Advertisement

Quick Links

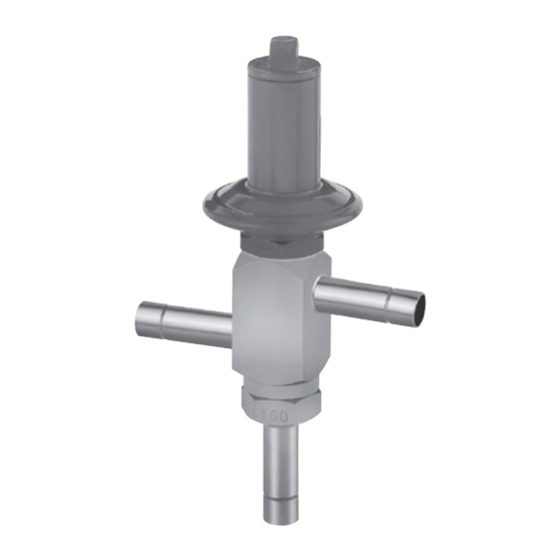

Head Pressure Control Valves

LAC-4 and LAC-4-DS

INSTALLATION AND SERVICING INSTRUCTIONS

SD-134 / 82021

INSTALLATION INSTRUCTIONS

To ensure proper performance, head

pressure control valves must be selected

and applied correctly. This is covered

thoroughly in Bulletin 90-30. However,

proper installation procedures are equally

important.

Valve Location/Piping Suggestions

LAC-4 valves can be installed in horizontal

or vertical lines, whichever best suits the

application and permits easy accessibil-

ity of the valves. However, consideration

should be given to locating these valves

so they don't act as oil traps or that solder

cannot run into the internal parts dur-

ing brazing. Care should also be taken

to install the valves with the flow in the

proper direction.

Figure 3 is a piping schematic only to illus-

trate the general location of the LAC-4

valve. In most cases the valve is located at

the condensing unit. When the condenser

is remote from the compressor, the usual

location is near the compressor. Spor-

lan recommends that recognized piping

references be consulted for assistance in

piping procedures. Sporlan is not respon-

sible for system design, any damage aris-

ing from faulty system design, or for mis-

application of its products. If these valves

are applied in any manner other than as

described in this bulletin, the Sporlan

warranty is void.

Inlet Strainer

- The need for an inlet

strainer is a function of system cleanliness.

Inlet strainers are available for the LAC-4

and LAC-4-DS (3/8" ODF fittings must

have a rolled stop to support the strainer).

Keep in mind that the LAC model actu-

ally has two inlet fittings (condenser and

discharge) and it may be desirable to use

an inlet strainer in both fittings.

Table 1

FITTING SIZE

3/8"

-

1/2"

Brazing Procedures

monly used brazing alloys for high side

usage are satisfactory. However, when sol-

dering or brazing, it is very important that

the internal parts be protected by wrap-

ping the valve with a wet cloth to keep the

body temperature below 250°F. Also, when

using high temperature solders, the torch

tip should be large enough to avoid pro-

longed heating of the copper connections.

And, always direct the flame away from the

valve body.

Test and Operating Pressures

dry gases such as nitrogen, CO

are often used for leak detection. Excessive

leak testing or operating pressures may

damage these valves or reduce the life of

the diaphragm or bellows.

CAUTION: Inert gases must be added

to the system carefully through a

pressure regulator. Unregulated gas

pressure can seriously damage the

system and endanger human life.

Never use oxygen or explosive gases.

The maximum pressure that this valve

can withstand without damage is 500 psig.

Care must be taken to keep test or operat-

ing pressures below this maximum rated

pressure.

INLET STRAINER

PART NUMBER

825-003

825-004

- Any of the com-

- Inert

or helium

2

Advertisement

Summary of Contents for Parker Sporlan LAC-4

- Page 1 Head Pressure Control Valves LAC-4 and LAC-4-DS INSTALLATION AND SERVICING INSTRUCTIONS SD-134 / 82021 INSTALLATION INSTRUCTIONS discharge) and it may be desirable to use an inlet strainer in both fittings. To ensure proper performance, head pressure control valves must be selected Table 1 and applied correctly.

- Page 2 Page 2 / SD-134 VALVE SETTINGS LAC - 4 LAC-4 Figure 1 The LAC-4 is available with 4 standard set- tings for various refrigerants as shown in Table 2. Some manufacturers’ systems use other settings which are critical to system operation e.g.

- Page 3 SD-134 / Page 3 Table 2 REFRIGERANT RECOMMENDED SETTINGS (PSI) 12, 134a, 513A 401A 22, 502, 407A, 407F, 448A, 449A 404A, 507, 402A Table 3 LOW AMBIENT (Winter) CAPACITIES - TONS Capacities are based on 0°F Evaporator, 94°F Condenser, 10°F Subcooled Liquid; Valve Setting of 100 psig for R-134a / 513A;...

- Page 4 The user must analyze all aspects of the application, follow applicable industry standards, and follow the information concerning the product in the current product catalog and in any other materials provided from Parker or its subsidiaries or authorized distributors.