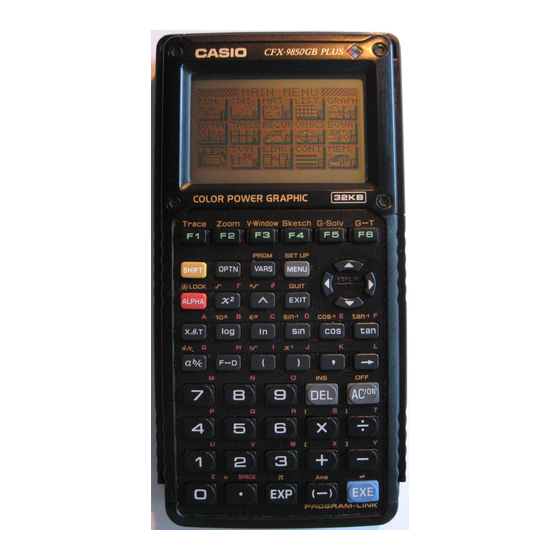

Casio CFX-9850G User Manual

Graphic scientific calculator

Hide thumbs

Also See for CFX-9850G:

- Calculations manual (72 pages) ,

- Programming manual (48 pages) ,

- Graphing manual (32 pages)

Table of Contents

Advertisement

GUIDELINES LAID DOWN BY FCC RULES FOR USE OF THE UNIT IN THE

U.S.A. (not applicable to other areas).

This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to Part 15 of the FCC Rules. These limits are de-

signed to provide reasonable protection against harmful interference in a resi-

dential installation. This equipment generates, uses and can radiate radio fre-

quency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equip-

ment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

Proper connectors must be used for connection to host computer and/or periph-

erals in order to meet FCC emission limits.

Connector SB-62

Important!

Please keep your manual and all information handy for future reference.

In no event shall CASIO Computer Co., Ltd. be liable to anyone for special, collateral,

incidental, or consequential damages in connection with or arising out of the purchase or

use of these materials. Moreover, CASIO Computer Co., Ltd. shall not be liable for any

claim of any kind whatsoever against the use of these materials by any other party.

• The contents of this manual are subject to change without notice.

• No part of this manual may be reproduced in any form without the express written

consent of the manufacturer.

NOTICE

FCC WARNING

Data Analyzer Unit to Power Graphic Unit

Advertisement

Table of Contents

Summary of Contents for Casio CFX-9850G

- Page 1 Please keep your manual and all information handy for future reference. In no event shall CASIO Computer Co., Ltd. be liable to anyone for special, collateral, incidental, or consequential damages in connection with or arising out of the purchase or use of these materials.

- Page 2 Before using the CASIO Data Analyzer for the first time... Main power supply batteries are not installed in the CASIO Data Analyzer when you purchase it. Be sure to use the following procedure to load main power supply batteries before using this data analyzer unit for the first time.

-

Page 3: Handling Precautions

Handling Precautions • Never insert a probe into an electrical outlet. Doing so creates the danger of electrical shock. • Never apply more than 30V to the analog channels (CH1, CH2, CH3), or more than 5.5V to the SONIC, DIG IN, or DIG OUT channels. Doing so can damage the data analyzer. -

Page 4: Table Of Contents

Contents Chapter 1: Getting Ready ........1 Unpacking ..................2 Probes ................... 2 CASIO Data Analyzer Overview ..........3 Sample Data ................. 3 Probes ................... 3 Channels ..................3 Data Analyzer and the CFX-9850G/CFX-9800G ......3 Command and Programs .............. 4 Conversion Equations and Post-processing ........ - Page 5 Chapter 2: Modes ..........15 Relationships Between Modes ............ 16 Communications Mode ............... 17 Multimeter Mode ................. 17 Internal Mode ................18 Data-Log Mode ................19 Setup Mode ................. 20 Auto-ID Probes ................21 Chapter 3: Commands and Programming ..23 Command Conventions and Formats ........

- Page 6 Command Reference ..............36 Command 0 - All Clear ..............36 Command 1 - CHANNEL SETUP ..........37 Command 2 - DATA TYPE AND DISPLAY SETUP ..... 43 Command 3 - SAMPLE AND TRIGGER SETUP ......45 Command 4 - CONVERSION EQUATION SETUP ..... 50 Command 5 - DATA RANGE SETUP ..........

-

Page 7: Manual Conventions

Precautionary and important information that requires attention Supplementary information • This manual covers operation with the CASIO CFX-9850G and CFX-9800G graphic scientific calculator models. All operations described for the CFX- 9850G also apply to the CFX-9950G. See the explanations for CFX-9850G procedures for information on how to operate the CFX-9950G. -

Page 8: Chapter 1: Getting Ready

Chapter 1: Getting Ready This chapter acquaints you with CASIO Data Analyzer key operations, dis- play indicators, and other basic information you need to know. It also tells you how to replace batteries, connect to a graphic scientific unit, and perform other set up procedures before beginning actual operation. -

Page 9: Unpacking

User’s Guide (this manual) EA-100 Probes The CASIO Data Analyzer comes with the following three probes. • Voltage probe: for sampling of voltages within a range of ±10V • Optical probe: for sampling of irradiance (radiant flux density) from 100 to 999* •... -

Page 10: Casio Data Analyzer Overview

Chapter 1: Getting Ready CASIO Data Analyzer Overview The CASIO Data Analyzer is a digital instrument you can use to sample and collect data on various everyday natural phenomena. The following sections provide information on using its probes and channels, and tell you how to connect to a graphic scientific calculator. -

Page 11: Command And Programs

Chapter 1: Getting Ready Command and Programs There are a total of 10 commands defined for this data analyzer unit: Com- mand 0 through Command 9. These commands can be used to specify such parameters as the type of data being sampled, the channel being used for sampling, the sample time, and the number of samples. -

Page 12: Data Filtering

Chapter 1: Getting Ready Data Filtering Static “noise” can sometimes cause sampled data to become corrupted, making it impossible to obtain accurate results from calculations and analy- sis. This data analyzer unit includes a data filtering system that eliminates noise and help to make sure that data is always accurate. Keyboard The front panel of this data analyzer unit has a liquid crystal display screen and eight keys. -

Page 13: Key Functions

Chapter 1: Getting Ready Key Functions The following describes the functions of each of the eight keys on the key- board. This section is intended more as a reference and contains information that may be difficult to understand at first glance. Don’t worry though, many of the expressions used in the following key function descriptions will be- come clearer after you read the section of this manual titled “Modes.”... - Page 14 Chapter 1: Getting Ready Description • Data-Log Mode: Each press of [CH-View] in this mode sequentially switches the channel whose data is on the dis- play. The channel indicator of the currently selected chan- nel flashes on the screen. [INTERNAL] Pressing this key while in the Communications Mode enters the Internal Mode.

-

Page 15: Reading The Display

Chapter 1: Getting Ready Reading the Display The data analyzer’s liquid crystal display (LCD) is divided among five areas, each of which indicates the status of a particular operation. Display Panel The display screen shows the current operating mode, the input/output chan- nel being used, and information about the current sampling operation. -

Page 16: Out-Of-Range Samples

Chapter 1: Getting Ready Area 3 (Sampling Status Area) The indicators in this area shows the current data sampling status. READY means the data analyzer is ready and standing by for data sampling, SAM- PLING indicates that a sampling operation is in progress, and DONE means that the sampling operation is finished. -

Page 17: Power Supply

Chapter 1: Getting Ready • Voltage: Less than –10V • Temperature: Less than –20°C • Light: Less than 100 Power Supply The data analyzer can be powered by four AA-size batteries or an optional AC adaptor (AD-A60024). This section tells you when you should replace batteries and how to connect the optional AC adaptor. -

Page 18: Battery Replacement Interval

Chapter 1: Getting Ready 2. Load four AA-size batteries into the battery compartment, making sure they are facing as shown in the illustration inside the battery compart- ment. 3. After loading batteries, replace the battery compartment cover. 4. Press [ON/OFF] to turn on power, which should make the screen shown below appear on the display. - Page 19 Chapter 1: Getting Ready • Never try to modify the power cord of the AC adaptor, do not allow it to become broken or cracked, and do not subject it to excessive bending, twisting, or pulling. Do not place heavy objects on top of the power cord and do not subject it to direct heat.

-

Page 20: Connecting The Data Analyzer To A Calculator

Chapter 1: Getting Ready Connecting the Data Analyzer to a Calculator The following procedure describes how to use the data communication cable that comes with the data analyzer to connect it to a CFX-9850G or CFX- 9800G graphic scientific calculator. Data communication cable (SB-62) 1. -

Page 21: Analog Input Channels

Chapter 1: Getting Ready Analog Input Channels CH1, CH2, and CH3 are analog input channels for connection of probes that measure electrical change. All three analog channels perform identical types of sampling. Ultrasonic Input Channel This channel is for connection of a distance sensor that can be used to meas- ure the distance from the probe to an object. -

Page 22: Chapter 3: Commands And Programming

Chapter 3: Commands and Programming Chapter 3: Commands and Programming This chapter describes how to set up the data analyzer and control it using commands sent from a connected CFX-9850G or CFX-9800G graphic sci- entific calculator. Command Conventions and Formats ........ 24 Programming .............. -

Page 23: Command Conventions And Formats

Chapter 3: Commands and Programming Command Conventions and Formats Commands sent from a connected CFX-9850G or CFX-9800G graphic sci- entific calculator can be used to make various settings and control opera- tions of the data analyzer. Commands Commands can be written as CFX-9850G list data or CFX-9800G matrix data in the format shown below. -

Page 24: Initial Settings

Chapter 3: Commands and Programming Number Description MULTIMETER MODE SETUP This command sets the Multimeter Mode unit of measurement for a particular channel. REQUEST STATUS This command creates a data list concerning the data analyzer’s current status (error status, probe connection data, etc.) being requested by the connected calculator. -

Page 25: Programming

Chapter 3: Commands and Programming Programming Programs can be input on the CFX-9850G graphic scientific calculator and then sent to the data analyzer to make it perform a series of tasks. • Note that data analyzer control programs can be input on the CFX-9850G graphic scientific calculator only. -

Page 26: Sending Commands From A Calculator To The Data Analyzer

Chapter 3: Commands and Programming Example Program The following is an example program written for the CFX-9850G. Cls ! CFX-9850G graph clear operation {1,0} " List 6 ! Clears all channel settings and data. Send(List 6) ! {1,1,1} " List 6 ! Specifies sampling with Auto-ID probe con- Send(List 6) ! nected to CH1. -

Page 27: Send(List) Examples

Chapter 3: Commands and Programming the list. When using the Send(List) command, you should specify the list that contains the commands by replacing “List” with a CFX-9850G List variable (List 1 through List 6). • Sending a new setup command (Command 1 or Command 3) clears all previously sampled data from data analyzer memory. -

Page 28: Matrix Data Example

Chapter 3: Commands and Programming 7. Repeat steps 5 and 6 as many times as necessary to send any other matrix data that you want. Matrix Data Example The following describes a typical example procedure for sending commands that set up the data analyzer for sampling of distance data with a distance sensor. -

Page 29: Transferring Sampled Data To A Calculator

Chapter 3: Commands and Programming Transferring Sampled Data to a Calculator This section explains how to send sampled data between the data analyzer and a connected CFX-9850G or CFX-9800G graphic scientific calculator for graphing and analysis. Transferring Data to the CFX-9850G The following explanations all apply to transferring data from the data analyzer to the CFX-9850G only. -

Page 30: Sample Program Using Receive(Variable)

Chapter 3: Commands and Programming • Note that the data transferred by a Receive(List) command execution is somewhat different when statistical post-processed data is involved. See P.34 “Using Receive(List) to Fetch Statistical Post-Processed Data”. The following are detailed explanations of how the Receive( command works with each type of parameter that can be specified with it. -

Page 31: Sample Operation Using Receive(List)

Chapter 3: Commands and Programming Sample Operation Using Receive(List) The following program fetches sampled data items and assigns them to CFX- 9850G list variables. Receive(List 1) Fetches up to 255 data items from the lowest num- bered channel*, and stores them in List 1. Receive(List 2) Fetches up to 255 data items starting from the next active channel, and stores them in List 2. -

Page 32: Sample Operation Using Receive(List) To

Chapter 3: Commands and Programming with the first derivative calculated for CH1 sample data, and the second de- rivative calculated for the SONIC channel. P.52 DATA RANGE SETUP parameters (Command 5) can be used to specify the data groups and data range to be transferred to the CFX-9850G. This com- mand comes in handy when you want to fetch only specific data items, or when there are more than 255 data items in data analyzer memory. -

Page 33: Using Receive(List) To Fetch Statistical Post-Processed Data

Chapter 3: Commands and Programming Two Receive(List) cycles are required in this example because there are more than 255 samples. Following the first two Receive(List) commands, a single Send(List) is necessary to verify the data fetches from the SONIC channel. The next Send(List) command specifies the data range of Receive(List4) and Receive(List5). -

Page 34: Using Receive

Chapter 3: Commands and Programming Using Receive( to Fetch Time Data Either relative or absolute time data recording can be specified with the time P.45 recording parameter of the SAMPLE AND TRIGGER SETUP (Command 3). Specifying 1 (absolute time on) or 2 (relative time on) records time data in seconds whenever data is being sampled. -

Page 35: Example Cfx-9800G Operation Following Data Transfer

Chapter 3: Commands and Programming Example CFX-9800G Operation Following Data Transfer 1. Enter the REG Mode. 2. Press [SHIFT] [SETUP] to enter the Setup Mode, and then set the follow- ing parameters. S-data: STO S-graph: DRAW 3. Use [Range] to specify the graph screen range (window) in accordance with the sampled data. -

Page 36: Command 1 - Channel Setup

Chapter 3: Commands and Programming Command 1 - CHANNEL SETUP Command 1 specifies various parameters for a channel where a probe is connected. Executing Command 1 clears all sampled data currently stored in data analyzer memory. Clears all previously stored data and returns all channels to their initial defaults. - Page 37 Chapter 3: Commands and Programming Auto-ID If Auto-ID is not activated, voltage in the range 0 to 5V is used. Voltage (±10V) Current (±10A) Based on Vin input, 1V = 1A. Resistance (1k% to 100k%) Period (0.000004 to 50 seconds) P.68 See “Period and Frequency Measurement”...

- Page 38 Chapter 3: Commands and Programming Trigger Threshold Parameter This parameter is used when period (5) or frequency (6) is specified as the operation parameter to set the level at which measurement starts. The initial default for this parameter is 1. A value in the range of –10 to +10 can be specified for this parameter to set in input voltage threshold value of –10V to +10V.

- Page 39 Chapter 3: Commands and Programming d/dt Only the indicator is on the display when this type of post- processing is selected. d/dt (first derivative and second derivative) d/dt indicators are on the display when this type of post-processing is selected. Statistics (mean, standard deviation, minimum, maximum) Derivative and statistical post-processing are performed using values pro- duced by conversion equations.

- Page 40 Chapter 3: Commands and Programming Channel 6 (DIG OUT) The following parameter settings apply only when Channel 6 (DIG OUT) is specified by the Command 1 channel parameter. Number of Data Elements Parameter This parameter applies to digital output only. It specifies the number of data elements included in a list.

- Page 41 Chapter 3: Commands and Programming Post-processing Result Stat Point Raw Data minX maxX & 1.0, 1.2, 1.1, 1.3 1.15 0.11 2.3, 4.0, 2.6, 3.2 3.03 0.65 3.5, 2.6, 3.7, 4.8 3.65 0.78 3.7, 4.2, 4.5, 5.2 0.54 4.8, 5.6, 4.3, 5.4 5.03 0.51 Cleared...

-

Page 42: Command 2 - Data Type And Display Setup

Chapter 3: Commands and Programming Command 2 - DATA TYPE AND DISPLAY SETUP Command 2 specifies the data type for data sent to a connected graphic scientific calculator. It is also used to specify whether or not channel data should be displayed during sampling. Syntax {2, Data Display CH, Data Type, REG X Data, REG Y Data, X-Data Post- Processing, Y-Data Post-Processing}... - Page 43 Chapter 3: Commands and Programming Data Type 1 (REG) The following are the parameter settings when the data type parameter set- ting is 1: REG X data, REG Y data, X-data post-processing, Y-data post- processing. REG X Data Parameter This parameter specifies which channel should be assigned as REG X data. The initial default for this parameter is 0.

-

Page 44: Command 3 - Sample And Trigger Setup

Chapter 3: Commands and Programming d/dt (first derivative) (second derivative) • Whenever 1 (first derivative) or 2 (second derivative) is specified for this parameter, you must also use Command 1 to specify the same setting for post-processing. DATA TYPE AND DISPLAY SETUP Example {2,1} 2 = DATA TYPE AND DISPLAY SETUP 1 = CH1 data display... - Page 45 Chapter 3: Commands and Programming Sample Time Parameter This parameter specifies how long sampling should be performed in sec- onds. Setting 0.001 for this parameter specifies that sampling should be per- formed for 1 millisecond. The initial default for this parameter is 0.5. 0.001 to 16000 Number of seconds...

- Page 46 Chapter 3: Commands and Programming Time Recording Parameter This parameter specifies whether time recording during sampling should be performed using absolute time or relative time. The initial default for this pa- rameter is 0. Time recording is not performed. Absolute time recording Actual time is recorded in seconds when sampling starts.

- Page 47 Chapter 3: Commands and Programming Trigger Threshold Parameter This parameter specifies the trigger level when any external trigger (any trig- ger other than manual triggering with the [TRIGGER] key) is specified for the trigger source parameter. The initial default for this parameter is 1. The trigger threshold setting range depends on the source specified by the trigger source parameter, as shown below.

- Page 48 Chapter 3: Commands and Programming • Whenever 5 (period) or 6 (frequency) is specified for the operation pa- rameter of Command 1 and 2 (CH1), 3 (CH2), or 4 (CH3) is specified for the clock source parameter of Command 3, the setting for the clock source parameter channel specified in by Command 3 must match the channel parameter of Command 1.

-

Page 49: Command 4 - Conversion Equation Setup

Chapter 3: Commands and Programming No filtering 5-point S-G smoothing 9-point S-G smoothing 17-point S-G smoothing 25-point S-G smoothing 3-point median filtering 5-point median filtering • No filtering is performed when the number of samples parameter of Com- mand 3 is –1 (real-time sampling). SAMPLING/TRIGGER SETUP Example {3,0.2,50} 3 = SAMPLING/TRIGGER SETUP... - Page 50 Chapter 3: Commands and Programming * Even if 0 is specified for this parameter, the conversion equation function remains enabled if the EQ indicator is on the display. Equation Type Parameter This parameter specifies the type of equation to be used for conversion. The initial default for this parameter is 1.

-

Page 51: Command 5 - Data Range Setup

Chapter 3: Commands and Programming CONVERSION EQUATION SETUP Examples {4,1,1,0,0,12,34} 4 = CONVERSION EQUATION SETUP 1 = Conversion equation 1 1 = Polynomial 0 = No display of units 0 = Constant K 12 = Constant K 34 = Constant K {4,2,3,2,2,5} 4 = CONVERSION EQUATION SETUP 2 = Conversion equation 2... - Page 52 Chapter 3: Commands and Programming Raw data Filtered data is returned when data filtering is turned on with the filter parameter of Command 3. d/dt Filtered data when data filtering is on. Filtered data when data filtering is on. Raw data Filter setting is ignored.

-

Page 53: Command 6 - Multimeter Mode Setup

Chapter 3: Commands and Programming DATA RANGE SETUP Examples {5,1,2} 5 = DATA RANGE SETUP 1 = Transfer data from CH1 2 = Filtered d data (when filtering is turned on with Command 1) {5,2,0,256,300} 5 = DATA RANGE SETUP 2 = Transfer data from CH2 0 = Filtered raw data (when filtering is turned on with Command 1) - Page 54 Chapter 3: Commands and Programming Channel 4 (SONIC) DIG IN channel Operation Parameter This parameter specifies the sampling unit for the Multimeter Mode. The following are the available operation parameter settings whenever Channel 1 (CH1), Channel 2 (CH2), or Channel 3 (CH3) is specified by the channel select parameter.

-

Page 55: Command 7 - Request Status

Chapter 3: Commands and Programming Command 7 - REQUEST STATUS Command 7 creates data analyzer status data, which can be sent to a con- nected CFX-9850G. Syntax Request Status This command creates a list that shows the system status and settings of the data analyzer. -

Page 56: Command 9 - Probe Calibrate

Chapter 3: Commands and Programming Command 9 - PROBE CALIBRATE Command 9 tells calibrates probe sampling values and is used to calibrate sampling levels when a high level of accuracy is required or when multiple probes are being used. Calibration is approximated using a linear equation and quadratic equation, with coefficients specified using this command’s coefficient parameter. - Page 57 Chapter 3: Commands and Programming Coefficient Parameter This parameter specifies the coefficients of the calibration equation being used. Two coefficients (a, b) are specified for the linear equation (ax + b), while three coefficients (a, b, c) are specified for a quadratic equation (ax + bx + c).

- Page 58 Chapter 3: Commands and Programming Example 2: Calibrating multiple probe levels The following example produces calibration values for use with temperature probes connected to two different data analyzers. Three calibration points are used. {1,0}"List 6! Send(List 6)! Specifies that the reference temperature {1,1,1}"List 6! probe is connected to CH1.

- Page 59 Chapter 3: Commands and Programming Example 3: Improving probe accuracy The following example produces calibration values for improving the accu- racy of sampling using a light probe. • When performing calibration to improve accuracy, it is necessary to first produce reference values using a high-accuracy measuring instrument. {1,0}"List 6! Send(List 6)! {1,1,1}"List 6!

-

Page 60: Multimeter Mode

Chapter 2: Modes Chapter 2: Modes This chapter provides detailed explanations of the Communications Mode, Multimeter Mode, Internal Mode, Data-Log Mode, and Setup Mode. Relationships Between Modes ........... 16 Communications Mode ............17 Multimeter Mode ..............17 Internal Mode ..............18 Data-Log Mode .............. - Page 61 Chapter 2: Modes Relationships Between Modes The data analyzer has five modes: Communications, Setup, Multimeter, In- ternal, and Data-Log. The operations in the Communications, Setup, and Multimeter modes are closely interrelated. The are the three basic configurations under which the data analyzer can be used.

-

Page 62: Communications Mode

Chapter 2: Modes Communications Mode The purpose of the Communications Mode is data sampling. While in this mode, the data analyzer receives setup commands from a connected calcu- lator, performs sampling, and then sends the sample data to the calculator. This mode has three data analyzer states: READY, SAMPLING, DONE. - Page 63 Chapter 2: Modes To enter the Multimeter Mode, press the [MODE] key while in the Communi- cations Mode. Press [MODE] again to return to the Communications Mode. The data analyzer is in the Multimeter Mode when the MULTIMETER indica- tor is on the display. To perform Multimeter Mode measurements using the SONIC channel, for example, press [MODE] to enter the Multimeter Mode and then press [CH- view] three times to select the SONIC channel.

- Page 64 Chapter 2: Modes Data-Log Mode This mode is for displaying data stored in data analyzer memory. Pressing [DataLOG] while in the Communications Mode enters the Data-Log Mode, which is indicated by the DATA-LOG indicator on the display. When you enter the Data-Log Mode, the channel indicator of the first channel for which there is data in memory starts to flash, and the first data item for that channel appears on the display.

- Page 65 Chapter 2: Modes Setup Mode This mode lets you set up the data analyzer manually without an external P.21 program for simple sampling jobs using an Auto-ID probe. In the Communications Mode, press [SHIFT] [MODE] to enter the Setup Mode, which is indicated by the READY, SAMPLING, and DONE indicators all flash- ing on the display.

- Page 66 Chapter 2: Modes displays the “Rel.” indicator. 7. When the setting you want to use is displayed, press [TRIGGER] to regis- ter it and return to the Communications Mode. • At this time confirm that an Auto-ID probe is connected and make sure that the READY indicator is on the display of the data analyzer, indicating it is in the READY state.

-

Page 67: Appendix A: Technical Reference

Appendix A: Technical Reference Appendix A: Technical Reference This appendix provides information on the error messages that appear on the display of the data analyzer, information about probes that come with the data analyzer, conversion equations, and other technical information. Error Messages .............. -

Page 68: Error Messages

Appendix A: Technical Reference Error Messages The data analyzer indicates an error by displaying “E.” followed by a 2-digit hexadecimal number. The first digit indicates the command that caused the error, while the second digit indicates the parameter that caused the error message (first parameter indicated by 1, second parameter by 2, and so on). -

Page 69: Temperature Probe

Appendix A: Technical Reference Temperature Probe The temperature probe that comes with the data analyzer uses a thermistor to measure the temperature of liquids. Changes in the temperature of the thermistor causes a corresponding change in its resistance, which is then converted to a temperature value. -

Page 70: Probe Precautions

Appendix A: Technical Reference Probe Precautions Temperature Probe • Never use the temperature probe with strong acid or alkaline solutions. • The measuring range of the temperature probe is –20°C to 130°C. Do not try to measure temperatures outside this range. •... -

Page 71: Connector Pinouts

Appendix A: Technical Reference Connector Pinouts The data analyzer uses British Telecom-type 6-pin probe connectors. CH1, CH2, CH3 SONIC DIG IN DIG OUT Echo Clock-In Clock-Out Init Vres Auto-ID D0 In D0 Out Auto-ID +5 Volt DC D1 In D1 Out +5 Volts DC D2 In D2 Out... -

Page 72: Conversion Equations

Appendix A: Technical Reference Conversion Equations Command 4 Type, Form, and Restrictions Command 4 conversion equations have certain calculation limitations. In particular, some conversion equations cannot perform calculations for nega- tive values. If a division by zero, power of a negative number, or other such error is en- countered by an equation, an overflow value is automatically applied to the operation. -

Page 73: Other Technical Information

Appendix A: Technical Reference Other Technical Information Clock-In Line Operation A low-going pulse (0-5V) on the External Clock-In line (part of the DIG IN channel) is used as the external clock. Data from the DIG IN channel can be read based on the internal sampling clock, so the External Clock-In line is not necessarily required. -

Page 74: Period And Frequency Measurement

Appendix A: Technical Reference Command 3: {3,1,70} 3 = SAMPLING AND TRIGGER SETUP 1 = Sampling time (1 second) 70 = Number of samples The manual trigger default is applied as the trigger source. The DOB outputs signals that correspond to the seven data nibbles. This sequences is repeated to the DIG OUT channel 10 times (70 samples/7 data elements). -

Page 75: Hard Trigger

Appendix A: Technical Reference Trigger Edge Edges for Measuring the Time Rising edge to rising edge (T = 0 to 2) Falling edge to falling edge (T = 1 to 3) Rising edge to falling edge (T = 0 to 1) Falling edge to rising edge (T = 1 to 2) •... -

Page 76: Command 1 - Channel Setup

Appendix B: Command Tables Appendix B: Command Tables Command 1 - CHANNEL SETUP ........72 Command 2 - DATA TYPE AND DISPLAY SETUP .... 73 Command 3 - SAMPLE AND TRIGGER SETUP ....74 Command 4 - CONVERSION EQUATION SETUP .... 75 Command 5 - DATA RANGE SETUP ......... - Page 77 Appendix B: Command Tables...

- Page 78 Appendix B: Command Tables...

- Page 79 Appendix B: Command Tables...

- Page 80 Appendix B: Command Tables...

- Page 81 Appendix B: Command Tables...

- Page 82 Appendix C: Troubleshooting / Other Information Troubleshooting ..............78 Specifications ..............79...

-

Page 83: Appendix C: Troubleshooting/Other Information

Appendix C: Troubleshooting/Other Information Troubleshooting The following provides information on what to do whenever you experience problems with data analyzer operation. Problem: Data analyzer power does not turn on and nothing appears on its display. Possible Causes and Recommended Actions: •... -

Page 84: Specifications

Appendix C: Troubleshooting/Other Information Specifications Model: ........ CASIO EA-100 Data Analyzer Power Supply: ....Four AA-size batteries (LR06 (AM3) or R6P (SUM-3)) or optional AC adaptor (AD-A60024) Power Consumption: ..1.5W Battery Life: ......LR06 (AM3): Approximately 12 hours (Continu-... - Page 85 CASIO ELECTRONICS CO., LTD. Unit 6, 1000 North Circular Road, London NW2 7JD, U.K.