Epson 2070 - LQ B/W Dot-matrix Printer Service Manual

Terminal printer

Hide thumbs

Also See for 2070 - LQ B/W Dot-matrix Printer:

- Technical brief (7 pages) ,

- User manual (168 pages) ,

- Product support bulletin (7 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

User Manual

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Epson 2070 - LQ B/W Dot-matrix Printer

-

Page 1: Service Manual

EPSON TERMINAL PRINTER LQ-2070 SERVICE MANUAL EPSON 4006244... - Page 2 NOTICE All right reserved. Reproduction of any part of this manual in any form wharsoever without SEIKO EPSON’s express written permission is forbidden. The contents of this manual are subject to change without notice. All efforts have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly appreciate being informed of them.

- Page 3 SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS. WARNING 1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN. 2. MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATIG PLATE.

- Page 4 Includes a step-by-step guide for product disassembly and assembly. Chapter 4 Includes a step-by step guide for addjustement. Chapter 5 Provides Epson-approved techniques for troubleshooting. Chapter 6 Describes prevetive maintenance techniques. The contents of this manual are subject to change without notice.

- Page 5 REVISION SHEET Revision Issued Date Revision Page Rev. A April 8,1996 1st issued...

- Page 6 TABLE OF CONTENTS CHAPTER 1. GENERAL DESCRIPTION CHAPTER 2. OPERATION PRINCIPLES CHAPTER 3. DISASSEMBLY AND ASSEMBLY CHAPTER 4. ADJUSTMENTS CHAPTER 5. TROUBLESHOOTING CHAPTER 6. MAINTENANCE APPENDIX...

-

Page 7: Table Of Contents

CHAPTER 1 Product Description Table of Contents 1.1 Specifications 1.1.1 Features..........1-1 1.1.2 Accessories . - Page 8 1-35 1.6 MAIN COMPONENTS 1.6.1 C186 MAIN Board Assembly........1-36 1.6.2 C166 PSB/PSE Board Assembly .

- Page 9 List of Tables Table 1-1. Items Included with the Printer ......1-3 Table 1-2. Consumables .......... .1-3 Table 1-3.

-

Page 10: Specifications

Product Description LQ-2070 Sendce Manual 1.1 Specifications These specifications provide statistical information for the LQ-2070 serial impact dot matrix printer. Features 1.1.1. The LQ-2070 is a 24pin serial impact dot-matrix printer suitable for the VAR (value addedreseller) market. The major features of this printer are: 300 characters per second (cps) High speed draft . -

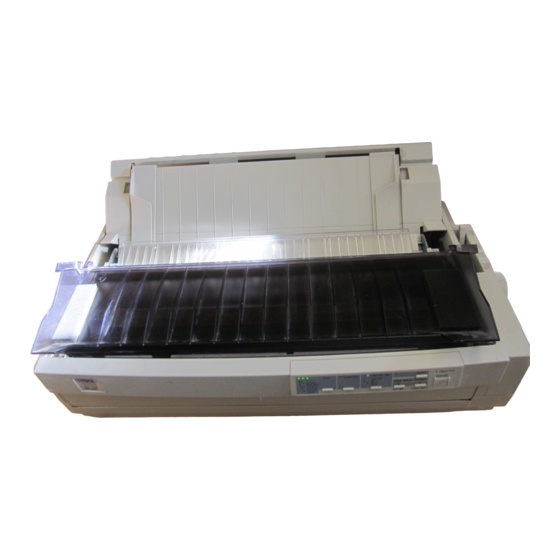

Page 11: Figure 1-1 Exterior View Of The Lq-2070

Product Description LQ-2070 Service Manual Figure 1-1 Exterior View of the LQ-2070 Rev.A... -

Page 12: Accessories

Product Description LCk2070 Service Manual 1.1.2. Accessories Items included in the printer carton Table 1-1 Items Included with the Printer Quantity Enclosed Items User’s guide Driver diskette Ribbon cartridge Power cord . Consumables Table 1-2 Consumables Part Number Consumable Item Ribbon cartridge S015083/S01 5086 soloo31/sol 0033... -

Page 13: Hardware Specifications

LQ-2070 Servioe Manual Product Description 1.2 Hardware Specifications This section provides detailed hardware specifications for the LQ-2070. 1.2.1 Printing Method Impact dot matrix . l?rintig method Black . Color 24 pins . Number of pins 12x 2 staggered . Pin arrangement 0.2 mm (0.0079 inch) print Pin diameter f)=108°*... -

Page 14: Printing Specifications

Product Description LQ-2070 Service Manual 1.2.2 Printing Specifications Copy capability 1 original+ 3copies Print speed and printable columns Table 1-4 Print Speed and Printable Columns Print Speed (cps) Mode Character Pitch Printable Columns Print Normal copy High-speed draft 10 cpi 10 cpi Draft 12 cpi... -

Page 15: Paper Handling Specifications

LQ-2070 Service Manual Product Description 1.2.3 Paper Handling Specifications (front, rear) Friction feed Feeding method (front, rear) Push tractor feed (front, rear, bottom) Push and pull tractor feed Front push tractor(option), mar push tractor, CSFbin 1 /bin 2 (Option) . Feeder Pull tractor (Option) and roll paper holder (Option) Manual insertion Front or rear in, top out... - Page 16 Product Description LQ-2070 Service Manual Set the paper thickness lever to the appropriate position, as . Paper thickness lever indicated in the following table. Table 1-7 Paper Thickness Lever Positions Paper Thickness (mm) Paper Thickness ( inches) Lever Position Maximum Minimum Minimum Maximum...

-

Page 17: Paper Specifications

LQ-2070 Service Manual Product Description Push-pull tractor feed release lever to the REAR PUSH/FRONT PUSH position. Set the Load paper from the front or rear entrance. Remove the paper eject assembly and attach the pull tractor unit. Remove any slack in the paper between the platen and pull tractor. . - Page 18 LC?-2070 Service Manual Product Description Printable area Figure 1-3 shows the printable area for cut sheets. The table b;low defines the abbreviations used in the figure. Table 1-10 Printable Area for Cut Sheets Abbreviations Single Sheet Multipart Refer to Table 1-8. PW (width) Refer to Table 1-9.

-

Page 19: Table 1-12 Specifications For Card Stock

LQ-2070 Service Manual Product Description Envelopes and Card Stock The following tables gives specifications for envelopes and card stock. Paper/media specifications Table 1-11 Specifications for Envelopes Rear Entry Front Entry Maximum Minimum Maximum Minimum (6.5”) No. 6 Width 166 mm envelopes Length 92 mm (3.6”) -

Page 20: Figure 1-4 Printable Area For Envelopes And Card Stock

Product Description LQ-2070 Service Manual Printable area The figure below shows the printable area for envelopes and card stock. Each ~bbreviation is defined-in the following table. Table 1-13 Printable Area for Envelopes and Card Stock Envelopes Card Stock Abbreviations Refer to Table 1-11. Refer to Table 1-12. - Page 21 LQ-2070 Service Manual Product Description Continuous Paper The following table gives specifications continuous paper. Paper/media specifications Table 1-14 Specifications for Continuous Paper (Single Sheet and Multipart) Rear Entry Bottom Entry Front Entry Minimum Maximum Minimum Maximum Minimum Maximum 406 mm 101 mm 406 mm 101 mm...

-

Page 22: Table 1-15 Printable Area For Continuous Paper

Product Description LQ-2070 Service Manual The figure below shows the printable area for continuous paper. Printable area Each abbreviation is defined in the following table. Table 1-15 Printable Area for Continuous Paper Abbreviations Continuous Paper PW (width) Refer to Table 1-14. PL (length) Refer to Table 1-14. -

Page 23: Figure 1-6 Label Size

LQ-2070 Service Manuai Product Description Continuous Paper with Labels The following table gives the specifications for continuous paper with Paper/media specifications labels. Table 1-16 Specifications for Continuous Paper with Labels Rear Entry Bottom Entry Front Entry Minimum Maximum Minimum Maximum Minimum Maximum Label size... -

Page 24: Figure 1-7 Printable Area For Roll Paper

Product Description Lt2-2070 Service Manual Roll Paper Note: Roll paper is not available in all models, and not available in the U.S. The following table shows specifications for roll paper. . Paper/media specifications Table 1-17 Specifications for Roll Paper Rear Entry Front Entry Maximum Minimum... -

Page 25: Ribbon Specifications

LQ-2070 Service Manuai Product Description 1.2.5 Ribbon Specifications Table 1-19 Statistics on the Ribbon Specification Item Fabric Type Black Color 8 million characters (draft, 10 cpi, 48dotcJ character) Ribbon life Dimension 506.0 mm (W) x 123.5 mm (D) x 23.0 mm (H) 19.92”... -

Page 26: Environmental Conditions

Product Description Service Manual LQ-2070 1.2.7 Environmental Conditions Table 1-22 explains the conditions the printer requires during operation and when not operating, Table 1-22 Environmental Requirements Item Specifications Temperature 5 to 35° C/41 to 95° F ( operating %1) 15to 25° C/59 to 77° F (operating X1,X 2) -30 to 60°... -

Page 27: Ce Marking

LQ-2070 Service Manual Product Description 1.2.10 CE Marking The following table lists CE marking information. Table 1-25 CE Marking EN60950 Low Voltage Directive 73/23 / EEC EN55022 class B EMC Directive 89/336/ EEC EN50082-1 , IEC801-2 IEC801-3 , IEC801-4 EN45501 Non-Automatic Weighing Instruments Directive 90/384/EEC 1.2.11 Physical Specifications Table 1-26 provides printer dimensions and weight. -

Page 28: Table 1-29 Environmental Conditions

Product Description LQ-2070 Service Manual . Stacker capacity Table 1-28 Capacity of the Stacker CSF Bin 1 CSF Bin 2 140 sheets (+$ 1) Single sheets ---- 100 sheets (~ 2) 15 sheets (% 3) Envelopes ---- 28 sheets (% 4) ---- Card stock 30 sheets (% 5) -

Page 29: Firmware Specifications

10.5pt., 8pt.-32pt. (every 2 pt.) EPSON Saris Serif 10.5pt., 8pt.-32pt. (every 2pt.) EPSON Roman T 10.5pt., 8pt.-32pt. (every 2pt.) EPSON Saris Serif H 10.5pt., 8pt.-32pt. (every 2pt.) Bar code fonts EAN-13, EAN-8, Interleaved 2 of 5, UPC-A, UPC-E, Code 39 Code 128, POSTNET... -

Page 30: 21Nterface Specifications

Product Description LQ-2070 Service Manual 1.3.2 Interface Specifications This printer provides a bidirectional 8-bit parallel interface and a Type B optional interface slot, standard. 1.3.2.1 Parallel Interface (Fotward Channel) 8-bit parallel, IEEE-P1284, compatibility mode Transmission mode 57-30360 (Amphenol) or equivalent Adaptable connector STROBE Synchronization... - Page 31 Product Description LC?-2070 Service Manual DATA T R O B E ‘ ~tsetu~< tstb BUSY & tbusy treadv~l> ACKNLG Figure 1-8 Data Transmission Timing Table 1-32 Maximum and Minimum Timings for Data Transmission Parameter Minimum Maximum - . . . setup 500 nsec -----...

-

Page 32: Parallel Interface (Reverse Channel)

Product Description LQ-2070 Service Manual 1.3.2.2 Parallel Interface (Reverse Channel) IEEE-P1284 nibble mode Transmission mode . Adaptable comector 57-30360 (Anphenol) or equivalent Synchronization Refer to the IEEE-P1284 Specification . Handshaking Refer to the IEEE-P1284 Specification TILcompatible (IEEE-P1284 level 1 device) Signal level Refer to the specification . -

Page 33: Interface Selection

[00 H][32 H] ..MFG: EPSON, CMD: ESCPC2-00, MDL: LQ-2070, CLS: PRINTER ESC/P2 IBM2391 ph.Is [00 H][33H] ..MGF: EPSON, CMD: PRPXL24-01, MDL: LQ-2070, CLS: PRINTER 1.3.2.3 Interface Selection The printer has 2 interfaces: the parallel interface and Type B optional interface. These interfaces are selected manually in default setting mode or selected automatically. - Page 34 Product Description LQ-2070 Service Manual 1.3.3 Paper Handling Sequence In this section, paper handling firmware sequences are described in several cases. Printer is on line (not in the pause state). Printer status No PE sensor detects that paper is loaded. The release lever position is set to continuous paper.

- Page 35 LQ-2070 Service Manual Product Description . Printer status The front PE sensor detects that paper is loaded in the front paper path. The release lever is set to continuous paper Table 1-36 Paper Handling Sequence 3 Result Occurrence Printer goes off or on line. PAUSE button pressed Printer Derforms a line feed.

- Page 36 Product Description LQ-2070 Service Manual Printer status The rear PE sensor detects that paper is loaded in the rear paper path. Release lever position is set to Fri&ion. Table 1-38 Paper Handling Sequence 5 Result Occurrence Printer goes on or off line. Pause button pressed Printer performs a line feed.

-

Page 37: Paperwidth Sensor Operation

LC?-2070 Service Manual Product DescrhXion 1.3.4. Paper Width (PW) Sensor Operation The PW sensor is mounted on the ribbon mask holder to measure the paper width and detect the top edge of the paper. However, in cases where print data is over the paper width, the image cut function does not operate in all modes. -

Page 38: Operating Instructions

Product Description LC?-2070 Service Manual 1.4 Operating Instructions This section provides detailed information about the LQ-2070 control panel buttons and LEDs. 1.4.1 Control Panel Operations The printer control panel contains 6 non-lock type push buttons and 8 LEDs for various printer functions. -

Page 39: Status Codes Indicated By The Leds And Beeper

LQ-2070 Service Manual Product Description Operations at power on Turning the printer on while pressing panel buttons executes the functions below: Table 1-42 Operation at Power On Function Button LQ self-test Load / Eject Draft self-test LF I FF Load I Eject and LF I FF Data dump Condensed... -

Page 40: Tearoff Function

Product Description LQ-2070 Service Manual 1.4.3 Micro Adjust Function The micro adjust function lets you set the TOF and tear off positions. After the printer is put in this mode, you can adjust the top of form (TOF) position up or down in increments of %16 inch pressing the button. -

Page 41: Self-Test Function

LQ-2070 Sewice Manual Product Description 1.4.5 Self-test Function Pressing the button while turning on the printer puts the printer in LQ self-test Load / Eject mode. Pressing the button while turning on the printer puts the printer in Draft self-test LF/FF mode. -

Page 42: Default Setting Function

Product Description LQ-2070 Service Manual 1.4.7 Default Setting Function Pressing the button while turning on the printer puts the printer in default setting mode. Pitch Some default printer settings can be changed in this operation. The method for setting defaults is described in the instruction sheets, which are printed out immediately after you enter the mode. -

Page 43: Bidirectional Adjustment Function

LQ-2070 Service Manual Product Description 1.4.9 Bidirectional Adjustment Function Pressing the button while turning on the printer puts the printer in bidirectional adjustment Pause mode. In this mode, you can adjust the bidirectional alignment for the following three modes: 1. Draft mode Draft copy mode 3. -

Page 44: Main Components

LC?-2070 Service Manual Product Description 1.6 MAIN COMPONENTS main of the LQ-2070 are designed for easy removal and repair. components The main components are: 0 C186 MAIN Board Assembly 0C166PSB/PSE Board Assembly (120 V/230V) 0 C165 PNL Bowd Assembly 0 Printer Mechanism Cl HousingAssembly The following figure shows the main components of the LQ-2070. -

Page 45: C186 Main Board Assembly

Product Description LQ-2070 Service Manual 1.6.1 C186 MAIN Board Assembly The C186 MAIN board consists of a TMP96C041AF CPU, an E05B13 gate array, a program/CG ROM, a PS-IWM, an EEPROM, etc. Head Driva ICI 1,14 PF Motor Driver TRANSISTOR TEA3718SDP IC 5 PS RAM IC12 ‘... -

Page 46: Housing Assembly

Product Description LQ-2070 Service Manual 1.6.5. Housing Assembly This consists of printer cover assembly, edge guide assembly, upper housing, lower housing assembly, etc. Figure 1:17 Housing Assembly 1-38 Rev.A... -

Page 47: Printer Mechanism

CHAPTER 2 Operating Principles Table of Contents 2.1 PRINTER MECHANISM OPERATION 2.1.1 Printing Mechanism ......... . 2-1 2.1.2 Carriage Movement Mechanism . - Page 48 List of Figures Figure 2-1. Principles of Printhead Operation ......2-1 Figure 2-2. Carriage Movement Mechanism......2-2 Figure 2-3.

-

Page 49: Printer Mechanism Operation

LQ-2070 Service Manual Operating Principles 2.1 PRINTER MECHANISM OPERATION This section describes the printer mechanism and explains how it works. 2.1.1 Printing Mechanism The printing mechanism is composed of the printhead, ink ribbon, and ribbon mask. The printhead is an 24-pin (12 pins 2) head for impact dot printing. -

Page 50: Carriage Movement Mechanism

Operation Principles LQ-2070 Servcie Manual 2.1.2 Carriage Movement Mechanism The carriage movement mechanism consists of the carriage assembly, carriage (CR) motor, timing belt, driven pulley, home position (HP) sensor, etc. The CR motor drives the timing belt. The carriage assembly is connected to the timing belt, which is moved by the CR motor. -

Page 51: Platen Gap Adjustment

LQ-2070 Service Manual Operating Principles 2.1.3 Platen Gap Adjustment You can adjust the platen gap (the gap between the platen and printhead) to allow the printer to use paper of different weights or thicknesses. When you move the platen gap adjust lever forward or backward, the carriage guide shaft rotates. -

Page 52: Paper Handling Mechanism

Operation Principles LQ-2070 Servcie Manual 2.1.4. Paper Handling Mechanisms During normal operation, paper is fed into the printer, advanced to the specified position, and then ejected from the printer. These paper-handling operations are performed by various paper handling mechanisms, such as tractors, platens, rollers, and gears. -

Page 53: Paper Advance Mechanism

LQ-2070 Service Manual Operating Principles 2.1.4.2. Paper Advance Mechanism This section describes how the friction and tractor advance mechanisms work to move the paper through the printer. 1. Friction Advance Method Paper is held between the platen and the paper guide rollers and between the paper tension roller and paper tension unit cover. - Page 54 Operation Principles LQ-2070 Servcie Manual 2. Push Tractor Method The push tractor method can be used with either the rear or front entrance. When the push tractor method is used with the rear entrance, the torque generated by the PF motor is transmitted to the push tractor gear through the PF motor pinion gear, paper advance reduction gear, and tractor reduction gear.

- Page 55 LQ-2070 Service Manual Operating Principles Rev.A...

- Page 56 Operation Principles LQ-2070 Servcie Manual 3. Pull Tractor Method The pull tractor advances paper in basically the same way as the push tractor. The push tractor is installed at the paper entrance and pushes paper into the printer. On the other hand, the pull tractor is installed at the paper exit and pulls paper out of the printer mechanism.

- Page 57 LQ-2070 Service Manual Operating Principles 4. Push-Pull Tractor Method The push-pull tractor method is a combination of the push and pull tractor methods. Two tractors advance the paper: one at the front paper entrance and the other at the rear paper entrance. They operate simultaneously to push and pull the paper through the printer mechanism.

- Page 58 Operation Principles LQ-2070 Servcie Manual 2-10 Rev.A...

-

Page 59: Paper Paths

LQ-2070 Service Manual Operating Principles 2.1.5 Paper Paths This section describes various paper paths through the printer mechanism. These paper paths are divided into four groups, depending on which entrance (top, rear, bottom, or front) is used to feed paper. The printer has two PE (paper end) sensors. - Page 60 Operation Principles LQ-2070 Servcie Manual 2. Rear Entrance Figures 2-13, 2-14, and 2-15 show the paper paths for tractor feeding using the rear entrance. You can use the rear entrance with any of the following paper feed methods: push tractor feed, pull tractor feed, or push-pull tractor feed.

- Page 61 LQ-2070 Service Manual Operating Principles As shown above in Figure 2-15, when you use the pull tractor with this printer, you must remove the paper eject cover, which includes the paper tension roller, from the printer mechanism. 3. Bottom Entrance Figure 2-16 shows the paper path for tractor feeding using the bottom entrance.

- Page 62 Operation Principles LQ-2070 Servcie Manual 4. Front Entrance Figures 2-17 through 2-20 show the paper paths for the front entrance. The front entrance can be used with any of the following paper feed methods: friction feed, push tractor feed, pull tractor feed, or push-pull tractor feed.

- Page 63 LQ-2070 Service Manual Operating Principles Down Rev.A 2-15...

-

Page 64: Ribbon Advance Mechanism

Operation Principles LQ-2070 Servcie Manual 2.1.6 Ribbon Advance Mechanism The ribbon is held between the ribbon advance roller (ribbon driven gear) and the ribbon pressure roller. When the carriage moves from left to right and vice versa on the CR guide shaft, the timing belt turns the belt-driven pulley. -

Page 65: Power Supply Operation

LQ-2070 Service Manual Operating Principles 2.2 POWER SUPPLY OPERATION The printer can be powered by either of two power supply boards: the C166 PSB (120 V) or C166 PSE (230 V) power supply. These boards are the same as the FX-2170. Additionally, the PSB and PSE boards function the same, except for a difference in primary circuitry. -

Page 66: Power Supply Circuit Operation

Operation Principles LQ-2070 Servcie Manual 2.2.2 Power Supply Circuit Operation The power supply circuit is composed of an RCC (ringing choke converter) system and the power switch circuit in the secondary circuitry. The power supply circuit has several protection and control circuits. This section describes these circuits. - Page 67 LQ-2070 Service Manual Operating Principles 3. +35 V Constant Voltage Control Circuit The +35 V constant voltage control circuit is illustrated below. +35V Line ZD51 ZD81 ZD82 ZD83 ZD84 ZD85 GND Line Figure 2-25 +35 V Line Constant Voltage Control Circuit The constant voltage control circuit operates to keep the 35 V line at 35 V 6 %.

- Page 68 Operation Principles LQ-2070 Servcie Manual 5. +35 V Line Over Current Protection Circuit The +35 V line over current control circuit is illustrated below. +35V Line Figure 2-27 +35 V Line Over Current Protection Circuit When the +35 V line becomes less than 27 V, Q82 and Q54 turn on, and PC1 turns on. Consequently, Q32 and Q31 turn off, and then switching FET Q1 shuts off.

- Page 69 LQ-2070 Service Manual Operating Principles 7. +5 V Line Constant Voltage Control Circuit The +5 V line constant voltage control circuit is shown below. +35V R 5 3 +5v Line ZD55 R 6 5 G N D IC51 TL494CN Figure 2-29 +5 V Line Constant Voltage Control Circuit Port 16 of IC51 (TL494CN) monitors the + 5 V line, and the voltage is compared with the standard voltage, which is input into port 15.

-

Page 70: Control Circuit

Operation Principles LQ-2070 Servcie Manual 2.3 CONTROL CIRCUIT The control circuit consists of the C186 MAIN board assembly and C165 PNL board This section describes the major components and explains how the boards work. 2.3.1 Overview of Control Circuit Operation The printer’s control circuit includes a TMP96C041AF CPU that runs at 17.20 MHz, an E05B24YA gate array, a 1M bit PS-RAM (8-bit bus, less than 100ns) , a 2M bit PROM (8-bit bus, less than 100ns), 4M CG (Standard Version) or 8M CG (NLSP Version). - Page 71 LQ-2070 Service Manual Operating Principles The following figure shows the data flow from the host computer to the printhead. Data sent from the host computer is converted to image data and transmitted to the printhead through the gate array. C P U T M P9 6 C 0 4 1 AF Option I/F R A M...

-

Page 72: System Reset Circuit

Operation Principles LQ-2070 Servcie Manual 2.3.2 System Reset Circuit Control circuits IC1 and IC2 are initialized when a RESET signal (LOW level) is output from port 1 (VOUT) of IC10. IC10 monitors the +5 V line on port 3, and resets under the following conditions: E05B24YA + 5 V R E S E T... -

Page 73: Cr Motor Driver Circuit

LQ-2070 Service Manual Operating Principles 2.3.4 CR Motor Driver Circuit The CR motor driver circuit is shown below. PG00 IN A PG01 IN-A CR A PG02 IN B PG03 CR-A IN-B Address CR B Data Line CR-B CRI0 C29, 30 SL A7 0 2 4 M Gate CRI1... -

Page 74: Pf Motor Driver Circuit

Operation Principles LQ-2070 Servcie Manual 2.3.5 PF Motor Driver Circuit The figure below shows the PF motor driver circuit. IC11 PF A P FI 1A OUTA PF-A OUTB P FI 0A PFFASEA PHASE +35V G a te Array GND1 GND2 GND3 PFHOLD GND4... -

Page 75: Sensor Circuits

LQ-2070 Service Manual Operating Principles 2.3.7 Sensor Circuits The CPU detects conditions of the following sensors: home position (HP) sensor, release sensors 1 and 2, platen gap (PG) sensor, rear and front paper end (PE) sensors, paper width (PW) sensor. + 5 V + 5 V + 5 V... - Page 76 CHAPTER 3 Disassembly and Assembly Table of Contents 3.1 OVERVIEW 3.1.1 Precautions..........3-1 3.1.2 Tools .

- Page 77 List of Figures Figure 3-1. Screw Types and Abbreviations ......3-3 Figure 3-2. Flowchart for Disassembling the Printer ..... . 3-4 Figure 3-3.

- Page 78 Figure 3-48. Removing the Gear Train Cover ......3-31 Figure 3-49. Engaging 5 Gears ........3-31 Figure 3-50.

-

Page 79: Overview

LQ-2070 Service Manual Disassembly and Assembly 3.1 OVERVIEW This section describes various points to note when disassembling and assembling the printer. 3.1.1 Precautions Follow the precautions below for disassembly or assembly. Before disassembling, assembling, or adjusting the printer, disconnect the power supply cable from the AC power socket. -

Page 80: Service Checks After Repair

Disassembly and Assembly LQ-2070 Service Manual 3.1.3 Service Checks After Repair Before returning the printer after service, use the check list in Table 3-3, which provides a record to make servicing and shipping more efficient. Table 3-3. Inspection Check List for the Repaired Printer Category Component Item to Check Is Check Required? -

Page 81: Specifications For Screws

LQ-2070 Service Manual Disassembly and Assembly 3.1.4 Specifications for Screws Table 3-4 lists the abbreviations used in the following sections for small parts, such as screws and washers. Table 3-4. Screw Types and Abbreviations Abbreviation Part Name Cross-recessed pan head S-tight screw Cross-recessed bind head B-tight screw Cross-recessed bind head S-tight screw Cross-recessed bind head N-tight screw... -

Page 82: Printer Disassembly And Assembly

Disassembly and Assembly LQ-2070 Service Manual 3.2. PRINTER DISASSEMBLY AND ASSEMBLY This section describes procedures for disassembling and assembling the main components of the printer. When the procedure for installing a component is simply the reverse of removing the component, this chapter does not describe the assembly procedure. -

Page 83: Before Starting Disassembly Procedures

LQ-2070 Service Manual Disassembly and Assembly 3.2.1. Before Starting Disassembly Procedures 1. Remove the following parts: Front edge guide assembly Front cover Bottom cover Rear edge guide assembly Printer cover Paper eject assembly Front/rear tractor assembly Ribbon cartridge Refer to the following figure. Figure 3-3 Before Starting the Disassembly Procedure Remove the paper eject cover and the front/rear tractor assembly by pushing to release the hooks at both sides. -

Page 84: Removing The Panel Board Assembly

Disassembly and Assembly LQ-2070 Service Manual 3.2.2. Removing the Panel Board Assembly Remove the printer cover and ribbon cartridge (see Section 3.2.1). Release the left clips for the panel board assembly by pushing them from the cutout located on the inside front of the upper housing assembly. Release the flexible flat cable (FFC) by pulling the lock cover for CN1, and then disconnect the FFC for CN1 from the C165 PNL board assembly. -

Page 85: Removing The Printhead

LQ-2070 Service Manual Disassembly and Assembly 3.2.3. Removing the Printhead Remove the printer cover and ribbon cartridge (see Section 3.2.1). Remove 2 CBS screws (3 10, F/Zn) securing the printhead to the CR assembly. Remove the printhead from the CR assembly. Disconnect 2 wide FFCs from the printhead and then disconnect the narrow FFC from the connector on the CR cover. -

Page 86: Removing The Hp Sensor

Disassembly and Assembly LQ-2070 Service Manual 3.2.4 Removing the HP Sensor Remove the printer cover, ribbon cartridge, front edge guide, and front cover (see Section 3.2.1). Disconnect the connector cable for the HP sensor. Remove the HP sensor by pushing up and releasing the 2 clips at the bottom of the HP sensor from the front paper entrance. - Page 87 LQ-2070 Service Manual Disassembly and Assembly Mount the onto the ribbon mask holder groove, aligning the bottom line of micro PW sensor assembly photo sensor to the bottom line of the groove. Whenever you remove the PW sensor assembly, clean the surface of the sensor by wiping it with a soft material.

-

Page 88: Removing The Platen Assembly

Disassembly and Assembly LQ-2070 Service Manual 3.2.6 Removing the Platen Assembly Remove the printer cover, ribbon cartridge, and platen knob (see Section 3.2.1). Release both locks for the left and right bushings (8 mm) by pushing the lever holder for the bushings outside, and then pulling the holder lever forward. -

Page 89: Removing The Upper Housing Assembly

LQ-2070 Service Manual Disassembly and Assembly 3.2.7 Removing the Upper Housing Assembly Remove the rear edge guide assembly, paper eject assembly, rear tractor unit, and printer cover (see Section 3.2.1). Remove the panel board assembly (see Section 3.2.2). Remove 4 CBB screws (4 14, F/Zn) securing the upper housing assembly. -

Page 90: Removing The Cr Motor Assembly

Disassembly and Assembly LQ-2070 Service Manual 3.2.8 Removing the CR Motor Assembly Remove the rear edge guide assembly, paper eject assembly, rear tractor unit, and printer cover (see Section 3.2.1). Remove the panel board (see Section 3.2.2) and upper housing assembly (see Section 3.2.7). Remove the 2 CR mounting screws securing the CR motor assembly. -

Page 91: Removing The Printer Mechanism

LQ-2070 Service Manual Disassembly and Assembly 3.2.9 Removing the Printer Mechanism Remove the rear/front edge guide assembly, front cover, paper eject assembly, rear/front tractor units, and printer cover (see Section 3.2.1). Remove the panel board assembly (see Section 3.2.2) and upper housing assembly (see Section 3.2.7). - Page 92 Disassembly and Assembly LQ-2070 Service Manual 3.2.9.1 Removing the PF Motor Remove the rear/front edge guide assembly, front cover, paper eject assembly, rear/front tractor unit, and printer cover (see Section 3.2.1). Remove the panel board (see Section 3.2.2) and upper housing assembly (see Section 3.2.7). Remove the printer mechanism (see Section 3.2.9).

-

Page 93: Removing The Pg Sensor Assembly

LQ-2070 Service Manual Disassembly and Assembly 3.2.9.2 Removing the PG Sensor Assembly Remove the rear/front edge guide assembly, front cover, paper eject assembly, rear/front tractor unit, and printer cover (see Section 3.2.1). Remove the panel board (see Section 3.2.2) and upper housing assemblies (see Section 3.2.7). Remove the printer mechanism (see Section 3.2.9 ). -

Page 94: Removing The Right Frame Assembly

Disassembly and Assembly LQ-2070 Service Manual 3.2.9.3 Removing the Right Frame Assembly Remove the rear/front edge guide assembly, front cover, paper eject assembly, rear/front tractor unit, and printer cover (see Section 3.2.1). Remove the panel board (see Section 3.2.2) and upper housing assembly (see Section 3.2.7). Remove the printer mechanism (see Section 3.2.9 ), CR motor assembly (see Section 3.2.8), PF motor, (see Section 3.2.9.1), and PG sensor assembly (see Section 3.2.9.2 ). - Page 95 LQ-2070 Service Manual Disassembly and Assembly Remove the right sub frame from the right frame assembly by disconnecting CN16 from the C186 MAIN board assembly. Remove the following 11 parts from the right frame assembly. 2 compression springs (200 g) 2 plain washers (8.2 x 0.5 x 15, S/Na) 2 spur gears (34.5 mm) 1 spur gear (34 mm) 1 spur gear (21 mm)

- Page 96 Disassembly and Assembly LQ-2070 Service Manual When you engage the release lever and release lever transmission to the tractor clutch cam, notice the points in the following figure. The tightening torque for the CBS screws (3 6, F/Zn) and (3 8, F/Zn) 0.78 ~ 0.98 Nm (8 ~ 10 Kg - cm) The tightening torque for the hexagon nut (standard, M4)

-

Page 97: Removing The Left Frame Assembly

LQ-2070 Service Manual Disassembly and Assembly 3.2.9.5 Removing the Left Frame Assembly Remove the rear/front edge guide assembly, front cover, paper eject assembly, rear/front tractor unit, and printer cover (see Section 3.2.1). Remove the panel board assembly (see Section 3.2.2), upper housing assembly (see Section 3.2.7), and then remove the printer mechanism (see Section 3.2.9 ). -

Page 98: Removing The Ribbon Drive (Rd) Assembly

Disassembly and Assembly LQ-2070 Service Manual 3.2.9.6 Removing the Ribbon Drive (RD) Assembly Remove the rear/front edge guide assembly, front cover, paper eject assembly, rear/front tractor unit, and printer cover (see Section 3.2.1). Remove the panel board (see Section 3.2.2) and upper housing assembly (see Section 3.2.7). Remove the printer mechanism (see Section 3.2.9). -

Page 99: Removing The Cr Assembly

LQ-2070 Service Manual Disassembly and Assembly 3.2.9.7 Removing the CR Assembly Remove the rear/front edge guide assembly, front cover, paper eject assembly, rear/front tractor unit, and printer cover. Remove the panel board (see Section 3.2.2) and upper housing assembly (see Section 3.2.7) . Remove the printer mechanism (see Section 3.2.9 ). - Page 100 Disassembly and Assembly LQ-2070 Service Manual Insert the timing belt properly into the 2 holding slots at the bottom of the CR assembly. Take up the timing belt slack between the two slots completely, as shown in the following figure. Insert the 2 oil pads into the proper positions in the CR assembly, as shown.

-

Page 101: Removing The Rear Pe Sensor Assembly

LQ-2070 Service Manual Disassembly and Assembly 3.2.9.8 Removing the Rear PE Sensor Assembly Remove the rear/front edge guide assembly, front cover, paper eject assembly, rear/front tractor unit, and printer cover. Remove the panel board (see Section 3.2.2) and upper housing assembly (see Section 3.2.7). Remove the printer mechanism (see Section 3.2.9). -

Page 102: Removing The C186 Main Board Assembly

Disassembly and Assembly LQ-2070 Service Manual 3.2.10 Removing the C186 MAIN Board Assembly Remove the rear/front edge guide assembly, front cover, paper eject assembly, rear/front tractor unit, and printer cover (see Section 3.2.1) Remove the panel board (see Section 3.2.2) and upper housing assembly (see Section 3.2.7). Disconnect the following connectors from the C186 MAIN board assembly. -

Page 103: Removing The C166 Psb/E Board Assembly

LQ-2070 Service Manual Disassembly and Assembly 3.2.11 Removing the C166 PSB/E Board Assembly Remove the rear/front edge guide assembly, front cover, paper eject assembly, rear/front tractor unit, and printer cover. Remove the panel board (see Section 3.2.2) and upper housing assembly (see Section 3.2.7). Remove the 5 CBB screws (3 12, F/Zn) securing the C166 PSB/E board assembly. -

Page 104: Disassembly And Assembly Of Csf Bin

Disassembly and Assembly LQ-2070 Service Manual 3.3. Disassembly and Assembly of CSF Bin 1 This section describes procedures for disassembling and assembling the optional cut sheet feeder. In general, you can install a component in the CSF simply by reversing the procedure for removing it. Therefore, this section does not describe assembly procedures in most cases. - Page 105 LQ-2070 Service Manual Disassembly and Assembly Be careful of the cable alignment for the CN1 connector cable and earth cables. Align those cables as shown in the following figure. If these cables is not aligned properly, the CSF gear cover cannot be assembled properly. Right CSF Frame Connector CN1 Connector CN2...

-

Page 106: Disassembling The Paper Support Block Assembly

Disassembly and Assembly LQ-2070 Service Manual 3.3.2 Disassembling Paper Support Block Assembly Remove the CSF gear cover. Refer to step 1 in Section 3.3.1. Remove the stepping motor. Refer to steps 2 and 3 in the Section 3.3.1. Remove the E-ring fixing the right edge of the paper feed shaft. Figure 3-41 Removing the E-ring Remove 1 gear (29 mm) from the right edge of the paper feed shaft. - Page 107 LQ-2070 Service Manual Disassembly and Assembly Figure 3-44 Removing the Paper Support Block Assembly Remove the paper support assembly along with the paper support shaft and paper shaft holder by pulling upward. Remove both paper feed rollers from both paper support assemblies. Paper Support Assembly Paper Loading Roller Cover Figure 3-45 Removing the Paper Loading Roller Cover Assembly...

- Page 108 Disassembly and Assembly LQ-2070 Service Manual Figure 3-46 Removing the Paper Eject Assembly Cover Thin Plastic Film Figure 3-47 Assembling the Paper Eject Assembly Cover 3-30 Rev.A...

- Page 109 LQ-2070 Service Manual Disassembly and Assembly 3.3.3 Removing the Paper Eject Assembly Cover Remove the paper eject assembly cover by releasing 2 clips located along both edges of the paper eject assembly cover, as shown in the following figure. Gear Train Cover Figure 3-48 Removing the Gear Train Cover When attaching the paper eject assembly cover to the CSF unit, pay attention to the position of 2 pieces of thin plastic film glued on the reverse side of the paper eject assembly cover, as shown in...

- Page 110 Disassembly and Assembly LQ-2070 Service Manual 3.4 Disassembly and Assembly of CSF Bin 2 3.4.1 Disassembling the Right Side Block E- ring CTPB Screw (3x8) Right CSF Frame Figure 3-50 Removing 1 E-ring and 2 CTBS Screws Remove the gear train cover by releasing the 4 clips shown in the following figure. Remove the following 5 gears and 1 spring from the right CSF frame.

- Page 111 LQ-2070 Service Manual Disassembly and Assembly 3.4.2 Disassembling the Paper Support Block Assembly Remove 1 E -ring fixing the paper feed roller shaft to the right CSF frame. Remove 2 CTBS (3 8) screws securing the paper support shaft to both right and left CSF frames. Remove both paper support assemblies along with the paper feed roller shaft and paper support shaft.

- Page 112 Disassembly and Assembly LQ-2070 Service Manual 3-34 Rev.A...

- Page 113 CHAPTER 4 Adjustments Table of Contents 4.1 ADJUSTMENT OVERVIEW 4.1.1 Required Adjustments ........4-1 4.1.2.

-

Page 114: Adjustment Overview

LQ-2070 Service Manual Adjustment 4.1 ADJUSTMENT OVERVIEW 4.1.1 Required Adjustments This section describes what adjustments are required after any part is removed or replaced. The following table shows the relationship between the repaired item and the adjustment. Table 4-1 Required Adjustments Platen Bi-d Print Factory... -

Page 115: Adjusting And Resetting The Printer

Adjustment LQ-2070 Service Manual 4.2 ADJUSTING AND RESETTING THE PRINTER 4.2.1 Platen Gap Adjustment If you have rotated or reassembled the rear CR guide shaft or parallelism adjustment bushing, or if printing is light or dark, even at the proper PG lever position, perform this adjustment with the printer in 3 positions: the 5th, 80th, and 130th columns. - Page 116 LQ-2070 Service Manual Adjustment Insert a thin screwdriver into the drilled hole at the right edge of the rear CR guide shaft and adjust the platen gap by moving the screwdriver forward or backward until the gap is large enough for a 0.38 mm thickness gauge but too narrow for a 0.41 mm thickness gauge. 10.

- Page 117 Adjustment LQ-2070 Service Manual 4.2.2 Bidirectional Print Alignment Adjustment This section describes the procedure for adjusting the bidirectional print alignment, required after mechanism repair. This procedure is also necessary if you replace the main board assembly or EEPROM, because the adjusted value is written to the EEPROM on the C186 MAIN board.

- Page 118 LQ-2070 Service Manual Adjustment < BI-D adjustment > > Mode 1 Mode 2 Mode 4 Cancel Print Value Write Default Speed [ RET ] [HOME] [ ESC] [SPACE] Figure 4-8 Bi-d Adjustment Menu 10. Highlight the mode by moving the cursor with the key, and then print the current Bi-d print alignment pattern for that mode by pressing SPACE.

- Page 119 Adjustment LQ-2070 Service Manual 4.2.2.2 Bi-d Print Alignment Adjustment from the Control Panel Turn the printer on while pressing the PAUSE button to put the printer into Bi-D adjustment mode. The printer prints out a guide sheet, containing 25 patterns in Draft mode. To adjust your printer, follow these steps 1.

-

Page 120: Factory Settings

LQ-2070 Service Manual Adjustment 4.2.3 Factory Settings This section describes the procedure to reset factory settings, which is necessary if the main board or EEPROM is replaced. You can perform this procedure only with the Settings Diskette. Notes: After you select factory settings in the Factory Setting File menu, be sure to run the “Check Pro. -

Page 121: Tpe Level Reset

Adjustment LQ-2070 Service Manual 4.2.4 TPE Level Reset This section describes the procedure to reset the TPE (top paper end) level. This operation is required when the PW sensor assembly is replaced, and if it is not performed, the printer does not recognize that the PW sensor has been replaced, which limits the ability of the new sensor to operate. - Page 122 Chapter 5 Troubleshooting Table of Contents 5.1 OVERVIEW 5.2 TROUBLESHOOTING INFORMATION 5.2.1 PRINTHEAD ..........5-1 5.2.2 SENSORS .

-

Page 123: Troubleshooting

LQ-2070 Service Manual Troubleshooting 5.1 OVERVIEW This chapter contains flowcharts and checkpoint tables to help you troubleshoot the printer. Flowcharts let you isolate a faulty unit based on abnormal symptoms. The checkpoint tables let you identify the faulty part or unit by checking the values or ranges listed for each component. 5.2 TROUBLESHOOTING INFORMATION This section gives troubleshooting information to let you check test points for replaceable units. -

Page 124: Sensors

Troubleshooting LQ-2070 Service Manual 5.2.2 Sensors Table 5-2 Sensor Test Points Sensor Test Method Test Pin Connector Meter Reading Number (Set Meter to DC Voltage. ) Number Open: +5 V Place one lead on pin 1 and the other lead on pin 2, and check the voltage while (Home position) 1: HP (HP Sensor) -

Page 125: Motors

LQ-2070 Service Manual Troubleshooting 5.2.3 Motors Table 5-3 Motor Test Points Test Method Motor Common Test Pin Connector (Set Meter to Ohms. Disconnect Meter Reading Number Number Motor from Main Board after the Number Printer is Powered off.) CR Motor Place one lead on pin 5 and the 10 % 1, 2, 3, 4... -

Page 126: Unit Level Troubleshooting

Troubleshooting LQ-2070 Service Manual 5.3 UNIT LEVEL TROUBLESHOOTING You may be able to identify the defective unit just from the symptom displayed. The table below provides the symptoms for a number of failures. Once you identify the problem, refer to the flowchart listed in the right-hand column of the table below to determine the cause of the problem. -

Page 127: Troubleshooting

LQ-2070 Service Manual Troubleshooting 1. Abnormal CR Operation START When the printer Is the Connector Connect the was powerd on, dose the CN 11 connected CN 11 CR motor rotate ? correctly ? correctly Y E S Dose Check the resistance of the CR motor Is the trouble the motor coils. - Page 128 Troubleshooting LQ-2070 Service Manual 2. Abnormal Paper Feed Operation 1 START Dose CN10 Connect it the PFmotor connected correctly. rotate? correctly? Is the When problem the printer is corrected? Go to flowchart powered on, 2-1. is paper ejected automatically? Is the resistance of the PF motor coils correct?

- Page 129 LQ-2070 Service Manual Troubleshooting 2. Abnormal Paper Feed Operation 2-1 Continued from flowchart 2. Wh en cut-sheet paper loaded paper is loaded, correctly, but continuous is it ejected paper not loaded automatically? at all ? YE S Y E S Is CN7 Connect CN7 connected...

- Page 130 Troubleshooting LQ-2070 Service Manual 3. Abnormal Control Panel Operation START D os e Check the Operate button the Operate button on the control panel using turn power on a mutometer. and off? Is the Replace the Do the Operate button Check them using PNL board.

-

Page 131: Abnormal Printing

LQ-2070 Service Manual Troubleshooting 4. Abnormal Printing START Date received from the Is the host is not printed selftest excecuted correctly. correctly ? Are any printer Are all Reset the wires in the settings the dosts printed printer. correct? printhead broken? Is the Dose... -

Page 132: Repairing The C166Psb/Pse Board Assembly

Troubleshooting LQ-2070 Service Manual 5.4 REPAIRING C166 PSB/PSE BOARD ASSEMBLY This section provides instructions to repair a defective power supply board assembly. It describes various symptoms, likely causes, and checkpoints. Checkpoints refer to proper waveforms, resistances, and other values to check when evaluating the operation of any potentially faulty component. Check these values and take the appropriate action. - Page 133 LQ-2070 Service Manual Troubleshooting Q1 is dead. Check that the resistance between the Replace source and drain is infinite. the Q1. Check the voltage waveform between the source and drain of the Q1. PC1 is dead. Check the voltage waveform between Replace pins 3 and 4 of the PC1.

- Page 134 Troubleshooting LQ-2070 Service Manual Table 5-6. Repairing the C166 PSB/PSE Board Assembly (Continued) Problem Cause Checkpoint Solution The 35 V and Q32 is dead. Check that the resistance between the Replace 5 V lines are collector and emitter is infinite. the Q32.

-

Page 135: Repairing The C186 Main Board Assembly

LQ-2070 Service Manual Troubleshooting 5.5 REPAIRING THE C186 MAIN BOARD ASSEMBLY This section provides instructions to repair the C186 MAIN board assembly. It describes various problems, symptoms, likely causes, and solutions. The checkpoint column provides proper waveforms, resistance values, and other information for each component of C186 MAIN. Note: This information is necessary only for servicers who repair to the component level. - Page 136 Troubleshooting LQ-2070 Service Manual Table 5-7. Repairing the C186 MAIN Board Assembly Problem Cause Checkpoint Solution Check the oscillator signal at pins 26 If the signal is not or 27 of the CPU correct, replace IC1 ( or replace the main board). Otherwise, replace CRU1.

- Page 137 LQ-2070 Service Manual Troubleshooting Table 5-7. Repairing the C186 MAIN Board Assembly Problem Cause Checkpoint Solution IC1 is defective. Check input signal waveform at 8 pin If the input signal on the both IC11 and IC14. is not correct, IC2 is defective. Check output signal waveform at 1 and replace IC1 or 15pin on the both IC11 and IC14.(CH1)

-

Page 138: Repairing The Printer Mechanism

Troubleshooting LQ-2070 Service Manual 5.6 REPAIRING THE PRINTER MECHANISM This section provides instructions for repairing the printer mechanism. It describes various problems, symptom, likely causes, checkpoints, and solutions. The checkpoint column shows items to be checked, including proper values to be set for each component of the printer mechanism. For replacement and adjustment instructions, see Chapter 3, Disassembly and Assembly, and Chapter 4, Adjustments. - Page 139 LQ-2070 Service Manual Troubleshooting Table 5-8. Repairing the Printer Mechanism Problem Symptom Cause Checkpoint Solution A foreign object Check the HP Remove the any is jammed sensor. foreign object. CR operation is between both The CR moves abnormal. terminals of the slightly and then HP sensor.

- Page 140 Troubleshooting LQ-2070 Service Manual Table 5-8. Repairing the Printer Mechanism Problem Symptom Cause Checkpoint Solution CN10 is Check CN10. Connect CN10 Abnormal The PF motor does disconnected correctly. paper feed not rotate at all. from the main board. The both rear Check the both Mount the rear and front PE...

- Page 141 LQ-2070 Service Manual Troubleshooting Table 5-8. Repairing the Printer Mechanism Problem Symptom Cause Checkpoint Solution CN12 or CN16 is Check the Connect the Abnoraml paper not connected connector. Refer CN12 or CN16 feed. Cut-sheet paper correctly. to page 3-19. correctly. is loaded The release Check the...

- Page 142 CHAPTER 6 Maintenance Table of Contents 6.1 PREVENTIVE MAINTENANCE 6.2 APPLYING LUBRICATION List of Figures Figure 6-1. Lubrication Points 1 and 3 ....... . . 6-2 Figure 6-2.

-

Page 143: Preventive Maintenance

6.2 APPLYING LUBRICATION EPSON recommends the printer be lubricated at the points illustrated to the following pages. Table 6-2 lists each point along with its recommended lubricant. The recommended lubricants are EPSON G-26 and O-2, which have been tested extensively and found to comply with the needs of this printer. (Table 6-1 provides details about these lubricants.) Before applying a lubricant, be sure the surface to be lubricated is clean. - Page 144 Maintenance LQ-2070 Service Manual Cam, Clutch, Tractor Spur Gear, 34.5 : Lubrication Point Ref. No.(1) : Lubrication Point Ref. No.(3) Figure 6-1. Lubrication Points 1 and 3 Gap Adjust Lever Platen Gap Adjustment Slot Lubricate all these slots Lubrication Point Ref. No. (2) Figure 6-2.

- Page 145 LQ-2070 Service Manual Maintenance : Lubrication Point Ref. No. 4 Figure 6-3. Lubrication Point 4 : Lubrication Point Ref. No.(5) : Lubrication Point Ref. No.(6-1) : Lubrication Point Ref. No.(6-2) : Lubrication Point Ref. No.(7) Figure 6-4. Lubrication Points 5, 6,and 7 : Lubrication Point Ref.No.8 Figure 6-5.

- Page 146 Maintenance LQ-2070 Service Manual Rev. A...

- Page 147 Appendix Table of Contents A.1. EXPANDED PRODUCTION COMMANDS A.2. EEPROM ADRESS MAP A.3 CONNECTOR SUMMARY A.4 CIRCUIT DIAGRAMS A-11 A.5 CIRCUIT BOARD COMPONENT LAYOUTS A-17 A.6 EXPLODED DIAGRAMS A-20 A.7. PARTS LIST A-26 List of Figures Figure A-1. Cable Connections ........A-5 Figure A-2.

- Page 148 Table A-15. Connector Pin Assignments - CN16 ......A-9 Table A-16.Parts Comparison Between LQ2070,LQ2170 and FX2170 ..A-10 Table A-17.Parts List .

- Page 149 LQ-2070 Service Manual Appendix A.1 EXPANDED PRODUCTION COMMANDS 1. Write Bidirectional Adjustment Data to EEPROM Format 1B 7C 00 06 00 00 FF 00 (in hex) dl d2 d3 Parameters Print speed (0: High speed draft /Draft, 1: Draft, 2: LQ) d2 , d3 Bi-d adjustment data to be written (units = 1/720 inch) n = FFF4H (–12)

- Page 150 Appendix LQ-2070 Service Manual A.2 EEPROM ADDRESS MAP Address Data Data Format Default 00H, 01H Reserved 0000H Area 1 02H, 03H Character table 0000H 0: PC437 1: PC850 2: PC860 selection (PC437) 3: PC863 4: PC865 5: PC861 6: BRASCII 7: Abicomp 8: ISO Latin 1 9: Roman8,...

- Page 151 LQ-2070 Service Manual Appendix Address Data Data Format Default Reserved 0000H Pitch direction 0: Bi-d, 1: Uni-d setting I/F mode selection 0: Auto I/F Selection, 1: Parallel I/F, 2: Type-B (Auto) Auto I/F wait time 10: 10 Sec., 30: 30 Sec., 00: 10 Sec. setting (10 sec.) Auto line feed...

- Page 152 Appendix LQ-2070 Service Manual Address Data Data Format Default Manual insertion 3 to 30 (by 0.1 sec.), 00H: 2 sec. when Normal 00H (2or wait time mode. (same as default) 3 sec.) 3sec.when Copy mode.(same as default) 2CH 1 Tear-off wait time 3 to 30 (by 0.1 sec.) , 00H: 3 sec.

- Page 153 LQ-2070 Service Manual Appendix A.3 CONNECTOR SUMMARY Figure A-1 illustrates how primary components are connected. Table A-1 summarizes functions and sizes of the connectors. Printer Mechanism PF Motor CR Motor PG Sensor Board Assy., C166 PSB / PSE Release Lever Position Sensor PE- Rear Sensor PE- Front Sensor HP Sensor...

- Page 154 Appendix LQ-2070 Service Manual Table A-1. Connector Summary Board Connector Function Pins Parallel interface Type B interface C166 PSB/PSE board assembly HP sensor Rear PE sensor Front PE sensor PW sensor MAIN Board Printhead Assembly Printhead CN10 PF motor CN11 CR motor CN12 Release lever position sensor...

- Page 155 LQ-2070 Service Manual Appendix Table A-5. Connector Pin Assignments – CN6 Signal Name Function Front paper end signal —- Signal GND Table A-6. Connector Pin Assignments - CN7 Signal Name Function TOP paper end signal —- Signal GND —- +5 VDC line —- +5 VDC line Table A-7.

- Page 156 Appendix LQ-2070 Service Manual Table A-8. Connector Pin Assignments – CN9 Signal Name Function Head data 3 HD11 Head data 11 Head data 2 HD19 Head data 19 Head data 7 — +35V +35 VDC line — +35V +35 VDC line —...

- Page 157 LQ-2070 Service Manual Appendix Table A-13. Connector Pin Assignments – CN14 Signal Name Function —- +35V +35 VDC line —- +5 VDC line HOLD CSF motor hold signal —- +35V +35 VDC line CSF motor phase -A CSF motor phase B —- Signal GND —-...

- Page 158 Appendix LQ-2070 Service Manual Table A-16 Parts Comparison Between LQ2070, LQ 2170 and FX 2170 LQ - 2070 (24pins) LQ -2170 (24pins) FX - 2170 (9pins) Main Board C186 C165 C165 PSB/PSE Board C166 C165 C165 Cover Open Sensor PG sensors Release Lever Located at both sides 2 on left side...

- Page 159 Appendix LQ-2070 Service Manual A.7.PARTS LIST Table A-17 Part No. Reference Table Ref. Description Parts Price List Name Lower Housing Housing Assy,.Lower Front Cover Cover,Front Upper housing Housing,Upper Rear Printer Cover Cover, Printer,Rear Printer Cover Cover,Assy.,Printer Font Edge Guide Edge Guide Assy.,Front Rear Edge Guide Edge Guide Assy.,Rear Bottom Cover...

- Page 160 LQ-2070 Service Manual Appendix Table A-17 Part No. Reerence Table (Continue) Ref. Description Parts Price List Name Ferrite Core Ferrite Core C.B.S.-Tite Screw C.B.S.-Tite Screw Upper Grounding I/F Plate Grounding Plate, I/F,Upper Main Board Assembly Board Assy., Main (For Europe) Main Board Assembly Board Assy.,Main Power Supply Board Assembly...

- Page 161 Appendix LQ-2070 Service Manual Table A-17 Part No. Reference Table(Continue) Ref. Description Parts Price List Name Rear PE Sensor Detector Assy., Rear Lower Paper Feed Driven Roller Roller,PF, Driven, Lower Paper Feed Roller Assembly Roller Assy., PF Extension Spring, 70 Extension Spring,70 Compression Spring,10.8 Compression Spring,10.8...

- Page 162 LQ-2070 Service Manual Appendix Table A-17 Part No. Reference Table(Continue) Ref. Description Parts Price List Name Left Bushing (8mm) Bushing, 8 Left Platen Platen Platen Gear Platen Gear Right Bushing (8mm) Bushing, 8 Right Platen Cover Cover,Platen PW Sensor Assembly Detector, Assy., PW Ribbon Mask Ribbon Mask...

- Page 163 Appendix LQ-2070 Service Manual Table A-17Part No. Reference Table (Continue) Ref. Description Parts Price List Name Oil Pad Oil Pad PG Sensor Holder Holder,Detector,PG Release Sensor Lever Lever, Release, Detector Paper Guide Middle Grounding Plate Grounding Plate, Paper Guide, Middle Release Sheet Sub Cap Sheet, Release, Cap, Sub Cable Holder...

- Page 164 LQ-2070 Service Manual Appendix Table A-17 Parts No. Reference Table (Continue) Ref. Description Parts Price List Name C.B.S. Screw C.B.S Screw C.F.P-Tite Screw, 2.6 X 8, F/Zn C.F.P.-Tite Screw, 2.6X8, F/Zn Hexagon Nut Hexagon Nut C.B.S. Screw C.B.S. Screw Print Head Print Head, DH24-0A-0 Rev.A A-31...

- Page 165 EPSON...