Table of Contents

Advertisement

Quick Links

SAFETY INSTRUCTIONS................................................................................................i

SYSTEM CONFIGURATION..........................................................................................iii

EQUIPMENT LISTS ....................................................................................................... iv

1. MOUNTING THE EQUIPMENT................................................................................1-1

1.1 Hull Unit ................................................................................................................................1-1

1.2 Processor Unit ......................................................................................................................1-8

1.3 Control Unit...........................................................................................................................1-9

1.4 Transceiver Unit ..................................................................................................................1-12

1.5 Grounding the Equipment ...................................................................................................1-12

1.6 Installing the Attachment Flange (option)............................................................................1-13

1.7 Cable Extension Kit (option) ...............................................................................................1-14

1.8 Installing the Attachment Kit (option)...................................................................................1-15

2. WIRING ....................................................................................................................2-1

2.1 How to Use the Crimping Tool, Pin Extractor ........................................................................2-1

2.2 Wiring....................................................................................................................................2-2

2.3 Processor Unit .................................................................................................................... 2-4

2.4 Transceiver Unit ..................................................................................................................2-10

2.5 Cable Extension Kit ............................................................................................................2-14

2.6 Input Voltage and Fuses .....................................................................................................2-18

3. ADJUSTMENT AND CHECK ...................................................................................3-1

3.1 Hull Unit Check .....................................................................................................................3-1

3.2 Heading Adjustment..............................................................................................................3-5

3.3 Configuring Own Ship Mark ..................................................................................................3-7

3.4 Other SYSTEM Menu Items .................................................................................................3-9

3.5 CONE Board Setting in the Processor Unit.........................................................................3-13

3.6 DIP Switch Setting ............................................................................................................3-14

4. CONNECTING THE EXTERNAL INTERFACE CS-120A ........................................4-1

PACKING LISTS ......................................................................................................... A-1

OUTLINE DRAWINGS ................................................................................................ D-1

INTERCONNECTION DIAGRAMS ............................................................................. S-1

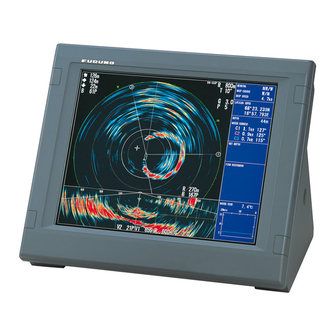

COLOR SCANNING SONAR

www.furuno.co.jp

Installation Manual

FSV-30/FSV-30S

Back

Advertisement

Table of Contents

Summary of Contents for Furuno FSV-30

-

Page 1: Table Of Contents

3.4 Other SYSTEM Menu Items ...3-9 3.5 CONE Board Setting in the Processor Unit...3-13 3.6 DIP Switch Setting ...3-14 4. CONNECTING THE EXTERNAL INTERFACE CS-120A ...4-1 PACKING LISTS ... A-1 OUTLINE DRAWINGS ... D-1 INTERCONNECTION DIAGRAMS ... S-1 Installation Manual FSV-30/FSV-30S www.furuno.co.jp Back... - Page 2 Nishinomiya, 662-8580, JAPAN Telephone : +81-(0)798-65-2111 : +81-(0)798-65-4200 Printed in Japan All rights reserved. Pub. No. IME-13230-F (TATA ) FSV-30/30S The paper used in this manual is elemental chlorine free. ・FURUNO Authorized Distributor/Dealer A : DEC F : DEC . 13, 2010...

-

Page 3: Safety Instructions

The installer of the equipment is solely responsible for the proper installation of the equipment. FURUNO will assume no responsibility for any damage associated with improper installation. WARNING Install the specified transducer tank in accordance with the installation instructions. - Page 4 CAUTION Maximum speed while the transducer is projected or being raised or lowered is as below, to prevent damage to the transducer. Projected 1200 mm stroke Max. 18 kt Max. 15 kt 1600 mm stroke Max. 15 kt Max. 12 kt Observe the following compass safe distances to prevent interference to a magnetic compass:...

-

Page 5: System Configuration

SYSTEM CONFIGURATION Loudspeaker Sub Monitor Echo Sounder, Current Indicator, other Navigator 1 Navigator 2 External Interface CS-120A (Note 1) 100/110/115/ 220/230 VAC, 1φ, 50/60 Hz TRANSCEIVER UNIT FSV-301 100/110/115/ 220/230 VAC, 1φ, 50/60 Hz Note 1: Power Kit FSV-2403 (option, installed in processor unit) required to connect CS-120A. -

Page 6: Equipment Lists

000-144-917 006-934-240 000-067-072 000-067-073 000-017-095 000-017-096 000-017-097 Remarks With cable For FSV-30 For FSV-30S 1200 mm stroke 1600 mm stroke Signal cable 10S2078 (between transceiver unit and hull unit, 8 m) For transceiver unit. See packing list. For processor unit CP10-04502, CP10-04506. -

Page 7: Mounting The Equipment

1. MOUNTING THE EQUIPMENT Do not apply paint, anti-corrosive sealant or contact spray to coating or plastic parts of the equipment. Those items contain organic solvents that can damage coating and plastic parts, especially plastic connectors. 1.1 Hull Unit Note 1: The raise/lower control box on the hull unit contains a motion sensor. Therefore, never drop the hull unit. - Page 8 • The space shown in the figure on the next page is required around the hull unit for wiring and maintenance. • If the ambient temperature around the unit will be below 0°C, provide the sonar compartment with a heater to keep the temperature above 0°C.

- Page 9 1.1.2 Shortening the retraction tank The retraction tank is 1300 mm in length when supplied. Shorten the tank as necessary so that the transducer positions well below the keel when it is fully lowered. The following table provides guidelines for shortening the tank. Refer also to the retraction tank installation drawing at the back of this manual.

- Page 10 1.1.3 Remarks for installation of retraction tank 1. Make, if possible, the installation location a double bottom structure. 2. Install, if possible, the tank on the keel where the tank can be most firmly fixed. 3. Install the reinforcement ribs as near as possible to the top of the retraction tank, allowing space for tightening of nuts and bolts.

- Page 11 1.1.4 Installing hull unit on retraction tank After welding the retraction tank and allowing sufficient time for cooling, install the hull unit as follows: 1. Clean the hull unit flange, the O-ring and O-ring groove. Coat them with a slight amount of grease.

- Page 12 Hex. Nut Spring Washer Flat Washer Bow Mark Hull Unit Flange O-ring Tank Flange Flat Washer Hex. Bolt Hex. Nut Spring Washer O-ring Flat Washer O-ring Retraction Tank Flat Washer Hex. Bolt Hex. Nut Spring Washer Stern side (seven locations) Bow side (17 locations) Installation of hull unit...

- Page 13 1.1.5 Installing stays (anti-vibration measure) Install stays from the top of the hull unit to the ship’s hull. The stays should be angle iron with a size of 75×75×9 mm or more and at least two pieces should be used; one each to ship’s bow and stern directions.

-

Page 14: Processor Unit

1.2 Processor Unit Mounting considerations When choosing a mounting location, keep in mind the following points: • The processor unit must be mounted upright. • Locate the unit out of direct sunlight and away from heat sources because of heat that can build up inside the cabinet. -

Page 15: Control Unit

Mounting procedure 1. Unfasten two bolts from the bottom of the front side of the processor unit. Pull the unit toward you to separate it from the mounting base. 2. Use six bolts (M6×20, supplied as installation material) to fix the mounting base. 3. - Page 16 1. To fix the control unit to a desired location at an angle, fasten the KB fixing plate to the control unit and desired location with two upset screws (M5×10, supplied) and two tapping screws (φ6.5, local supply) as below. FSV-30 2. Set dust cover (supplied) to the control unit. 1-10 467±1...

- Page 17 Passing the cable through the bottom of the control unit (for permanent mounting) For permanent mounting methods (2) and (3), the control cable can be passed through the bottom of the control unit as follows: 1. Unfasten eight screws (M4) to remove the cover from the bottom of the control unit. 2.

-

Page 18: Transceiver Unit

1.4 Transceiver Unit The physical distance between the hull unit and the transceiver unit should be no more than 5 m. The transceiver unit should be mounted on a mounting base (shipyard supply) whose dimensions are as shown in the outline drawing of the transceiver unit at the back of this manual. -

Page 19: Installing The Attachment Flange (Option)

1.6 Installing the Attachment Flange (option) The attachment flange permits use of the tank for the CSH-20 series using the 1200 mm stroke transducer. Attachment flange Type: OP10-27, Code no: 000-067-050) Name Attachment flange 10-077-5802 O-ring CO 0318A (V585) Hex. nut M20 SUS304 Flat washer M20 SUS304... -

Page 20: Cable Extension Kit (Option)

1.7 Cable Extension Kit (option) For extension of the transducer cable between the hull unit and the transceiver unit, use the cable extension kit (option), which includes a junction box. The kit is available in 5 m or 15 m extension lengths. Below are the contents of each kit. Name: Cable Extension Kit, Type: FSV-305-5, Code No.: 000-067-072 Name Junction box... -

Page 21: Installing The Attachment Kit (Option)

1.8 Installing the Attachment Kit (option) The attachment kit permits use of the tank for the CSH-20 series using the 1600 mm stroke transducer and FSV-243E/244E. Attachment kit (Type: OP10-24, Code no.: 006-943-530) Name Insulation gasket (1) Insulation gasket (2) 1. - Page 22 Flange of hull unit O-ring Insulation gasket (1) Insulation gasket (2) Flat washer Spring washer Hex. nut Hex. nut Stern side (Seven locations) 1-16 Spring washer O-ring Insulation gasket Insulation gasket (2) Flat washer Spring washer Installation of attachment kit Hex.

-

Page 23: Wiring

2. WIRING 2.1 How to Use the Crimping Tool, Pin Extractor A special crimping tool is necessary for connection of wires to the contact pins of the 38P connector. The pin extractor removes the contact pin from the connector body. This paragraph describes how to crimp and extract the contact pin. -

Page 24: Wiring

100/110/115/ 220/230 VAC 1φ, 50/60 Hz 100/110/115/ 220/230 VAC DPYCYS-2.5 *2 1φ, 50/60 Hz Wiring FSV-30 CONTROL UNIT FSV-3001 Monitor (Local supply) Monitor cable (Local supply) *1: If connector may loosen by vibration monitor cable may also be connected inside. - Page 25 0.6 m 14.0 m Hull unit side Note that the amount of cable inside the cable clamp on the cable between the hull unit and transceiver unit may be shorted depending on cable length. Transceiver unit side (40 pin) 0.38 m (34 pin) 0.07 m Clamp point...

-

Page 26: Processor Unit

2.3 Processor Unit Cables (10S2074, 10S1258-1 and control cable) from the various units are connected to the CONE Board (10P6905) in the processor unit. Divide cables attached to the back of the processor unit between right and left side. Tie each group with a cable tie at the position 15 cm from connectors. - Page 27 Fabrication of connector 00-8016-038-313761HV (CN-A101) Shield Vinyl Sheath Core Fabrication of cable for connector 00-8016-038-313761HV Positioning guide pins Guide pins of the connector identify the mating receptacle. They are; • Guide pin A (Large): 1 • Guide pin B (Small): 1 Anticorrosive Sheath Armor...

- Page 28 2.3.2 Power cable Attach the NCS-253-P connector (CN-A110) to the power cable DPYCY-1.5 (Japan Industrial Standard (JIS) cable) or the equivalent. Attach the connector to the processor unit. Armor Solder lead wire to armor and connect it to #1 pin of connector. 2.3.3 Control cable Attach the control cable (10S2074 or 10S2075) to the CN-A103 connector in the processor unit.

- Page 29 2.3.4 Optional equipment With connection of a navigator and electronic fishing equipment, the FSV-30 provides true motion presentation, target lock, echo sounder picture, FNZ marker presentation, and digital indication of position, water temperature and depth. Use the SRCN connectors (optionally supplied, Type: CP10-4801, Code no.: 006-934-240) to connect equipment to the rear of the processor unit.

- Page 30 Cable with armor Armor Vinyl sheath Solder unused cores and earth to braided shield. Solder earth wire. Wind vinyl tape. Cable without armor Solder unused cores and earh wire to braided shieeld. Vinyl sheath Wind vinyl tape J5 (CIF1) J7 (GYRO) J8 (LOG) J10 (FNZ) J13 (EXT-KP)

- Page 31 Synchronizing with echo sounder or other sonar To synchronize the transmission of the FSV-30 with an echo sounder or other type of sonar, make connections as shown below. For current driven KP input Processor unit For voltage driven KP (12 V) input...

-

Page 32: Transceiver Unit

2.4 Transceiver Unit 2.4.1 Fabrication of connector 00-8016-038-313761HV (CN-B101) Shield Vinyl Sheath Core Fabrication of cable for 00-8016-038-313761HV Shorten the unused wires appropriately and treat their ends with vinyl tape to prevent short circuit. Positioning guide pins Use the tool shown below to position guide pins. Connector Guide Pin Guide Pin A (large) - Page 33 1 3 - L CN-B210 CN-B209 CN-B208 CN-B207 16-L TRX-10 TRX-9 TRX-8 TRX-7 SB-1909 07-L EL12P EL9P SM18P SM8P SM12P EL3P J201 J202 J203 J204 J205 J206 J301 J302 J303 SM12P EL4P YL8P Transceiver unit, inside view CN-B206 CN-B205 CN-B204 CN-B203 CN-B202 CN-B201...

- Page 34 2.4.2 Fabrication of power cable type DPYCYS-2.5 (TB-B101) Fabricate the cable DPYCYS-2.5 as below for connection to the power source. Anticorrosive sheath Fabrication of cable type DPYCYS-2.5 2.4.3 Hull control cable (10S2078) Connect the hull control cable (10S2078) to the CN-B102 in the transceiver unit. Note: The same type of connector is fitted at each end, however the connector which has a larger portion of its sheath removed should be connected to the transceiver unit.

- Page 35 2.4.4 Wiring in transceiver unit 1. Open the transceiver unit cover. 2. Plug the P1 and P2 connectors at the end of signal cables into the proper receptacles in the transceiver unit, referring to the interconnection diagram at the back of this manual. 3.

-

Page 36: Cable Extension Kit

2.5 Cable Extension Kit The length of the cable between the hull unit and transceiver unit is 5 meters. If a longer cable is required, use the cable extension kit, which consists of a junction box and a 5 or 15 meter cable. - Page 37 3. Lead in cable thru the appropriate location on the cable clamp and fix cable with appropriate CKS clamp. Connect each cable to circuit board as shown in the figure on the previous page. Signal cable (10S2240) connects to “JUNCTION BOX” display side. 4.

- Page 38 2.5.2 Raise/Lower control box Connect the power cable (3φ) and the transceiver unit cable (10S2078) as shown below. TB-C101 Connect the power cable TPYCY-4 (Japan Industrial Standard) or the equivalent cable to this terminal board. LED (Red) For detection of phase reversal on 3 phase power cable Confirm LED after completing the installation.

- Page 39 Vinyl Sheath Armor sheath (Clamp here by cable clamp.) Power cable fabrication M4(yellow) x 3 FV5.5-4 2-17...

-

Page 40: Input Voltage And Fuses

2.6 Input Voltage and Fuses The transceiver unit is shipped from the factory with its input voltage set for 230 VAC and a 10 A fuse inserted in F601 and F602. For other voltages, change toggle switch positions and fuses as below. Input voltage Set the toggle switches S603, S604 and S605 according to input voltage, referring to the table below. -

Page 41: Adjustment And Check

3. ADJUSTMENT AND CHECK 3.1 Hull Unit Check Note: Before conducting this check (at the dry dock) transmission must be stopped. Default setting of TX power is OFF. Confirm that transmission is off as follows: 1. Turn on the power, and then press the [MENU] key to show the main menu. 2. - Page 42 3. Choose INITIAL SETTING and press the [MENU] key. THIS ITEM IS DEFINED AS NON- CHANGEABLE ITEM, ARE YOU SURE TO CHANGE IT TO CHANGEABLE ? 4. Choose YES and press the [MENU] key. 5. Choose TEST and press the [MENU] key. 6.

- Page 43 How to check the hull unit 1. Press the POWER (|) switch on the control unit to turn on the equipment. Confirm that “ ON” lamp above the POWER switch and the Transducer switches of the control unit 2. Confirm that the 5V and UP lamps on the raise/lower control box are lit. 3.

- Page 44 8. Check that LEDs on the panel of the raise/lower control box light as follows: 1) UP, MD and DN LEDs light when corresponding limit switch is kicked. 2) UP and DOWN LEDs light while UP and DOWN switches are pressed and extinguish when the switches are released.

-

Page 45: Heading Adjustment

3.2 Heading Adjustment When the BOW mark on the flange of the hull unit cannot be directed toward ship’s bow, adjust the heading so an echo which is dead ahead appears dead ahead on the display. 1. Referring to the previous section, set the TX (transmission) to ON. 2. - Page 46 LANGUAGE HEADING ADJUST : 0 ES2 SELECT ES DRAFT OFFSET : 0.0 m EVENT KEY AUTO TILT SELECT USER PROG TRACKBALL SPEED HULL UNIT STROKE OTHERS menu, HEADING ADJUST 6. Choose ▲ or ▼ to choose direction (plus or minus, respectively) in which to increment or decrement setting and then press the [MENU] key to set.

-

Page 47: Configuring Own Ship Mark

3.3 Configuring Own Ship Mark Set own ship’s dimensions and the location of the transducer to accurately display the own ship mark on the display. 1. Press the [MENU] key to display the SYSTEM menu. 2. Use the trackball to choose OWN SHIP MARK and press the [MENU] key. 3. - Page 48 5. Choose ▲ or ▼ and then operate the [MENU] key to set the ship’s length (15 to 150 m). 6. Choose QUIT to finish the setting. 7. Set the SHIP’S WIDTH (5 to 30 m), TD POSITION 1 (5 to 50 m) or TD POSITION 2 (-10.0 to 10.0 m) similarly.

-

Page 49: Other System Menu Items

3.4 Other SYSTEM Menu Items This section mainly shows you how to set up according to external equipment connected. Default settings are underlined. 3.4.1 INTERFACE SETTING menu NMEA 1 BAUD RATE Set the transmission rate for the NMEA 1 port. (4800 bps, 9600 bps, 19200 bps, 38400 bps) NMEA 2 BAUD RATE Set the transmission rate for the NMEA 2 port. - Page 50 3.4.2 EXT DATA SETTING menu DATE & TIME Choose the input format for data and time data. (NONE, CIF, NMEA) HEADING Choose the input format for heading data. (NONE, AD10S, CIF, NMEA) LOG PULSE Set the log pulse rate for the log signal. (200 p/NM, 400 p/NM) SPEED &...

- Page 51 WIND Choose the input format for wind data. (NONE, CIF, NMEA) NET DEPTH Choose the input format for net depth data. (NONE, CIF, PULSE) Data sentences (NMEA 0183, FURUNO proprietary) NMEA Input Position (L/L) GGA, GLL, GNS, RMA, RMC Heading...

-

Page 52: Others Menu

3.4.3 OTHERS menu LANGUAGE Choose the language to use. (JAPANESE, ENGLISH) HEADING ADJUST See “3.2 Heading Adjustment”. ES2 SELECT Choose the equipment connected to the ES2 port; echo sounder or net recorder. (ES, NET REC) ES DRAFT OFFSET When connecting an echosounder, you may enter the ship’s draft if you prefer to display depth from the draft rather than depth from the transducer. -

Page 53: Cone Board Setting In The Processor Unit

2. For ES1, adjust R168 to suppress noise, and then adjust R209 so that the picture condition is similar to that of connected echo sounder connected to the FSV-30. 3. For ES 2, adjust R119 to suppress noise, and then adjust R167 so that the picture condition is similar to that of echo sounder connected to the FSV-30. -

Page 54: Dip Switch Setting

3.6 DIP Switch Setting J496, J497 DCON board (10P6984 or 10P6984A) IFES board (10P6983) I F E A L D Processor unit, inside view 3.6.1 CIF2/NMEA2 connector interface selection The signal format for the CIF2/NMEA2 port (at the back of the processor unit) can be set for CIF or NMEA by DIP switch S2-8 on the IFES Board (10P6983). - Page 55 ES2/NET J496 Note: The SIGOUT (AC signal) terminal and REC terminal (DC signal) in the output port are provided for a FURUNO echosounder. Therefore, when using the SIGOUT terminal, it is not necessary to change the above-mentioned jumper setting. 3-15...

- Page 56 (This page intentionally left blank.) 3-16...

-

Page 57: Connecting The External Interface Cs-120A

4. CONNECTING THE EXTERNAL INTERFACE CS-120A When upgrading from the CSH-20 series sonar, the External Interface CS-120A can be used. Connect the CS-120A to the processor unit as shown on the next page. However, we recommend that you connect external devices directly to the processor unit, to avoid signal delay. - Page 58 2. Remove two upset screws, detach the plugs J503, J502, J501, J504, J506 and J507, and then pull out the power module. Protection sheet VH4P Power supply VH5P Upset screws M5x25 SUS 2 pcs. 3. Fix the power supply pcb (supplied) to the power module with spacers (supplied). 4.

- Page 59 8. Set the DIP switch on the DCON Board as follows. Input port DIP switch setting on DCON Board CIF1 S3-#2: ON NMEA 2/CIF 2 S3-#3: ON DCON Board (10P6984 or 10P6984A) Note: If the CIF1 format is selected, change baud rate to 2400 bps. See CIF BAUD RATE on page 3-9 for details.

- Page 60 (This page intentionally left blank.)

- Page 71 Y. Hatai...

- Page 72 Y. Hatai...

- Page 73 Takahashi T Y. Hatai...

- Page 74 Takahashi T Y. Hatai...

- Page 75 Y. Hatai...

- Page 77 D-10...

- Page 78 This page is intentionally left blank.

-

Page 79: Interconnection Diagrams

シロ 13 WHT チャ 12 BRN +12V シロ 12 WHT 外部モニター MONITOR CABLE EXT. MONITOR TITLE FSV-30/30S T.YAMASAKI 9/Jul/08 カラースキャニングソナー 名称 T.TAKENO 9/Jul/08 相互結線図 18/Jul/08 R.Esumi MASS NAME COLOR SCANNING SONAR INTERCONNECTION DIAGRAM 10-080-0101-0 C1323-C02- D FURUNO ELECTRIC CO., LTD. - Page 80 データ収録装置 DATA RECORDER メンテナンス専用 FOR MAINTENANCE 魚探 I/F 02S8040,6m ES I/F VI-1100A 外部KP CO-0.2x5P EXTERNAL KP 外部スピーカ EXTERNAL SPEAKER SEM-21Q CS-120A 注記 *1)造船所手配 *2)オプション。 *3)コネクタは工場にて取付済み。 *4)コネクタクランプでアースに落とす。 *5)IFES基板S2 #8にて選択。 工場出荷時はCIF(OFF)。 NOTE *1: SHIPYARD SUPPLY. *2: OPTION. *3: CONNECTOR PLAG FITTED AT FACTORY. *4: GROUND THRU CONNECTOR CLAMP.