Fujitsu PRIMERGY TX200 S6 Operating Manual

Hide thumbs

Also See for PRIMERGY TX200 S6:

- Options manual (124 pages) ,

- Service supplement manual (56 pages)

Summary of Contents for Fujitsu PRIMERGY TX200 S6

- Page 1 Operating Manual - English PRIMERGY TX200 S6 Server Operating Manual Edition July 2010...

-

Page 2: Copyright And Trademarks

– The contents of this manual may be revised without prior notice. – Fujitsu assumes no liability for damages to third party copyrights or other rights arising from the use of any information in this manual. – No part of this manual may be reproduced in any without the prior written permission of Fujitsu. - Page 3 Before reading this manual For your safety This manual contains important information for safely and correctly using this product. Carefully read the manual before using this product. Pay particular attention to the accompanying manual "Safety notes and other important information" and ensure these safety notes are understood before using the product.

- Page 4 (hereafter, "high safety use"). Customers should not use this product for high safety use unless measures are in place for ensuring the level of safety demanded of such use. Please consult the sales staff of Fujitsu if intending to use this product for high safety use.

- Page 5 Only for the Japanese market: Although described in this manual, some sections do not apply to the Japanese market. These options and routines include: – USB Flash Module (UFM) – CSS (Customer Self Service) Operating Manual TX200 S6...

- Page 6 Operating Manual TX200 S6...

-

Page 7: Table Of Contents

Contents Preface ......11 Concept and target groups for this manual ..12 Documentation overview . - Page 8 Contents Connecting devices to the server ....59 Connecting the server to the mains ....60 4.5.1 Using cable ties .

- Page 9 Contents Screen remains blank ..... 86 Flickering stripes on monitor screen ... . . 87 No screen display or display drifts .

- Page 10 Contents 8.2.5.1 Installing system fan 1 (and 3) ....112 8.2.5.2 Installing system fan 2 (and 4) ....113 8.2.5.3 Closing the server .

-

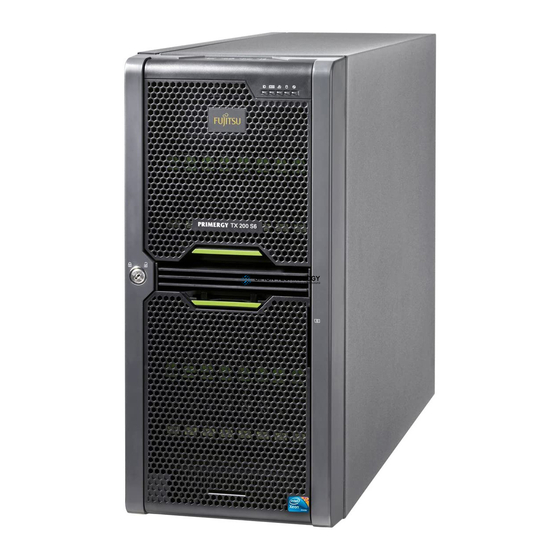

Page 11: Preface

Preface The PRIMERGY TX200 S6 server is an Intel-based server for mid-size and large companies. The server is suitable for use as a file server and also as an application, information or Internet server. It is available as a floorstand or rack model. -

Page 12: Concept And Target Groups For This Manual

Preface Concept and target groups for this manual This operating manual describes how to install, set up and operate your server. This operating manual is intended for those responsible for installing the hardware and ensuring that the system runs smoothly. It contains all the information you need to put your PRIMERGY TX200 S6 into operation. - Page 13 Internet. The overview page showing the online documentation available on the Internet can be found using the URL (for EMEA market): http://manuals.ts.fujitsu.com. The PRIMERGY server documentation can be accessed using the Industry standard servers navigation option. For the Japanese market please use the URL: http://primeserver.fujitsu.com/primergy/manual.html.

-

Page 14: Features

Concept - LSC" manual on the ServerView Suite DVD 2). In addition, CSS errors are displayed in the ServerView Operations Manager, the server management software from Fujitsu. In the event of errors, the ServerView Operations Manager refers you directly to the affected component and its order information in the Illustrated Spares catalog of the server in question. - Page 15 Preface System board The features of the system board are described in the technical manual for the system board D2799 for the hardware and in the BIOS Setup manual for the firmware. Trusted Platform Module (TPM) A Trusted Platform Module (TPM) for safer storage of keys can be implemented as an option.

- Page 16 Preface Hard disk drives The server is shipped with one of the following drive cages: – For up to four 3.5-inch SAS/SATA hard disk drives: Up to four SAS/SATA HDD modules can be used in the drive cage. Each HDD module can accommodate a SAS/SATA hard disk drive with a maximum height of 1 inch.

- Page 17 Preface Onboard SATA controller A SATA controller is integrated on the system board; up to four SATA hard disk drives can be connected to the controller. The LSI Embedded MegaRAID software (SATA Software RAID) supports RAID levels 0, 1 and 10. For more information on configuring the controller, see section "Configuring the onboard SATA controller"...

- Page 18 Preface Further information on other SAS/SATA RAID controllers (e.g. for operating external SAS/SATA hard disk drives or tape drives) is available on ServerView Suite DVD 2 under Industry Standard Servers - Expansion Cards - Storage Adapters - LSI RAID / SCSI Controllers. Accessible drives The server has three 5.25-inch bays that can be used in various ways: The individual bays can be equipped with any 3.5-inch drives (height:1.6 inch).

- Page 19 Preface Power supply In its basic configuration the server has a permanently installed power supply unit or a hot-plug power supply unit that adjusts automatically to any mains voltage in the range 100 V - 240 V. Besides the hot-plug power supply unit, a second hot-plug power supply unit can be installed optionally to serve as a redundant power supply.

- Page 20 ASR&R (Automatic Server Reconfiguration and Restart) restarts the system in the event of an error and automatically "hides" the defective system components. The PDA (Prefailure Detection and Analysis) technology from Fujitsu Technology Solutions analyzes and monitors all components that are critical for system reliability.

- Page 21 Preface iRMC S2 with integrated management LAN connector The features of the iRMC S2 Advanced Video Redirection and Remote Storage are available as an option. The iRMC S2 (integrated Remote Management Controller) is a BMC with integrated management LAN connector and expanded functionality that was previously only available with additional plug-in cards.

- Page 22 Server management is implemented using the ServerView Operations Manager supplied and the PDA (Prefailure Detection and Analysis) technology from Fujitsu. PDA reports the threat of a system error or overload at an early stage, allowing preventive measures to be taken.

- Page 23 PRIMERGY diagnostic LEDs fitted on the system board show which component (memory module, processor, fan or expansion card) is not functioning properly. The Flash EPROM program supplied with the Fujitsu utilities supports a fast BIOS update. With the iRMC S2 (integrated Remote Management Controller) on the system board, the PRIMERGY TX200 S6 server can also be maintained and serviced remotely.

- Page 24 ServerView Remote Management ServerView Remote Management is the remote management solution from Fujitsu for PRIMERGY servers. ServerView Remote Management and the relevant hardware components integrated on the system board allow remote monitoring and maintenance as well as fast restoration of operation in the event of errors.

-

Page 25: Notational Conventions

Preface Notational conventions The following notational conventions are used in this manual: Text in italics indicates commands or menu items. "Quotation marks" indicate names of chapters and terms that are being emphasized. Ê describes activities that must be performed in the order shown. -

Page 26: Technical Data

Preface Technical data Electrical data Rated voltage range 100 V - 240 V Frequency 47 Hz - 63 Hz Rated current with basic configuration 100 V oder 240 V / 1.3 A - 0.6 A Max. rated current 100 V - 127 V oder 200 V - 240 V / 9.5 A - 4.0 A Effective power max. - Page 27 Preface Mechanical specifications Floorstand Rack Width (with anti-tilt bracket) 205 mm (306 mm) 482 mm Total depth 584 mm 570 mm Installation depth ----- 596 mm Height 444 mm 5 HU Dimension notes Floorstand width 306 mm with tilt protection; depth measured excludes handles on redundant PSU.

- Page 28 Preface Noise level with standard fan and standard power supply units Sound power level L (ISO 9296) 5.2 B (standby) 5.7 B (operating) Sound pressure level at adjacent position 34 dB (A) (standby) (ISO 9296) 36 dB (A) (operating) Noise level with redundant system fans and redundant power supply Sound power level L (ISO 9296) 5.5 B (standby)

-

Page 29: Installation Steps, Overview

Installation steps, overview This chapter contains an overview of the steps you need to carry out to install your server. Links take you to sections where you can find more detailed information about the respective steps: Ê At first, please take notice of the safety instructions in chapter "Important information"... - Page 30 Installation steps, overview Ê Configure the server and install the desired operating system and applications. The following options are available: – Remote installation with the ServerView Installation Manager: With the ServerView Suite DVD 1 provided, you can configure the server and install the operating system in a convenient manner.

-

Page 31: Important Information

Important information In this chapter you will find essential information regarding safety when working on your server. Safety instructions The following safety instructions are also provided in the manual "Safety notes and other important information". This device meets the relevant safety regulations for IT equipment. If you have any questions about whether you can install the server in the intended environment, please contact your sales outlet or our customer service team. - Page 32 Important information Before starting up CAUTION! During installation and before operating the device, observe the instructions on environmental conditions for your device (see section "Technical data" on page 26). If the server has been moved from a cold environment, condensation may form both inside and on the outside of the machine.

- Page 33 Important information CAUTION! Ensure that the power sockets on the device and the properly grounded power outlets are freely accessible. The On/Off button or the main power switch (if present) does not isolate the device from the mains power supply. To disconnect it completely from the mains power supply, unplug all network power plugs from the properly grounded power outlets.

- Page 34 Important information CAUTION! Proper operation of the system (in accordance with IEC 60950-1 resp. EN 60950-1) is only ensured if the casing is completely assembled and the rear covers for the installation slots have been fitted (electric shock, cooling, fire protection, interference suppression).

- Page 35 Important information CAUTION! Install the screw removed during installation/detaching Internal Options in former device/position. To use a screw of the different kind causes a breakdown of equipment. The installation indicated on this note is sometimes changed to the kind of possible options without notice. Batteries CAUTION! Incorrect replacement of batteries may lead to a risk of explosion.

- Page 36 Important information Working with CDs/DVDs/BDs and optical drives When working with devices with optical drives, these instructions must be followed. CAUTION! Only use CDs/DVDs/BDs that are in perfect condition, in order to prevent data loss, equipment damage and injury. Check each CD/DVD/BD for damage, cracks, breakages etc. before inserting it in the drive.

- Page 37 Important information Do not contaminate the CD/DVD/BD surface with fingerprints, oil, dust, etc. If dirty, clean with a soft, dry cloth, wiping from the center to the edge. Do not use benzene, thinners, water, record sprays, antistatic agents, or silicone-impregnated cloth. Be careful not to damage the CD/DVD/BD surface.

- Page 38 Important information Modules with Electrostatic-Sensitive Devices Modules with electrostatic-sensitive devices are identified by the following sticker: Figure 1: ESD label When you handle components fitted with ESDs, you must always observe the following points: Switch off the system and remove the power plugs from the power outlets before installing or removing components with ESDs.

-

Page 39: Energy Star

Important information Other important information: During cleaning, observe the instructions in section "Cleaning the server" on page Keep this operating manual and the other documentation (such as the technical manual, documentation DVD) close to the device. All documentation must be included if the equipment is passed on to a third party. -

Page 40: Ce Conformity

Consult the dealer or an experienced radio/TV technician for help. Fujitsu is not responsible for any radio or television interference caused by unauthorized modifications of this equipment or the substitution or attachment of connecting cables and equipment other than those specified by Fujitsu. The correction of interferences caused by such unauthorized modification, substitution or attachment will be the responsibility of the user. -

Page 41: Transporting The Server

Important information The use of shielded I/O cables is required when connecting this equipment to any and all optional peripheral or host devices. Failure to do so may violate FCC and ICES rules. WARNING: This is a class A product. In a domestic environment this product may cause radio interference in which case the user may be required to take adequate measures. -

Page 42: Notes On Installing The Server In The Rack

Important information Notes on installing the server in the rack CAUTION! For safety reasons, at least two people are required to install the server in the rack because of its weight and size. (For the Japanese market, please refer to " 安全上の注意およびその 他の重要情報... -

Page 43: Environmental Protection

Important information Environmental protection Environmentally-friendly product design and development This product has been designed in accordance with the Fujitsu standard for "environmentally friendly product design and development". This means that key factors such as durability, selection and labeling of materials, emissions, packaging, ease of dismantling and recycling have been taken into account. - Page 44 Details regarding the return and recycling of devices and consumables within Europe can also be found in the "Returning used devices" manual, via your local Fujitsu branch or from our recycling center in Paderborn: Fujitsu Technology Solutions Recycling Center D-33106 Paderborn Tel.

-

Page 45: Hardware Installation

Hardware installation CAUTION! Follow the safety instructions in the chapter "Important information" on page Do not expose the server to extreme environmental conditions (see "Ambient conditions" on page 27). Protect the server from dust, humidity and heat. Make sure that the server is acclimatized for the time indicated in this table before putting it into operation. -

Page 46: Unpacking The Server

Hardware installation Unpacking the server CAUTION! Follow the safety instructions in chapter "Important information" on page The server must always be lifted or carried by at least two people. (For the Japanese market, please refer to " 安全上の注意およびその他の 重要情報 ".) Do not unpack the server until it is at its installation location. -

Page 47: Setting Up The Floorstand Model

Hardware installation Setting up the floorstand model If you are not installing a PRIMERGY TX200 S6 floorstand model, skip this section and continue reading at section "Installing/removing the rack model" on page CAUTION! Follow the safety instructions in chapter "Important information" on page Ê... -

Page 48: Mounting The Anti-Tilt Bracket

Hardware installation 4.2.1 Mounting the anti-tilt bracket The anti-tilt bracket is only necessary for the redundant configuration (with two hot-plug power supplies). Figure 2: Mounting the anti-tilt bracket Ê Place the server on the anti-tilt bracket. Ê Fasten the anti-tilt bracket using the two knurled screws (1). Operating Manual TX200 S6... -

Page 49: Installing/Removing The Rack Model

4.3.1 Rack system requirements The rack systems from Fujitsu PRIMECENTER Rack, DataCenter Rack and 19-inch standard rack (for the Japanese market) support the installation of PRIMERGY servers. Installation in most current rack systems from other manufacturers (3rd party racks) is also supported. - Page 50 Hardware installation For PRIMECENTER Racks and DataCenter Racks: The mounting of the rails in the different racks is described in the next sections. Installation of the cable management is described in detail in the Technical Manual for the respective rack. For 19-inch standard rack (for the Japanese market): For information on mounting of the rails in the 19-inch standard rack (for the Japanese market) please refer to the next sections or the "...

- Page 51 Hardware installation +/- 1,6mm Figure 3: Mechanical requirements Operating Manual TX200 S6...

-

Page 52: Installation In Primecenter/Datacenter/ 19-Inch Standard Rack

Hardware installation – You must ensure that the safety mechanisms on the server, e.g. stoppers or retaining systems, are functioning correctly. – The shape of the rack support uprights must ensure that the support systems can be bolted to the front. The support systems have a linear alignment feature to ensure that they can be adjusted to different rack depths. - Page 53 Hardware installation Fitting the support bracket When mounting the left support system in the corresponding rack, the supplied support bracket must first be mounted flush with the underside of the device on the rear left support upright. Figure 4: Fitting the support bracket Ê...

- Page 54 Hardware installation Installing the support systems Figure 5: Fit the left support system in the PRIMECENTER/DataCenter rack Ê Position the left support system in the support bracket (insert retaining bolts) - see (1). For the Japanese market: There is no support bracket. Please position the support system directly on the support upright.

- Page 55 Hardware installation The support system no longer has to be fixed to the front support upright because the easy lock engages and ensures a firm fit. Ê Insert (3) the safety lock into the easy lock (snap fit). CAUTION! Ensure that the safety lock has been inserted before the server is inserted! Ê...

- Page 56 Hardware installation Inserting the server Figure 7: Inserting the server (a) Figure 8: Inserting the server (b) Operating Manual TX200 S6...

-

Page 57: Installation In 3Rd Party Racks

4.3.3 Installation in 3rd party racks The support systems from Fujitsu are suitable for use in any 3rd party racks for standard servers (installation depth 714 - 785 mm) without restrictions. Ê Refer to the manual from the rack manufacturer for details of the mechanical installation and the climatic conditions. - Page 58 Hardware installation Under certain circumstances, you will not be able to use some of the parts from the rack installation kit supplied - you will need to use original 3rd party rack parts instead. Racks with installation depth of 735 mm The lengths of the telescopic rails do not need to be adjusted with respect to each other for the installation in rack systems with 735 mm installation depth.

-

Page 59: Connecting Devices To The Server

Hardware installation Connecting devices to the server The connectors for external devices are on the front and rear of the server. The additional connectors available on your server depend on the expansion cards installed. The standard connectors are indicated by symbols and color coding: Figure 9: Connector panel on the rear side 1 Management LAN connector (LAN 1) 2 Shared LAN connector (LAN 2) -

Page 60: Connecting The Server To The Mains

Hardware installation Connecting the monitor Ê Connect the monitor to the video connector of the server (see figure 9 on page 59). Ê Connect the power cable of the monitor to a grounded mains outlet of the in- house mains and/or to the mains socket strip of the rack. CAUTION! The rated current for the monitor is indicated on the technical data label on the monitor or in the operating manual for the monitor. - Page 61 Hardware installation Figure 10: Connecting the server to the mains Ê Connect the power cord to the server power supply unit (1). Ê Connect the mains plug to a grounded mains outlet (2) in the in-house power supply network or a power outlet of the socket strip (3) in the rack (see technical manual for the rack).

-

Page 62: Using Cable Ties

Hardware installation 4.5.1 Using cable ties As an option, you can secure the power cable using a cable tie to ensure that the insulated connector cannot be disconnected from the server accidentally. The cable tie is included in the accessories pack that is delivered together with the server. -

Page 63: Notes On Connecting/Disconnecting Cables

Hardware installation Notes on connecting/disconnecting cables CAUTION! Always read the documentation supplied with the device you wish to connect. Never connect, or disconnect cables during a thunderstorm. Never pull on a cable when disconnecting it. Always take hold of the cable by the plug. - Page 64 Hardware installation Operating Manual TX200 S6...

-

Page 65: Starting Up And Operation

Starting up and operation CAUTION! Follow the safety instructions in chapter "Important information" on page Access to the drives (floorstand model) 5.1.1 Access to the accessible drives Figure 12: Removing the drive cover and snapping it into the hard disk drive cover Ê... - Page 66 Starting up and operation Figure 13: Removing the drive cover from the hard disk drive cover Ê Carefully pull out on the green release lever (1) and lift off the drive cover (2). Operating Manual TX200 S6...

-

Page 67: Access To The Hdd Modules

Starting up and operation 5.1.2 Access to the HDD modules Figure 14: Removing the hard disk cover Ê Unlock the server (1). Ê Remove the hard disk cover (2). The hard disk drive cover is replaced and the server locked in the reverse order. Operating Manual TX200 S6... -

Page 68: Control Elements And Indicators

Starting up and operation Control elements and indicators 5.2.1 Front of server Figure 15: Front of server (example: rack model) 1 3 x USB connectors 6 Power-on indicator / On/Off button 2 ID indicator / ID button 7 Reset button 3 CSS indicator 8 NMI button 4 Global Error indicator... -

Page 69: Id Card

Starting up and operation 5.2.1.1 ID card You can pull out the ID card as far as it will go and push it back in again. The ID card contains various system information, such as the product name, serial number, order number, MAC addresses and DNS name. 5.2.1.2 Control elements On/Off button... -

Page 70: Leds On The Control Panel

Starting up and operation 5.2.1.3 LEDs on the control panel Power indicator (two-color) Glows green when the server is switched on. Lights up orange when the server is switched OFF, but mains voltage is present (standby mode). Hard disk activity indicator (green) Lights up green when an internal hard disk drive is accessed. -

Page 71: Indicators On The Drives

Starting up and operation CSS indicator (yellow) – Lights up yellow if a prefailure event was detected for a CSS component that you can fix yourself (for reasons of precaution) with the CSS concept. – Flashes yellow if an error was detected that you can fix yourself with the CSS concept. - Page 72 Starting up and operation Hard disk drive indicators Figure 16: Indicators on the 3.5 inch and 2.5 inch HDD modules 1 HDD BUSY (green) – Lit: HDD in active phase (drive active, drive being accessed) – Does not light: HDD inactive 2 HDD FAULT (orange) (in conjunction with a RAID controller) SAS server variant...

-

Page 73: Rear Of Server

Starting up and operation 5.2.2 Rear of server 5.2.2.1 Indicators on the connector panel CSS, Global Error and ID indicators Figure 17: Indicators on the connector panel: CSS, Global Error and ID indicators 1 CSS, Global Error and ID indicators (yellow, orange and blue) Global Error indicator (orange) –... - Page 74 Starting up and operation CSS indicator (yellow) – Lights up yellow if a prefailure event was detected for a CSS component that you can fix yourself (for reasons of precaution) with the CSS concept. – Flashes yellow if an error was detected that you can fix yourself with the CSS concept.

- Page 75 Starting up and operation LAN indicators Figure 18: Indicators on the connector panel: LAN indicators LAN activity indicator (management LAN) Lights up green if a LAN connection exists. Does not light up if no LAN connection exists. Flashes green when a LAN transfer is in progress. LAN transfer rate indicator (management LAN) Lights up green for a LAN transfer rate of 100 Mbit/s.

-

Page 76: Indicators On The Hot-Plug Power Supply Unit

Starting up and operation 5.2.2.2 Indicators on the hot-plug power supply unit Figure 19: Indicators on the hot-plug power supply units Indicator on hot-plug power supply unit (two colors) Flashes green when the server is switched off, but mains voltage is present (standby mode). -

Page 77: Switching The Server On And Off

Starting up and operation Switching the server on and off CAUTION! It nothing appears on the screen but flickering stripes after switching on the server, switch the server off immediately (see chapter "Troubleshooting and tips" on page 85). The On/Off button does not disconnect the server from the mains voltage. - Page 78 Starting up and operation If the operating system does not switch the server off automatically, press the On/Off button for at least four seconds and/or send a control signal for power button override. Other On/Off options Besides the On/Off button, the server can be switched ON and OFF in the following ways: –...

-

Page 79: Configuring The Server

Starting up and operation Configuring the server This section contains information about configuring the server and installing the operating system. Make sure that the power saving functions are disabled in the Power menu of the BIOS Setup during operation. 5.4.1 Configuring the onboard SATA controller A 6-port SATA controller is integrated on the system board. -

Page 80: Configuring The Server And Installing The Operating System With The Serverview Installation Manager

Starting up and operation A separate utility is available to the controller for MegaRAID configuration. For further information, refer to the "SAS Software User’s Guide" (on the ServerView Suite DVD 2 under Industry Standard Servers - Expansion Cards - Storage Adapters - LSI Configuration Software). Further information on modular RAID controllers is provided in the "Modular RAID Controller Installation Guide"... -

Page 81: Configuring The Server And Installing The Operating System Without The Serverview Installation Manager

Starting up and operation If you are using the ServerView Installation Manager, you can skip the following section on how to configure the server and install the operating system. Continue from section "Cleaning the server" on page 5.4.4 Configuring the server and installing the operating system without the ServerView Installation Manager Configure onboard SATA controller... -

Page 82: Cleaning The Server

Starting up and operation Cleaning the server CAUTION! Switch the server off and disconnect the power plugs from the properly grounded power outlets. Do not clean any interior parts yourself; leave this job to a service technician. Do not use any cleaning agents that contain abrasives or may corrode plastic. -

Page 83: Property And Data Protection

Property and data protection The floorstand model is protected against unauthorized opening by a lock. Apart from this, the server is also fitted with an intrusion detection switch which enables the ServerView Operations Manager program to detect and log any removal of the side cover or top cover and the cover for the HDD modules. - Page 84 Property and data protection Operating Manual TX200 S6...

-

Page 85: Troubleshooting And Tips

Troubleshooting and tips CAUTION! Follow the safety instructions in the "Safety notes and other important information" manual and in chapter "Important information" on page If a fault occurs, attempt to resolve it using the measures described: – in this chapter, –... -

Page 86: Server Switches Itself Off

Troubleshooting and tips Server switches itself off Server Management has detected an error Ê Check the error list of System Event Log in ServerView Operations Manager or in the iRMC S2 web interface, and attempt to eliminate the error. Screen remains blank Monitor is switched off Ê... -

Page 87: Flickering Stripes On Monitor Screen

Troubleshooting and tips Flickering stripes on monitor screen CAUTION! Switch off the server immediately. Risk of damaging the server. Monitor does not support the set horizontal frequency Ê Find out which horizontal frequency your monitor screen supports. You will find the horizontal frequency (also known as line frequency or horizontal deflection frequency) in the documentation for your monitor. -

Page 88: Incorrect Date And Time

Troubleshooting and tips Incorrect date and time Ê Set the date and time in the operating system or in the BIOS Setup under the Main menu, using System Date and System Time respectively. Note that the operating system may affect the system time. For example, the operating system time may deviate from the system time under Linux, and would overwrite the system time in the default setting on shutdown. -

Page 89: Added Drive Reported As Defective

Troubleshooting and tips Added drive reported as defective RAID controller is not configured for this drive The drive was probably installed when the system was switched off. Ê Reconfigure the RAID controller for the drive using the corresponding utility. Information is provided in the documentation for the RAID controller. Ê... -

Page 91: Css Components

CSS components This chapter describes how to handle CSS components and how to identify defective CSS components and replace them yourself. Further information on the CSS concept is provided in the "ServerView Suite Local Service Concept - LSC" manual on the ServerView Suite DVD 2. -

Page 92: Hot-Plug Components

CSS components Hot-plug components This section describes how to handle hot-plug components and how to modify your server hardware (e.g. adding/replacing hot-plug power supply units or hot- plug HDD modules). The hot-plug procedure increases the availability of system operation and guarantees a high degree of data integrity and failsafe performance. -

Page 93: Hot-Plug Hard Disk Drives

CSS components Ê Remove the power cable from the installed power supply unit. Ê Push the green catch in the direction of the arrow (1) while pulling the power supply unit out of its mounting location (2) by the handle. Ê... - Page 94 CSS components Depending on the OS, you can configure the write cache settings for the hard disk drives. However, disable the write cache for use in this server. If the power failure should occur while the write cache is enabled, cached data may be lost. When disposing of, transferring, or returning a hard disk unit, wipe out the data on the drive for your own security.

-

Page 95: Inch Hdd Module And Dummy Module

CSS components 8.1.2.1 3.5-inch HDD module and dummy module Figure 21: 3.5-inch HDD module and dummy module Dummy module Tabs for unlocking the dummy module HDD module (installation frame with hard disk drive installed) Indicators HDD Busy (LED green) HDD Fault (LED orange) For description see section "Hard disk drive indicators"... -

Page 96: Inch Hdd Module And Dummy Module

CSS components 8.1.2.2 2.5-inch HDD module and dummy module Figure 22: 2.5-inch HDD module and dummy module Dummy module Tabs for unlocking the dummy module HDD module (installation frame with hard disk drive installed) Indicators HDD Busy (LED green) HDD Fault (LED orange) For description see section "Hard disk drive indicators"... -

Page 97: Handling Hard Disk Drives And Hdd Modules

CSS components 8.1.2.3 Handling hard disk drives and HDD modules Hard disk drives incorporated in the HDD modules are highly sensitive electromagnetic devices and must be handled with great care. Incorrect handling can cause partial or total failure of the hard disk drives. These failures can result in data errors and to a loss of data or to total corruption of the hard disk drive. -

Page 98: Floorstand: Removing The Hard Disk Cover

CSS components 8.1.2.4 Floorstand: removing the hard disk cover For a floorstand server you make the HDD modules accessible by removing the hard disk cover: Figure 23: Removing the hard disk cover Ê Unlock the server (1). Ê Remove the hard disk cover (2). The hard disk drive cover is replaced and the server locked in the reverse order. -

Page 99: Removing/Installing The Dummy Module

CSS components 8.1.2.5 Removing/installing the dummy module Free slots are provided with dummy modules. Remove the dummy module before installing an additional HDD module. Figure 24: Removing/installing the dummy module (example: 3.5-inch dummy module) Ê Press both tabs on the dummy module together until the locking mechanism disengages (1). -

Page 100: Installing The Hdd Module

CSS components 8.1.2.6 Installing the HDD module Unlocking the HDD module Figure 25: Unlocking the 3.5-inch and 2.5-inch HDD modules Ê Release the locking mechanism by pressing the locking button (1). Ê Push the handle of the HDD module fully in the direction of the arrow (2). The HDD module is now unlocked. - Page 101 CSS components Installing the HDD module Figure 26: Installing the 3.5-inch and 2.5-inch HDD modules Ê Unlock the HDD module as described in section "Unlocking the HDD module" on page 100. Ê Carefully push the HDD module into the empty slot (1) until it stops. Ê...

-

Page 102: Removing The Hdd Module

CSS components 8.1.2.7 Removing the HDD module CAUTION! Only remove a HDD module during operation if the drive is not currently being accessed. Observe the control LEDs for the corresponding HDD modules (see "Hard disk drive indicators" on page 72). Under no circumstances should you remove a HDD module while the system is in operation if you are not sure that the hard disk drive is operated by a RAID controller and belongs to a disk array that is... -

Page 103: Non-Hot-Plug Components

CSS components Ê Install the new HDD module, as described in "Installing the HDD module" on page 101. CAUTION! If you have removed a HDD module and do not install a new one in its place, put the dummy module back in its place for cooling, to comply with EMC regulations (regulations regarding electromagnetic compatibility), and for protection against fire. -

Page 104: Opening The Server And Identifying The Defective Css Component

CSS components 8.2.1 Opening the server and identifying the defective CSS component 8.2.1.1 Opening the server CAUTION! The device can be seriously damaged if it is opened without authorization or if repairs are attempted by untrained personnel. It is essential to observe the safety instructions in chapter "Important information"... -

Page 105: Removing System Fan 2 (And 4)

CSS components 8.2.1.2 Removing system fan 2 (and 4) Figure 28: System fan 2 and system fan 2&4 The standard system fan 2 has just one fan cable; the redundant system fan 2&4 (double fan) has two fan cables (as two fans are integrated internally). The procedure for installing and removing both system fans is identical except for connecting the fan cables. -

Page 106: Removing System Fan 1 (And 3)

CSS components Ê Disconnect the fan cable from the connector FAN2 (if there is a second fan cable, disconnect this from FAN4) on the system board (see the technical manual for the system board D2799). Ê Press the two green locks of the air duct together (1). Ê... -

Page 107: Identifying A Css Component

CSS components Figure 31: Example: Removing system fan 1&3 Ê Disconnect the fan cable from the connector FAN1 on the system board (if there is a second fan cable, disconnect this from FAN3). Ê Push the locking lever in the direction of the arrow (1). Ê... -

Page 108: Replacing A Memory Module

CSS components 8.2.2 Replacing a memory module 8.2.2.1 Removing a defective memory module Figure 32: Removing a memory module Ê Press the securing clips on both sides of the memory slot concerned outward. (1). Ê Pull the defective memory module out of the slot (2). 8.2.2.2 Installing a new memory module CAUTION! -

Page 109: Replacing The System Fan

CSS components 8.2.3 Replacing the system fan CAUTION! Since the standard system fans 1 and 2 are not redundant, these system fans have to be replaced immediately. If one of the four redundant system fans (1&3 and 2&4) fails, one of the two predetermined fans (system fan 3 and 4) increases its power to ensure that the server is cooled properly. -

Page 110: Replacing An Expansion Card

CSS components 8.2.4 Replacing an expansion card 8.2.4.1 Removing a defective expansion card Figure 34: Removing a defective expansion card Ê If necessary, remove the cables from the defective expansion card. Ê Push the lever upwards (1). Ê Press onto the clip and remove it. Ê... -

Page 111: Installing A New Expansion Card

CSS components 8.2.4.2 Installing a new expansion card Figure 35: Installing a new expansion card Ê Carefully press the new expansion card into the slot until it clicks into place (1). Make sure that the lug on the slot cover clicks into place in the corresponding hole. -

Page 112: Reinstalling The Fans And Closing The Server

CSS components 8.2.5 Reinstalling the fans and closing the server 8.2.5.1 Installing system fan 1 (and 3) Figure 36: Installing system fan 1 (and 3) Ê Place the hooks of system fan 1 (and 3) into the recesses on the rear of the server (1). -

Page 113: Installing System Fan 2 (And 4)

CSS components 8.2.5.2 Installing system fan 2 (and 4) Ê Connect the fan cable to the connector FAN2 (if there is a second fan cable, connect this in FAN4) on the system board (see the technical manual for the system board D2799). Figure 37: Installing system fan 2 (and 4) Ê... -

Page 114: Closing The Server

CSS components 8.2.5.3 Closing the server Figure 38: Closing the server (example: floorstand model) Ê Pull the locking lever as far as it will go and insert the side cover in the five recesses (see small arrows) of the housing (1). Ê... -

Page 115: Appendix: Server Specification

Appendix: server specification This section explains the specifications for the server. The specifications for this server are liable to be updated without any notice. Please be forewarned. System Board System board type D2799 Chipset Intel 5500 Processor Processor quantity and 1or 2 Intel Xeon processors type Memory Modules Configuration... - Page 116 Appendix: server specification Serial 2 (9-pin) 1 x serial RS-232-C, optional - occupies an unused slot LAN / Ethernet (RJ-45) 1 x Gbit/s Ethernet Service LAN (RJ45) 1 x dedicated service LAN connector for iRMC S2 (10/100 Mbit/s) Service LAN traffic can be switched to shared onboard Gbit LAN port Onboard or integrated controllers RAID Controller...

- Page 117 Appendix: server specification PCI-Slots PCI-Express 2.0 x4 2 x full height (1x long, 1x short) (mech. x8) PCI-Express 2.0 x8 2 x full height (1x notched, thus usable for x16 cards operating in x8 mode) PCI-Express x4 (mech. 1 x full height Slot notes PCI slot: 32-bit / 33 MHz, 5 V;...

- Page 118 Appendix: server specification Service displays ServerView Local Service Panel (LSP) (optional): ServerView Local Service Display (LSD) Weight Weight up to 36.8 kg Weight notes Weight may vary depending on actual configuration Rack mounting kit Rack mounting kit as option; for the Japanese market, the reack mounting kit is standard Dimensions (Base unit specific) Floor-stand (W x D x H) 205 (306) x 584 x 444 mm...

- Page 119 Appendix: server specification Electrical values Power supply 1x standard, 1x hot-plug or 2x redundant configuration Max. output of single 685 W power supply Standard power supply 700 W output Hot-plug power supply 800 W output Rated voltage range 100 - 240 V Rated frequency range 47- 63 Hz Rated current max.

- Page 120 Appendix: server specification Operating Manual TX200 S6...

-

Page 121: Index

Index USB connector 3rd party rack video connector installing in consumables requirements control elements control panel correcting faults acclimatization time 45, CSS indicator 68, 71, Advanced Video Redirection ambient conditions ASR&R data manipulation availability data protection data security DataCenter rack installing server batteries requirements... - Page 122 Index environmental protection installation frame error hard disk drive indicators drifting display on monitor HDD module drive “dead” acclimatization time drive defective installation frame incorrect date installing incorrect time hot-plug HDD module no display on monitor hot-plug power supply unit power-on indicator does not hot-spare memory, memory light...

- Page 123 Index power supply unit labels cable clamp LAN activity indicator hot-plug 60, LAN transfer rate, indicator indicators laser information replacing light emitting diode (LED) standard lithium battery power supply, redundant Low Voltage Directive 26, power-on indicator does not light PRIMECENTER Rack MAC address requirements Main memory...

- Page 124 Index SAS/SATA RAID controller technical data configuring transport saving energy troubleshooting screen unpacking error message ventilation clearance flickering weight remains blank server management shows flickering stripes ServerView Installation Manager 23, SDDC, Single Device Data Correction ServerView Operations Manager security function supported functions serial number 46, ServerView Remote...

- Page 125 Index service transport damage 29, transporting the server troubleshooting Trusted Platform Module unpacking, server USB connector 59, using the cable clamp ventilation clearance video connector weight Operating Manual TX200 S6...