforcement 795R Tire Valve 102173X CounterWeight, R.H. STD551137 Washer, Lock 3/8 Engine, (See Breakdown) Briggs Model No.

- Page 45 TILLER - - MODEL NUMBER 917.296020 TRANSMISSION transmission 19.5b PART PART DESCRIPTION DESCRIPTION 188554 Transmission Assembly (Includes 150737 Ground Shaft Assembly Key Nos. 2-52) 143008 Bearing, Shaft, Ground Drive R.H. 188482 Gearcase, L.H. w/Bearing 106388X Spacer 0.70 x 1.00 x 1.150 (Includes Key No.

- Page 46 TILLER - - MODEL NUMBER 917.296020 TINE SHIELD .j" tine shield 14 in PART PART DESCRIPTION DESCRIPTION STD541037 Nut Hex 3/8-16 73900500 Nut, Lock Hex Fig 5/16-18 unc 8393J Pin, Stake, Depth 102156X Stake, Depth 74930632 Bolt Hex 3/8-16 x 2 12000035 Ring, Klip 180847...

- Page 47 TILLER - - MODEL NUMBER 917.296020 TINE ASSEMBLY tine ipb 99 2 PART PART DESCRIPTION DESCRIPTION 4459J Tine, Outer, L.H. 4460J Tine, Outer, R.H. 132673 Pin, Shear 132722 Assembly, Hub and Plate, R.H. 6554J Tine, Inner, L.H. 6555J Tine, Inner, R.H. 3146R Clip, Hairpin 132721...

- Page 48 Decal, Shift Indicator 157984 Decal, Tine, Shield, Counter Rotating Tines 120075X Decal, Warning, Rotating Tines 163094 Decal, Tine Depth Stake 162215 Decal, Tine, Shield, Warning Dom 171078 Decal, Rewind 167156 Decal, Craftsman IC 194914 Decal, Engine 400502 Manual, Owner's (Eng/Span)

- Page 49 TILLER - - MODEL NUMBER 917.296020 ENGINE, BRIGGS & STRATTON - - MODEL NUMBER 120202-0417-E1 15A_ 718 _ 11330 REPAIR MANUAL [10_OWNER'SMANUALI...

- Page 50 TILLER - - MODEL NUMBER 917.296020 ENGINE, BRIGGS & STRATTON - - MODEL NUMBER 120202-0417-E1 1251 1091 692 _ 276_ 95 _ 276_ 977 CARBURETOR GASKET 276_ 633AQ 121 CARBURETOR OVERHAUL _425 163% 1341 127 _ 633AO 358 ENGINE GASKET 1022...

- Page 51 TILLER - - MODEL NUMBER 917.296020 ENGINE, BRIGGS & STRATTON - - MODEL NUMBER 120202-0417-E1 65 _ 1211 689 _ 1036 EMISSIONS LABEL ]1 1329 REPLACEMENT ENGINE I 1005 1095 VALVE GASKET SET I O7O I O22 209A 209_ 836A_ 836 _ 188_ 190 __...

- Page 52 TILLER - - MODEL NUMBER 917.296020 ENGINE, BRIGGS & STRATTON - - MODEL NUMBER 120202-0417-E1 PART PART DESCRIPTION DESCRIPTION Line-Fuel (Cut to Required 699510 Cylinder Assembly 691050 Length) 299819 • Seal-Oil (Magneto Side) Screw (Control Bracket) 699486 Head-Cylinder 699479 Screw (Fuel Tank) 698210 •...

- Page 53 TILLER - - MODEL NUMBER 917.296020 ENGINE, BRIGGS & STRATTON - - MODEL NUMBER 120202-0417-E1 PART DESCRIPTION 692076 Boot-Spark Plug 694257 Spacer Deflector-Muffler 393757 690661 Screw (Muffler Deflector) 691855 Spring-Friction 690572 Spring-Detent 690959 Pin-Locating 692565 Gear-Timing 692564 Retainer-E Ring Gear-Idler 692566 Retainer 694258...

- Page 56 Your Home For repair - in your home - of all major brand appliances, lawn and garden equipment, or heating and cooling systems, no matter who made it, no matter who sold it! For the replacement parts, accessories owner's manuals that you need to do-it-yourself. For Sears professional installation of home appliances and items like garage door openers and water heaters.