Summary of Contents for Trane RT-PRC010-EN

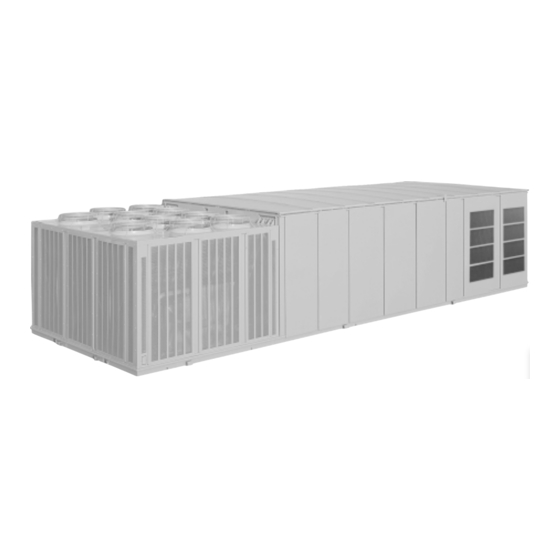

- Page 1 Packaged Rooftop Air Conditioners ® IntelliPak Rooftops 20 - 130 Tons — 60 Hz 20 - 75 Tons 90 - 130 Tons RT-PRC010-EN October 2001...

-

Page 2: Introduction

Trane IntelliPak ® Rooftop line the number one choice for today and the future. Trane’s rooftop Unit Control Module (UCM), an innovative, modular microprocessor control design, coordinates the actions of the IntelliPak rooftop in an efficient manner and allows for stand-alone operation of the unit. -

Page 3: Table Of Contents

RT-PRC010-EN Contents Introduction Features and Benefits Application Considerations Selection Procedure Model Number Description General Data Performance Data Performance Adjustment Factors Controls Electric Power Dimension and Weights Mechanical Specifications Options... -

Page 4: Features And Benefits

• Final filters • Barometric relief • 50 percent modulating exhaust with forward-curved fans • Trane’s air quality (Traq™) sensor • Modulating Gas Heat • 10 year limited warranty on Full Modulation Gas Heat • 100 percent modulating exhaust with forward-curved fans •... - Page 5 • Factory-wired and commissioned controls assure efficient and reliable rooftop operation. • Trane Scroll compressors are used on 20 to 130 ton units. They are designed for tough industrial operation and meet demanding operating conditions both in efficiency and reliability.

- Page 6 Simplifying The Comfort System At Trane, we think new technology and innovation should bring you more capabilities, more flexibility and at the same time be able to give you...

-

Page 7: Comfort Control

The unloading characteristics of a Trane FC fan with inlet guide vanes result in superior part load performance. Variable Frequency Drives (VFD) - Page 8 400,000 hours of laboratory testing and field operation. This work combined with over 25 patents makes Trane the worldwide leader in air conditioning scroll compressor technology. Chart illustrates low torque variation of 3-D Scroll compressor vs reciprocating compressor.

-

Page 9: Application Considerations

The reason for either a return air fan or an exhaust fan is to control building pressure. The Trane 100 percent modulating exhaust system with Statitrac does a better job controlling building pressure than return fans simply... - Page 10 The 50 percent exhaust system is a single FC exhaust fan with half the air- moving capabilities of the supply fan system. The experience of The Trane Company is that a non-modulating exhaust system selected for 40 to 50 percent of nominal supply CFM can be applied successfully.

- Page 11 Trane has two ways to accomplish horizontal supply and/or return. The first applies to all IntelliPak® Rooftop units. Special field supplied curbs are installed that use the unit’s standard discharge...

- Page 12 Figure AC-3 is a simplified sketch showing which panels can be used for horizontal supply and/or return. On 90 to 130 ton units, only one side of the extended casing may be used for horizontal supply because of the location of the unit control panel. There are, however, on SXHF models two panels (Panels A) on the side opposite the control box which can be removed...

- Page 13 CAUTION!: The ventilation override system should not be used to signal the presence of smoke caused by a fire. Trane can provide five (5) different ventilation override sequences on both CV and VAV IntelliPak® Rooftops. For your convenience the sequences can be factory preset or fully field editable from the Human Interface Panel or Tracer®.

- Page 14 This bulletin includes sound power data on Trane’s IntelliPak Rooftops 20 to 130 tons. Ask your local Trane representative for this informative engineering bulletin. The VariTrane® Computerized Duct Design Program can be used to analyze the truck duct, run-out duct, VAV control unit and terminal unit noise attenuation.

- Page 15 Figure AC-5. Improper RT-PRC010-EN Application Considerations Figure AC-4 — Unit Placement Figure AC-5 — Duct Design Proper 1.

-

Page 16: Selection Procedure

This section outlines a step-by-step procedure that may be used to select a Trane single-zone air conditioner. The sample selection is based on the following conditions: • Summer outdoor design conditions — 95 DB/76 WB ambient temperature • Summer room design conditions —78 DB/65 WB •... - Page 17 Assume a hot water supply temperature of 190 F . Subtract the mixed air temperature from the hot water temperature to determine the ITD (initial temperature difference). RT-PRC010-EN Selection Procedure Chart SP-1 — Fan Motor Heat MOTOR BRAKE HORSE POWER ITD = 190 F - 65.4 F = 125 F .

- Page 18 Return duct static pressure = 0.65 inches Trane roof curb (Table PD-43) = 0.12 inches Total return system negative static pressure = 0.77 inches Exhaust fan cfm = 12,000 cfm From Table PD-47 , the required bhp is 3.45 hp at 574 rpm.

- Page 19 RT-PRC010-EN Selection Procedure In order to better illustrate this procedure, the following example is used: Consider a 60 ton rooftop unit that is to deliver 18,000 actual cfm at 3-inches total static pressure (tsp), 55 F leaving air temperature, at an elevation of 5,000 ft.

-

Page 20: Model Number Description

= Remote Human Interface = Ventilation Override Module = Extended Grease Lines = Access Doors = Inter-Processor Communica tion Bridge = Trane Communication Interface Module = Spring Isolators = Factory-Powered 15A GFI Convenience Outlet = VFD Line Reactor RT -PRC010-EN... - Page 21 = High-Efficiency Motors (Supply and Exhaust) M = Remote Human Interface = Ventilation Override Module = Extended Grease Lines = Access Doors = Inter-Processor Communication Bridge = Trane Communication Interface Module = VFD Line Reactor = Factory-Powered 15A GFI Convenience Outlet...

-

Page 22: General Data

Table GD-1— General Data — 20-40 Tons 20 Ton Compressor Data Number/Size (Nominal) 2/10 Ton Model Scroll Unit Capacity Steps (%) 100/50 3450 Evaporator Fans Number/Size/Type 2/15”/FC Number of Motors Hp Range 3-15 Cfm Range 4000-9000 ESP Range — (In. WG) 0.25-4.0 Exhaust Fans Number/Size/Type... - Page 23 4. The firing rate of the unit can vary from 33% of the Heater Mbh up to the nameplate rating of the unit. 5. The firing rate of the unit can vary from pilot rate of 125,000 Btuh up to the nameplate rating of the unit. RT-PRC010-EN General Data 25 Ton 12 —...

- Page 24 Table GD-2 — General Data — 50-75 Tons 50 Ton Compressor Data Number/Size (Nominal) 2/10, 2/15 Ton Model Scroll Unit Capacity Steps (%) 100/80/60/30 3450 Evaporator Fans Number/Size/Type 2/20”/FC Number of Motors Hp Range Cfm Range 10000-22500 ESP Range — (In. WG) 0.25-4.0 Exhaust Fans 100%...

- Page 25 4. The firing rate of the unit can vary from 33% of the Heater Mbh up to the nameplate rating of the unit. 5. The firing rate of the unit can vary from pilot rate of 125,000 Btuh up to the nameplate rating of the unit. 6. 40 Hp available as standard in 460 volt only. RT-PRC010-EN General Data 55 Ton 60 Ton 20 —...

- Page 26 Table GD-3 — General Data — 90-130 Tons 90 Ton Compressor Data Number/Size (Nominal) 2/10, 4/15 Ton Model Scroll Unit Capacity Steps (%) 100/69/38/19 3450 Evaporator Fans Number/Size/Type 2/28”/AF Number of Motors Hp Range 30-80 Cfm Range 27,000-45,000 ESP Range — (In. WG) 1.0-4.75 Exhaust Fans Number/Size/Type...

- Page 27 Notes: 1. This information is rated and tested in accordance with ARI Standard 360-93 for large unitary equipment up to 25 tons. These Trane products can be found in the current ARI Directory. 2. IPLV — Integrated Part Load Value 3.

-

Page 28: Performance Adjustment Factors

Table PAF-1 — Enthalpy of Saturated AIR Wet Bulb Temperature Btu Per Lb. 15.23 15.70 16.17 16.66 17 .15 17.65 18.16 18.68 19.21 19.75 20.30 20.86 21.44 22.02 22.62 23.22 23.84 24.48 25.12 25.78 26.46 27 .15 27 .85 28.57 29.31 30.06 30.83... - Page 29 294 294 294 294 308 254 Notes: 1. All capacities shown are gross and have not considered indoor fan heat. 2. CAP = Total gross cooling capacity (MBH). 3. SHC = Sensible heat capacity (MBH). RT-PRC010-EN Performance Data Ambient Temperature Entering Wet Bulb...

-

Page 30: Performance Data

Table PD-3 — 25 Ton Gross Cooling Capacity — STANDARD CAPACITY Evaporator Coil With Scroll Compressor (F) CAP SHC CAP SHC CAP SHC 245 179 272 148 301 5000 246 205 272 173 301 141 248 230 273 198 301 165 253 253 273 223 301 265 207 292 164 320 118 7000... - Page 31 433 433 433 433 446 385 Notes: 1. All capacities shown are gross and have not considered indoor fan heat. 2. CAP = Total gross cooling capacity. 3. SHC = Sensible heat capacity. RT-PRC010-EN Performance Data Ambient Temperature Entering Wet Bulb...

- Page 32 Table PD-7 — 40 Ton Gross Cooling Capacity — STANDARD CAPACITY Evaporator Coil With Scroll Compressor (F) CAP SHC CAP SHC CAP SHC 395 289 438 237 483 179 8000 396 329 438 278 483 226 399 371 439 319 483 265 406 406 439 359 484 306 425 331 468 263 514 189 11000...

- Page 33 721 721 721 721 747 633 Notes: 1. All capacities shown are gross and have not considered indoor fan heat. 2. CAP = Total gross cooling capacity. 3. SHC = Sensible heat capacity. RT-PRC010-EN Performance Data Ambient Temperature Entering Wet Bulb...

- Page 34 Table PD-11 — 55 Ton Gross Cooling Capacity — STANDARD CAPACITY Evaporator Coil With Scroll Compressor (F) CAP SHC CAP SHC CAP SHC 637 470 706 384 782 291 12000 639 537 707 453 782 365 646 608 708 520 782 432 662 662 710 587 783 501 679 532 750 423 827 305 16000...

- Page 35 876 876 876 876 922 776 Notes: 1. All capacities shown are gross and have not considered indoor fan heat. 2. CAP = Total gross cooling capacity. 3. SHC = Sensible heat capacity. RT-PRC010-EN Performance Data Ambient Temperature Entering Wet Bulb...

- Page 36 Table PD-15 — 70 Ton Gross Cooling Capacity — STANDARD CAPACITY Evaporator Coil AIR- FLOW (F) CAP SHC CAP SHC CAP SHC 742 558 824 449 913 327 16000 749 650 826 537 914 424 763 746 830 628 916 513 792 792 837 719 919 603 781 622 862 492 952 341 20000...

- Page 37 90 1056 1056 1056 1056 1129 870 Notes: 1. All capacities shown are gross and have not considered indoor fan heat. 2. CAP = Total Gross Cooling Capacity 3. SHC = Sensible Heat Capacity RT-PRC010-EN Performance Data Ambient Temperature (F) Entering Wet Bulb (F)

- Page 38 Table PD-18 — 90 Ton Gross Cooling Capacity — STANDARD CAPACITY Evaporator Coil AIR- FLOW (F) CAP SHC CAP SHC CAP SHC 929 749 1029 583 1137 408 27000 944 888 1033 719 1139 548 978 978 1039 852 1143 685 90 1031 1031 1054 990 1147 817 959 812 1057 622 1166 423 32000...

- Page 39 90 1439 1439 1439 1439 1490 1289 Notes: 1. All capacities shown are gross and have not considered indoor fan heat. 2. CAP = Total Gross Cooling Capacity. 3. SHC = Sensible Heat Capacity. RT-PRC010-EN Performance Data Ambient Temperature Entering Wet Bulb...

- Page 40 Table PD-22 — 115 Ton Gross Cooling Capacity With 5-Row I-F Evaporator Coil — 100% Load AIR- FLOW (F) CAP SHC CAP SHC CAP SHC 75 1234 993 1361 776 1496 539 31000 80 1254 1176 1365 950 1499 724 85 1297 1297 1376 1126 1503 898 90 1366 1366 1396 1307 1507 1074 75 1263 1056 1387 816 1523 550...

- Page 41 3.71 High Heat 3.85 4.84 5.62 6.18 Table PD-27 — Properties of Steam Steam Pressure (Psig) Temperature Of Steam (F) RT-PRC010-EN Performance Data Air Temperature Rise Vs Unit Cfm Air Temperature Rise Vs Unit Cfm 28,350 30,250 32,550 34,750 25 Nominal Ton Unit...

- Page 42 Table PD-28 — 20 to 75-Tons Electric Heat Air Temperature Rise Total Input 4000 6000 102.4 23.6 15.7 170.6 39.3 26.2 238.8 55.0 36.7 307 .1 47 .2 375.3 57 .7 443.6 511.8 580.1 648.3 Notes: 1. Maximum permitted air temperature rise; 20-30 tons (UL — 50 F) (CSA — 60 F), 40 — 60 ton (UL/CSA — 50 F). 2.

- Page 43 1. Capacities expressed as MBh per initial temperature difference (ITD) between the entering air temperature to the hot water coil and the entering water temperature. Ethylene glycol or other capacities can be determined from the Trane heating coil computer program. Capacity and pressure drop of ethylene glycol varies greatly with temperature and concentration.

- Page 44 1547 Notes: 1. Fan performance for 20 and 25 ton rooftops is identical. However, note maximum motor hp size for each size. Contact your local Trane representative for information on oversized motors. 2. Shaded areas at table extremes note non-standard Bhp or Rpm selection. Contact your local Trane representative for more information.

- Page 45 3 HP 800 RPM 700 RPM 600 RPM 500 RPM 2000 4000 6000 8000 Note: 1. Important: Maximum static pressure leaving the rooftop is 4.0” H RT-PRC010-EN Performance Data 20 HP 15 HP 10 HP 10000 12000 14000 16000 18000 O positive.

- Page 46 15.99 Notes: 1. Fan performance for 20 and 25 ton rooftops is identical. However, note maximum motor hp size for each size. Contact your local Trane representative for information on oversized motors. 2. Shaded areas at table extremes note non-standard Bhp or Rpm selection. Contact your local Trane representative for more information.

- Page 47 800 RPM 700 RPM 600 RPM 500 RPM 2000 4000 6000 Note: 1. Important: Maximum static pressure leaving the rooftop is 4.0” H RT-PRC010-EN Performance Data 20 HP 8000 10000 12000 14000 16000 O positive. The static pressure drops from the supply fan to the space cannot exceed 4.0” H (20, 25 Tons) S_HFC20 &...

- Page 48 Notes: 1. Shaded areas at table extremes note non-standard Bhp or Rpm selection. Contact your local Trane representative for more information. 2. Supply fan performance table includes internal resistance of rooftop. For total static pressure determination, system external static must be added to appropriate component static pressure drops (evaporator coil, filters, optional economizer, optional exhaust fan, optional heating system, optional cooling only extended casing, optional roof curb).

- Page 49 800 RPM 700 RPM 3 HP 600 RPM 500 RPM 2000 4000 6000 Note: 1. Important: Maximum static pressure leaving the rooftop is 4.0” H RT-PRC010-EN Performance Data 25 HP 20 HP 15 HP 10 HP 7.5 HP 5 HP 8000...

- Page 50 Notes: 1. Shaded areas at table extremes note non-standard Bhp or Rpm selection. Contact your local Trane representative for more information. 2. Supply fan performance table includes internal resistance of rooftop. For total static pressure determination, system external static must be added to appropriate component static pressure drops (evaporator coil, filters, optional economizer, optional exhaust fan, optional heating system, optional cooling only extended casing, optional roof curb).

- Page 51 800 RPM 700 RPM 3 HP 600 RPM 500 RPM 4000 Note: 1. Important: Maximum static pressure leaving the rooftop is 4.0” H RT-PRC010-EN Performance Data 25 HP 20 HP 8000 12000 16000 O positive. The static pressure drops from the supply fan to the space cannot exceed 4.0” H...

- Page 52 Notes: 1. Fan performance for 40, 50, and 55 ton rooftops is identical. However, note maximum motor hp size for each size. Contact your local Trane representative for information on oversized motors. 2. Shaded areas at table extremes note non-standard Bhp or Rpm selection.

- Page 53 500 RPM 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000 22000 24000 26000 28000 30000 Note: 1. Important: Maximum static pressure leaving the rooftop is 4.0” H RT-PRC010-EN Performance Data 40 HP 30 HP 25 HP 20 HP O positive.

- Page 54 Notes: 1. Fan performance for 40, 50, and 55 ton rooftops is identical. However, note maximum motor hp size for each size. Contact your local Trane representative for information on non-standard motors. 2. Shaded areas at table extremes note non-standard Bhp or Rpm selection.

- Page 55 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000 22000 24000 26000 28000 30000 Note: 1. Important: Maximum static pressure leaving the rooftop is 4.0” H RT-PRC010-EN Performance Data 40 HP 30 HP 25 HP O positive. The static pressure drops from the supply fan to the space cannot exceed 4.0” H...

- Page 56 39.07 Notes: 1. Fan performance for 60, 70 and 75 ton rooftops are identical. However, note maximum motor hp size for each size. Contact your local Trane representative for information on non-standard motors. 2. Shaded areas at table extremes note non-standard Bhp or Rpm selection. Contact your local Trane representative for more information.

- Page 57 10 HP 600 RPM 7.5 HP 500 RPM 3000 6000 9000 12000 Note: 1. Important: Maximum static pressure leaving the rooftop is 4.0” H RT-PRC010-EN Performance Data 50 HP 40 HP 30 HP 25 HP 15 HP 15000 18000 21000...

- Page 58 Notes: 1. Fan performance for 60, 70 and 75 ton rooftops are identical. Contact your local Trane representative for information on non-standard motors. 2. Shaded areas at table extremes note non-standard Bhp or Rpm selection. Contact your local Trane representative for more information.

- Page 59 10 HP 600 RPM 7.5 HP 500 RPM 3000 6000 9000 12000 Note: 1. Important: Maximum static pressure leaving the rooftop is 4.0” H RT-PRC010-EN Performance Data 50 HP 40 HP 30 HP 20 HP 15 HP 15000 18000 21000...

- Page 60 Table PD-40 — Supply Fan Performance WITH VARIABLE FREQUENCY DRIVE or WITHOUT INLET GUIDE VANES — 90 Ton Std. 0.250 0.500 27000 4.62 6.01 28000 5.03 6.51 29000 5.46 7 .03 30000 5.92 7 .58 31000 6.40 8.14 32000 6.92 8.73 33000 7.46...

- Page 61 Notes: 1. Shaded areas indicate non-standard BHP or RPM selections. Contact your local Trane representive for more information. 2. Supply fan performance table includes internal resistance of rooftop. For total static pressure determination, system external static must be added to appropriate component static pressure drops, (evaporator coil, filters, optional economizer, optional heating system, optional roof curb).

- Page 62 Table PD-41 — Supply Fan Performance WITH INLET GUIDE VANES — 90 Ton Std. 0.250 0.500 27000 6.14 7 .25 28000 6.76 7 .92 29000 7.42 8.62 30000 8.13 9.37 31000 8.88 10.17 32000 9.68 11.01 33000 10.53 11.90 34000 11.42 12.84 35000...

- Page 63 Notes: 1. Shaded areas indicate non-standard BHP or RPM selections. Contact your local Trane representive for more information. 2. Supply fan performance table includes internal resistance of rooftop. For total static pressure determination, system external static must be added to appropriate component static pressure drops, (evaporator coil, filters, optional economizer, optional heating system, optional roof curb).

- Page 64 Table PD-42 — Supply Fan Performance WITH VARIABLE FREQUENCY DRIVE or WITHOUT INLET GUIDE VANES — 105, 115, 130 Ton Std. 0.250 0.500 31000 6.40 8.14 32000 6.92 8.73 33000 7.46 9.36 34000 8.02 10.01 35000 8.62 10.69 36000 9.25 11.41 37000 9.90...

- Page 65 Notes: 1. Shaded areas indicate non-standard BHP or RPM selections. Contact your local Trane representive for more information. 2. Supply fan performance table includes internal resistance of rooftop. For total static pressure determination, system external static must be added to appropriate component static pressure drops, (evaporator coil, filters, optional economizer, optional heating system, optional roof curb).

- Page 66 Table PD-43— Supply Fan Performance WITH INLET GUIDE VANES — 105,115,130 Tons Std. 0.250 0.500 31000 8.88 10.17 32000 9.68 11.01 33000 10.53 11.90 34000 11.42 12.84 35000 12.37 13.83 36000 13.38 14.88 37000 14.44 15.98 38000 15.55 17 .14 39000 16.72 1002...

- Page 67 Notes: 1. Shaded areas indicate non-standard BHP or RPM selections. Contact your local Trane representive for more information. 2. Supply fan performance table includes internal resistance of rooftop. For total static pressure determination, system external static must be added to appropriate component static pressure drops, (evaporator coil, filters, optional economizer, optional heating system, optional roof curb).

- Page 68 Table PD-44 — Component Static Pressure Drops (in. W.G.) Evaporator Coil Nominal Standard High Capacity SFHF/G Tons 4000 .07 6000 .13 8000 .21 9000 .26 10000 .31 12000 .41 5000 .10 6000 .13 — 7500 .19 10000 .31 11000 .36 12500 .44 14000 .52 1.05...

- Page 69 5. Horizontal roof curbs assume 0.50” static pressure drop or double the standard roof curb pressure drop, whichever is greater. 6. No additional pressure loss for model SXHF. 7. 90-130 ton roofcurbs adds no pressure drop. RT-PRC010-EN Performance Data Heating System...

- Page 70 Table PD-46 — 20-75 — Tons Supply Air Fan Drive Selections 3 Hp 5 Hp Nominal Drive Drive Tons 1000 1100 1000 1100 50/55 70/75 Table PD-47 — 90-130 — Tons Supply Air Fan Drive Selections 15 Hp 20 Hp Drive No.

- Page 71 718 32.41 737 33.24 758 Notes: 1. Shaded areas indicate non-standard drive selections. These drive selections must be manually factory selected. 2. Refer to General Data Table for minimum and maximum hp’s. RT-PRC010-EN Performance Data Negative Static Pressure 0.750 1.000 1.250...

- Page 72 Table PD-50 — 20-75 Tons — 100% Exhaust Fan Drive Selections Nominal 3 Hp Tons Drive No Drive No 50/55 70/75 Table PD-51 — 90-130 Tons —100% Exhaust Fan Drive Selections 15 HP 20 HP Nominal Drive Drive Tons 105-130 Performance Data 5 Hp...

- Page 73 672 12.29 699 12.94 20000 16.20 737 16.62 758 17 .18 Note: 1. Shaded areas indicate non-standard drive selections. These drive selections must be manually factory selected. RT-PRC010-EN Performance Data Negative Static Pressure (In. W.G.) 0.600 0.800 0.30 0.45 0.58 0.51...

- Page 74 Table PD-54— 50% Exhaust Fan Drive Selections Nominal 1½ HP Unit Size Drive No 50/55 70/75 105/115/130 Performance Data 3 HP 5 HP Drive No Drive No 1000 7½ HP 15 HP Drive No Drive No RT -PRC010-EN...

-

Page 75: Controls

The range is determined by the supply air pressure setpoint and supply air pressure deadband, which are set through the Human Interface Panel. RT-PRC010-EN Controls Inlet guide vane assemblies installed on the supply fan inlets regulate fan capacity and limit horsepower at lower system air requirements. - Page 76 Heating: Hot Water or Steam On units with hot water or steam heating, the supply air temperature can be controlled to a heating set point during the Occupied mode. The supply air temperature heating set point and deadband are user-defined at the Human Interface Panel.

- Page 77 RT-PRC010-EN Controls CV Units Only Sequence Of Operation Occupied Zone Temperature Control Cooling/Economizer During Occupied cooling mode, the economizer (if provided) and mechanical cooling are used to control zone temperature. If the enthalpy of outside air is appropriate to use “free cooling”,...

- Page 78 Controls Gas Heating: Modulating Gas Upon a call for heating, the UCM closes the heating contacts, beginning the firing sequence. First, the heat exchanger combustion blower begins operation. Upon positive proving of combustion airflow, a pre-purge cycle is executed. Then the ignition sequence takes place. If ignition is not proven, the ignition transformer is de-energized.

- Page 79 RT-PRC010-EN Controls Control Sequences of Operation Common to Both VAV and CV Units Space Pressure Control — Statitrac™ A pressure transducer is used to measure and report direct space (building) static pressure. The user- defined control parameters used in this control scheme are space static pressure setpoint and deadband.

- Page 80 Controls guide vanes open and the exhaust fan should be turned off. - Supply fan - On. - Supply fan VFD - On (60 Hz) (if equipped) - Inlet guide vanes/VAV boxes - Open (if equipped). - Exhaust fan - Off, exhaust dampers - Closed (if equipped).

- Page 81 System Module (GBAS) is used to (VAV/CV Units) provide broad control capabilities for building automation systems other than the Trane’s Tracer® system. A field provided potentiometer or a 0-5 vdc signal can be applied to any of the inputs of the GBAS to provide: Analog Inputs —...

- Page 82 Occupied/Unoccupied input on the RTM This input accepts a field supplied switch or contacts closure such as a time clock. Trane Tracer® System The Trane Tracer System can control the Occupied/Unoccupied status of the rooftop. Timed Override Activation — ICS...

-

Page 83: Electric Power

NEC 240-6, select the next higher standard fuse rating. NOTE: If the selected RDE is greater than the selected MOP value, RT-PRC010-EN Electrical Data then reselect the RDE value to equal the MOP value. - Page 84 Table ED-1 — 20-130 Tons Electrical Service Sizing Data Compressor Number Standard Nominal Capacity Tons Coil Type Unit KW (ea) Std and Hi-Cap Std and Hi-Cap Std and Hi-Cap Std and Hi-Cap Std and Hi-Cap Std and Hi-Cap Std and Hi-Cap Hi-Cap Std and Hi-Cap Std and Hi-Cap...

- Page 85 Voltage Module KW 83.3 72.2 138.8 120.3 194.3 168.4 249.8 216.5 305.3 264.6 Note: Electric heat FLA are determined at 208, 240, 480 and 600 volts. RT-PRC010-EN Electrical Data 10.8 10.8 10.8 10.8 10.8 14.4 11.2 18.0 14.0 18.0 14.0 21.6...

-

Page 86: Dimension And Weights

Figure DD-1 — 20-75 Ton Cooling Only Unit Dimensions — SAHF Table DD-1 — Cooling Only Unit Dimensions (Ft. In.) — SAHF Nominal Tons 20 & 25 21-9 21-9 27-0 50 & 55 29-8 27-0 70 & 75 27-0 Dimensional Data 14-0 12-6... - Page 87 Figure DD-1 — 20-75 Ton Cooling Only Unit Dimensions — SAHF Continued DETAIL “A” COVERS 20, 25, 30, 50 AND 55 TON UNITS RT-PRC010-EN Dimensional Data (20 - 75 Tons) DETAIL “B” COVERS 40, 60, 70 AND 75 TON UNITS...

- Page 88 Figure DD-2 — 20-75 Ton Heating/Cooling Unit Dimensions Table DD-2 — Heating/Cooling Unit Dimensions (Ft. In.) — SEHF , SFHF , SSHF , SLHF , SXHF Nom. Tons 20 & 25 24-1 24-1 30-2 50 & 55 32-10 30-2 70 & 75 30-2 Note: High Heat...

- Page 89 The curb acts as a plenum between the ductwork and the unit return opening. A retainer clip is used to secure the adjustable filler piece to the roof curb. *“P” dimension is 5’ 6” on 60, 70, 75 Tons SEHF (Units with electric heat). **“R” dimension is 2’ 5 ” on 60, 70, 75 Tons SEHF (Units with electric heat). RT-PRC010-EN Dimensional Data ”...

- Page 90 Figure DD-4 — 90, 105, 115, 130 Ton Heating/Cooling and Cooling Only Rooftops Figure DD-5 — 90 - 130 Tons — Service Clearance (SEE NOTE 4) Dimensional Data Notes: 1. Provide unrestricted clearance over the condenser fans. 2. A minimum clearance of 2’ 4-1/2” is required to open the hinged control panel doors.

- Page 91 Figure DD-6 — 90 - 130 Ton Roof Curb Dimensions Cross Section Thru Roof Curb and base pan RT-PRC010-EN Dimensional Data SECTION B-B (90 - 130 Tons)

-

Page 92: Variable Air Volume Vav

Dimensional Data Field Installed Sensors SINGLE SETPOINT SENSOR WITH SYSTEM FUNCTION LIGHTS (BAYSENS021*) PROGRAMMABLE NIGHT -SETBACK SENSOR (BAYSENS020*) Note: 1. Remote sensors are available for use with all zone sensors to provide remote sensing capabilities. (Variable Air Volume VAV) RT -PRC010-EN... -

Page 93: Constant Volume Cv

Note: 1. Remote sensors are available for use with all zone sensors to provide remote sensing capabilities. RT-PRC010-EN Dimensional Data Field Installed Sensors PROGRAMMABLE NIGHT-SETBACK SENSOR (BAYSENS019*) (Constant Volume CV) DUAL SETPOINT, MANUAL/AUTOMATIC CHANGEOVER SENSOR WITH SYSTEM FUNCTION LIGHTS (BAYSENS010*) - Page 94 ZONE TEMPERATURE SENSOR W/TIMED OVERRIDE BUTTON AND LOCAL SETPOINT ADJUSTMENT (BAYSENS014) TEMPERATURE SENSOR (BAYSENS016*) Note: 1. Remote sensors are available for use with all zone sensors to provide remote sensing capabilities. Dimensional Data Integrated Comfort™ System Sensors ZONE TEMPERATURE SENSOR W/TIMED OVERRIDE BUTTONS (BAYSENS013*) ALSO AVAILABLE SENSOR ONLY (BAYSENS017*) REMOTE MINIMUM POSITION POTENTIOMETER CONTROL (BAYSTAT023*) (CV and VAV)

- Page 95 2. Weights shown represent approximate operating weights and have a ±5% accuracy. ACTUAL WEIGHTS ARE STAMPED ON THE UNIT NAMEPLATE. 3. If unit is not as specified in note 1, you must reference RT-EB-103 for more details, as well as for point loading and center of gravity. RT-PRC010-EN Weights...

-

Page 96: Options

Options A full range of factory-installed modular options are available on standard ship cycles, allowing your rooftop design to best suit each individual application. Cooling Only/Heating Casings • Cooling Only — Two casing choices are available, one designed for high airside efficiency and one for sound sensitive applications. - Page 97 Includes factory installed and tested variable frequency drives (VFD) to provide supply fan motor speed modulation. RT-PRC010-EN Options VFD receives 0-10vdc from the unit microprocessor based upon supply static pressure and causes the drive to...

- Page 98 Remote Human Interface Panel must have a IPCB installed into it. • Trane Communication Interface Module — provides interface to Trane’s Integrated Comfort system (ICS), which allows control and monitoring of the rooftop by a Tracer building management system.

-

Page 99: Mechanical Specifications

Direct-drive, 3600 rpm, suction gas-cooled hermetic motor. Trane 3-D Scroll compressor includes centrifugal oil pump, oil level sightglass and oil charging valve. Each compressor shall have crankcase heaters installed,... - Page 100 AIR HANDLING SYSTEM Supply Fan 20 - 75 Ton Units All supply fans shall have two double- inlet, forward-curved fans mounted on a common shaft with fixed sheave drive and shall be dynamically balanced and tested in factory. Supply fan shall be test run in unit as part of unit test and unit shall reach rated rpm before the fan shaft passes through first critical speed.

- Page 101 Barometric relief dampers shall relieve building overpressurization, when that overpressurization is great enough to overcome the return duct pressure drops. RT-PRC010-EN Mechanical Specifications 50 percent exhaust air fan option One, double inlet, forward-curved fan shall be mounted rigidly to base with fixed sheave drive.

- Page 102 Mechanical Specifications Outside Air General Three outside air options: 100 percent return air, 0 to 25 percent manually controlled outside air, and 0-100 percent fully modulating economizer. Manual outside air option Manually controlled outside air damper shall provide up to 25 percent outside air. Manual outside air damper shall be set at desired position at unit start-up.

-

Page 103: Heating System

All units shall be fire tested prior to shipment. • Heat Exchanger shall be tubular two pass design with 16-gauge stainless steel primary and 18-gauge stainless RT-PRC010-EN Mechanical Specifications steel secondary heat exchanger surfaces. Free floating design shall eliminate expansion and contraction stresses and noises. - Page 104 An American Standard Company www.trane.com For more information contact your Since The Trane Company has a policy of continuous product and product data improvement, it reserves the local district office, or e-mail us at comfort@trane.com right to change design and specifications without notice.